Изберете език:

STET Triboelectrostatic separation has been used for the commercial beneficiation of coal combustion fly ash to produce a low carbon product for use as a cement replacement in concrete for nearly 20 years….

Изтегляне на PDFF. Hrach, S. Gasiorowski, H.Guicherd

ST оборудване & Технологии LLC (STET), 101 Хамптън авеню, Needham MA 02494 САЩ

CONFERENCE: Vietbuild Хо Ши Мин – юни 2015

КЛЮЧОВИ ДУМИ: Triboelectrostatic, Обогатяването, Dry Fly Ash, Carbon Separation ABSTRACT

STET Triboelectrostatic separation has been used for the commercial beneficiation of coal combustion fly ash to produce a low carbon product for use as a cement replacement in concrete for nearly twenty years. With 18 separators in 12 coal-fired power plants across the world, ST оборудване & Технологии LLC (STET) patented electrostatic separator has been used to produce over 15 Million tonnes of low carbon product.

To date, commercial beneficiation of fly ash has been performed exclusively on dry “run of station” ash. STET’s electrostatic beneficiation technology reduces the carbon content of coal fly ash, producing consistent, low carbon ash for use as a substitute for cement. Fly ash with carbon levels up to 25% have been used to produce ash with a controlled carbon level of 2 ± 0.5%. A carbon-rich product is simultaneously produced to recover the fuel value of the carbon.

ВЪВЕЖДАНЕТО

На американската въглища пепел асоциация (ACAA) годишно изследване на производството и използването на въглища летлива пепел съобщава, че между 1966 and 2011, над 2.3 billion short tons of fly ash have been produced by coal-fired utility boilers.1 Of this amount, приблизително 625 милиона тона са били използвани резултатен, най-вече за производство на цимент и бетон. Въпреки това, останалите 1.7+ милиарда тона са предимно намерени в депа или пълни ponded impoundments. While utilization rates for freshly generated fly ash have increased considerably over recent years, with current rates near 45%, приблизително 40 million tons of fly ash continues to be disposed of annually. While utilization rates in Europe have been much higher than in the US, considerable volumes of fly ash have also been stored in landfills and impoundments in some European countries. An excessive amount of unburned carbon in fly ash is the most common problem. The American Association of State Highway and Transportation Officials (AASHTO) and European Standards (EN 450 Category A) require that the amount of unburned carbon in fly ash, measured by loss on ignition (LOI) not exceed 5% by weight. Въпреки това, starting in the mid-1990s, installation of mandated NOx control equipment at coal-fired power plants increased the carbon (LOI) content of much of the previously marketable fly ash. Further requirements to reduce NOx and other power plant emissions have resulted in the contamination of fly ash with ammonia. As a consequence, while understanding the benefits of using fly ash in concrete continues to increase, the availability of suitable quality fly ash is decreasing. Processes to economically beneficiate off-quality fly ash are thus also of increasing interest to the power and concrete industries. STET has pioneered such processes for both carbon and ammonia removal from fly ash.

TECHNOLOGY OVERVIEW – FLY ASH CARBON SEPARATION

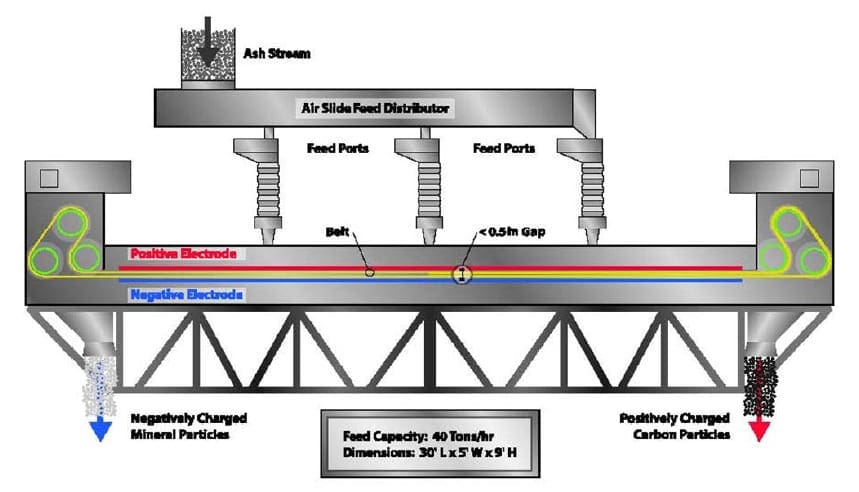

In the STET carbon separator (Фигура 1), the material is fed into the thin gap between two parallel planar electrodes. The particles are triboelectrically charged by interparticle

контакт. The positively charged carbon and the negatively charged mineral (in freshly generated ash that has not been wetted and dried) са привлечени от противоположни електроди. The particles are then swept up by a continuous moving belt and conveyed in opposite directions. Коланът премества частиците в съседство с всеки електрод към противоположните краища на. Високата скорост на ремъка също позволява много високи пропускания, до 36 тона на час в един сепаратор. Малката разлика, high voltage field, countercurrent flow, vigorous particle-particle agitation and self-cleaning action of the belt on the electrodes are the critical features of the STET separator. Чрез контролиране на различни параметри на процеса, като скорост на ремъка, the feed point, и процент на фуражите, процесът на STET произвежда ниска ЛОИ муха пепел при въглеродно съдържание по-малко от 1.5 за да 4.5% from feed fly ashes ranging in LOI from 4% към над 25%.

Фигура. 1 STET Separator

Разделител дизайн е сравнително прост и компактен. Машина, проектирана за обработка 36 тона на час е приблизително 9 м (30 Фута.) дълъг, 1.5 м (5 Фута.) широк, and 2.75 м (9 Фута.) високо. Коланът и свързаните ролки са единствените движещи се части. Електродите са стационарни и съставена от подходящо устойчив материал. The belt is made of nonconductive plastic. The separator’s power consumption is about 1 киловатчас на тон материал, преработен с по-голямата част от мощността, консумирана от два мотора, задвижващи колана.

Процесът е изцяло сух, requires no additional materials other than the fly ash and produces no wastewater or air emissions. The recovered materials consist of fly ash reduced in carbon content to levels suitable for use as a pozzolanic admixture in concrete, and a high carbon fraction useful as fuel. Използването на двата потока продукти 100% решение за отстраняване на проблеми с изхвърлянето на.

RECOVERED FUEL VALUE OF HIGH-CARBON FLY ASH

In addition to the low carbon product for use in concrete, brand named ProAsh®, the STET separation process also recovers otherwise wasted unburned carbon in the form of carbon-rich fly ash, branded EcoTherm™. EcoTherm™ has significant fuel value and can easily be returned to the electric power plant using the STET EcoTherm™ Return system to reduce the coal use at the plant. When EcoTherm™ is burned in the utility boiler, the energy from combustion is converted to high pressure /high-temperature steam and then to electricity at the same efficiency as coal, Обикновено 35%. The conversion of the recovered thermal energy to electricity in ST Equipment & Technology LLC EcoTherm™ Return system is two to three times higher than that of the competitive technology where the energy is recovered as low-grade heat in the form of hot water which is circulated to the boiler feed water system. EcoTherm™ is also used as a source of silica and alumina in cement kilns, displacing the more expensive raw materials, such as shale or bauxite, which are used in cement production. Utilizing the high carbon EcoTherm™ ash either at a power plant or a cement kiln, maximizes the energy recovery from the delivered coal, reducing the need to mine and transport additional fuel to the facilities.

STET’s Talen Energy Brandon Shores, SMEPA R.D. Мороу, NBP Belledune, RWEnpower Didcot, EDF Energy West Burton, and RWEnpower Aberthaw fly ash plants, all include EcoTherm™ Return systems. The essential components of the system are presented in Figure 2.

Фигура. 2 EcoTherm™ Return system

STET ASH PROCESSING FACILITIES

Controlled low LOI fly ash is produced with STET’s technology at twelve power stations throughout the U.S., Канада, the U.K., Полша, и Република Корея. ProAsh® fly ash

has been approved for use by over twenty state highway authorities, както и много други агенции за. ProAsh® също е сертифицирана по Канадската асоциация по стандарти и en 450:2005 стандарти за качество в Европа. Ash processing facilities using STET technology are listed in Table 1.

Таблица 1. STET Commercial Operations

| Полезност / Power Station | Местоположение | Начало на Търговски Операции | Facility Details |

|---|---|---|---|

| Duke Energy – Roxboro Station | North Carolina САЩ | Sept. 1997 | 2 Сепаратори |

| Тален Енергия - Brandon Shores Station | Maryland САЩ | Април 1999 | 2 Сепаратори 35,000 ton storage dome. Ecotherm™ Return 2008 |

| ScotAsh (Lafarge / Scottish Power Joint Venture) - Гара Лонганет | Scotland Великобритания | Октомври. 2002 | 1 Разделител |

| Jacksonville Electric Authority - St. John’s River Power Park, Е-мейл | Флорида САЩ | Май 2003 | 2 Сепаратори Coal/Petcoke blends Ammonia Removal |

| South Mississippi Electric Power Authority R.D. Мороу Station | Mississippi САЩ | Януари. 2005 | 1 Разделител Ecotherm™ Return |

| New Brunswick Power Company Belledune Station | New Brunswick, Канада | Април 2005 | 1 Разделител Coal/Petcoke Blends Ecotherm™ Return |

| RWE npower Didcot Station | England Великобритания | Август 2005 | 1 Разделител Ecotherm™ Return |

| Talen Energy Brunner Island Station | Pennsylvania САЩ | Декември 2006 | 2 Сепаратори 40,000 Ton storage dome |

| Tampa Electric Co. Big Bend Station | Флорида САЩ | Април 2008 | 3 Сепаратори, Двоен проход 25,000 Ton storage dome Ammonia Removal |

| RWE npower Aberthaw Station (Lafarge Cement UK) | Wales Великобритания | Септември 2008 | 1 Разделител Ammonia Removal Ecotherm™ Return |

| EDF Energy West Burton Station (Lafarge Cement UK, Cemex) | England Великобритания | Октомври 2008 | 1 Разделител Ecotherm™ Return |

| ZGP (Лафарж цимент Полша / Сиех Яникосода JV) | Полша | Март 2010 | 1 Разделител |

| Korea South-East Power Yeongheung Units 5&6 | Южна Корея | Септември 2014 | 1 Разделител Ecotherm™ Return |

| Лафарж цимент Полша Warsaw | Полша | 2016 | 1 Разделител |

ЗАКЛЮЧЕНИЯ

Maximizing the utilization of fly ash as a cement substitute in concrete production substantially reduces the carbon dioxide emissions associated with construction activity. Въпреки това, pollution control systems implemented by the coal-fired power stations have resulted in a reduction of available fly ash meeting concrete-grade specifications. Further degradation of fly ash quality is expected due to further reductions in allowable gas emissions. In order to avoid loss of this valuable resource of material for concrete production as well as reduction of greenhouse gas emissions associated with concrete construction, processes for restoring the quality of the fly ash in an economic and environmentally viable way are needed.

The beneficiation of fly ash with STET processes further increases the supply of this important material. The STET beneficiation processes continue to be the most extensively applied methods to upgrade otherwise unusable fly ash to high-value materials for cement replacement in concrete. Eighteen SETT carbon separators are currently in place with over 100 machine-years of operation.

ProAsh® has found wide acceptance in the concrete industry as a premium fly ash requiring far less monitoring of air entrainment requirements due to less LOI variability than other ashes. Returning the high-carbon concentrate from the STET process to the boiler at a power plant allows recovery of the recovered carbon fuel value at an efficiency similar to coal. STET offers economical means to recover ash for high-value use that would otherwise be landfilled. Electrostatic carbon separation and Ecotherm™ return to the boiler provide a modular solution to a utility’s fly ash needs. These processes can be implemented in phases, or as a single project.

ПРЕПРАТКИ

[1] American Coal Ash Coal Combustion products and Use Statistics:

https://www.acaa-usa.org/Publications/Production-Use-Reports/