Select Puo:

ST Helmets & Technology LLC (STET) tribo-electrostatic lebanta kgaoganyo thekenoloji lumella bakeng sa molemo oa diminerale e ntle li-powders tse nang le mahlale a ommeng ka botlalo. The kgaoganyo STET e hantle loketseng bakeng sa karohano ea e ntle haholo (<1μm) ho tekano mahoashe (500μm) likaroloana, ka lehlakoreng le leng ho ba bang dithulaganyo electrostatic karohano hore ba ka tloaelo ho lekanyetsoa feela likaroloana >75μm ka boholo. STET e ka katleho beneficiated tšepe disampole manya ho akarelletsa le li matha-ba-ka tšepe, tailings le itabirite le dikahare tšepe fepa ka ho tloha 30-55%. fumanoeng ke liteko li bontša hore tlaase sehlopheng tšepe tšepe ka ntlafatswa ho limaraka khoebo (58-65% Fe) ha ka nako hana silica ke sebelisa STET lebanta kgaoganyo. Mona, le pokellong ea sephetho liteko le ho ithuta pele sa dikopo monyetla oa theknoloji STET tsa indasteri ea tšepe tse hlahisoang. The lithuto tsa selelekela e kenyeletsa ea phahameng flowsheets le patlotlhotlhwa ya moruo ya dikopo kgethile. Diphepetso tse amanang le ho amohelwa oa theknoloji e le papiso ho theknoloji e hona joale e fumaneha bakeng sa ho e lokisa ya difaene tsepe ea ba boetse ba buisana.

1.0 Selelekela

Tsepe ea ke bone ho fetisisa karolo ea tloaelehile karolong e ka holimo ea lefatše 'me ke ea bohlokoa bakeng sa ntshetsopele lefatše moruong le tšepe difeme [1-2]. Tšepe tšepe na e mengata e fapaneng ka lik'hemik'hale haholo-holo bakeng sa Fe dikahare 'me se amahanngoang gangue liminerale [1]. Major tšepe behang liminerale tse hematite, goethite, limonite le magnetite [1,3] le contaminants sehloohong tšepe tšepe tse 2 le Al2O3. E mong le e depositi matsoai na le litšobotsi tse lona ikhethang mabapi le tšepe le gangue behang liminerale, 'me ka hona e hloka e fapaneng tsa mahloriso mokhoa [4].

Morao-rao e lokisa lipotoloho tsa tšepe behang liminerale li ka kenyeletsa gravimetric mahloriso, mahloriso a khoheli, le mehato flotation [1,3]. Leha ho le joalo, lipotoloho morao-rao diphepetso tse teng ka ho ya ka e lokisa ea tšepe difaene manya le slimes [4-6]. dithekeniki Gravimetric kang ikhara li felle feela ka ho phatsa boholo le ka ba feela tlameha tsela e sebetsang hantle ya go tlhoma tlhaloganyo mo hematite le magnetite bakeng sa boholo karoloana ka holimo 75μm [5]. Metsi le omileng tlase matla a khoheli a karohano (LIMS) dithekeniki li sebelisetsoa ho ho sebetsa e phahameng-sehlopheng tšepe tšepe le thepa matla a khoheli a kang magnetite ha metsi phahameng-matla a khoheli a karohano e sebediswa ho arole ba tšepe behang liminerale le thepa fokolang a khoheli a kang hematite tloha liminerale gangue. mekhoa khoheli diphepetso tse teng ka lebaka la ho hlokahalang bona bakeng sa manya a tšepe ho ba bonolo hore masimo a khoheli [3]. Flotation e sebediswa ho fokotsa diteng tsa litšila tlaase sehlopheng tšepe tšepe, empa e felle feela ka ho litšenyehelo tsa reagents, le ho ba teng ha silica, ea alumina e ngata slimes le liminerale carbonate [4,6]. Ho ba sieo ha ho e lokisa ho eketsehileng tlaase ho linoka bakeng sa hana melapo ea eboyi o motle tšepe tla qetella lokeng ka tailings letamo le [2].

Tailings lahla le ho e lokisa ya difaene tšepe fetohile bohlokoa oa ho boloka tikoloho le ho hlaphoheloa ea matlotlo tšepe, ho latellana, 'me ka hona ho sebetsa le ea tšepe tailings manya le difaene ho indasteri e meepo e hōlileng ka ho bohlokwa[7].

Leha ho le joalo, le ho e lokisa ya tailings tšepe le difaene ntse phephetsa ka tsela flowcharts setso le theknoloji e ka hoo mefuta e meng beneficiation kang tribo-electrostatic karohano e bebofala ya ka dipehelo tsa manya diminerale le phatsa boholo ka 'na ba ba le thahasello e kholo. Omella electrostatic sebetsa le ea tšepe limpho manya le monyetla oa ho fokotsa ditjeo le metsi tailings isa molokong o mong ho amahanngoa le gravimetric tsa moetlo, flotation le metsi lipotoloho khoheli karohano.

STET e ntshetswa pele tshebetso ho arohana hore nolofalletsa karohano sebetsang hantle ya fofa molora le liminerale latela karabelo ea bona ha a pepesa ho ea tšimo e itseng ea motlakase. theknoloji e se e sebelisoa ka katleho ho indasteri fofa molora le liindasteri liminerale indasteri; le STET e jwale hlahloba tse ling openings maraka moo separators bona ka fana ka se molemo oa tlhōlisano. E mong oa limmarakeng targeted ke ntlafatso ea manya o motle tšepe.

STET entseng lithuto tsa tlhotlhomisa le tšepe 'maloa tšepe le diphetho liteko ho letsatsi li bontšitse hore difaene tlaase sehlopheng tsepe ea ka ntlafatswa ka STET tribo-electrostatic lebanta kgaoganyo. The STET omileng electrostatic karohano thulaganyou e fana ka menyetla tse ngata tse fetang mekhoa metsi ea setso e lokisa, ho akarelletsa le matla a ho hlaphoheloa metle 'me ba marang-o motle tšepe e neng e tla ka tsela e nngwe ho lahlehileng ho tailings ha sebetsana le thekenoloji tse teng. Holim'a moo, theknoloji e hloka ha noang metsi, eo ho fella ka ho felisoa ha pompa, thickening le omisa, hammoho le ditjeo efe kapa efe le likotsi tse amanang le kalafo metsi le ho lahla; ha ho na metsi tailings lahla - morao tjena ho hlōleha phahameng-profil ea tailings matamo li totobatsa nako e telele kotsing ea ho boloka tailings metsi; le, ha lik'hemik'hale tse eketsehileng hlokahala, eo ka lebaka leo negates litšenyehelo e tsoelang pele ea reagents le simplifies lumella.

Tsepe ea ke indasteri le matla ka hore e tšoane le ea tšepe tse ling botlaaseng. Sena ke ka lebaka la ho 'maraka lona feto-fetoha, khōlō meqolo tlhahiso ea amehang le ngollana ditshenyehelo bobeli ka motse-moholo 'me a mahlakoreng sebetsa [8] hammoho le ho ba sieo ha phapanyetsano bohareng hubs tse kang London tšepe Exchange. Sena se fetolela ka kgutlang e khōlō hore lia khoneha ha rockets theko ho ea holimo 'me lehare tšesaane margins ha maemo a tse direr. Sena ke lebaka le leng ka mor'a le meqolo e khōlō ho hlahisoeng le khatiso e etsoang tabeng ditjeo tlhahiso ea tlaase unit trust.

Mona, diphetho tsa ho ithuta screening ea indasteri tsepe ea pele ke STET le Soutex e hlahisoa e le hore ho khetholla niches eo thekenoloji STET ka fana ka e Molemo a moruo ha ho bapisoa ho theknoloji e feta tloaelehileng. Soutex ke liminerale sebetsana le metallurgy consultancy le nang le boiphihlelo ho qapa, go lekanyetsa le ho sebetsa tsepe ea dithulaganyo tse fapa-fapaneng tsa mahloriso, ka kutloisiso e sa CAPEX, OPEX hammoho le litšobotsi tse mebaraka ya tšepe indasteri manya. Ho ithuta sena, Soutex faneng bokgoni lona ka ho hlahloba dikopo monyetla oa karohano triboelectrostatic ka manya a tšepe. pharalla Soutex 'e ne e akarelletsa ntshetsopeleng flowsheet le taelo ea motse-moholo oa boholo ho ithuta-boemo ba le ho sebetsa likhakanyo theko. Sena se lekolang pampiri tse tharo tsa dikopo ho fetisisa tšepisa fumanwa, boemong e botekgeniki le litšenyehelo. dikopo tsena tse tharo li ne li tsejoa e le: Ntlafatso ea difaene tsepe ea ka meepo Australia DSO; scavenging ba mamelisise o motle tšepe hematite / concentrators magnetite; le, metamorphism ba rua Fe tailings tloha Brazilians tshebetso.

2.0 STET Triboelectrostatic lebanta la kgaoganyo

Liteko li ne li khanna sebelisa bencheng ka tekanyo tribo-electrostatic lebanta kgaoganyo. Bencheng ka tekanyo e etsa liteko e karolong e qalang ea tse tharo mohato thekenoloji thulaganyou e kenngwa tshebetsong ho akarelletsa sekasekale bencheng ka tekanyo, motsamaisi-tekanyo e etsa liteko le ho kenngwa tshebetsong khoebo tekanyo. The kgaoganyo benchtop e sebediswa bakeng sa ho screening 'bakeng sa bopaki bo tribo-electrostatic tjhaja le ho fumana hore na lintho tse bonahalang le ke nkgetheng molemo bakeng sa ho beneficiation electrostatic. Ho se tšoane ka sehloohong pakeng tsa mong le e sengoathoana sa thepa tse hlahisoang Lethathamo 1. Ha thepa sebelisoa ka hare ho e mong le e mohato fapana ka boholo, tshebetso molao-motheo e feletseng e tšoanang.

STET e hlahlojoa disampole maloa tsepe ea ka bencheng tekanyo e le mokhatlo oa bohlokoa le ea tšepe le ho hana silicates 'nile ha hlokomeloa (sheba Lethathamo 2). maemo liteko li ne li khetha e le hore oa tšepe hlaphoheloa vs.. tšepe keketseho e mothinya ka huleloa 'me hamorao ka sebelisoa e le input bakeng sa ea mohlala sebetsa a moruo

tafole 2. diphetho bencheng ka tekanyo e ka tšepe fapaneng tšepe

| Exp | Feed Fe wt.% | sehlahisoa Fe wt.% | Absolute Fe Increase % | Fe hlaphoheloa % | SiO2 Rejection % | D10 (μm) | D50 (μm) | D90 (μm) |

|---|---|---|---|---|---|---|---|---|

| 1 | 39.2 | 50.6 | 11.4 | 91.5 | 63.9 | 5 | 23 | 59 |

| 2 | 39.4 | 60.5 | 21.1 | 50.8 | 96.0 | 5 | 23 | 59 |

| 3 | 30.1 | 48.0 | 17.9 | 70.6 | 84.6 | 1 | 18 | 114 |

| 4 | 29.9 | 54.2 | 24.3 | 56.4 | 93.7 | 1 | 18 | 114 |

| 5 | 47.0 | 50.2 | 3.2 | 96.6 | 35.3 | 17 | 62 | 165 |

| 6 | 21.9 | 48.9 | 27.0 | 41.2 | 96.6 | 17 | 62 | 165 |

| 7 | 47.6 | 60.4 | 12.8 | 85.1 | 96.9 | 17 | 62 | 165 |

| 8 | 35.1 | 44.9 | 9.8 | 89.0 | 54.2 | 3 | 61 | 165 |

| 9 | 19.7 | 37.4 | 17.7 | 76.0 | 56.8 | 5 | 103 | 275 |

| 10 | 54.5 | 62.5 | 8.0 | 86.3 | 77.7 | 5 | 77 | 772 |

| 11 | 54.6 | 66.5 | 11.9 | 82.8 | 95.6 | 8 | 45 | 179 |

(See Karolo 3.0, Figure 4). Tlatsetso diphetho liteko bontsha diphetho karohano ka disampole manya a tšepe sebelisa STET thekenoloji tse hlahisoang sengoliloeng fetileng ke STET ka tšepe e lokisa manya [9].

tafole 1. Tse tharo-mohato thulaganyou e kenngwa tshebetsong ho sebedisa STET tribo-electrostatic lebanta kgaoganyo thekenoloji.

| Phase | Used For: | Electrode Length | Type of Process |

|---|---|---|---|

| 1- Bench Scale Evaluation | Qualitative Evaluation | 250cm | Batch |

| 2- Pilot Scale Testing | Quantitative evaluation | 610cm | Batch |

| 3- Commercial Scale | Commercial Production | 610cm | Continuous |

E le ka bonoa Lethathamo 1, phapang ka sehloohong pakeng tsa kgaoganyo benchtop le motsamaisi-tekanyo e le separators khoebo-tekanyo e ke hore bolelele ba kgaoganyo benchtop ke hoo e ka bang 0.4 linako tse bolelele ba diyuniti motsamaisi-tekanyo e le ea khoebo-tekanyo e. E le bokgoni kgaoganyo ke mosebetsi wa bolelele eleketrode, bencheng ka tekanyo e etsa liteko ka se sebelisoa e le ka nkang sebaka sa liteko motsamaisi tekanyo. Pilot tekanyo liteko ke ke ho hlokahala ho fumana hore na isa tekanyong ea karohano eo tshebetso STET ka fihlella ka tekanyo e khoebo, le ho fumana hore na STET thulaganyou e ka kopana le liphofu sehlahiswa tlas'a ditefello fanoeng iphepe. Ka lebaka la ho se tšoane ha a sebetsang a bolelele karohano ho tloha bencheng tekanyo e ho motsamaisi tekanyo e, diphetho ka tloaelo ho ntlafatsa ka tekanyo e motsamaisi.

2.1 opereishene Molao-motheo

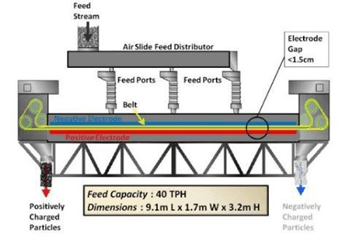

Ka tribo-electrostatic lebanta kgaoganyo (ka bona Figure 1 le Figure 2), lintho tse bonahalang feptjoang ka lekhalo tšesaane 0.9 - 1.5 cm, pakeng tsa tse peli tse li-electrode e tšoanang planar.

likaroloana li triboelectrically qosoa ke interparticle o ikopanye. Ka mohlala, tabeng ea e sampole tšepe se se akaretsang haholo hematite le quartz likaroloana matsoai, ea sebele qosoa (hematite) le hlonamisitsoe

likaroloana li triboelectrically qosoa ke interparticle o ikopanye. Ka mohlala, tabeng ea e sampole tšepe se se akaretsang haholo hematite le quartz likaroloana matsoai, ea sebele qosoa (hematite) le hlonamisitsoe

qosoa (quartz) ba khahloa ke li-electrode bo fapaneng. likaroloana li ebe hoholoa ho fihlela ke e tsoelang pele ho fallela lebanta bulehileng-letlooeng le fetisoa ka litaelo bo fapaneng. Lebanta susumelletsa ho likaroloana haufi le e mong le e eleketrode nģ'a lipheletsong fapaneng kgaoganyo ho. The stats jwale phallo ya likaroloana arola le tsoele pele triboelectric tjhaja ke thulana phatsa-phatsa e fana ka bakeng sa karohano selotlolo sethaleng le ho fella ka ho hloka sekoli babatsehang le hlaphoheloe ka unit trust le 'ngoe-fetisetsana. Lebanta lumella sebetsa ka ntle le e marang o motle likaroloana ho akarelletsa le likaroloana tse nyenyane tse ho feta 20μm, ka ho fana ka mokhoa oa ho a sa khaotse a hloekisa holim 'a li-electrode ho le tlosa e metle likaroloana, e neng e tla ka tsela e nngwe ho ikamahanya le holim 'a li-electrode ho. The phahameng lebanta lebelo hape nolofalletsa throughputs ho fihlela ho 40 tonnes ka hora ka kgaoganyo e le 'ngoe ka ho sa khaotse a fetisa boitsebiso bo bongata ho tsoa kgaoganyo ho. Ke ho laola entsprechen tse fapa-fapaneng thulaganyou e, sesebediswa dumella gogolo ea sehlopheng matsoai le hlaphoheloe.

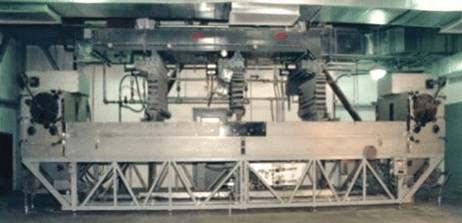

Moralo kgaoganyo ke batlang e bonolo. Lebanta le rollers se amahanngoang ke likarolo feela ho fallela. li-electrode ho ba ema le entsoe ka le lintho tse bonahalang haholo tsoarellang. The lebanta ke karolo consumable e leng hloka infrequent empa nako le nako Phetolo, tshebetso eo o khona ho ho tlatswa ka opareitara e le 'ngoe ka feela 45 metsotso. The kgaoganyo eleketrode bolelele ke hoo e ka bang 6 limithara tse (20 feat.) le bophara 1.25 limithara tse (4 feat.) bakeng sa e tletseng boholo diyuniti khoebo (ka bona Figure 3). The tshebediso ya matla e ka tlase ho 2 kWh ka tonne boitsebiso sebetswa ka ho fetisisa ea matla a chesa ke Motors tse peli khanna lebanta.

tshebetso e ommeng ka ho feletseng, hloka ha thepa tse eketsehileng 'me a hlahisa metsi litšila kapa mesi e kotsi moeeng. Bakeng sa karohano matsoai le kgaoganyo fana ka thekenoloji ho fokotsa tšebeliso ea metsi, eketsa pokello bophelo le / kapa hlaphoheloa le reprocess tailings.

tshebetso e ommeng ka ho feletseng, hloka ha thepa tse eketsehileng 'me a hlahisa metsi litšila kapa mesi e kotsi moeeng. Bakeng sa karohano matsoai le kgaoganyo fana ka thekenoloji ho fokotsa tšebeliso ea metsi, eketsa pokello bophelo le / kapa hlaphoheloa le reprocess tailings.

The compactness ea tsamaiso e lumella tenyetsehe merero tlhomamiso. The tribo-electrostatic lebanta karohano thekenoloji ke robust le industrially proven le ile la pele e sebelisoa industrially ho e lokisa ya mashala combustion e fofa molora ka 1995. thekenoloji ke atleha ho arola likaroloana k'habone ho tswa ho go tuka ga molelo fella oa mashala, ho tswa ho le kang khalase le likaroloana aluminosilicate matsoai ka fofa molora. theknoloji e bile phetha karolo nolofalletsa recycle ea matsoai ho rua fofa molora ka Phetolo samente tlhahiso ka konkreiti.

Ho tloha 1995, tse fetang 20 tonnes milione tsa sehlahisoa fofa molora di sebetswa ke STET separators hlomamisa ka USA. Histori liindasteri tsa fofa molora STET karohano e ngotsweng Lethathamo 3.

Ka liminerale sebetsa, le triboelectric lebanta kgaoganyo thekenoloji 'nile la sebelisoa ho arohana e mengata e fapaneng ea thepa ho akarelletsa calcite / quartz, talc / magnesite, le barite / quartz.

tafole 3. Industrial kopo ya tribo-electrostatic lebanta karohano ho fofa molora

| utility / seteishene matla | Location | Qala khoebo tshebetso | setsing lintlha |

|---|---|---|---|

| Duke Energy - Roxboro Station | North Carolina USA | 1997 | 2 Separators |

| lipuo Energy- Brandon Shores | Maryland USA | 1999 | 2 Separators |

| Scotland Power- Longannet Station | Scotland UK | 2002 | 1 kgaoganyo |

| Jacksonville Electric-St. Johns River Power Park | Florida USA | 2003 | 2 Separators |

| Motlakase oa South Mississippi -R.D. Morrow | Mississippi USA | 2005 | 1 kgaoganyo |

| New Brunswick Power-Belledune | New Brunswick Canada | 2005 | 1 kgaoganyo |

| OF npower-Didcot Station | Engelane UK | 2005 | 1 kgaoganyo |

| Seteishene sa Sehlekehleke sa Talen Energy-Brunner | Pennsylvania USA | 2006 | 2 Separators |

| Tampa Electric-Big Bend Station | Florida USA | 2008 | 3 Separators |

| OF npower Aberthaw-Station | Wales UK | 2008 | 1 kgaoganyo |

| EDF Energy-West Burton Station | Engelane UK | 2008 | 1 kgaoganyo |

| ZGP (Lafarge Cement / Ciech Janikosoda JV) | Poland | 2010 | 1 kgaoganyo |

| Korea Boroa-bochabela Power- Yeongheung | Korea Boroa | 2014 | 1 kgaoganyo |

| PGNiG Termika-Sierkirki | Poland | 2018 | 1 kgaoganyo |

| Khampani ea Taiheiyo Cement-Chichibu | Japane | 2018 | 1 kgaoganyo |

| Armstrong Fly Fly Ash- Samente ea Ntsu | Philippines | 2019 | 1 kgaoganyo |

| Korea Boroa-bochabela Power- Samcheonpo | Korea Boroa | 2019 | 1 kgaoganyo |

3.0 mokgweng

tse tharo (3) Maemong a di khetholloa bakeng sekasekale ka ho eketsehileng le ho ba sebetswa ka taelo ea boholo ho ithuta-boemo ba moruo le kotsi / monyetla tlhahlobo. sekasekale e thehiloeng ho rua ho ka 'nang ea opareitara e tla lemoha ka kokotisaka thekenoloji STET e ka flowsheet dimela bona.

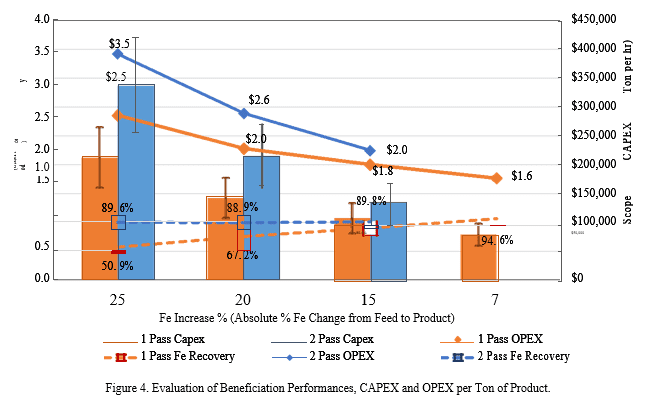

Performance tsa kgaoganyo STET hakanngoa latela bencheng liteko tekanyo e phethile (sheba Lethathamo 2). Ya data bokella ka tšepe e sa tšoaneng tšepe lumelloa ho lekanyetsa ea mohlala hlaphoheloa eo e ne e sebelisoa ho bolela esale pele ka ho hlaphoheloa ho tse tharo (3) lithuto tsa nyeoe e 'ngoe. Figure 4 e bontša liphello tsa ea mohlala ho ya ka dipehelo tsa liketso le ditjeho. The hlaphoheloa tšepe e bontša ka ho toba ka mekoallo ea, against the iron beneficiation in %Fe. Ka bencheng tekanyo e etsa liteko, ka fetisetsana le 'ngoe ka STET ho lekoa hammoho le tse peli ka fetisetsana flowsheet. Peli fetisetsana flowsheets akarelletsa scavenging tsa mehatla rougher, Ka lebaka leo e ntseng e eketseha ea hlaphoheloa haholo. Leha ho le joalo, ena e ama mechine STET eketsehileng le ditjeho Ka hona e phahameng. The phoso mekoallo ho fetela ho CAPEX mekoallo bontša CAPEX theko phetoho ho itšetlehile ka boholo ba taba oa porojeke. Sebopego se se tshwaraganyang CAPEX lipalo fokotseha le boholo-taba oa porojeke. Ka mohlala, bakeng sa manya tloaelehileng lekoa ka tse peli-fetisetsana flowsheet, e leng keketseho ea 15% ka sehlopheng tšepe (i.e. ho tswa 50% Fe ke 65% Fe) o ne a tla bolela esale pele oa tšepe hlaphoheloa ya 90%. Lower tšepe recoveries ba ka boithaopo le sebelisitsoe ka latelang lithuto tsa nyeoe e 'ngoe e le hore ba nahane ka ho lahleheloa ke ntho ea tlhaho ea ho hlaphoheloa ha hlahisa e phahameng sehlopheng tsepe ea concentrates.

Bakeng sa e mong le e ithuta hlahletsoe nyeoe, flowsheet ka e ho fanoa ka taelo ea boemo ba boholo le feela thepa ka sehloohong ho bontšoa e le hore ho tšehetsa sekasekale litšenyehelo. Bakeng sa e mong le e flowsheet, moruo li hakanyetsoa tlas'a dihlopha tse latelang: motse-moholo oa litšenyehelo (CAPEX); sebetsa litšenyehelo (OPEX); le, Lekgetho. Mothating ona screening, boemo ba ho nepahala bakeng sa e mong le e sehlopha e ka "taelo ea boholo" (± 50%).

Main thepa CAPEX hakanngoa sebelisa databases hare (Ka ntle ke Soutex) le qotsa thepa ha fumaneha. Lintlha neng li ikemiselitse ho theha litsenyehelo tsa ho ditjeo bobeli e tobileng le e sa tobang. STET itseng CAPEX makgabane hape e kenyeletsa thepa ea mahareng le laola, ikemela ka factorization tlaase bakeng sa tlhomamiso le kaho bakeng sa sengoathoana ena ea thepa. The fopholetsa OPEX e entsoe ka tokiso, manpower, matla le ditjeho consumable. Likarolo botekgeniki fanoeng ke tshebetso flowsheet tshehetsa theko sekasekale bobeli ya ka dipehelo tsa CAPEX le OPEX, le theko likarolo amanang le ho hlongoa le tshebediso ya STET tribo-electrostatic lebanta kgaoganyo ne hakanngoa sebelisa STET polokelongtshedimosetso ea merero ea phethoa le tšepe manya bencheng tekanyo e mosebetsi teko.

Lipalo le sebelisitsoe ka theko latelang patlotlhotlhwa tse tswang Figure 4. Ka mohlala, bakeng sa manya tloaelehileng lekoa ka tse peli-feta ho tsepamisa mohopolo le ho eketsa ya 15% ka sehlopheng tšepe (i.e. ho tswa 50% Fe ke 65% Fe) e ne e tla chelete pota 135 000$ ka ton / H ka CAPEX le 2 $ / sa t ka OPEX (boima ba lithane mamelisise tšepe). Kaha sena se ne a rerile ka ithuta screening, ho ile ha etsoa qeto ea ho lula re khomaretse mekhoa e tloaetsoeng ka ditheko sehlahisoa le ho phethisa and analysis nahanela e bapisiwa le sehlopheng sa ho qetela le theko sehlahisoa. E le ea November 2019, 62% Seaborne trades tsepe ea pota 80USD / sa t, le volatility phahameng haholo.

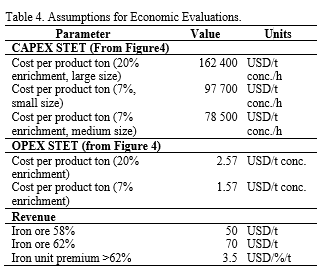

The Premium ka tsepe ea unit trust mamelisisa e boetse ke hloka botsitso haholo le itšetlehile ka lintho tse ngata tse kang contaminants le litlhoko tsa ho tloha itseng moreki. Phapang theko pakeng 65% tšepe le 62% tšepe e kamehla fetola ka nako. ka 2016, phapang e ne e fokolang haholo (pota 1 $/t/%Fe) empa 2017-2018, le Premium hloa haufi le 10 $/t/%Fe. Ka nako ea ho ngola sena, e hona joale ho pota 3 $/t/%Fe [10]. tafole 4 e bontsa kgethile mekgwatiriso moralo sebediswa bakeng sa fopholetsa costing.

tafole 4. Likhopolong tsa patlotlhotlhwa Economic.

Nako payback hakanngoa ho tloha selemo sa pele sa ho hlahisoeng. Bakeng sa e mong le e-taba oa porojeke, e eketsehileng tse peli (2) lilemo tse lokela ho hopola bakeng sa kaho. Melemo phallo ea chelete (ditshenyehelo le matlotlo) ba discounted ho tloha qalong ea ea kaho.

Nako payback hakanngoa ho tloha selemo sa pele sa ho hlahisoeng. Bakeng sa e mong le e-taba oa porojeke, e eketsehileng tse peli (2) lilemo tse lokela ho hopola bakeng sa kaho. Melemo phallo ea chelete (ditshenyehelo le matlotlo) ba discounted ho tloha qalong ea ea kaho.

4.0 Beneficiation a thulaganyo ya tshebetso DSO omileng

thomello otlolohileng manya (DSO) diporojeke tse di hlahisa molumo kholo ka ho fetisisa tsa manya a tšepe ka lefatše, haholo-holo ho fepa marakeng Sechaena 'me boholo ba molumo o tsoa Australia Bophirimela (WA) le Brazil. ka 2017, molumo oa manya a tšepe hlahisoa WA feta 800 boima ba lithane tse limilione tse 'me bophahamo ba modumo Brazil e ne e le ho pota 350 boima ba lithane tse limilione tse [11]. Le thulaganyo beneficiation ke haholo bonolo, bopilweng hangata ba sithabetsa, ho hlatsoa le ho di arola [12].

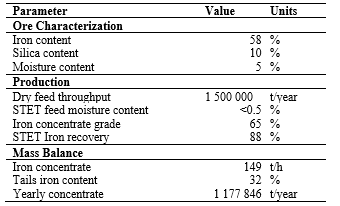

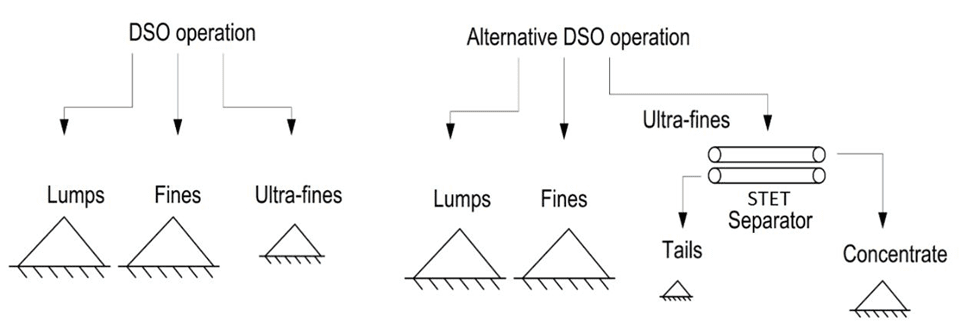

Beneficiation of-difaene marang ho hlahisa ka 65% Fe mamelisisa e le monyetla oa bakeng sa 'marakeng DSO. Tsela e nkiloeng ho hlahloba melemo STET thekenoloji bakeng sa diporojeke DSO ke khoebo ea-theoha pakeng tsa hlahisa o teng tlaase sehlopheng tšepe marang-difaene le e meng ea ho hlahisa sehlahisoa sa ka eketsa boleng mora STET beneficiation. The flowsheet sisintsweng (Figure 5) nahana ka shell DSO tshebetso ka WA e neng e tla hona joale Export har'a lihlahisoa tsa lona marang-difaene ka 58% Fe. The mefuta e meng e ne e tla shebana le marang-difaene e le hore ho eketsa boleng ba sehlahisoa ho qetela. tafole 5 limpho tse ling tsa ka litekanyetso moralo le ea phahameng le boima ho leka-lekana le sebelisitsoe ka fopholetsa ya matlotlo. The orebody ya ka dipehelo tsa sehlopheng le bokgoni ba ha ba emela e porojeke e ne a le teng empa ho ena le hoo e tloaelehileng ea DSO porojeke e ne ka ho ya ka boholo le ho hlahisoeng.

tafole 5. Marang-o motle DSO Beneficiation Plant Design litekanyetso le Misa Balance.

Figure 5. Flowsheets bapisoa ka DSO khoebong-theoha

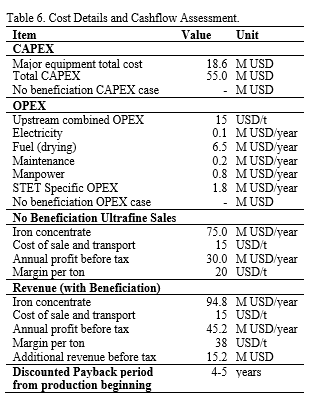

tafole 6 limpho le ea phahameng CAPEX, OPEX le hakanngoa lekgetho. The CAPEX Khakanyo e kenyeletsa go tlaleletsa ka e ncha ea inehetseng oona tsamaisong mojaro-tsoa (loadout sesiu le koloi play loading), hammoho le tsamaiso ea STET. E le hore ho hlahloba u khutlele ha flowsheet sisintsweng, tshekatsheka a moruo e entsoeng ho pota mosebetsi oa matsoho-theoha pakeng tsa beneficiation nyeoe e 'ngoe le rekisa sehlahisoa tlaase sehlopheng. Tabeng beneficiation, molumo e fokotsehile empa Premium ka diyuniti tšepe eketsa theko pabatsong haholo. Ka OPEX ho, fopholetsa e fanoe bakeng sa nyolosa sebetsa manya (meepo, sithabetsa, di baya ka ditlhopha le tšoarang).

Ho sa tsotellehe ho fokotsa molumo haholo, khutla ho thahasellisa fuoa Premium ka phahameng sehlopheng tsepe ea mamelisise. The khutla manolotsoeng e itšetlehileng ka eona haholo ka Premium ena, eo e se e ntse e eketseha ka lilemo tse 'maloa tse fetileng ka lebaka la ho litaba tsa tikoloho. Ka o ile a bontša ka holimo (tafole 6), le khahlehang moruo joalo morero o itšetlehile haholo ka theko phapang pakeng 58% tšepe le 65% tšepe. Ka sekasekale ena hona joale, theko ena Premium ne 30.5 $/sa t, eo bontša hoo e ka bang hona joale 'maraka boemo bo. Leha ho le joalo, ena Premium tefello e histori di akareditse go tsewa tswa 15 - 50 $/sa t.

5.0 Scavenging Process ka matla a khoheli e

karohano Plant

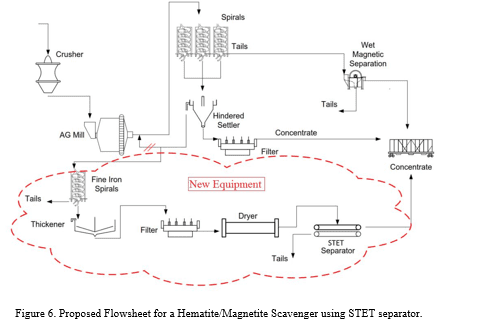

Tšepe concentrators ka Amerika Leboea sebakeng tšebeliso matla a khoheli ea mahloriso e leng tsela e sebetsang hantle ya go tlhoma tlhaloganyo mo hematite le magnetite, haholo-holo bakeng sa boholo karoloana ka holimo 75μm [5,13]. Hematite / dimela magnetite sebakeng sena ka tloaelo ho sebelisa likaroloana ka tshebetso karohano mathomo le hape tsona li sebelisa Low matla Magnetic arohana mehato (LIMS). A taba tloaelehile hore batho ba ka mose ho dimela hematite / magnetite ke hlaphoheloa ea tšepe e thumisehileng e tailings tšepe e ngata, hangata e fihle maemo e phahameng ho 20%. Phephetso ka sehloohong e amanang le hematite e metle, e le e ntle tšepe ka hang ho hlaphoheloa ke ikhara le ke impervious ho LIMS sebediswa ho hlaphoheloa o motle magnetite. Ka papiso, le STET kgaoganyo ke haholo e atlehang ka arola likaroloana o motle, ho akarelletsa le likaroloana tlase microns 20μm moo LIMS le likaroloana tse sa sebetsa. Ka lebaka leo,, se khaphatsehang tswa hydrosizer hloekile (sitisoa mojaki) fepa scavenger ikhara ke ho loketse molemo bakeng sa thekenoloji STET. The flowsheet sisintsweng e fanoa ka Figure 6.

Ka phetolo ena, bofubelu tabanya mola totobatsa thepa e ncha ka hare ho e semela o teng. Tlasa flowsheet sisintsweng, ho ena le ho recirculated, ho sitisoa mojaki nala li ne li tla sebetswa ke ikhara scavenging sebetsa ka maemo a fapaneng ho feta ikhara rougher. A mamelisise o motle tšepe ne li ka hlahisoa le ho omisitsoeng. The mamelisise omisitsoeng tla ebe ho lebisoa ho kgaoganyo STET e le hore ho hlahisa mamelisisa e qetellang ea sehlopheng salable. Tefiso sehlahisoa ka marketed ka thoko kapa hammoho setseng ho hlahisoeng tsepamong.

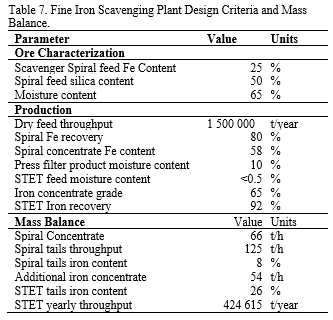

tafole 7 limpho mekgwatiriso moralo le ea phahameng le boima ho leka-lekana le sebelisitsoe ka fopholetsa ya matlotlo.

tafole 8 limpho le ea phahameng CAPEX, OPEX le hakanngoa lekgetho.

and analysis Sena se bontša hore ho khutla ha phethisa scavenging oa potoloho amang STET thekenoloji e motle 'me e fana ka tiisetso e nngwe hape ho nahanela.

Molemo o mong oa ho omisa e ntle tšepe mamelisise ha ke bapisa ho theknoloji e gaisana mo ke molemong amanang sephetho ho tswa tse bonahalang ho tshwara latelang mahloriso. e ntle haholo metsi mamelisise ke mathata mabapi filtara, tshwara le lipalangoang. Freezing mathata ka literene 'me fluxing ka likepe e fetolela ho omisa ea mamelisisa e ntle haholo ka linako tse ling e tlamang. STET aa ageletsweng omisa ka lebaka leo, ba molemo.

6.0 Beneficiation ea Brazil Tailings

depositi

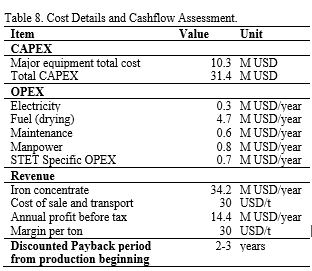

Beneficiation tsa tailings o motle bonahala ka eketsang boleng kopo ya processors ho valorize theknoloji STET, e le mohlodi e khabeloa fatše le fumaneha bakeng sa theko e tlase. Ha a ntse a tsepe ea tailings mobung ho jara maemo phahameng le ea tšepe ba teng le libakeng tse ngata, libakeng moo dithepa ba e bonolo e lokela ho ba le tokelo ea ho sekasekale ho eketsehileng. Brazil mobung nang phahameng limaraka Fe le maqiti haufi o teng tsa dibopeho tsa motheo ho tsamaisa ka emela monyetla o motle bakeng sa processors ho rua molemo ho kenngwa tshebetsong ha STET tribo-electrostatic thekenoloji. The flowsheet sisintsweng (Figure 7) se nahana ka shell Fe e ngata ea Brazil tailings tshebetso oo STET thekenoloji ne e tla ba feela beneficiation thulaganyou e.

Beneficiation tsa tailings o motle bonahala ka eketsang boleng kopo ya processors ho valorize theknoloji STET, e le mohlodi e khabeloa fatše le fumaneha bakeng sa theko e tlase. Ha a ntse a tsepe ea tailings mobung ho jara maemo phahameng le ea tšepe ba teng le libakeng tse ngata, libakeng moo dithepa ba e bonolo e lokela ho ba le tokelo ea ho sekasekale ho eketsehileng. Brazil mobung nang phahameng limaraka Fe le maqiti haufi o teng tsa dibopeho tsa motheo ho tsamaisa ka emela monyetla o motle bakeng sa processors ho rua molemo ho kenngwa tshebetsong ha STET tribo-electrostatic thekenoloji. The flowsheet sisintsweng (Figure 7) se nahana ka shell Fe e ngata ea Brazil tailings tshebetso oo STET thekenoloji ne e tla ba feela beneficiation thulaganyou e.

depositi e nkoa e le khōlō hoo ho fana ka lilemo tse mashome fepa ka ka selemo le selemo tekanyo ea 1.5 M ton / selemo. Bakeng sa boemo bona, le manya fepa ka e ntse khabeloa fatše ka D50 tsa ~ 50μm le manya ne ho tla hlokahala ho ho shoveled, isoa ebe omisitsoeng pele tribo-electrostatic beneficiation. mamelisisa e ne e tla ka nako eo ho laela ka literene / likepe le tailings e ncha e ne e tla tse bokeletsoeng ka mehahong eo e mecha.

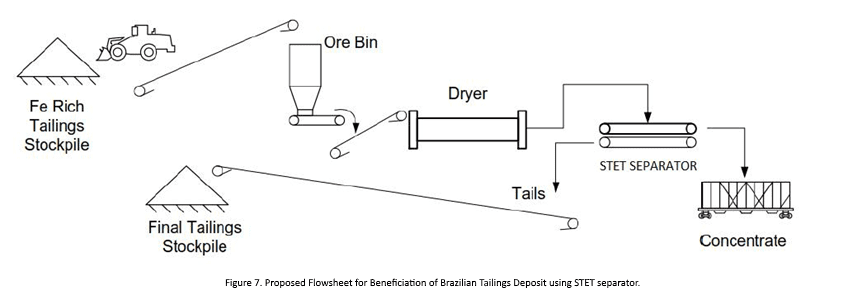

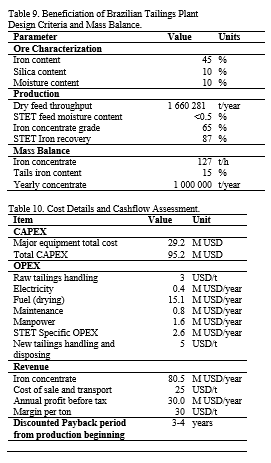

tafole 9 limpho mekgwatiriso moralo le ea phahameng le boima ho leka-lekana le sebelisitsoe ka fopholetsa ya matlotlo. tafole 10 limpho le ea phahameng CAPEX, OPEX le hakanngoa lekgetho.

Ka o ile a bontša ka ho Lethathamo 10, ka ho khutla ha phethahatsa thekenoloji STET bakeng sa beneficiation tsa tailings Brazil e motle. Ho feta moo, ho tloha e ka pono ea tikoloho le flowsheet sisintsweng e boetse e molemo nna jalo e le beneficiation tsa tailings omileng tla fokotsa tailings boholo le ka holim'a metsi 'me e ne e tla fokotsa likotsi tse amanang le metsi tailings lahla.

Ka o ile a bontša ka ho Lethathamo 10, ka ho khutla ha phethahatsa thekenoloji STET bakeng sa beneficiation tsa tailings Brazil e motle. Ho feta moo, ho tloha e ka pono ea tikoloho le flowsheet sisintsweng e boetse e molemo nna jalo e le beneficiation tsa tailings omileng tla fokotsa tailings boholo le ka holim'a metsi 'me e ne e tla fokotsa likotsi tse amanang le metsi tailings lahla.

7.0 Puisano le likhothaletso

The kgaoganyo STET e se e atlehile ho bontša ka bencheng tekanyo e ho arohaneng manya o motle tšepe, Ka lebaka leo, ho fana ka processors ka mokhoa bukeng ho hlaphoheloa difaene tse neng li tla ka litsela tse ling ho le thata ho tsamaiso ho limaraka sellable le theknoloji e leng teng.

The flowsheets hlahlojoa ke STET le Soutex ke mehlala ea ho e lokisa tšepe manya eo a ka rua molemo ka ho omileng triboelectrostatic karohano. The tse tharo (3) flowsheets nts'etsoa fanoa ka ithuta sena li sa bo khethehileng le mekhoa e meng ea tse ling lokela ho hopola. Sena ithuta selelekela e bontša hore dithulaganyo scavenging amang tlaase omisa ditjeo, DSO tshebetso le tailings beneficiation na le monyetla o motle oa ho atleha khoebo.

Molemo o mong ka ho e lokisa e omeletseng e ka tailings polokelo - tse jwale bolokoa tailings bokhothokhotho matangoana – e ommeng tailings ne ba tla ba molemo oa ho felisa ea bohlokoa kotsi tikoloho. Tsa morao tjena le hantle phatlalatsoa tailings letamo le ho hlōleha totobatsa hore ho hlokahala hore taolo ya tailings.

The ditsenngwateng ho ithuta hona sebelisoa ho manolla tsepe ea sehlopheng le hlaphoheloe ne bencheng tekanyo e sephetho karohano sebelisa disampole tsepe ea ho tloha libakeng tse ngata. Leha ho le joalo, le diminerale le tokoloho litšobotsi tsa e mong le e manya e ikhethang, Ka hona disampole moreki tsepe ea lokela ho hlahlojoa ka bencheng kapa motsamaisi tekanyo e. Ka bohato bo latelang ea ho hōla, le flowsheets tharo hlahlojoa ka pampiri sena se lokela ho ithuta ka ho qaqileng ka ho eketsehileng.

Qetellong, theknoloji e tse ling tse jwale tlas'a ithuta bakeng sa tšepe hlaphoheloa o motle kang WHIMS, Jigs le reflux classifiers. E se e ka a tseba hore ba bangata ba metsi dithulaganyo karohano ba sebetse hantle bakeng sa likaroloana tlas'a 45μm 'me ka hona thekenoloji STET ka' na na le bo ruisang molemo ho ka mefuta e fapaneng e ntle haholo, ka STET e bone liketso tse ntle le fepa ka e le e thumisehileng e 1μm. A kgwebo ya-theoha ka puo ea khale ho ithuta ho bapisa le theknoloji e bontšitsoeng ka STET lokela ho khanna, e neng e tla kenyeletsa tsa tekolo tse tshebetso, bokgoni, theko, joalo-joalo. Ka tsela eo, ba tsoane molemo ka ho fetisisa bakeng sa STET ka totobatsa le hloekisitsoeng.

References

1. Lu, L. (Ed.) (2015), "Tšepe Tšepe: diminerale, Processing tsa moruo Tikoloho ", Elsevier.

2. Ferreira, H., & lebese, M. G. P. (2015), "Phuputso e entsoeng Cycle Tekolo Life of meepo tsepe ea", Journal ea tlhahiso hloekile, 108, maq. 1081-1091.

3. Filippov, L. O., Severov, V. V., & Filippova, ke. V. (2014), "An kakaretso ya beneficiation ea tšepe tšepe ka tsela khutlisetsang cationic flotation", koranta ea machaba ea sebetsa matsoai, 127, maq. 62-69.

4. Sahoo, H., Rath, S. S., Rao, D. S., Mishra, B. K., & ho, B. (2016), "Karolo ea silica le ea alumina dikahare ka flotation ea tšepe tšepe", Journal ea machaba ea matsoai Processing, 148, maq. 83-91.

5. letangoana la ho sesa, Claude, et al a (2014), “Size hlaphoheloa etsang kou oa liminerale tse ikhara indasteri bakeng sa lokisa tšepe oxide e tšepe.” liminerale Engineering 65, maq 115-123.

6. Luo, X., Wang, Y., Wen, S., Ma, M., letsatsi, C., Yin, W., & Ma, le. (2016), "Phello ea liminerale carbonate ka quartz flotation boitšoaro ba tlas'a maemo a khutlisetsang anionic flotation ea tšepe tšepe", Journal ea machaba ea matsoai Processing, 152, maq. 1-6.

7. da Silva, F. L., Araújo, F. G. S., Teixeira, M. P., Gomes, R.C., & Kruger, F. L. (2014), "Thuto ea tsa ho hlaphoheloa le ho botjha ha thepa ea tailings tswa mahloriso tsa manya a tšepe bakeng sa tlhahiso ea ceramic", letsopa International, 40(10), maq. 16085-16089.

8. Bielitza, Mark P. (2012), “Litebello bakeng sa 2020 Tšepe Market Tšepe. Ditirisanommogo Analysis ba dipharologanyo Market le kotsi fokotsa Strategies” Books, Rainer Hampp Publishing, khatiso 1, nomoro 9783866186798, Jan-Jun.

9. Rojas-Mendoza, L. F. Hrach, k. Flynn le A. Saahil. (2019), "Dry beneficiation ea tlaase sehlopheng tšepe difaene manya sebelisa tribo-motlakase lebanta kgaoganyo", Ka dipuisano tsa SME Conference selemo & Expo le CMA 121st National Bophirimela morafo Conference Denver, Colorado - February 24-27, 2019.

10. China Tšepe Tšepe Spot Index Price (CSI). Ntsa khatiso ho tloha-http://www.custeel.com/en/price.jsp

11. U.S. Geological Survey (USGS) (2018), "Tšepe Tšepe e", ka Tšepe Tšepe Lipalo-palo le lesedi.

12. Jankovic, A. (2015), "Tsa a tsepe ea comminution le theknoloji e tlhophiso. tšepe tšepe. -http://dx.doi.org/10.1016/B978-1-78242-156-6.00008-3.

Elsevier Ltd.

13. Richards, R. G., et al a. (2000), “Matla a khoheli karohano ya marang-o motle (- 0.1 limilimithara) liminerale sebelisa separators spiral.” liminerale Engineering 13.1, maq. 65-77.