Odaberite jezik:

STET Triboelectrostatic separation has been used for the commercial beneficiation of coal combustion fly ash to produce a low carbon product for use as a cement replacement in concrete for nearly 20 years….

Preuzmi PDFF. Hrach, S. Gasiorowski, H.Guicherd

ST oprema & Tehnologije LLC (STET), 101 Hampton Avenue, Needham MA 02494 SJEDINJENE AMERIČKE DRŽAVE

CONFERENCE: Vietbuild Ho Chi Minh City – lipanj 2015

KLJUČNE RECI: Triboelectrostatic, Beneficiation, Dry Fly Ash, Carbon Separation ABSTRACT

STET Triboelectrostatic separation has been used for the commercial beneficiation of coal combustion fly ash to produce a low carbon product for use as a cement replacement in concrete for nearly twenty years. With 18 separators in 12 coal-fired power plants across the world, ST oprema & Tehnologija LLC (STET) patented electrostatic separator has been used to produce over 15 Million tonnes of low carbon product.

To date, commercial beneficiation of fly ash has been performed exclusively on dry “run of station” ash. STET je Elektrostatski beneficiation tehnologija smanjuje sadržaj ugljik ugljena pepela, producing consistent, niskougljicni pepeo za upotrebu kao zamjena za cement. Fly ash with carbon levels up to 25% have been used to produce ash with a controlled carbon level of 2 ± 0.5%. A carbon-rich product is simultaneously produced to recover the fuel value of the carbon.

UVOĐENJE

Američki ugljena pepela Udruga (ACAA) godišnji pregled proizvodnje i korištenja ugljena pepela izvještava da je između 1966 i 2011, preko 2.3 billion short tons of fly ash have been produced by coal-fired utility boilers.1 Of this amount, približno 625 million tons have been beneficially used, mostly for cement and concrete production. Međutim, the remaining 1.7+ billion tons are primarily found in landfills or filled ponded impoundments. While utilization rates for freshly generated fly ash have increased considerably over recent years, with current rates near 45%, približno 40 million tons of fly ash continues to be disposed of annually. While utilization rates in Europe have been much higher than in the US, considerable volumes of fly ash have also been stored in landfills and impoundments in some European countries. Pretjerana količina nesagorenog ugljika u mušnom pepelu je najčešće problem. Američka asocijacija državnih službenika za autoput i transport (AASHTO) i evropskih standarda (HR 450 Kategorija A) zahtijevaju da količina negorenog ugljika u mušu pepelu, mjereno gubitkom pri paljenju (LOI) ne prelazi 5% po tezini. Međutim, starting in the mid-1990s, instalacija obavezne NOx kontrolne opreme u elektranama na ugalj povećala je ugljik (LOI) sadržaj mnogo ranije trzisnog muha pepela. Daljnji zahtjevi za smanjenje NOx i ostale elektrane emisija dovela do kontaminacije letećeg pepela s amonijakom. Kao posljedica toga, while understanding the benefits of using fly ash in concrete continues to increase, dostupnost prikladna kvaliteta pepela se smanjuje. Su procesi za ekonomski kvalietno letećeg pepela sa kvalitetom tako i povećanja interesa za moć i betonske industrije. STET has pioneered such processes for both carbon and ammonia removal from fly ash.

TECHNOLOGY OVERVIEW – FLY ASH CARBON SEPARATION

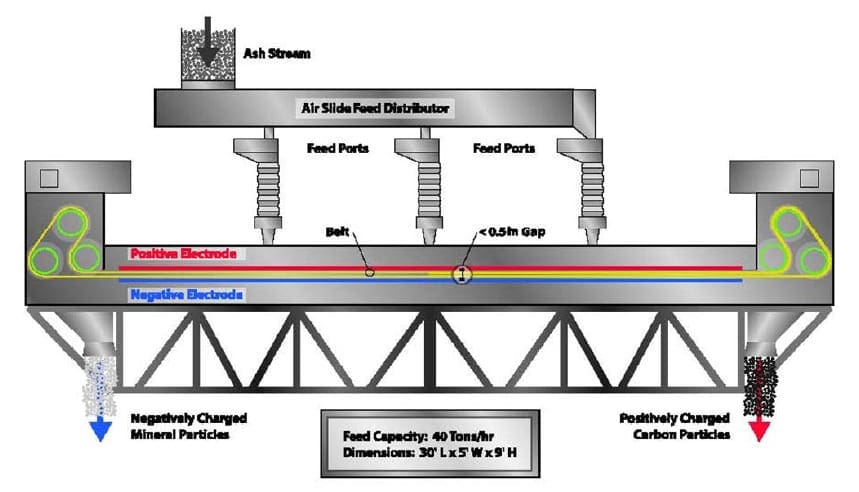

U STET separatoru ugljika (Slika 1), the material is fed into the thin gap between two parallel planar electrodes. The particles are triboelectrically charged by interparticle

Kontakt. The positively charged carbon and the negatively charged mineral (in freshly generated ash that has not been wetted and dried) privlače ih suprotne elektrode.. Čestice su onda zahvatio neprekinutom pojasu kreće i prenio u suprotnim smjerovima. Pojas potezi uz svake elektrode prema suprotnim stranama separator čestica. Visoki pojas brzinom omogućuje vrlo visoku propusnost, do 36 tona na sat na jednom razdjelnika. Mali razmak, polja visokog napona, countercurrent flow, snažan čestica-čestica uznemirenost i samočišćenja djelovanja remen na elektrode su kritične značajke STET razdjelnika. Kontroliranjem raznih parametara procesa, kao što je brzina pojasa, the feed point, i brzina hranjenja, STET proces proizvodi niski LOI leteći pepeo pri sadržaju ugljika manjem od 1.5 da 4.5% od feed muha pepeo u rasponu u LOI od 4% na više 25%.

Smokvu. 1 STET Separator

Razdjelnik dizajn je relativno jednostavna i kompaktna. Mašina dizajnirana za obradu 36 tone na sat je približno 9 m (30 FT.) Dugo, 1.5 m (5 FT.) Široko, i 2.75 m (9 FT.) Visoko. Jedini pokretni dijelovi su pojas i povezan Valjci. Elektrode su stacionarni i sastoji se od odgovarajuće izdržljiv materijal. The belt is made of nonconductive plastic. The separator’s power consumption is about 1 Kilowatt-sat po tonu materijala obrađen sa većinom energije koju su konzumirali dva motora koja voze remen..

Proces je potpuno suh., requires no additional materials other than the fly ash and produces no wastewater or air emissions. Pronađeni materijali se sačinjavaju od mušice pepeo smanjenog u sadržaju ugljika na nivoe pogodan za upotrebu kao pozzolanski admiksture u betonu, i visok ugljicni razlomak koristan kao gorivo. Utočište oba toka proizvoda pruža 100% rješenje za letenje problema s odlaganjem pepela.

RECOVERED FUEL VALUE OF HIGH-CARBON FLY ASH

In addition to the low carbon product for use in concrete, brand named ProAsh®, odvajanje STET obraditi i obnova inače izgubiti neizgorenu ugljik u obliku ugljik-bogat letećeg pepela, potpuno novo EcoTherm™. EcoTherm™ ima značajne goriva vrijednost i mogu lako vratiti do električne centrale pomoću STET EcoTherm™ Return system to reduce the coal use at the plant. Kada EcoTherm™ je izgorjela u korisnost kotla, the energy from combustion is converted to high pressure /high-temperature steam and then to electricity at the same efficiency as coal, Obično 35%. The conversion of the recovered thermal energy to electricity in ST Equipment & Technology LLC EcoTherm™ Povratni sistem je dva do tri puta veći od konkurentne tehnologije gdje se energija oporavlja kao nisko-razredna toplota u obliku tople vode koja cirkulira u sistem vode za kotlovsku hranu. EcoTherm™ is also used as a source of silica and alumina in cement kilns, displacing the more expensive raw materials, such as shale or bauxite, which are used in cement production. Utilizing the high carbon EcoTherm™ pepeo ili u elektrani ili cementna kila, maksimizira energetski oporavak od isporučene ugljena, smanjenje potrebe za moje i prijevoz dodatno gorivo od sadržaja.

STET’s Talen Energy Brandon Shores, IRENA SMEPA. Sutra, NBP Belledune, RWEnpower Didcot, EDF energije zapadni Burton, and RWEnpower Aberthaw fly ash plants, Svi sadrže EcoTherm™ Povratak sustavi. Bitne komponente sustava prikazani su na slici 2.

Smokvu. 2 EcoTherm™ Sisteme

OBJEKTI ZA OBRADU STET PEPELA

Controlled low LOI fly ash is produced with STET’s technology at twelve power stations throughout the U.S., Kanada, U.K., Poljska, i Republika Koreja. ProAsh® fly ash

has been approved for use by over twenty state highway authorities, kao i mnoge druge agencije specifikacije. ProAsh® je takođe sertifikovan od strane Kanadske asocijacije za standarde i EN 450:2005 standardi kvalitete u Europi. Ash processing facilities using STET technology are listed in Table 1.

Tablica 1. STET komercijalne operacije

| Elektroprivreda / Power Station | Lokaciju | Početak Reklame Operacije | Detalji o objektu |

|---|---|---|---|

| Duke Energy – Roxboro Station | Sjeverna Karolina SJEDINJENE AMERIČKE DRŽAVE | Sept. 1997 | 2 Separatori |

| Talen energija - Brandon Shores Station | Maryland SJEDINJENE AMERIČKE DRŽAVE | April 1999 | 2 Separatori 35,000 kupola za pohranu tona. Ecotherm™ Return 2008 |

| ScotAsh (Lafarge / Scottish Power Joint Venture) - Longannet stanica | Škotska VELIKA BRITANIJA | Oct. 2002 | 1 Znak za razdvajanje |

| Jacksonville Electric Authority - St. John's River Power Park, FL | Floridi SJEDINJENE AMERIČKE DRŽAVE | Svibanj 2003 | 2 Separatori Coal/Petcoke blends Ammonia Removal |

| South Mississippi Electric Power Authority R.D. Sutra Station | Mississippi SJEDINJENE AMERIČKE DRŽAVE | Jan. 2005 | 1 Znak za razdvajanje Ecotherm™ Return |

| New Brunswick Power Company Belledune Station | New Brunswick, Kanada | April 2005 | 1 Znak za razdvajanje Coal/Petcoke Blends Ecotherm™ Return |

| RWE npower Didcot Station | Engleska VELIKA BRITANIJA | August 2005 | 1 Znak za razdvajanje Ecotherm™ Return |

| Talen Energy Brunner Island Station | Pennsylvania SJEDINJENE AMERIČKE DRŽAVE | Prosinac 2006 | 2 Separatori 40,000 Kupola za skladištenje tona |

| Tampa Electric Co. Stanica Big Bend | Floridi SJEDINJENE AMERIČKE DRŽAVE | April 2008 | 3 Separatori, dvostruki prolaz 25,000 Kupola za skladištenje tona Ammonia Removal |

| RWE npower Aberthaw Station (Lafarge Cement UK) | Vels VELIKA BRITANIJA | Rujna 2008 | 1 Znak za razdvajanje Ammonia Removal Ecotherm™ Return |

| EDF energije zapadni Burton Station (Lafarge Cement UK, Cemex) | Engleska VELIKA BRITANIJA | Listopad 2008 | 1 Znak za razdvajanje Ecotherm™ Return |

| ZGP (Lafarge Cement Poljska / Ciech Janikosoda JV) | Poljska | Ožujka 2010 | 1 Znak za razdvajanje |

| Korea South-East Power Yeongheung Units 5&6 | Južna Koreja | Rujna 2014 | 1 Znak za razdvajanje Ecotherm™ Return |

| Lafarge Cement Poljska Warsaw | Poljska | 2016 | 1 Znak za razdvajanje |

CONCLUSIONS

Maksimiziranje ikorištenja mušice pepela kao zamjene cementa u proizvodnji betona umnogome smanjuje emisiju ugljičnog dioksida povezanu s građevinskom aktivnošću. Međutim, pollution control systems implemented by the coal-fired power stations have resulted in a reduction of available fly ash meeting concrete-grade specifications. Further degradation of fly ash quality is expected due to further reductions in allowable gas emissions. In order to avoid loss of this valuable resource of material for concrete production as well as reduction of greenhouse gas emissions associated with concrete construction, potrebni su procesi za obnavljanje kvaliteta mušice pepela na ekonomski i ekološki održiv način.

The beneficiation of fly ash with STET processes further increases the supply of this important material. The STET beneficiation processes continue to be the most extensively applied methods to upgrade otherwise unusable fly ash to high-value materials for cement replacement in concrete. Eighteen SETT carbon separators are currently in place with over 100 strojno-godine operacije.

ProAsh® has found wide acceptance in the concrete industry as a premium fly ash requiring far less monitoring of air entrainment requirements due to less LOI variability than other ashes. Returning the high-carbon concentrate from the STET process to the boiler at a power plant allows recovery of the recovered carbon fuel value at an efficiency similar to coal. STET offers economical means to recover ash for high-value use that would otherwise be landfilled. Electrostatic carbon separation and Ecotherm™ return to the boiler provide a modular solution to a utility’s fly ash needs. These processes can be implemented in phases, or as a single project.

REFERENCE

[1] American Coal Ash Coal Combustion products and Use Statistics:

https://www.acaa-usa.org/Publications/Production-Use-Reports/