Yan Language:

Barite ni jc, nipa ti sẹlẹ ni, barium-orisun erupe. barium, atomiki nọmba 56, derives awọn oniwe orukọ lati Greek ati ki o tumo eru. Barite ni a tun mo bi baryte. Awọn jc-ede ninu eyi ti owo idogo ti barite ti wa ni Lọwọlọwọ ri ni o wa ni United States, China, India ati Morocco. Barite ká ga iwuwo ati kemikali inertness ṣe awọn ti o ohun bojumu ni erupe ile fun ọpọlọpọ awọn ohun elo.

Awọn kemikali agbekalẹ fun barite ni BaSO4. O ni o ni kan to ga kan pato walẹ ti 4.50 g / cm3. Awọn oniwe-Mohs líle ni 3.0 to 3.5. Barite, eyi ti o le wa ni ri ni orisirisi kan ti awọ pẹlu ofeefee, brown, funfun, blue, grẹy, tabi paapa colorless, ojo melo ni o ni a vitreous to pearly luster.

Barite le ri ni apapo pẹlu mejeeji ti fadaka ati ki o nonmetallic ni erupe ile idogo. Lati wa ni aje dada fun isediwon, barite maa nilo lati wa ni awọn predominant ohun elo ti ni a idogo. Awọn orisi ti idogo ninu eyi ti o ti wa ni deede ri ni isan, péye, ati bedded. Isan ati péye idogo o wa ti hydrothermal Oti, nigba ti bedded idogo ti wa ni sedimentary.

Major idogo ni United States ti a ti ri ni Georgia, Missouri, Nevada ati Tennessee. ni Canada, awọn ni erupe ile ti a ti mined ninu awọn Yukon Territory, Nova Scotia ati Newfoundland. ni Mexico, barite idogo ti a ti se awari ni Hermosillo, Pueblo, Monterrey ati Durango.

The overwhelming majority of the barite that is mined is used by the petroleum industry as a weighting material in the formulation of drilling mud. Barite increases the hydrostatic pressure of the drilling mud allowing it to compensate for high-pressure zones experienced during drilling. The softness of the mineral also prevents it from damaging drilling tools during drilling and enables it to serve as a lubricant. The American Petroleum Institute (API) has established specifications for the use of barite in drilling mud.

Dry Barite Beneficiation

STET has both pilot scale and commercial experience processing barite to remove gangue such as silicates, iron, and alumina. Low-grade barite beneficiation with a specific gravity between 3.5 - 4.0 has been successfully upgraded using the STET process to product API-grade barite.

STET can demonstrate that the dry electrostatic separation process offers many advantages over traditional wet processing methods (flotation) pẹlu:

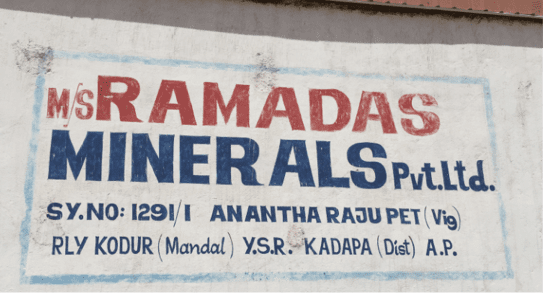

Disrupting a new industry is always a challenge. ST Equipment & Technology and Ramadas Minerals Pvt. Ltd. in India understand this challenge well. Ramadas Minerals contacted STET to perform testing of a low grade barite / quartz sample produced at the APMDC barite mine in Andhra Pradesh, India. The material was a low grade tailings product from the mining process. It contained too much silica to be sellable as a high SG barite product, and was being produced in large volumes. What was needed was a process to transform the mining waste to usable product. Wet processing (flotation) was one alternative technology being considered.

Testing at the STET pilot facility demonstrated excellent separation results for the barite powder. The STET separator was able to achieve the goal of +4.20 SG barite through a single separation step.

The STET separator was fit into the existing building, which was originally designed to house a flotation facility. The STET separator installation resulted in significant savings of space, in relation to the previously designed flotation facility. Ni afikun, a substantial reduction in capital and operating cost was realized.

Contact STET to learn more about dry processing of barite.