Select Language:

ST Qalabka & technology LLC (STET) technology SEPARATOR suunka tribo-electrostatic ogol yahay ee ka -faa'iideysiga macdanta fiican budo leh tiknoolijiyad gebi ahaanba qallalan oo heer sare ah. SEPARATOR STET waxaa sidoo aduu kala ganaax aad u (<1μm) si dhexdhexaad ah aan dhab ahayn (500μm) Qurub, in la barbardhigo hababka kale ee isa-soociddiisa electrostatic in caadi ahaan ku koobnayn Qurub >75μm ee size. STET ayaa si guul leh beneficiated baarka iron ore oo ay ku jiraan baxsad-of-anigaa senti, tailings iyo itabirite ku jira bir ah feed laga bilaabo 30-55%. Natiijooyinka tijaabo ah ayaa tilmaamaya in senti bir-fasalka hooseeyo la casriyeeyay kartaa fasalada ganacsi (58-65% Fe) iyadoo isla gaala silica adigoo isticmaalaya STET SEPARATOR suunka. halkan, compendium ah natiijada tijaabo iyo waxbarasho bilow ah ee codsiyada filasho technology STET for warshadaha birta ah waxaa lagu soo bandhigay. The waxbarashada hordhaca ah waxaa ka mid ah flowsheets heer sare ah iyo qiimeynta dhaqaalaha ee codsiyada la doortay. Caqabadaha la xiriira korsashada ee technology iyo is barbardhig teknoolajiyada hadda diyaar u ah howsha ganaax iron ore waxaa sidoo kale ka hadlay.

1.0 Hordhac

Iron dhadhaab waa element afaraad ee ugu badan ee qolof dhulka iyo waxay muhiim u tahay horumarinta dhaqaalaha caalamiga ah iyo wax soo saarka steel [1-2]. senti Iron leeyihiin tiro balaadhan ee Halabuurka kiimikada gaar ahaan content Fe iyo macdan gangue la xiriira [1]. macdanta birta-dhalista Major waa hematite, goethite, limonite iyo magnetite [1,3] iyo sunta ugu weyn ee senti ay bir yihiin 2 iyo Al2O3. deposit macdanta kasta wuxuu leeyahay dabeecadihiisa u gaarka ah marka la eego birta iyo gangue sita macdanta, oo sidaas daraaddeed waxay u baahan tahay farsamo-fiirsashada kala duwan [4].

wareeggeedii processing Modern ee macdanta birta dhalista ka mid noqon kara fiirsashada gravimetric, fiirsashada magnetic, iyo tallaabooyinka sabeynta [1,3]. Si kastaba ha ahaatee, wareeggeedii casriga ah caqabadaha la joogo marka la eego processing of ganaax macdanta birta iyo slimes [4-6]. farsamooyinka Gravimetric sida spirals ku kooban by size walxaha iyo waxa kaliya ee loo arko hab hufan ee xoogga hematite iyo magnetite for jajab size kor 75μm ah [5]. Qoyan iyo qalalan low-xoogga-soociddiisa magnetic (Maccido) farsamooyinka waxaa loo isticmaalaa si loo farsameeyo senti bir-fasalka sare leh guryaha magnetic xoog sida magnetite halka qoyan-xoojinta sare-soociddiisa magnetic waxaa loo isticmaalaa in la kala saaro macdanta dhalista bir leh guryaha magnetic daciif ah sida hematite ka macdanta gangue. Hababka magnetic caqabadaha joogo sabab u baahan yahay, waayo, iron ore ay u noqon nugul beeraha magnetic [3]. Sabeynta ee loo isticmaalo si loo yareeyo content ee nijaasta ahaa in senti bir-fasalka hooseeyo, laakiin waxaa xadiday qiimaha reagents, iyo joogitaanka silica, slimes iyo macdan carbonate alumina-hodan [4,6]. Maqnaanshaha of processing geysto dheeraad ah ee gaaloobay durdurro diido bir wanaagsan ku dhamaan doonaa tuuray in a dam tailings [2].

Tailings qubo iyo processing ee ganaaxa bir ah ayaa noqotay mid muhiim u ah ilaalinta deegaanka iyo ka soo kabashada ee qiimaha leh birta, siday u kala horreeyaan, oo sidaas daraaddeed processing ee tailings macdanta birta iyo ganaax in warshadda macdan qodista ayaa koray in muhiimadda[7].

Si kastaba ha ahaatee, processing ee tailings bir ah iyo ganaaxyo ayaa weli u babac via Tusaha Taxan dhaqanka iyo teknoolajiyada beneficiation sidaas daraaddeed kale sida soociddiisa tribo-electrostatic taas oo xannibaad yar marka la eego baaxadda mineralogy ore iyo walxaha laga yaabaa inay noqdaan oo xiiso leh. Qallaji processing electrostatic of hadiyado iron ore fursad si loo yareeyo kharashka iyo jiilka tailings qoyan la xidhiidha gravimetric dhaqanka, sabeynta iyo wareeggeedii-soociddiisa magnetic qoyan.

STET ayaa soo saaray geedi socod-soociddiisa oo awood isa-soociddiisa ku ool ah ash dhoobnayd iyo macdanta ah sida ay jawaab markii loo feydo a beerta korontada gaar ah. technology ayaa si guul leh u codsatay in industry ash dhoobnayd iyo warshadaha macdanta warshadaha; iyo STET ayaa hadda sahaminta kale ee furan suuqa meesha separators ay soo bandhigi kartaa faaido dhinaca tartanka ah. Mid ka mid ah suuqyada lala beegsaday waa casriyaynta jidadku of iron ore wanaagsan.

STET wuu oofiyey waxbarashada shidaal dhowr senti bir iyo natiijada tijaabada taariikhda ayaa muujisay in ganaax iron ore-fasalka hooseeyo la casriyeeyay karaa iyadoo qofka la SEPARATOR suunka STET tribo-electrostatic. The habka STET-soociddiisa electrostatic qalalan waxay bixisaa faa'iidooyinka badan hab dhaqameed processing qoyan, ay ka mid yihiin awood u leh inay soo kabsadaan u wanaagsan oo aalladda wanaagsan birta lahaa haddii kale lagu lumin inay tailings haddii la technology hadda jira ka baaraandegidda. Intaa waxaa dheer, technology ay u baahan tahay ma isticmaalka biyaha, kaas oo natiijada in tirtiridda shubto, dhagid iyo qallajinta, iyo sidoo kale wixii kharashka iyo khataraha la xiriira daaweynta biyaha iyo qashin; ma tailings qoyan qashin - dhawaan fashilaad-profile sare ee tailings xireenno ayaa iftiimiyay khatarta muddada-dheer ee kaydinta tailings qoyan ah; iyo, ma kiimikada dheeraad ah loo baahan yahay, oo sidaas daraaddeed masaxdaa kharashka joogtada ah ee reagents iyo nayaa saamaxdo.

Iron dhadhaab waa warshadaha la firfircoon in ka biraha kale saldhig oo kala duwan. Tan waxa u sabab ay suuqa isbedela, ka Muga saarka weyn ku lug iyo dhiganta kharashka labada on caasimadda iyo dhinacyada ka hawlgala [8] iyo sidoo kale maqnaanshaha sarrifka dhexe Hubs sida Biraha London ee Exchange. Arrintani waxay horseedaa celinta weyn in waa u suurtoobaan markii gantaallo qiimaha sii weynayd iyo xadad mandiil khafiif ah marka xaaladda waa direr. Tani waa mid ka mid ah sababta ka dambeysa Muga saarka weyn oo xoogga on kharashka wax soo saarka unit hooseeyo.

halkan, Natiijada daraasad baarista ee warshadaha iron ore horumartay by STET iyo Soutex la soo bandhigay si ay u aqoonsadaan niches taas oo technology STET ku soo bandhigi kartaa faa'iido dhaqaale marka loo barbardhigo teknoolajiyada more caadiga ah. Soutex waa macdan ah ka baaraandegidda iyo latalin metallurgy oo uu leeyahay waayo aragnimo naqshadaynta, fiican oo ka hawlgala geeddi socodka kala duwan fiirsashada iron ore, fahamka ee shirkadda Sentech ah, OPEX iyo sidoo kale dhinacyada suuq ee warshadaha birta ore ka. Waayo, daraasaddan, Soutex bixiyo ay khibrad qiimeeyo codsiyada iman kara kala triboelectrostatic ee iron ore. Soutex 'baaxadda ka mid ahaa horumarinta flowsheet iyo si caasimada heerka waxbarasho-magnitude oo qiyaasta kharashka ka hawlgala. warqad baadhayaa Tani saddex ka mid ah codsiyada ugu ballanqaadaan ugu helay, on heer farsamo iyo dhaqaale. Saddexdan codsiyada loo aqoonsaday: Casriyeyn ah oo ganaax iron ore ee macdanta Australian DSO; faganaya of shancosbitaal bir wanaagsan in hematite / concentrators magnetite; iyo, reprocessing taajirka-Fe tailings ka hawlgallada Brazil.

2.0 STET Triboelectrostatic Belt SEPARATOR

Tijaabo ayaa la sameeyay iyadoo la isticmaalayo kursiga keydka baaxad tribo-electrostatic SEPARATOR suunka a. imtixaanka kursiga keydka-miisaanka waa wajiga hore ee geedi socodka a saddex waji technology fulinta oo ay ku jiraan qiimaynta keydka baaxad, imtixaanka pilot-baaxadda iyo fulinta ganacsi oo baaxad. SEPARATOR benchtop Waxaa loo isticmaalaa in lagu sameynayaa caddeynta xukun tribo-electrostatic iyo si loo ogaado haddii ay wax a uu yahay musharaxa wanaagsan beneficiation electrostatic. Faraqa ugu weyn ee u dhexeeya gabal kasta ee qalabka waxaa lagu soo bandhigay Shaxda 1. Iyada oo qalabka loo isticmaalo gudahood marxalad kasta kala duwan ee size, Mabda 'hawlgalka aasaas ahaan waa isku mid.

STET ayaa qiimeeyaa dhowr shay-baarka iron ore ugu miisaanka kursiga keydka iyo dhaqdhaqaaqa weyn oo bir ah iyo diidmada silicates ayaa la arkay (Eeg Shaxda 2). xaaladaha tijaabo ayaa la xushay si ay u soo kabashada bir ah vs. qalooca kordhinta birta waxaa loo qeybin karo oo dambe loo isticmaalo talooyin ah model dhaqaale ka hawlgala

Miis 2. Natiijooyinka keydka baaxad on senti kala duwan birta

| Ex | feed Wax yar wt.% | Product Wax yar wt.% | Fe dhammaystiran Kordhiyo % | Fe Recovery % | SiO2 Diidmo % | D10 (μm) | D50 (μm) | D90 (μm) |

|---|---|---|---|---|---|---|---|---|

| 1 | 39.2 | 50.6 | 11.4 | 91.5 | 63.9 | 5 | 23 | 59 |

| 2 | 39.4 | 60.5 | 21.1 | 50.8 | 96.0 | 5 | 23 | 59 |

| 3 | 30.1 | 48.0 | 17.9 | 70.6 | 84.6 | 1 | 18 | 114 |

| 4 | 29.9 | 54.2 | 24.3 | 56.4 | 93.7 | 1 | 18 | 114 |

| 5 | 47.0 | 50.2 | 3.2 | 96.6 | 35.3 | 17 | 62 | 165 |

| 6 | 21.9 | 48.9 | 27.0 | 41.2 | 96.6 | 17 | 62 | 165 |

| 7 | 47.6 | 60.4 | 12.8 | 85.1 | 96.9 | 17 | 62 | 165 |

| 8 | 35.1 | 44.9 | 9.8 | 89.0 | 54.2 | 3 | 61 | 165 |

| 9 | 19.7 | 37.4 | 17.7 | 76.0 | 56.8 | 5 | 103 | 275 |

| 10 | 54.5 | 62.5 | 8.0 | 86.3 | 77.7 | 5 | 77 | 772 |

| 11 | 54.6 | 66.5 | 11.9 | 82.8 | 95.6 | 8 | 45 | 179 |

(See Section 3.0, Jaantuska 4). natiijada tijaabo dheeraad ah oo muujinaysa natiijooyin separation on baarka iron ore la isticmaalayo technology STET waxaa lagu soo bandhigay in la daabaco hore by STET on bir processing ore [9].

Miis 1. geedi socodka fulinta saddex waji oo isticmaalaya STET technology SEPARATOR suunka tribo-electrostatic.

| Phase | Loo Adeegsaday: | Dhererka korantada | Nooca Nidaamka |

|---|---|---|---|

| 1- Miisaanka kursiga keydka qiimeynta | Qualitative qiimeynta | 250cm | Dufcaddii |

| 2- Miisaanka pilot Tijaabinaya | taranta qiimaynta | 610cm | Dufcaddii |

| 3- ganacsiga Miisaanka | ganacsiga Production | 610cm | Sii socda |

Sida laga arki karo in Table 1, farqiga ugu weyn ee u dhexeeya SEPARATOR benchtop iyo pilot-baaxadda iyo separators ganacsi baaxad waa in dhererka SEPARATOR benchtop waa qiyaastii 0.4 jeer dhererka unugyada pilot-baaxadda iyo ganacsi oo baaxad. Sida oolnimada SEPARATOR waa shaqo ah oo dhererkeedu yahay koronto ah, imtixaanka kursiga keydka-miisaanka ma loo isticmaali karaa bedel imtixaanka pilot-baaxadda. imtixaanka Pilot-qiyaasta loo baahan yahay si loo ogaado inta uu la egyahay-soociddiisa oo ah in geeddi-socodka STET wuxuu gaadhi karaa at baaxadda ganacsiga, iyo si loo ogaado haddii habka STET kulmi kartaa bartilmaameedyada sheyga hoos heerka feed siiyey. Maaddaama ay farqiga u dherer-soociddiisa firfircoon ka baaxad keydka iskeelka pilot, Natiijooyinka caadiga ah loo horumariyo heerka pilot.

2.1 Operation Mabda'a

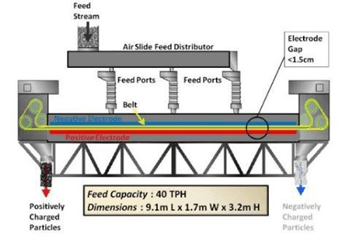

In SEPARATOR tribo-electrostatic suunka (arki Jaantuska 1 iyo Jaantuska 2), wax la quudiyey galay farqiga khafiif ah 0.9 - 1.5 cm u dhexeeya labada electrodes planar isku midka ah.

qayb ka yihiin triboelectrically eedeeyay by xiriir interparticle. Tusaale ahaan, in ay dhacdo muunad bir ah oo ka kooban inta badan hematite iyo quartz qayb ka macdanta, ugu wanaagsan eedeeyay (hematite) iyo si xun u

qayb ka yihiin triboelectrically eedeeyay by xiriir interparticle. Tusaale ahaan, in ay dhacdo muunad bir ah oo ka kooban inta badan hematite iyo quartz qayb ka macdanta, ugu wanaagsan eedeeyay (hematite) iyo si xun u

lagu eedeeyay (quartz) waxaa soo jiitay in electrodes soo horjeeda. qayb ka yihiin ka dibna isagoo xaaqan oo ay si joogto ah u dhaqaaqin suunka-mesh furan iyo gaadhsiiyey jiho ka soo horjeeda. Suunka guuro qayb ka ku xiga si ay koronto kasta xagga ugu shishaysa soo horjeeda ee SEPARATOR ah. counter socodka hadda ka mid ah qayb ka kala oo joogtada ah triboelectric xukun by shilalka walxaha-walxaha siinayaa a kala go'ida iyo natiijooyinka multi-yada ka khayroon daahirnimo fiican iyo soo kabashada ee unit-hal baas. Suunka oggolaanayaa processing on qayb ka wanaagsan oo aalladda wanaagsan oo ay ku jiraan qayb ka yar 20μm, oo siinaya hab in si joogto ah u nadiifi dusha sare ee electrodes iyo ka saar Qurub ganaax ah, taas oo haddii kale u hoggaansamaan lahaa inuu dusha sare ee electrodes ah. The xawaaraha suunka sare ayaa sidoo kale u saamaxaaya ilaa throughputs in 40 tan saacadiiba hal SEPARATOR a by joogto ah gudbinayeen soo baxay wax of SEPARATOR ah. By gacanta beegyada uu nidaamka kala duwan, qalabka u oggolaanaysa in ayna fasalka macdanta iyo soo kabashada.

design SEPARATOR waa mid yara fudud. The suunka iyo rollers la xiriira waa qaybo ka mid kaliya uusan u dhaqaaqin. electrodes waa taagan oo ka kooban qalab heer sare raagaya. Suunka waa qayb ka mid ah taas oo u baahan consumable si kaladuwan laakiin wareegsan bedelka, geedi kaasoo kara inuu buuxiyo hal shaqaale ah oo kaliya 45 daqiiqo. dhererka koronto SEPARATOR waa qiyaastii 6 mitir (20 ft.) iyo width ah 1.25 mitir (4 ft.) for size buuxa unugyada ganacsi (arki Jaantuska 3). isticmaalka Awooda waa in ka yar 2 kWh halkii Tan oo wax baaraandegi leh ugu xoogga baabbi'iyey laba matoorrada wadista suunka.

Geedi socodka gebi ahaanba qalalan, wuxuu u baahan yahay ma qalab dheeraad ah oo soo saarta oo aan lahayn biyo qashinka ama qiiqa hawada. Kala macdanta SEPARATOR bixisaa technology ah si loo yareeyo isticmaalka biyaha, kordhiyo nolosha reserve iyo / ama soo kabsado iyo reprocess tailings.

Geedi socodka gebi ahaanba qalalan, wuxuu u baahan yahay ma qalab dheeraad ah oo soo saarta oo aan lahayn biyo qashinka ama qiiqa hawada. Kala macdanta SEPARATOR bixisaa technology ah si loo yareeyo isticmaalka biyaha, kordhiyo nolosha reserve iyo / ama soo kabsado iyo reprocess tailings.

compactness The nidaamka u oggolaanaysa in dabacsanaan naqshadooda rakibaadda. technology The tribo-electrostatic-soociddiisa suunka waa adag iyo industrially xaqiijiyay oo markii ugu horaysay la industrially codsatay in ay howsha ash dhuxusha Daqsi sari ee 1995. technology waa wax ku ool ah kala qayb carbon ka sari ee aan dhamaystirnayn oo dhuxusha, ka qayb macdanta aluminosilicate madxafka in ash Daqsi. Technology ayaa qeyb muhim ah in awood recycle of ash macdanta qaniga Daqsi bedelka cement ee wax soo saarka la taaban karo a.

Tan iyo markii ay 1995, ka badan 20 milyan oo tan oo ash dhoobnayd alaabta lagu farsameeyo by separators STET ku rakiban ee USA. Taariikhda warshadaha ee Daqsi-soociddiisa STET ash waxaa ku qoran Shaxda 3.

In macdanta processing, technology SEPARATOR suunka triboelectric ayaa loo isticmaalay in lagu kala tiro balaadhan oo ah qalabka ay ku jiraan calcite / quartz, Rusheyn kartaa / magnesite, iyo barite / quartz.

Miis 3. codsiga Industrial nijaasta suunka tribo-electrostatic for ash dhoobnayd

| utility / saldhiga korontada | Location | Bilawga ganacsiga hawlaha | Facility faahfaahinta |

|---|---|---|---|

| Duke Energy - Roxboro Station | North Carolina USA | 1997 | 2 Separators |

| luqadaha Energy- Brandon xeebaha | Maryland USA | 1999 | 2 Separators |

| Power Scottish- Longannet Station | Scotland UK | 2002 | 1 SEPARATOR |

| Jacksonville Electric-St. Beerta Korantada ee Johns River | Florida USA | 2003 | 2 Separators |

| South Mississippi Power Power -R.D. Morrow | Mississippi USA | 2005 | 1 SEPARATOR |

| New Brunswick Power-Belledune | New Brunswick Kanada | 2005 | 1 SEPARATOR |

| OF loo kansalay-Didcot Station | England UK | 2005 | 1 SEPARATOR |

| Luuqadaha Saldhigga Jasiiradda Tamarta-Brunner | Pennsylvania USA | 2006 | 2 Separators |

| Tampa Electric-Big laab Station | Florida USA | 2008 | 3 Separators |

| OF loo kansalay Aberthaw-Station | Wales UK | 2008 | 1 SEPARATOR |

| EDF Energy-West Burton Station | England UK | 2008 | 1 SEPARATOR |

| ZGP (Lafarge Cement / Ciech Janikosoda JV) | Poland | 2010 | 1 SEPARATOR |

| Korea Koonfur Power- Yeongheung | South Korea | 2014 | 1 SEPARATOR |

| PGNiG Termika-Sierkirki | Poland | 2018 | 1 SEPARATOR |

| Shirkadda Cuntada ee Sibheiyo -Cihibu | Japan | 2018 | 1 SEPARATOR |

| Armstrong Fly Ash- Celement Cement | Filibiin | 2019 | 1 SEPARATOR |

| Korea Koonfur Power- Samcheonpo | South Korea | 2019 | 1 SEPARATOR |

3.0 Tabaha

saddex (3) Xaaladaha ayaa loo aqoonsaday qiimeyn dheeraad ah oo waxaa loo soo maro si ah dib u eegista heer waxbarasho-magnitude dhaqaalaha dunida iyo khatarta / fursad. Qiimaynta ku salaysan yahay faa'iidada ka iman kara shaqaale ah Arkaa lahaa iyagoo kaashanaya technology STET ee ay dhirta ee flowsheet.

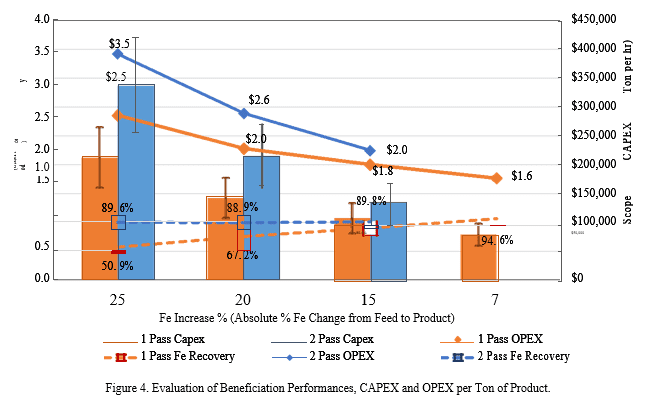

Performance of SEPARATOR STET waxaa lagu qiyaasay sida uu sheegay baaritaano baaxad keydka sameeyaa (Eeg Shaxda 2). xogta la ururiyey la senti kala duwan birta loo ogol yahay dhaqmaan ee model-kabashada ah taas oo loo adeegsadey in la saadaaliyo kabashada saddex ah (3) daraasado. Jaantuska 4 muujinayaa natiijada model ah marka la eego qaab iyo kharashka. kabashada bir ah waxaa si toos ah lagu tilmaamay on gudban, ka soo horjeedka ka-faa'iideysiga birta ee% Fe. In imtixaanka kursiga keydka iskeelka, hal baas dhex STET la tijaabiyey sidoo kale flowsheet laba-baas. flowsheets Laba-baas ku lug baarto oo ka mid ah dabo weynaaday, Sidaa darteed kordhaya kabashada ku ool ah. Si kastaba ha ahaatee, tani waxay ku mashiinada STET dheeraad ah iyo kharashka sidaas daraaddeed sare. ulaha gudban ka baadi badan qataarrada Sentech tilmaamaya qiimaha Sentech kala duwanaansho ku xidhan tahay size mashruuca. Tirooyinka Sentech dhexe hoos u leh size mashruuca. Tusaale ahaan, waayo ore caadiga ah imtixaannay flowsheet laba-baas, koror ah 15% fasalka birta (i.e. ka 50% Fe in 65% Fe) saadaaliyo lahaa dib u soo kabashada bir ah 90%. kabsanaya bir Hoose ayaa si iskood ah loo isticmaalo ee daraasado soo socda si ay u fiirsan khasaaraha soo jireenka ah ee soo kabashada marka saara darajada sare xoogga iron ore.

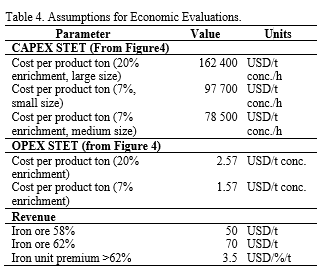

Waayo, waxbarasho kiis kasta, flowsheet la soo bandhigay si ah heerka magnitude oo kaliya qalabka ugu weyn ee lagu muujiyay si ay u taageeraan qiimaynta dhaqaale. Waayo, mid kasta oo flowsheet, dhaqaalaha waxaa lagu qiyaasay hoos qaybaha soo socda: Capital kharashka (Sentech); kharashka ka hawlgala (OPEX); iyo, Revenue. Marka marxaladdan baarista, heerka sax waayo category kasta waa at the "Si of magnitude" (± 50%).

Sentech qalabka Main lagu qiyaasay isticmaalka database gudaha (Ay bixiyaan Soutex) iyo xigashooyin qalabka marka la heli karo. Waxyaabaha ayaa dabadeed tilmaantay in la dhiso kharashka labada kharashka si toos ah iyo si aan toos ahayn. qiimaha Sentech gaar STET ayaa sidoo kale waxaa ka mid ah qalabka sare oo gacanta ku, xaq factorization hoose loogu rakibo iyo dhismaha, waayo, intan yar ee qalabka. qiimaysay OPEX wuxuu ka kooban yahay dayactirka, shaqaale, xoog iyo kharashka consumable. The arrimaha farsamo ay bixiyaan habka taageero flowsheet qiimeynta kharashka labada eego Sentech iyo OPEX, iyo xubno kharashka la xiriira rakibaadda iyo isticmaalka STET tribo-electrostatic SEPARATOR suunka lagu qiyaasay iyadoo la isticmaalayo database STET mashaariic dhameystirtay iyo iron ore qiyaasta kursiga keydka shaqada imtixaanka.

Tirooyinka loo isticmaalo ee qiimeynta kharashka soo socda ayaa ka soo jeeda Jaantuska 4. Tusaale ahaan, waayo ore caadiga ah la baadhay iyada oo laba-mari fiirsashada iyo kordhin ah 15% fasalka birta (i.e. ka 50% Fe in 65% Fe) ku kici lahaa agagaarka 135 000$ per ton / h ee shirkadda Sentech iyo 2 $ / t in OPEX (tan oo shancosbitaal birta). Maadaama ay tani waxaa loogu tala galay sidii daraasad baarista, waxaa la go'aamiyay in ay sii muxaafidka on binta alaabta oo aad yeeshid falanqaynta dareen oo ay kasoo horjeeddo fasalka ugu dambeeya iyo qiimaha wax soo saarka. Sida of November 2019, 62% Seaborne Xirfado iron ore agagaarka 80USD / t, la Degenaansho aad u dheer.

premium The on iron ore shancosbitaal unit sidoo kale waa mid aad u kacsan oo ku xidhan tahay qodobo badan oo ay ka mid yihiin sunta iyo baahida ka macaamiisha gaar ah. Farqiga u dhexeeya qiimaha 65% birta iyo 62% bir ah waxaa si joogto ah la beddelo oo wakhtiga. In 2016, farqiga u ahaa yar (ku dhowaad 1 $/t /% Fe) laakiin 2017-2018, premium ka fuusho u dhow 10 $/t /% Fe. Waqtiga qoraal this, waxa uu hadda ku jiraa ku dhawaad 3 $/t /% Fe [10]. Miis 4 shows xulay shuruudaha design loo isticmaalo qiimaysaa ujecel.

Miis 4. Malo Qiimeynta Dhaqaalaha.

bulshsada waxaa lagu qiyaasay ka sannaddii kowaad oo-soo-saarka. Waayo, mashruuc kasta, ah laba dheeraad ah (2) sano waa in la tixgeliyo dhismaha. The qiyamka kaashka (kharashka iyo dakhliga) waxaa laga dhimay tan iyo bilowgii dhismaha.

bulshsada waxaa lagu qiyaasay ka sannaddii kowaad oo-soo-saarka. Waayo, mashruuc kasta, ah laba dheeraad ah (2) sano waa in la tixgeliyo dhismaha. The qiyamka kaashka (kharashka iyo dakhliga) waxaa laga dhimay tan iyo bilowgii dhismaha.

4.0 habka Beneficiation hawlgal DSO qalalan ah

ore Direct maraakiibta (DSO) Mashaariicda soo saaro mugga weyn ee iron ore ee dunida, ugu horayn quudinta suuqa Chinese iyo in ka badan mugga uu ka yimaado Western Australia (WA) iyo Brazil. In 2017, mugga of iron ore soo saaray WA dhaafto 800 million tons iyo mugga Brazil ee ahayd qiyaastii 350 million tons [11]. geeddi socodka beneficiation waa mid aad u fudud, oo badanaaba ka kooban burburiyo, dhaqidda iyo kala soocidda [12].

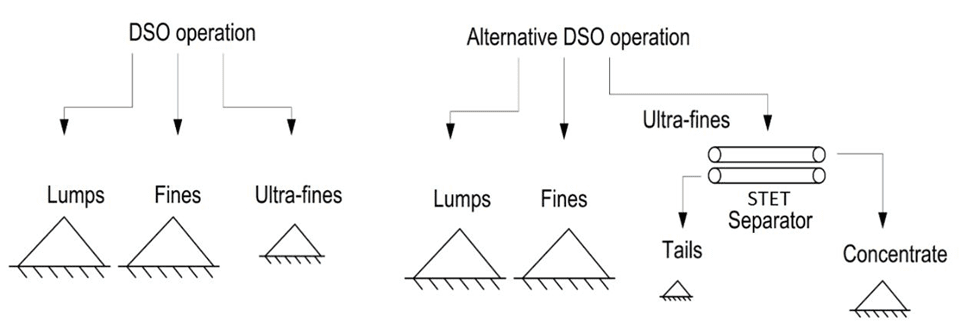

Beneficiation ee aalladda ganaax in ay curiyaan ah 65% Fe shancosbitaal fursad u tahay suuqa DSO ah. Tallaabada loo qiimeeyo faa'iidooyinka technology STET mashaariicda DSO waa ganacsiga-off ah oo u dhexeeya soo saara birta-fasalka hooseeyo aalladda ganaax jira oo kale oo ka mid ah soo saara wax soo saarka leh qiimaha ku daray ka dib markii beneficiation STET. flowsheet la soo jeediyey (Jaantuska 5) tixgelinaysaa hawlgal DSO khayaalka in WA in hadda ka mid ah waxyaabaha ay aalladda ganaax at dhoofin lahaa 58% Fe. kale waxay xoogga lahaa aalladda ganaax si ay u kordhiyaan qiimaha wax soo saarka final. Miis 5 Hadiyadaha qaar ka mid ah shuruudaha design iyo dheelitirka heer sare ah mass ee loo isticmaalo in qiimaysay ee dakhliga. orebody The eego darajada iyo awoodda ma matalaan mashruuc jira laakiin halkii mashruuc DSO caadiga ah marka la eego size iyo wax soo saarka.

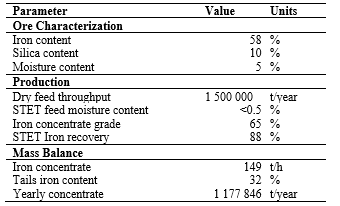

Miis 5. Ultra-ganaax DSO Beneficiation Plant Design Shuruudaha iyo miisaan Mass.

Jaantuska 5. Flowsheets Marka la barbar dhigo in DSO ah ganacsiga-off

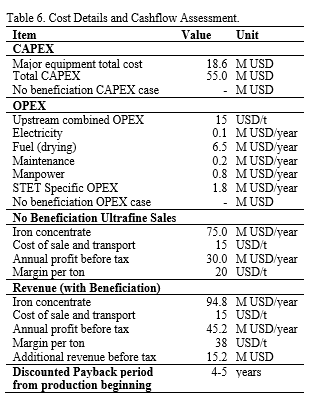

Miis 6 Hadiyadaha Sentech heer-sare ah, OPEX oo lagu qiyaasay dakhliga. qiyaasta Sentech waxaa ka mid ah dheer ee nidaamka load-out quduuska cusub (Shiiloh loadout iyo loading baabuur), iyo sidoo kale nidaamka STET ah. In si ay u qiimeyso soo laabashada flowsheet la soo jeediyay, falanqaynta dhaqaale la sameeyo agagaarka ganacsiga-off ah oo u dhexeeya kiiska beneficiation iyo iibinta wax soo saarka-fasalka hoose. Xaaladdan oo beneficiation ah, mugga waa la dhimay, laakiin lacagta on unugyada bir kordhisaa qiimaha iibka si weyn u. In OPEX ah, qiimaysay ah waxaa la siiyaa nidaaminta ore kheyraad (macdanta, burburiyo, kala saarista iyo taabato).

Inkastoo yaraynta mugga weyn u, soo celinta xiiso siiyey premium on fasalka sare shancosbitaal iron ore. xisaab celinta waa si sare ugu xiran premium this, kaas oo la sii kordheysa ee dhowrkii sano ee la soo dhaafay ay sabab u tahay arrimaha deegaanka. Sida ka muuqatay war kor ku xusan (Miis 6), soo jiidashada dhaqaale ee mashruuc oo kale waa heer sare ah ku tiirsan tahay farqiga qiimaha u dhexeeya 58% birta iyo 65% birta. In this qiimaynta hadda, premium qiimaha intaasu waxay ahayd 30.5 $/t, taas oo ka tarjumaysa qiyaastii xaaladda suuqa ee hadda. Si kastaba ha ahaatee, premium qiimaha this ayaa taariikh ahaan dhaxaysey 15 - 50 $/t.

5.0 Faganaya Geeddi-socodka ee cuf a

Plant Kala

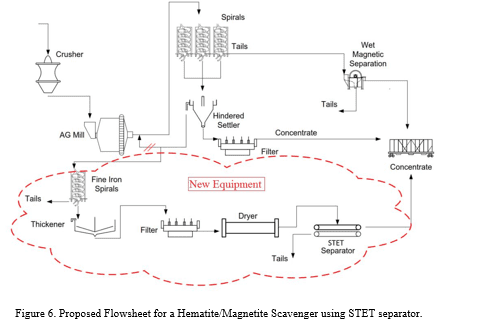

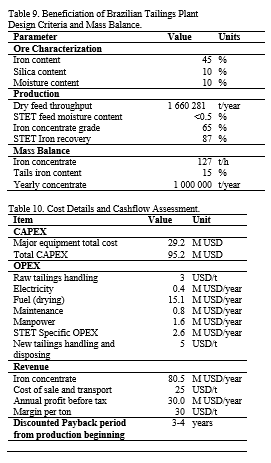

concentrators Iron ee North America isticmaalka gobolka fiirsashada cuf taasoo ah hab wax ku ool ah ee xoogga hematite iyo magnetite ah, gaar ahaan jajab size kor 75μm ah [5,13]. Hematite / dhirta magnetite ee gobolka this caadi ahaan u isticmaasho spirals sidii geeddi-soociddiisa hoose iyo sidoo kale ku daraan Lixaadka tallaabooyinka Kala magnetic Low (Maccido). arrin A caadiga ah ee guud ahaan dhirta hematite / magnetite waa kabashada bir ah sida tailings birta lacagaha inta badan ay gaaraan heerarka u sarraysaa sida 20%. Hawsha ugu weyn ee la xiriira hematite wanaagsan, sida bir oo ganaax dhib la soo kabsaday karo by spirals iyo waa boogeed Maccido loo isticmaalo inuu ka soo kabsado magnetite wanaagsan. Marka la barbardhigo, SEPARATOR STET waa heer sare ah wax ku ool ah ugu kala qayb wanaagsan, oo ay ku jiraan qayb ka hoos microns 20μm meesha Maccido iyo spirals waa wax ku ool ah ka yar. Sidaa darteed, faafi ka hydrosizer nadiifiye (qariib hor joogsaday) quudinta spirals gabacsatada waa taam wanaagsan technology STET. flowsheet la soo jeediyey waxaa soo bandhigay Jaantuska 6.

In qaabeynta this, line ka dumisaan cas muujineysaa qalab cusub warshad ah ee hadda jira. Under flowsheet la soo jeediyay, halkii lagu recirculated, qulqulaya qariib hor joogsaday loo hawl lahaa by spirals baarto howlgala xaaladaha kala duwan ka badan spirals weynaaday. shancosbitaal bir wanaagsan ayaa laga soo saari kari lahaa oo la engejiyey. shancosbitaal The la qalajiyey lahaa ka dibna lagu hagaajin SEPARATOR STET ah si ay u soo saaraan shancosbitaal ah kama dambaysta ah ee fasalka iibsami. wax soo saarka wanaagsan ayaa si gooni gooni ah ama si wadajir ah loo suuq karaa saarka ururiye haray.

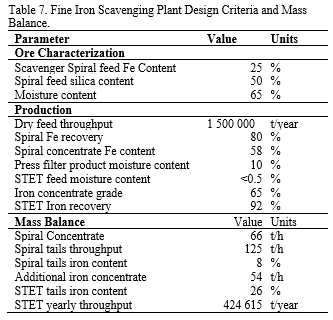

Miis 7 Hadiyadaha shuruudaha design iyo isku dheeli tiro heer sare ah loo isticmaalo ee ku qiimaysaa dakhliga.

Miis 8 Hadiyadaha Sentech heer-sare ah, OPEX oo lagu qiyaasay dakhliga.

Falanqaynta Tani waxay muujinaysaa in soo laabashada fulinta circuit baarto ku lug technology STET waa soo jiidasho leh oo lagu xirayo tixgelin dheeraad ah.

Faa'iidada kale ee qalajinta shancosbitaal bir wanaagsan marka la barbar in ay teknoolajiyada ku tartamaya waa lacagta la xiriira ka dhasha maaraysay wax fiirsashada soo socda. shancosbitaal aad u wanaagsan qoyan waa dhibaato la xidhiidha shaandhaynta, maaraysay iyo gaadiidka. Hakinta dhibaato tareenada iyo fluxing doomo Eebay qalajiyo of shancosbitaal aad u wanaagsan oo mararka qaarkood khasab ah. STET qalajiyo gundhig Sidaa darteed ma noqon kartaa faa'iido.

6.0 Beneficiation ee reer Brazil Tailings

deposit

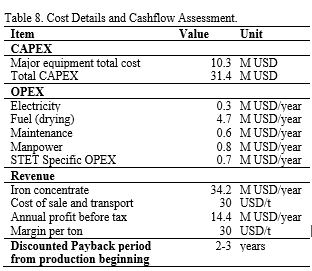

Beneficiation of tailings wanaagsan u muuqataa sida codsiga qiimo-daray ah Processor si valorize technology STET ah, sida khayraadka la Barandho dhulka oo diyaar u ah qiime jaban. Iyadoo tailings iron ore kayd sita heerarka sare ee birta ay joogaan meelo badan, meelaha logistics waa fudud waa in ay mudnaanta qiimaynta dheeraad ah. kayd Brazil ay ku jiraan fasalada Fe sare oo istaraatiiji ah oo ku yaalla meel u dhow kaabayaasha gaadiidka ee hadda jira taagan fursad fiican Processor lacagta ka hirgelinta STET technology tribo-electrostatic. flowsheet la soo jeediyey (Jaantuska 7) u aragtaa a Fe-hodanka ah hawlgalka tailings Brazil khayaalka, taas oo technology STET noqon lahaa geedi socodka beneficiation kaliya.

Beneficiation of tailings wanaagsan u muuqataa sida codsiga qiimo-daray ah Processor si valorize technology STET ah, sida khayraadka la Barandho dhulka oo diyaar u ah qiime jaban. Iyadoo tailings iron ore kayd sita heerarka sare ee birta ay joogaan meelo badan, meelaha logistics waa fudud waa in ay mudnaanta qiimaynta dheeraad ah. kayd Brazil ay ku jiraan fasalada Fe sare oo istaraatiiji ah oo ku yaalla meel u dhow kaabayaasha gaadiidka ee hadda jira taagan fursad fiican Processor lacagta ka hirgelinta STET technology tribo-electrostatic. flowsheet la soo jeediyey (Jaantuska 7) u aragtaa a Fe-hodanka ah hawlgalka tailings Brazil khayaalka, taas oo technology STET noqon lahaa geedi socodka beneficiation kaliya.

deposit waxaa loo arkaa in ay ku filan oo waaweyn si ay u bixiyaan sano oo feed heerka sannadle ah 1.5 M ton / sanadkii. Waayo, seenyadan, ore feed waa la Barandho dhulka la D50 ah ~ 50μm iyo ore u baahan doona in laga shoveled, gaadiid ka dibna la qalajiyey ka hor beneficiation tribo-electrostatic. shancosbitaal The lahaa ka dibna lagu shubto tareenada / maraakiibta iyo tailings cusub la keensadeen lahaa xarunta cusub.

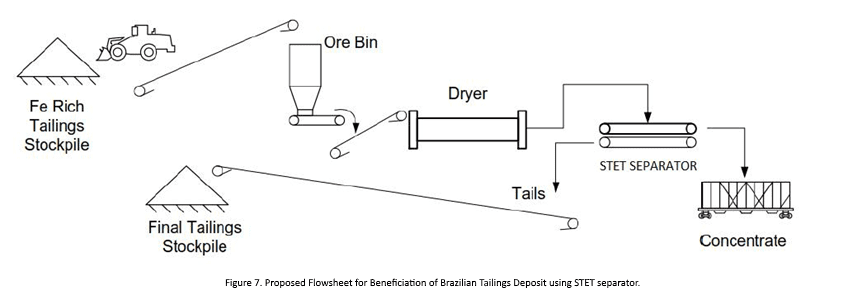

Miis 9 Hadiyadaha dheelitirka shuruudaha design iyo heer-sare mass ee loo isticmaalo in qiimaysay ee dakhliga. Miis 10 Hadiyadaha Sentech heer-sare ah, OPEX oo lagu qiyaasay dakhliga.

Sida ka muuqatay war Table 10, soo laabashada fulinta technology STET for beneficiation ee tailings Brazil waa soo jiidasho leh. Waxaa intaa dheer, eegaysana deegaanka flowsheet la soo jeediyey waxay sidoo kale waa sidaa faa'iido sida beneficiation ee tailings qalalan yareeyo lahaa tailings size iyo dusha iyo sidoo kale yareyn lahaa khatarta la xariirta tailings qoyan qubo.

Sida ka muuqatay war Table 10, soo laabashada fulinta technology STET for beneficiation ee tailings Brazil waa soo jiidasho leh. Waxaa intaa dheer, eegaysana deegaanka flowsheet la soo jeediyey waxay sidoo kale waa sidaa faa'iido sida beneficiation ee tailings qalalan yareeyo lahaa tailings size iyo dusha iyo sidoo kale yareyn lahaa khatarta la xariirta tailings qoyan qubo.

7.0 Dood iyo Talooyin

SEPARATOR STET ayaa si guul leh u soo bandhigay ee qiyaasta kursiga keydka si ore oo kala duwan birta wanaagsan, Sidaa darteed bixiya Processor hab sheeko ah inuu ka soo kabsado ganaax in si kale noqon lahaa ay adag tahay in nidaamka fasalada IIBSAMAYA la teknoolajiyada hadda jira.

flowsheets The qiimeeyo STET iyo Soutex ayaa tusaale u ah processing iron ore oo laga yaabaa in ay ka faa'iideystaan-soociddiisa triboelectrostatic qalalan. saddex The (3) flowsheets horumaray bandhigay daraasaddan ma aha gaar ah iyo waxyaabaha kale ee kale waa in la tixgeliyaa. Daraasadani waxay hordhac ah ayaa tilmaameysa in geedi socodka baarto lug kharashka qalajiyo hooseeyo, hawlgallada DSO iyo tailings beneficiation leeyihiin fursad wanaagsan oo guul ganacsi.

Faa'iidada kale ee processing qalalan waa on tailings kaydinta - oo hadda ku kaydsan yihiin in balliyada tailings weyn – sida tailings qalalan lahaa faa'iido ah ee baabi'inta halista deegaanka muhiim ah. tailings Recent iyo sidoo kale shaaciyey fashilaad xidheenka muujiyo baahida loo qabo maareynta tailings.

The gashiga in daraasaddan loo isticmaalaa in lagu bir xisaabiyaan fasalka ore iyo soo kabashada ahaayeen keydka natiijada soociddiisa qiyaasta la isticmaalayo shaybaarka iron ore gobollada kala duwan. Si kastaba ha ahaatee, mineralogy iyo xoraynta sifooyinka ore kasta waa mid gaar ah, Sidaa darteed baarka iron ore macaamiisha waa in la qiimeeyaa keydka ama qiyaasta pilot. In talaabo xiga ee horumarinta, saddexda flowsheets qiimeeyo in warqad this waa in la soo bartay si tafaasiil dheeraad ah.

Ugu dambeyntii, teknoolajiyada kale ee haatan ka yar tahay waxbarasho kabashada bir wanaagsan sida hawada, Jigs iyo classifiers reflux. Waxaa hore u la og yahay in geedi socodka badan oo isa-soociddiisa oo qoyan noqon hawlqabad la'aan waayo qayb ka hoos 45μm oo sidaas daraaddeed technology STET laga yaabo ayaa ka faa'ido badan ee kala duwan ee aad u wanaagsan, sida STET arkay qaab wanaagsan la feed sida wanaagsan sida 1μm. ganacsiga-off A rasmi ah waxbarasho barbar farsamooyinka daliishaday la STET waa in la qabtaa, taas oo ka mid ah qiimaynta waxqabadka, awoodda, kharashka, iwm. Sidaas Misbaax ugu fiican ee STET la iftiimiyay karo oo la safeeyey.

tixraacyada

1. Lu, L. (Ed.) (2015), "Iron Ore: Mineralogy, Processing iyo Daryeelka Deegaanka ", Elsevier.

2. Ferreira, H., & caanaha, M. G. P. (2015), "Daraasad Assessment Cycle Life birta macdanta ore", Journal of-soo-saarka ka nadiifsan, 108, pp. 1081-1091.

3. Filippov, L. O., Severov, V. V., & Filippova, I. V. (2014), "Guud ee beneficiation ee senti bir via sabeynta cationic reverse", joornaal Caalamiga ah ee processing macdanta, 127, pp. 62-69.

4. Sahoo, H., Rath, S. S., Rao, D. S., Mishra, B. K., & ah, B. (2016), "Doorka silica iyo alumina content in sabeynta ee senti bir ah", International Journal of Macdanta Processing, 148, pp. 83-91.

5. pool, Claude, et al (2014), “gooladaha kabashada Size of minerals in spirals warshadaha for senti xabagta bir processing.” macdanta Engineering 65, pp 115-123.

6. Luo, X., Wang, Y., Wen, S., Ma, M., Sun, C., Yin, W., & Ma, Oo. (2016), "Saamaynta of minerals carbonate ku saabsan hab dhaqanka sabeynta quartz ku hoos jira xaalad ah sabeynta dambe anionic of senti bir ah", International Journal of Macdanta Processing, 152, pp. 1-6.

7. da Silva, F. L., Araújo, F. G. S., Teixeira, M. P., Gomes, R.C., & Kruger, F. L. (2014), "Study oo ka mid ah dib u soo kabashada iyo dib u warshadaynta ee tailings ka fiirsashada of iron ore, waayo wax soo saarka ee dhoobada", dhoobada International, 40(10), pp. 16085-16089.

8. Bielitza, Mark P. (2012), “Rajada laga waayo, 2020 Iron Ore Suuqa. Taranta Analysis of Dynamics Market iyo Xeeladaha Yaraynta Halista” Books, Rainer Hampp Publishing, edition 1, tirada 9783866186798, Jan-Jun.

9. Rojas-Mendoza, L. F. Hrach, K. Flynn iyo A. Gupta. (2019), "Beneficiation qallalan ee ganaaxa iron ore-fasalka hooseeyo isticmaalaya SEPARATOR tribo-korontada suunka", In ka qaadista of Shirkii sanadlaha ee SME & Expo oo CMA 121aad National Western Macdanta Shirka Denver, Colorado - February 24-27, 2019.

10. Shiinaha Iron Ore Spot Price Index (CSI). Baxey ka http://www.custeel.com/en/price.jsp

11. xoreeyo. Geological Survey (USGS) (2018), "Iron Ore", in Iron Ore Statistics iyo macluumaadka.

12. Jankovic, A. (2015), "Isbeddellada in comminution iron ore iyo farsamooyinka kala soocidda. Iron Ore. http://dx.doi.org/10.1016/B978-1-78242-156-6.00008-3.

Elsevier Ltd.

13. Richards, R. G., et al. (2000), “separation of cuf aalladda wanaagsan (- 0.1 mm) macdanta isticmaalaya separators muquuninta.” macdanta Engineering 13.1, pp. 65-77.