Select Puo:

The ST Helmets & Technology LLC (STET) tribo-electrostatic lebanta kgaoganyo e loketse hantle bakeng sa ho una molemo haholo (<1μm) ho tekano mahoashe (500μm) liminerale tsa liminerale, ka phallo e phahameng haholo. Fumanoeng liteko tsa bontša bokhoni ba kgaoganyo STET ho beneficiate ba disampole bauxite ke eketseha ea alumina ha ka nako e tšoanang ho fokotsa arabelang le palo yohle silica. Theknoloji ea STET e hlahisoa e le mokhoa oa ho ntlafatsa le ho tsepamisa mohopolo ho li-depositi tsa bauxite bakeng sa ts'ebeliso ea tlhahiso ea alumina. Sebetsa omileng le kgaoganyo STET tla fella ka ho fokotsa ditjeo tsa ho sebelisa mechini ea hloekisoang ka lebaka la tshebediso ya tlaase ea soda le ho e caustic, Ho boloka matla ka lebaka la molumo o tlase oa li-oxide tsa inert le phokotso ea masalla a alumina a ho hloekisa (ARR kapa seretse se sefubelu). Holim'a moo, theknoloji ea STET e ka fana ka tsa alumina tse hloekisang melemo e meng ho kenyelletsa le mehloli e eketsehileng ea likwari, Katoloso ea bophelo ba setsi sa likhohola tse khubelu, le bophelo bo eketsehileng ba ts'ebetso ea merafong e teng ea bauxite ka ho ntlafatsa ts'ebeliso ea lits'ebetso tsa likhopo le ho phahamisa pholoso. Sehlahisoa se se nang metsi le se se nang lik'hemik'hale se hlahisoang ke ts'ebetso ea STET se ka sebelisoa bakeng sa ho etsa samente ka bongata ntle le kalafo ea pele, ho fapana le seretse se sefubelu se nang le ts'ebeliso e ntle e fokolang.

1.0 Selelekela

tlhahiso ea aluminium ke ea bohlokoa bohareng bakeng sa lefapha meepo le metallurgy le motheo bakeng sa mefuta e fapaneng ya le liindasteri [1-2]. Ha a ntse a aluminium ke atileng ka ho fetisisa metallic elements fumanoa lefatšeng, ka palo yohle mabapi 8% ea karolong e ka holimo ea Lefatše, e elements e ke arabelang 'me ka hona ha e tlhaho [3]. Kahoo, aluminium ho rua litlhoko tsa manya ho e hloekisitsoeng ho hlahisa lihlahisoa tsa ea alumina le aluminium, sephetho le molokong bohlokoa ba litlhaka kahare [4]. Jwalo ka boleng ba bauxite mobung lefatšeng ka bophara fokotseha, ho moloko oa eketseha masalla, posing diphephetso tseo ho ea alumina le aluminium ho etsa indasteri ya ka dipehelo tsa sebetsana ditjeo, ditshenyehelo tsa ho lahla le ama tikoloho [3].

Le ka sehloohong a simolla boitsebiso bakeng sa aluminium ho hloekisoa ke bauxite, a lefatše a ka sehloohong khoebo mohloli oa aluminium [5]. Bauxite ke ntlafalitse aluminium hydroxide sedimentary lefika, hlahiswa ho tloha laterization le bosa a mafika ruileng oxides tšepe, oxides aluminium, kapa ka bobeli ka tloaelo nang quartz le clays joaloka kaolin [3,6]. mafika Bauxite na le boholo ba ya aluminium liminerale gibbsite (Al(OH)3), boehmite (mdlody-Alo(OH)) le diaspore (a-Alo(OH)) (tafole 1), le hangata tsoakane le tse peli oxides tšepe goethite (FeO(OH)) le hematite (Fe2O3), e aluminium letsopa matsoai kaolinite, tse nyenyane tsa anatase le / kapa titania (TiO2), ilmenite (FeTiO3) le litšila tse ling tsa ka tse nyenyane kapa mosaletsa bokae [3,6,7].

Mantsoe trihydrate le monohydrate tse sebediswang ka mehla ke indasteri ho phapang mefuta e sa tšoaneng ea bauxite. Bauxite hore e ka ho feletseng kapa hoo e ka bang tsohle le behang gibbsite e bitsoa trihydrate manya; haeba boehmite kapa diaspore ke liminerale ka sehloohong e bitsoa monohydrate manya [3]. Metsoako ea gibbsite le boehmite ke lintho tse tloaelehileng mefuta eohle ea bauxites, boehmite le diaspore tlase tloaelehile hore batho ba, le gibbsite le diaspore seoelo. E mong le e mofuta oa limpho bauxite manya le mathata a hona ipatlele ya ka dipehelo tsa diminerale sebetsa le beneficiation bakeng sa moloko oa ea alumina [7,8].

tafole 1. Lik'hemik'hale tsa Gibbsite, Boehmite le Diaspore [3].

| Sebopeho sa Lik'hemik'hale | Gibbsite AL(OH)3 or Al2O3.3H2The | Boehmite ALO(OH) or Al2The3.H2The | Diaspore ALO(OH) or Al2The3.H2The |

|---|---|---|---|

| Al2The3 wt% | 65.35 | 84.97 | 84.98 |

| (OH) wt% | 34.65 | 15.03 | 15.02 |

Bauxite mobung ke ha namela libakeng tse lefatšeng ka bophara, hangata li etsahala libakeng tse chesang tse mongobo kapa tropike [8]. Bauxite meepo la bobeli metallurgical le batho bao e seng metallurgical sehlopheng tšepe e analogous ho meepo oa liminerale tse ling liindasteri. Ka tloaelo, le beneficiation kapa kalafo ya bauxite e felle feela sithabetsa, sieving, ho hlatsoa, le omisa tsa manya a sa jese litheohelang [3]. Flotation e se e hiriloe ho ntlafatso ya itseng tlaase sehlopheng bauxite tšepe, Leha ho le joalo ha lea ka proven haholo khetha ho lahla kaolinite, le sesosa se seholo sa silica arabelang haholo-holo bauxites trihydrate [9].

The bongata ba bauxite hlahisitseng lefatšeng e sebediswa e le fepa ka bakeng sa ho etsa thepa ea ea alumina dessyecik tshebetso Bayer, Mokgwa wa metsi a nang le khemikhale e nang le metsi a mangata moo Al_2 O_3 e qhibilihang ka ntle ho lefika la bauxite ka ho sebelisa tharollo e nang le soda e nang le soda le mocheso o phahameng le khatello [3,10,11]. Ka mor'a moo, le bongata ba ea alumina e sebelisoa e le fepa ka bakeng sa tlhahiso ea tšepe aluminium ka tsela tshebetso Hall-Héroult, eo e akarelletsa ho electrolytic phokotso ya ea alumina ka hlatsoa ka cryolite (Na3AlF6). Ho nka ka 4-6 boima ba lithane bauxite omisitsoeng ho lihlahisoa 2 sa t ya ea alumina, eo ka chenchana chai 1 sa t tsa tšepe aluminium [3,11].

Tsela Bayer e qadile ke ho kopanya hlatsoa le khabeloa fatše bauxite le tharollo Leach. La sephetho slurry nang 40-50% -butle ka nako eo pressurized le halefile le mouoane. Ka mohato ona ba bang ba ea alumina e qhibiliha le e bopa qhibilihang ka har'a sodium aluminate (NaAlO2), empa ka lebaka la ho ba teng ha silica arabelang, e rarahaneng sodium aluminium metaborate hape precipitates eo e emela ho felloa ke bobeli ea alumina le soda. The slurry sephetho le e hlatsoa, le masalla generated (i.e., khubelu seretse) e decanted. Sodium aluminate e ebe tseko joaloka aluminium trihydrate (Al(OH)3) ka tshebetso seeding. La sephetho caustic soda tharollo e recirculated ka tharollo Leach. Qetellong, le e tlhotliloeng le hlatsoa tiileng ea alumina trihydrate e thunya kapa calcined ho lihlahisoa ea alumina [3,11].

Leaching thempereichara e ka 'na Range ho tloha 105 ° C ho 290 ° C le likhatello ngollana Range ho tloha 390 kPa ho 1500 kPa. Ka tlaase mocheso ho mekoloko ba sebediswa bakeng sa bauxite seo hoo e ka bang tsohle tse ea alumina fumaneha se teng ka gibbsite. Lithemparetjha tse phahameng li hlokahala ho digedepositsst bauxite e nang le liperesente tse kholo tsa boehmite le diaspore. Maemong a thempereichara ea 140 ° C kapa ka tlase ke lihlopha tsa gibbsite le kaolin tse qhibilihang ka har'a joala bo nang le soda mme ka hona mocheso o joalo o khethoa bakeng sa ts'ebetso ea alumina ea trihydrate . Ha thempereichara e khōlō ho feta 180 ° C ea alumina joale ka trihydrate le monohydrate ke revocable ka tharollo 'me clays bobeli' me a lokolle quartz ba arabelang [3]. maemo a ho sebetsa tse jwalo ka mocheso, khatello le reagent litekanyetso li behoa ba susumetsoa ke mofuta oa bauxite 'me ka hona e mong le e hloekisoang ea alumina e lumellanang le mofuta itseng oa manya bauxite. Tahlehelo ea theko e phahameng caustic soda (NaOH) le moloko oa khubelu seretse ba bobeli e amanang le boleng ba bauxite sebelisoa mosebetsing oa ho hloekisa. Ka kakaretso, ho theola Al_2 O_3 dikahare tsa bauxite, e kholoanyane molumo oa khubelu seretse hore tla generated, e le mekhahlelo e bao e seng Al_2 O_3 ba hana ka khubelu seretse. Holim'a moo, a phahameng kaolinite kapa arabelang silica dikahare tsa bauxite, seretse ho feta tse khubelu tla generated [3,8].

Phahameng sehlopheng bauxite na le ho fihlela ho 61% Al_2 O_3, 'me ba bangata mobung bueloang bauxite -typically hlalositsweng ka sehlopheng bao e seng metallurgical- ke hantle tlase ena, ka linako tse ling e le tlase ka 30-50% Al_2 O_3. Hobane sehlahisoa e lakatsehang ke ho hloka sekoli phahameng

Al_2 O_3, le oxides setseng ka bauxite ho (Fe2O3, SiO2, TiO2, lintho tse bonahalang manyolo) ba aroloa ho ba Al_2 O_3 le lahla e le litlhaka kahare ea alumina hloekisoang (ARR) kapa tse khubelu seretse ka tsela tshebetso Bayer. Ka kakaretso, e ka tlaase boleng ba bauxite (i.e., theola litaba tsa Al_2 O_3) seretse ho feta tse khubelu e hlahisoang ka thane e le ea sehlahisoa ea alumina. Holim'a moo, esita le ba bang ba Al_2 O_3 behang liminerale, haholo-holo kaolinite, hlahisa liphetoho tse sa rateheng-morao nakong tshebetso ho hloekisoa le ho lebisa ho eketseha ha seretse molokong o mong ka o mofubelu, hammoho le ho lahleheloa ke e bitsang chelete e ngata caustic soda lik'hemik'hale, e khōlō polygonal theko ka bauxite thulaganyou e hloekisa [3,6,8].

Red seretse kapa ARR emela e khōlō le ka-ea e-ba phephetso ho indasteri e aluminium [12-14]. Red seretse na le bohlokoa barrel caustic lik'hemik'hale tse setseng ho tloha tsamaiso e hloekisa, le ke haholo alkaline, hangata e le ph ya 10 - 13 [15]. E hlahisoang ka meqolo e kholo lefatšeng ka bophara - latela USGS ho, hakanngoa lefatše ea alumina hlahisoeng ha e ne e le 121 boima ba lithane tse limilione tse ka 2016 [16]. Sena se ile sa fella ka ho hakanngoa 150 boima ba lithane tse limilione tse seretse khubelu generated nakong eona eo [4]. Ho sa tsotellehe ho etsa lipatlisiso e tsoelang pele, khubelu seretse jwale o maloa litsela tsa ka mokhoa oa thekiso solofetsang ho molemo botjha tšebeliso. Ho hakanngoa hore e fokolang haholo ea khubelu seretse ke hamolemo botjha e sebediswa lefatšeng ka bophara [13-14]. Ho ena le hoo, seretse khubelu e pumped ho tswa ho hloekisoang ea alumina ka impoundments polokelo kapa landfills, moo e bolokwa le leihlo ka theko e kholo [3]. Ka lebaka leo,, bobeli ngangisano moruo le tikoloho ka etswa bakeng sa ho ntlafatsa boleng ba bauxite pele ho hloekisoa, ka ho khetheha haeba Ntlafatso joalo ho ka etsoa ka tlase eneji, le dithekeniki 'meleng karohano.

Ha a ntse a mehloli proven tsa bauxite ba lebelletswe ho qetela bakeng sa lilemo tse ngata, boleng ba mehloli eo ka moruong accessed e fokotseha [1,3]. bakeng sa refiners, ba leng khoebo ea sebetsana bauxite ho ho etsa ea alumina, le tšepe 'me qetellong a aluminium, ena ke ntho e thata ka boleloang bobeli lichelete le tikoloho

mekhoa Dry kang karohano electrostatic ka 'na ho thahasella ea indasteri ea bauxite bakeng sa pele ho ea mahloriso ea bauxite pele ho tshebetso Bayer. mekhoa Electrostatic karohano hore sebelisa ho ikopanya, kapa tribo-motlakase, tjhaja ke dintlha ka botlalo e thahasellisang ka lebaka la bokhoni ba bona ba arohane e le tse ngata tse metsoako e nang le conductive, kokabolaka, le likaroloana seka-conductive. Tribo-motlakase tjhaja etsahala ha discrete, likaroloana dissimilar a thulana le ba bang, kapa ka holim'a boraro, sephetho le ka holim 'qoso phapang pakeng tsa mefuta e' meli phatsa. pontšo ea ho le boholo ba phapang qoso itšetlehile karolo e 'ngoe ka ho se tšoane ha elektrone amana (kapa mosebetsi mosebetsi) pakeng tsa mefuta e sa phatsa. Karohano ka ka nako eo ho fihlellwa sebelisa ya kwa sebelisoa tšimo motlakase.

mokhoa ona o 'nile sebelisoa industrially ka paatsepama mahala-ho oa mofuta separators. Ka separators mahala-ho oa, likaroloana pele fumana qoso, ebe oe ka matla a khoheli ka sesebediswa sa le hanyetsa li-electrode e sebetsang e matla ea tšimo ea motlakase ho hlokomoloha ka tsela ya likaroloana ka latela letšoao le boholo ba tlhokomelong ea bona holim ' [18]. Free-ho oa separators ka ba molemo bakeng sa ho likaroloana mahoashe empa ha e atlehang ka ho sebetsana le likaroloana molemo ho feta ka 0.075 ho 0.1 limilimithara [19-20]. E mong oa ka ho fetisisa tšepisa tsoelo-pele e ncha ka karohano omileng matsoai ke tribo-electrostatic lebanta kgaoganyo. theknoloji ena e atoloswa ho phatsa boholo mefuta e fapaneng ya ho molemo likaroloana ho feta tloaelehileng theknoloji e electrostatic karohano, ka mefuta e fapaneng moo feela flotation e atlehile nakong e fetileng.

Tribo-electrostatic karohano utilizes se tšoane motlakase qoso pakeng tsa thepa e hlahisitsoeng ke ho ikopanya le holim 'kapa triboelectric tjhaja. Ka litsela tse sa fetelelitsoeng, ha thepa tse peli tse a kopana, boitsebiso le amana le phahame bakeng sa electros maruo dieleketerone kahoo ba fetoha mpe, ha lintho tse bonahalang le ka tlaase le elektrone e amana file positive,.

The ST Helmets & Technology (STET) tribo-electrostatic lebanta kgaoganyo e fana ka bukeng beneficiation eang pele ho mamelisisa bauxite tšepe. The STET omileng karohano thulaganyou e fana ka bauxite bahlahisi kapa refiners bauxite le monyetla oa ho etsa mesebetsi ea pele ho Bayer-thulaganyou e ntlafatso ya manya bauxite ho ntlafatsa boleng. Mokhoa ona o na le melemo e mengata, ho kopanyelletsa le tse: Ho fokotseha ha sebetsa litsenyehelo tsa ho hloekisoang ka lebaka la ho noa ka tlaase ea soda caustic ka ho fokotsa input arabelang silica; chelete ka eneji, le nakong ea hloekisa ka lebaka la ho bophahamo ba modumo ea oxides inert theola (Fe2The3, Tio2, Bao e seng arabelang Sio2) kena ka bauxite; boima phallo nyenyane tsa bauxite ho hloekisoang le tlhokahalo ka tlaase matla a ho mocheso le pressurize; ho fokotseha ha khubelu seretse molokong o mong ka bophahamo ba modumo (i.e., khubelu seretse ho karo-karolelano ea alumina) ke ho tlosa silica arabelang le inert oxide e; le, tiisa mesifa laola input bauxite boleng eo ho fokotsa thulaganyou e o tshwenyang le dumella refiners ho shebiloeng loketseng arabelang boemo ba silica ho e fumantsa hloeke khesoa. Ntafaditsweng boleng laola iphepe bauxite ho hloekisoang hape maximizes uptime le tlhahiso. Ho feta moo, ho fokotseha ha khubelu seretse bophahamo ba modumo fetolela ka kalafo le ho lahla ka tlase ditjeo le tshebediso molemo tsa landfills o teng.

The preprocessing tsa manya bauxite pele ho tshebetso Bayer a ka fana ka menyetla ea bohlokoa ka ho ya ka sebetsana le thekiso ea tailings. Ho fapana le tse khubelu seretse, tailings tswa omileng thulaganyou e electrostatic na ha lik'hemik'hale 'me u se ke ua emela nako e telele tikoloho polokelo melato. Ho fapana le tse khubelu seretse, ommeng ka lihlahisoa / tailings tswa pele ho sebetsana bauxite tshebetso ka sebelisoa ka proizvodnje samente e le ha ho na e hlokahalang ho tlosa sodium, e leng ke kotsi ho proizvodnje samente. Ha e le hantle - bauxite e se e ntse e tloaelehile hore batho ba lintho tse bonahalang e tala bakeng sa samente difeme Portland. Extending bueloang bophelo ba leng teng merafong bauxite e ka boela ea e ile ea fihla ka ho ntlafatsa koari tshebediso le maximizing hlaphoheloa.

2.0 liteko

2.1 thepa

STET khanna lithuto tsa pele ho mehla ea bokgono tse fetang 15 disampole fapaneng bauxite ho tloha libakeng tse sa tšoaneng lefatšeng ka bophara sebelisa kgaoganyo bencheng ka tekanyo. tsena, 7 disampole fapaneng ne

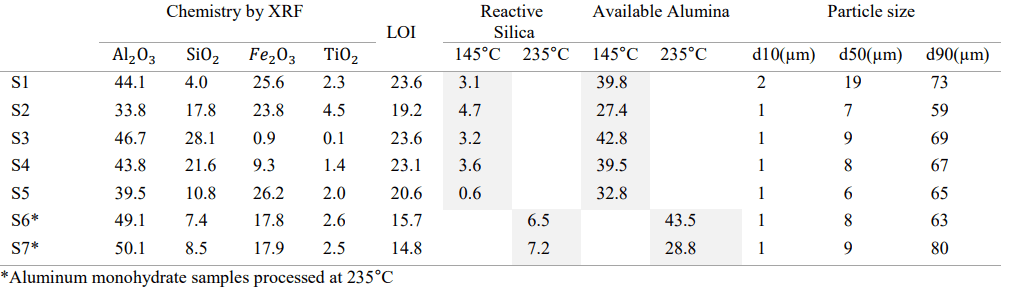

tafole 2. Fella ea lik'hemik'hale and analysis disampole bauxite.

2.2 mekhoa

Liteko li ne li khanna sebelisa bencheng ka tekanyo tribo-electrostatic lebanta kgaoganyo, o fano hlalositsweng ka 'benchtop kgaoganyo'. Bencheng ka tekanyo e etsa liteko e karolong e qalang ea tse tharo mohato thekenoloji thulaganyou e kenngwa tshebetsong (sheba Lethathamo 3) ho akarelletsa le bencheng ka tekanyo sekasekale, motsamaisi-tekanyo e etsa liteko le ho kenngwa tshebetsong khoebo tekanyo.

The kgaoganyo benchtop e sebediswa bakeng sa ho screening 'bakeng sa bopaki bo tribo-electrostatic tjhaja le ho fumana hore na lintho tse bonahalang le ke nkgetheng molemo bakeng sa ho beneficiation electrostatic. Ho se tšoane ka sehloohong pakeng tsa mong le e sengoathoana sa thepa tse hlahisoang Lethathamo 3. Ha thepa sebelisoa ka hare ho e mong le e mohato fapana ka boholo, tshebetso molao-motheo e feletseng e tšoanang.

tafole 3. Tse tharo-mohato thulaganyou e kenngwa tshebetsong ho sebedisa STET tribo-electrostatic lebanta kgaoganyo thekenoloji

| Phase | Used for: | Electrode Length cm | Type of Process |

|---|---|---|---|

| 1- Bench Scale Evaluation | Qualitative Evaluation | 250 | Batch |

| 2- Pilot Scale Testing | Quantitative evaluation | 610 | Batch |

| 3- Commercial Scale Implementation | Commercial Production | 610 | Continuous |

E le ka bonoa Lethathamo 3, phapang ka sehloohong pakeng tsa kgaoganyo benchtop le motsamaisi-tekanyo e le separators khoebo-tekanyo e ke hore bolelele ba kgaoganyo benchtop ke hoo e ka bang 0.4 linako tse bolelele ba diyuniti motsamaisi-tekanyo e le ea khoebo-tekanyo e. E le bokgoni kgaoganyo ke mosebetsi wa bolelele eleketrode, bencheng ka tekanyo e etsa liteko ka se sebelisoa e le ka nkang sebaka sa liteko motsamaisi tekanyo. Pilot tekanyo liteko ke ke ho hlokahala ho fumana hore na isa tekanyong ea karohano eo tshebetso STET ka fihlella, le ho fumana hore na STET thulaganyou e ka kopana le liphofu sehlahiswa tlas'a ditefello fanoeng iphepe. Ho ena le hoo, le kgaoganyo benchtop e sebediswa ea ho busa tsoa thepa nkgetheng tse hlola a bontša karohano leha e le efe bohlokoa ka boemo ba motsamaisi-tekanyo e. Results fumana ka bencheng ka tekanyo e tla bao e seng optimized, le karohano a hlokomela e ka tlase ho e neng e tla ho ketekoa ka khoebo boholo bo lekaneng STET kgaoganyo.

Leka ka dimela motsamaisi ke ho hlokahala hore pele ho khoebo tekanyo e dulang, Leha ho le joalo, liteko ka bencheng ka tekanyo e kgothaletswa e le karolong e qalang ea tshebetso kenngwa tshebetsong bakeng sa lintho tse bonahalang leha e le efe. Ho feta moo, maemong a eo ho eona ho fumaneha lintho tse bonahalang e le felle, le benchtop kgaoganyo fana sesebelisoa le thuso ya ho ho screening ea merero bokgoni ba le atlehileng. (i.e., diprojekeng tse moreki le indasteri liphofu boleng ka ba ile ba kopana ho sebelisa thekenoloji STET).

2.2.1 STET Triboelectrostatic lebanta la kgaoganyo

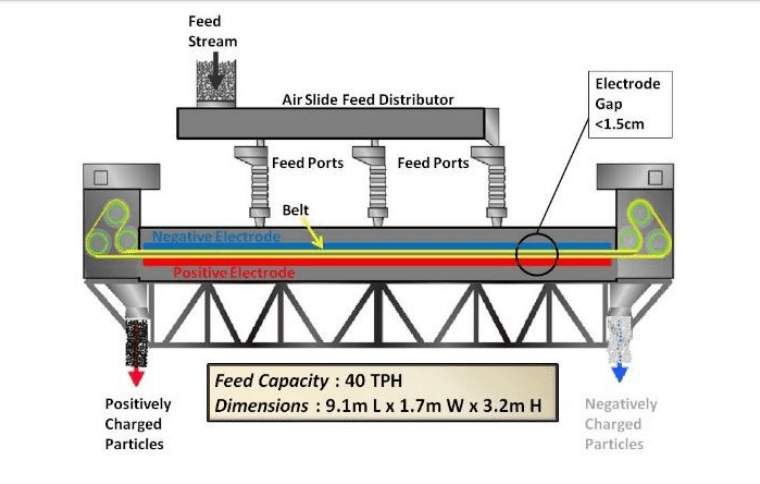

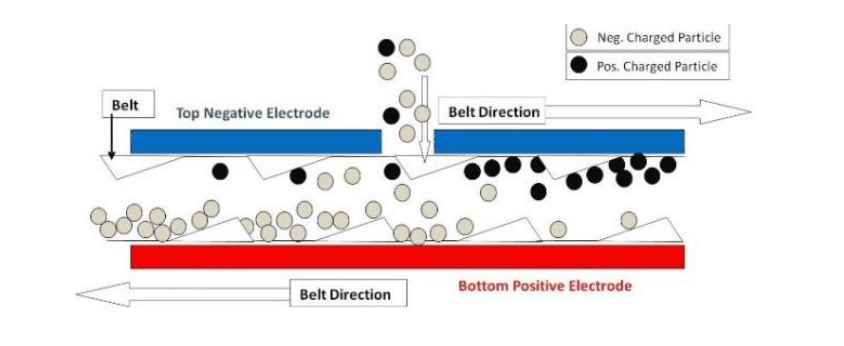

Ka tribo-electrostatic lebanta kgaoganyo (Figure 1 le Figure 2), lintho tse bonahalang feptjoang ka lekhalo tšesaane 0.9 - 1.5 cm, pakeng tsa tse peli tse li-electrode e tšoanang planar. likaroloana li triboelectrically qosoa ke interparticle o ikopanye. Ka mohlala, tabeng ea ea sampole bauxite eo constituents ka sehloohong ke gibssite, kaolinite le quartz likaroloana matsoai, ea sebele qosoa (gibssite) le hlonamisitsoe qosoa (kaolinite le quartz) ba khahloa ke li-electrode bo fapaneng. likaroloana li ebe hoholoa ho fihlela ke e tsoelang pele ho fallela lebanta bulehileng-letlooeng le fetisoa ka litaelo bo fapaneng. Lebanta susumelletsa ho likaroloana haufi le e mong le e eleketrode nģ'a lipheletsong fapaneng kgaoganyo ho. Ea tšimo ea motlakase ho hlokahale feela susumelletsa likaroloana karoloana e nyenyane ea disentimitara ka ho fallela ka phatsa tswa letšehali-fallela letona fallisetseng le molapo. The stats jwale phallo ya likaroloana arola le tsoele pele triboelectric tjhaja ke thulana phatsa e fana ka bakeng sa karohano selotlolo sethaleng le ho fella ka ho hloka sekoli babatsehang le hlaphoheloe ka unit trust le 'ngoe-fetisetsana. The phahameng lebanta lebelo hape nolofalletsa throughputs phahameng haholo, ho fihlela ho 40 tonnes ka hora ka kgaoganyo e le 'ngoe. Ke ho laola entsprechen tse fapa-fapaneng thulaganyou e, sesebediswa dumella gogolo ea sehlopheng matsoai le hlaphoheloe.

Figure 1. Tlhohlomiso tsa triboelectric lebanta kgaoganyo

Moralo kgaoganyo ke batlang e bonolo. Lebanta le rollers se amahanngoang ke likarolo feela ho fallela. li-electrode ho ba ema le entsoe ka e lintho tse bonahalang ka nepo tsoarellang. lebanta e entsoe ka lintho tse bonahalang polasetiki. The kgaoganyo eleketrode bolelele ke hoo e ka bang 6 limithara tse (20 feat.) le bophara 1.25 limithara tse (4 feat.) bakeng sa e tletseng boholo diyuniti khoebo. The tshebediso ya matla e ka tlase ho 2 kilowatt-hora ka tonne boitsebiso sebetswa ka ho fetisisa ea matla a chesa ke Motors tse peli khanna lebanta.

Figure 2. Dintlha tsa libaka karohano

tshebetso e ommeng ka ho feletseng, hloka ha thepa tse eketsehileng 'me a hlahisa metsi litšila kapa mesi e kotsi moeeng. Bakeng sa karohano matsoai le kgaoganyo fana ka thekenoloji ho fokotsa tšebeliso ea metsi, eketsa pokello bophelo le / kapa hlaphoheloa le reprocess tailings.

The compactness ea tsamaiso e lumella tenyetsehe merero tlhomamiso. The tribo-electrostatic lebanta karohano thekenoloji ke robust le industrially proven le ile la pele e sebelisoa industrially ho e lokisa ya mashala combustion e fofa molora ka 1997. thekenoloji ke atleha ho arola likaroloana k'habone ho tswa ho go tuka ga molelo fella oa mashala, ho tswa ho le kang khalase le likaroloana aluminosilicate matsoai ka fofa molora. theknoloji e bile phetha karolo nolofalletsa recycle ea matsoai ho rua fofa molora ka Phetolo samente tlhahiso ka konkreiti.

Ho tloha 1995, tse fetang 20 tonnes milione tsa sehlahisoa fofa molora di sebetswa ke STET separators hlomamisa ka USA. Histori liindasteri tsa karohano fofa molora e ngotsweng Lethathamo 4.

Ka liminerale sebetsa, le triboelectric lebanta kgaoganyo thekenoloji 'nile la sebelisoa ho arohana e mengata e fapaneng ea thepa ho akarelletsa calcite / quartz, talc / magnesite, le barite / quartz.

Figure 3. Commercial tribo-electrostatic lebanta kgaoganyo

tafole 4. Industrial kopo ya tribo-electrostatic lebanta karohano ho fofa molora.

| utility / seteishene matla | Location | Qala tshebetso khoebo | dintlha setsing |

|---|---|---|---|

| Duke Energy - Roxboro Station | North Carolina USA | 1997 | 2 Separators |

| lipuo Energy- Brandon Shores | Maryland USA | 1999 | 2 Separators |

| Scotland Power- Longannet Station | Scotland UK | 2002 | 1 kgaoganyo |

| Jacksonville Electric-St. Johns River Power Park | Florida USA | 2003 | 2 Separators |

| Motlakase oa South Mississippi -R.D. Morrow | Mississippi USA | 2005 | 1 kgaoganyo |

| New Brunswick Power-Belledune | New Brunswick Canada | 2005 | 1 kgaoganyo |

| OF npower-Didcot Station | Engelane UK | 2005 | 1 kgaoganyo |

| Seteishene sa Sehlekehleke sa Talen Energy-Brunner | Pennsylvania USA | 2006 | 2 Separators |

| Tampa Electric-Big Bend Station | Florida USA | 2008 | 3 Separators |

| OF npower Aberthaw-Station | Wales UK | 2008 | 1 kgaoganyo |

| EDF Energy-West Burton Station | Engelane UK | 2008 | 1 kgaoganyo |

| ZGP (Lafarge Cement / Ciech Janikosoda JV) | Poland | 2010 | 1 kgaoganyo |

| Korea Boroa-bochabela Power- Yeongheung | Korea Boroa | 2014 | 1 kgaoganyo |

| PGNiG Termika-Sierkirki | Poland | 2018 | 1 kgaoganyo |

| Khampani ea Taiheiyo Cement-Chichibu | Japane | 2018 | 1 kgaoganyo |

| Armstrong Fly Fly Ash- Samente ea Ntsu | Philippines | 2019 | 1 kgaoganyo |

| Korea Boroa-bochabela Power- Samcheonpo | Korea Boroa | 2019 | 1 kgaoganyo |

2.2.2 liteko bencheng ka tekanyo

Liteko tse tloaelehileng tsa ts'ebetso li ile tsa etsoa ho potoloha sepheo se ikhethileng sa ho eketsa mohopolo oa Al_2 O_3 le ho fokotsa khatello ea liminerale tsa gangue. Liteko li ne li khannoa ka kgaoganyo benchtop tlas'a maemo methaka, le liteko etsoa lefahla ho etsisa boemo tsitsitseng, le ho netefatsa hore ofe kapa ofe carryover e le hantle ho ka khonehang ho tloha boemong bo fetileng o ne a sa e nahana. Pele ho e mong le e teko, e nyenyane ea fepa ka-potlana sampole ile bokella (khethoa e le 'Feed'). Holim 'a beha divariabole tsohle tshebetsong, lintho tse bonahalang tse o ile a fepa ka kgaoganyo benchtop sebelisa motlakase vibratory abelang ka setsi sa kgaoganyo benchtop. Disampole ne bokella qetellong ea mong le e teko le litekanyo ea bofelo sehlahisoa 1 (khethoa e le 'E1') le qetellong sehlahisoa 2 (khethoa e le 'E2') ba ne ba ikemiselitse ho sebelisa molao-ka-khoebo ea tshephile tekanyo e. Bakeng sa disampole bauxite, 'E2' tsamaisanang le sehlahisoa bauxite e ngata. Bakeng sa e mong le e behiloeng ea potlana-disampole (i.e., Feed, E1 le E2) MOLAO, ka sehloohong oxides sebopeho ke XRF, arabelang silica le fumaneha ea alumina o ne a ikemiselitse. XRD characterization ile a etsa ka khetha-potlana disampole.

3.0 Liphetho le puisano

3.1. disampole diminerale bo

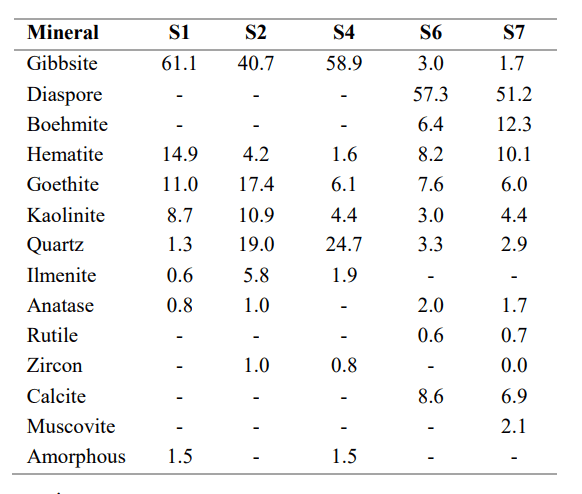

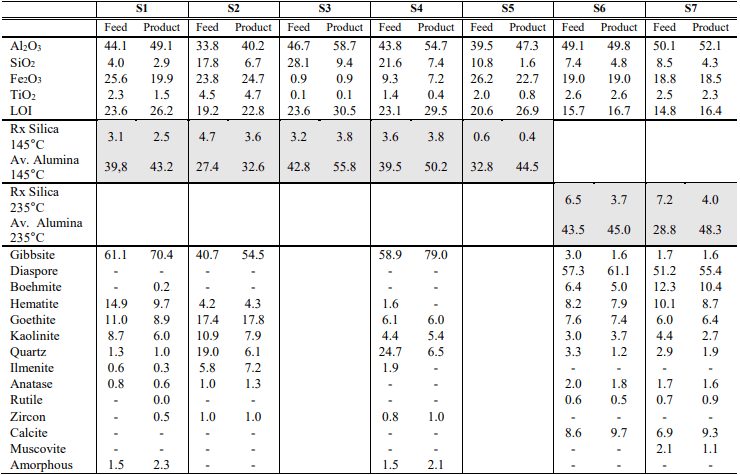

Results tsa ditirisanommogo ditshekatsheko XRD bakeng disampole fepa ka a kenyelelitsoe Lethathamo 5. Boholo ba disampole ba ne ba haholo-holo a qapa ea gibbsite le palo e sa tšoaneng ea goethite, hematite, kaolinite, le quartz. Ilmenite le anatase hape ho neng ho bonahala ka palo e nyenyane ka boholo ba disampole ho.

Ho na le e ne e le phetoho e matsoai sebopeho bakeng S6 le S7 ka disampole tsena fepa ka ba ne ba haholo-holo a qapa ea diaspore le tjhelete nyenyane tsa calcite, hematite, goethite, boehmite, kaolinite, gibbsite, quartz, anatase, le rutile ntse lemoha. E mohato amorphous hape o ne a lemoha ka S1 le S4 le di akareditse go tsewa ho tloha hoo e ka bang 1 ho 2 liphesente tse. Ena e ne e ka etsahala hore ebe ka lebaka la ho ka ho ba teng ha matsoai ka smectite, kapa lintho tse bonahalang bao e seng bonaletsang. Ho tloha ka boitsebiso boo ne o ke ke ka ho toba lekanya, diphetho tsa disampole tsena li lokela ho nkoa e lekantsoeng.

3.2 Liteko bencheng ka tekanyo

Letoto la balehela ho lona teko ne a etsa ka 'ngoe sampole matsoai ikemiseditse ho maximizing Al2O3 le fokotseha SiO_2 dikahare. Mefuta e go tlhoma tlhaloganyo mo ho sehlahisoa bauxite e ngata e tla bontsha gore go ya tjhaja boitšoaro ba-positive,. Results li bontšitsoe Lethathamo 6

tafole 5. XRD ho hlahloba disampole iphepe.

tafole 6. Summary Results.

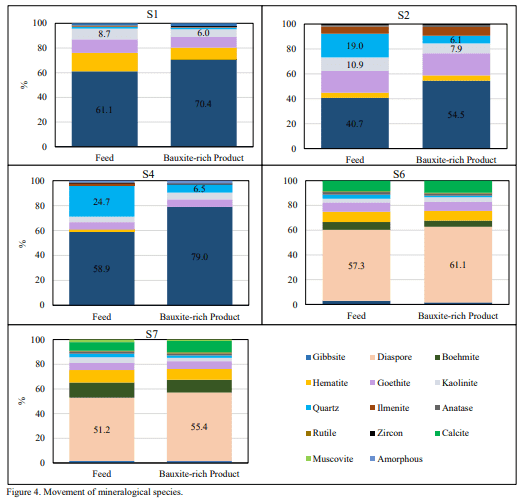

Leka le STET benchtop kgaoganyo bontša mokhatlo oa bohlokoa oa Al2O3 bakeng disampole tsohle. Karohano ya Al2O3 ile a hlokomela bakeng sa S1-5 tse neng li le haholo-holo gibbsite, le hape bakeng sa S6-7 tse neng li le haholo-holo diaspore. Holim'a moo, likarolo tse ling tse khōlō tsa Fe2O3, SiO2 le TiO2 bontša mokhatlo oa bohlokoa maemong a mangata. Bakeng sa disampole tsohle, motsamao oa le tahlehelo ka thothetsang molelo (MOLAO) lateloa motsamao oa Al2O3. Ho latela silica arabelang le fumaneha ea alumina, bakeng sa S1-5 tse hoo e ka bang tsohle gibbsite (aluminium trihydrate) makgabane lokela ho hopola ka 145 ° C ha bakeng S6-7 ao matsoai ka sehloohong ke diaspore (aluminium monohydrate) makgabane lokela ho lekanyetswa go ya ka ho 235 ° C. Bakeng sa disampole tsohle leka le kgaoganyo STET benchtop bontša keketseho mohlomong ka ea alumina fumaneha le phokotso ea bohlokoa ho silica arabelang ho sehlahisoa bakeng sa bobeli trihydrate le monohydrate disampole bauxite. Motsamao oa mefuta e ka sehloohong matsoai ne a boetse a hlokomela 'me e ka ho hlaka tse bontšitsoeng tlaase mona ka Figure 4.

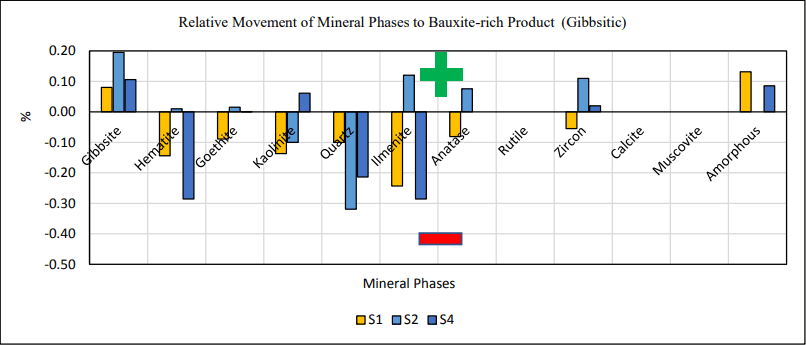

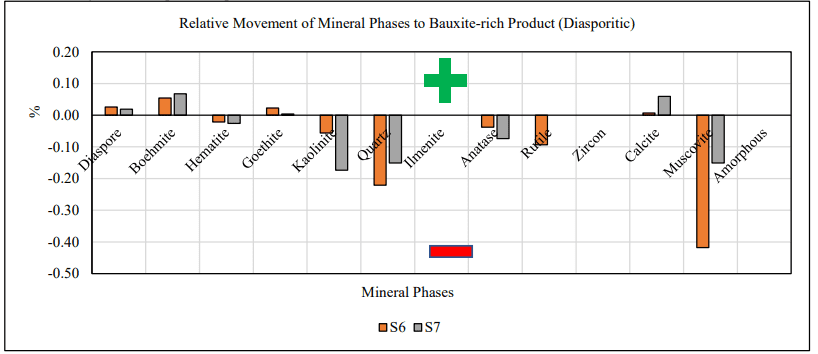

Ka ho ya ka diminerale, STET benchtop kgaoganyo bontša mahloriso tsa ea alumina behang mefuta gibbsite le diaspore ho sehlahisoa bauxite e ngata ha ka nako ho hana mefuta e meng e gangue. Figures 5 le 6 bontša selectivity tsa mekhahlelo e matsoai ho bauxite e ngata sehlahisoa bakeng trihydrate le monohydrate disampole, ho latellana. Selectivity ile balwa e le phapang pakeng tsa boima deportment ho sehlahisoa bakeng sa e mong le e mefuta matsoai le ka kakaretso boima hlaphoheloa ho sehlahisoa. A selectivity positive, ke e bontsha gore ho tsepamisa mohopolo matsoai ho sehlahisoa bauxite e ngata, le tsa e akaretsang-positive tjhaja boitšoaro bo. fapana, le boleng ba mpe selectivity ke e bontsha gore ho tsepamisa mohopolo ho coproduct bauxite-itsetlehe, le tsa e akaretsang tjhaja boitšoaro ba mpe.

Bakeng sa trihydrate disampole tsohle tlaase mocheso (i.e., S1, S2 le S4) kaolinite bontšitse e mpe lefisa boitšoaro ba le concentrated ho bauxite-itsetlehe sebedisana sehlahisoa ha gibbsite concentrated ho sehlahisoa bauxite e ngata (Figure 5). Bakeng sa monohydrate disampole tsohle phahameng mocheso (i.e., S6 le S7) bobeli arabelang silica behang liminerale, kaolinite le quartz, bontšitse e mpe lefisa boitšoaro bo. Bakeng sa ea bobeli, diaspore le boehmite tlalehela sehlahisoa bauxite-ba ruileng le ba bontšitse ntle tjhaja boitšoaro bo (Figure 6).

Figure 5. Selectivity tsa mekhahlelo e matsoai ho sehlahisoa.

Figure 6. Selectivity tsa mekhahlelo e matsoai ho sehlahisoa.

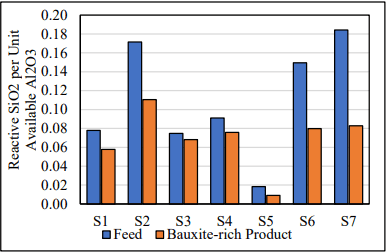

Litekanyo tsa ea alumina fumaneha le silica arabelang bontsha mokhatlo oa mohlomong. Bakeng sa bauxites tlaase mocheso (S1-S5), ka tjhelete e ya arabelang silica joale ka yuniti ya ea alumina fumaneha ile fokotswa ho tloha 10-50% ka thōko a lekanyelitsoeng (Figure 7). A phokotso tšoanang ile a hlokomela ka bauxites phahameng mocheso (S6-S7) e le ka bonoa Figure 7.

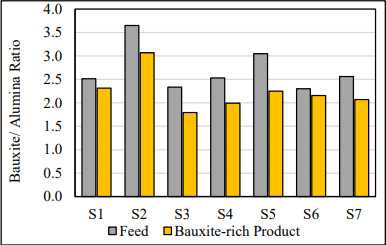

The bauxite ho karo-karolelano ea alumina ile balwa e le pitikololo tsa ea alumina fumaneha. The bauxite ho karo-karolelano ea alumina ile fokotseha ke pakeng 8 - 26% ho latela ho lekanyelitsoeng ho disampole tsohle lekoa (Figure 8). Sena ke e nang le morero e le ho emela e phokotso lekanang ka phallo boima ba bauxite e lokelang ho feptjoa ho tshebetso Bayer.

Figure 7. Arabelang SiO2 ka yuniti ya Available Al2O3

Figure 8. Bauxite ho ea alumina karo-karolelano.

3.3 puisano

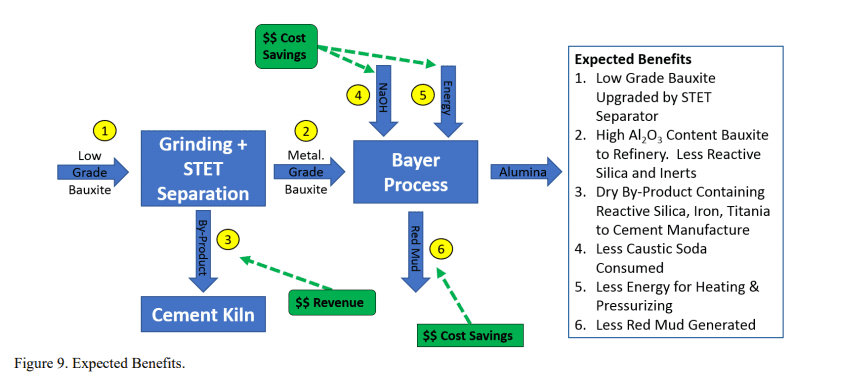

Ya data liteko bontša hore STET kgaoganyo eketsehileng fumaneha Al2O3 ha ka nako fokotsa SiO_2 dikahare. Figure 9 limpho e tlhaloganyong temperaturdiagramm ea melemo e lebeletsoe amanang le phokotseho ya silica arabelang le keketseho ea ea alumina fumaneha pele ho Process Bayer. The bangodi hakanya hore molemong lichelete ho e ea alumina mohloekisi ne e tla ba ka mefuta e fapaneng ya $15-30 USD ka thane e le ea sehlahisoa ea alumina. Sena se bontša hore ho qojoa theko tloha soda caustic lahlehileng ho de-silicaton sehlahisoa (DSP), chelete matla a ho fokotsa input tsa bauxite ho hloekisoang ho, phokotso seretseng molokong o mong ka le lefubedu le le e nyenyane le molapo matlotlo generated tloha rekisa tlaase sehlopheng bauxite ka sehlahisoa ho bahlahisi samente. Figure 9 Likemiso melemo lebeletsoe ea ho phethahatsa STET triboelectrostatic thekenoloji ka bolela'ng ho pele ho mamelisisa bauxite manya pele tshebetso Bayer.

Tlhomamiso ya STET karohano tshepetso bauxite pele ho sebetsa ka ho phethwa ka ka hloekisoang ea alumina kapa bauxite ka ka boeona. Leha ho le joalo, tshebetso STET hloka omileng sila tsa tšepe bauxite pele ho karohano, ho lokolla ho gangue, Ka lebaka leo, le dithepa tsa ho sila le ho sebetsana le bauxite ho hloekisoang ka 'na ba ho feta e tobileng.

E le khetho e 'ngoe – omeletsa bauxite ba ne ba tla fatše sebelisa omileng hantle e thehilweng sila thekenoloji, ka mohlala le paatsepama rolara leloala kapa tshusumetso leloala. The bauxite khabeloa fatše ba ne ba tla arohana ka tshebetso STET, le phahameng-ea alumina sehlahisoa bauxite romeloa ho hloekisoang ea alumina. Ho hlongoa sila omileng ne a tla lumella bakeng sa ho felisa metsi sila ka tloaelo sebediswa nakong tshebetso Bayer. E nahana hore litšenyehelo tsa ho sebelisa mehaho ea sila ommeng ka ba le kakanyo feela e ka bapisoang le theko ho sebelisa mehaho ea metsi sila, haholo-holo ho nahana ka e sila le metsi a etsa kajeno o etsoa ka motsoako le haholo alkaline, ea isang ho ditjeo khōlō tokiso.

Omeletsa tlaase sehlopheng bauxite sebedisana sehlahisoa (tailings) ho tloha tsamaiso e karohano e ne e tla rekisoa ho proizvodnje samente e le mohloli o ea alumina. Bauxite tloaelo ekeletsoa proizvodnje samente, le omileng sebedisana sehlahisoa, ho fapana le tse khubelu seretse, ha e na le sodium e neng e ka thibela ho e sebelisa ka ho proizvodnje samente. Sena se fana ka hloekisoang le mokhoa oa valorizing lintho tse bonahalang hore o ne a tla ka tsela e nngwe Tsoa ho feta tlhoekisong e khubelu seretse, le tla hloka polokelo nako e telele, emetseng theko e.

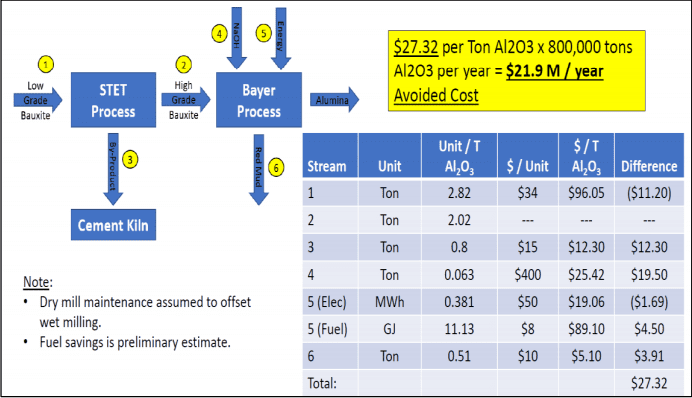

E le manolotsoeng theko ho sebelisa mehaho e etsoang ke bangodi ba hakanya morero molemong oa $27 USD ka thane e le ea ea alumina, le tshusumetso ya kgolo ya fihlellwa ka ho fokotseha ha soda caustic, ho fokotseha ha seretse se sefubelu, valorization ea sebedisana sehlahiswa le mafura a chelete ka lebaka la ho bophahamo ba modumo ka tlaase ea bauxite ho hloekisoang ho. Ka lebaka leo, e 800,000 ton ka hloekisoang selemo ka lebella ho mo thusa lichelete tsa $21 M USD ka selemo (sheba Figure 10). and analysis Sena ha se nahana ka chelete eo ae bokeletseng bokgoni ba ho tswa ho fokotsa bohlokoa kapa dithepa ditshenyehelo tsa bauxite, e ka ho eketsehileng ho ntlafatsa ka mo porojekeng e khutla.

Figure 10. Melemo ea arabelang silica Phokotso le Available ea alumina keketseho e.

4.0 Nahanisisa

Ka kakaretso, sebetsa ommeng le STET kgaoganyo e fana ka menyetla ea ho hlahisa boleng bakeng sa bahlahisi ba bauxite le refiners. Ea pele ho sebetsa pele ho bauxite hloekisoa tla fokotsa ditjeo lik'hemik'hale, fokotsa bophahamo ba modumo ea seretse khubelu generated le fokotsa thulaganyou e o tshwenyang. STET thekenoloji ka lumella processors bauxite ho retelehela bao e seng metallurgical sehlopheng ka metallurgical sehlopheng bauxite - eo ka fokotsa tlhokeho ya bauxite imported le / kapa atolosa exiting bophelo koari mohlodi. thulaganyou e STET ka boela ho sebediswa ho hlahisa boleng bo phahameng bao e seng metallurgical sehlopheng le metallurgical sehlopheng bauxite, le samente sehlopheng bauxite ka lihlahisoa pele ho tshebetso Bayer.

Tsela STET hloka hanyane pele ho kalafo ya matsoai le o sebetsang ka bokgoni ba phahameng - ho fihlela ho 40 melumo e ka hora. tshebediso ya Energy e ka tlase ho 2 kilowatt-lihora tse ka thane e le ea lintho tse bonahalang sebetswa. Ho feta moo, tshebetso STET ke botlalo commercialized thekenoloji ka liminerale sebetsana, 'me ka hona ha e hloka ho ntshetsa pele ea theknoloji e ncha.

References

1. Bergsdalen, Havard, Anders H. Strømman, le Edgar G. Hertwich (2004), “The aluminium indasteri-hlokomela tikoloho, theknoloji le ho hlahisoeng”.

2. ho, Subodh K., le Weimin Yin (2007), “Lefatšeng ka bophara moruo aluminium: Puso jwale ea indasteri ea” A re ke re 59.11, maq. 57-63.

3. Vincent G. Hill & Errol D. Sehnke (2006), "Bauxite", ka Industrial liminerale & Rocks: thepa ea, Markets, le sebelisang, Society bakeng sa morafo, Metallurgy le morolo Inc., Englewood, CO, maq. 227-261.

4. Evans, Ken (2016), “historing, diphepetso tse, le liphetoho tse ncha ka taolo ya le tšebeliso ea masalla bauxite”, Journal of ntshetsopele e tshwarellang Metallurgy 2.4, maq. 316-331

5. Gendron, Robin S., Mats Ingulstad, le Espen Storli (2013), "Aluminium manya: moruo lipolotiki tsa lefatše bauxite indasteri ", UBC Tobetsa.

6. Hose, H. R. (2016), “Bauxite diminerale”, Bohlokwa bala ka Light tšepe, Springer, Cham, maq. 21-29.

7. Authier-Martin, Monique, et al a. (2001),”The diminerale tsa bauxite bakeng sa ho hlahisa smelter-sehlopheng ea alumina ", A re ke re 53.12, maq. 36-40.

8. Hill, V. G., le R. J. Robson (2016), “The tlhophiso ea bauxites tswa Bayer dimela ka pono”, Bohlokwa bala ka Light tšepe, Springer, Cham, maq. 30-36.

9. Songqing, gu (2016). “Se-china Bauxite le Litšusumetso Eona ka ea alumina Production ka China”, Bohlokwa bala ka Light tšepe, Springer, Cham, maq. 43-47.

10. Habashi, Fathi (2016) “A lilemo tse makholo a ya Process Bayer bakeng sa ea alumina Production” Bohlokwa bala ka Light tšepe, Springer, Cham, maq. 85-93.

11. Adamson, A. N., E. J. Bloore, le A. R. Carr (2016) “melao-motheo ea Bayer thulaganyou e moralo”, Bohlokwa bala ka Light tšepe, Springer, Cham, maq. 100-117.

12. Anich, Ivan, et al a. (2016), “The ea alumina Technology Roadmap”, Bohlokwa bala ka Light tšepe. Springer, Cham, maq. 94-99.

13. Liu, Wanchao, et al a. (2014), “tsa tekolo tse tikoloho, tsamaiso le tshebediso ya khubelu seretse ka China”, Journal of hloekile Production 84, maq. 606-610.

14. Evans, Ken (2016), “historing, diphepetso tse, le liphetoho tse ncha ka taolo ya le tšebeliso ea masalla bauxite”, Journal of ntshetsopele e tshwarellang Metallurgy 2.4, maq. 316-331.

15. Liu, Yong, Chuxia Lin, le Yonggui Wu (2007), “Characterization ya khubelu seretse tsoa ka ho kopantswe Bayer Process le bauxite calcination mokhoa”, Journal of thepa kotsi 146.1-2, maq. 255-261.

16. U.S. Geological Survey (USGS) (2018), "Bauxite le ea alumina", ka Bauxite le ea alumina Lipalo-palo le lesedi.

17. Paramguru, R. K., P. C. Rath, le V. n. Misra (2004), “Trends ka khubelu seretse tshebediso-tlhahlobo”, matsoai Processing & Extractive Metall. Tšen. 2, maq. 1-29.

18. Manouchehri, H, Hanumantha Roa, k, & Fors Mountain, k (2000), "Tlhahlobo ea motlakase Mekhoa arohana, Karolo 1: likarolo tse ka sehloohong, liminerale & Metallurgical Processing ", volume. 17, ha ho na. 1, maq 23-36.

19. Manouchehri, H, Hanumantha Roa, k, & Fors Mountain, k (2000), "Tlhahlobo ea motlakase Mekhoa arohana, Karolo 2: e sebetsang nahanelwa, liminerale & Metallurgical Processing ", volume. 17, ha ho na. 1, maq 139-166.

20. Ralston O. (1961), Electrostatic arohana ea dilo tse di komota tsoakane Granular, Elsevier Publishing Company, ha e sa hatisoa.