Roghnaigh Teanga:

ST Trealamh & Technology LLC s (STET) deighilteoir crios Triboelectrostatic (figiúr 1) Tá an cumas léirithe a phróiseáil cáithníní fíneáil ó 1995 scaradh carbóin unburned ó mhianraí fuinseog eitilt i stáisiúin chumhachta guail-fired i Meiriceá Thuaidh, Europe and Asia to produce a concrete grade Pozzolan for use as a cement substitute. 1 Trí thástáil monarcha treorach, in-ngléasra tionscadail taispeána agus / nó oibríochtaí tráchtála, STET’s separator has demonstrated Beneficiation of many minerals including potash, barite, cailcít, agus talc.2

Ós rud é go bhfuil an suim linn sa teicneolaíocht seo curtha cáithníní ar a gcumas a phróiseáil faoi bhun 0.1 mm, an teorainn saor in aisce-titim agus druma deighilteoirí rolla traidisiúnta, the upper particle size limit of STET’s current design has not been a focus of the development of the technology in the past. ach, efforts are under way to increase it by design changes. STET mhonaraíonn faoi láthair dhá méideanna maidir le toilleadh ainmniúil 40 agus 23 tonna méadrach in aghaidh na huaire.

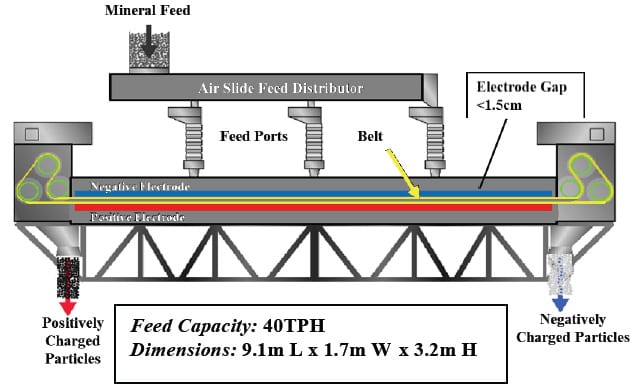

figiúr 1: ST Trealamh & Teicneolaíochta Triboelectric Chreasa Deighilteoir

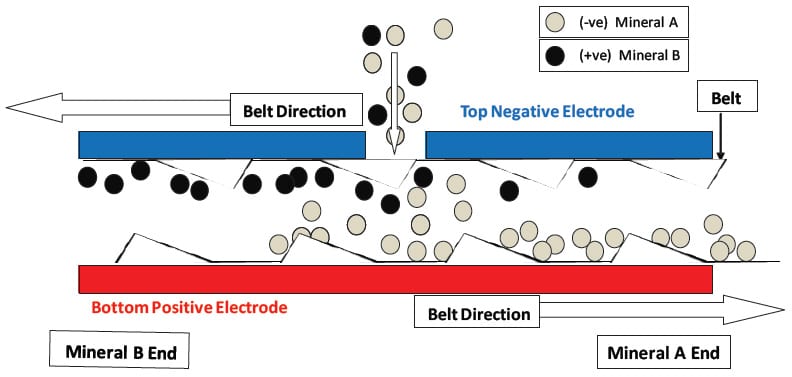

Na prionsabail a bhaineann le hoibriú an deighilteoir STET léirithe i bhFigiúirí 2 & 3. Na cáithníní chun dochair ag an éifeacht triboelectric trí-cháithnín-le cáithníní imbhuailtí san dáileoir beatha sleamhnán aeir agus laistigh den bhearna idir na leictreoidí. Tá an voltas i bhfeidhm ar na leictreoidí idir ± 4 agus ± 10kV i gcoibhneas le talamh, giving a total voltage difference of 8 chun 20 kV. An crios, atá déanta as plaisteach neamhsheoltach, Is mogalra mór le thart 60% ceantar oscailte. Is féidir leis an cáithníní pas a fháil go héasca tríd na oscailtí i crios.

figiúr 2: Scéimreach de STET Deighilteoir

Feed Cumas: 40TPH Toisí: 9.1m L x 1.7m W x 3.2m H

The flow patterns and particle-to-particle contact within the electrode gap that is established by the moving belt are key to the effectiveness of the separator. Ar theacht isteach sa bhearna idir na leictreoidí na cáithníní luchtaithe go diúltach á mealladh ag na fórsaí réimse leictreach do na leictreoidí dearfacha bun. Na cáithníní atá luchtaithe go dearfa á mealladh chun an leictreoid diúltach barr. Is é an luas an crios lúb leanúnach athraitheach ó 4 chun 20 m / s. The geometry of the belt cross-direction strands serves to sweep the particles of the electrodes moving them towards the proper end of the separator and back into the high shear zone between the oppositely moving sections of the belt. Toisc go bhfuil an dlús líon na gcáithníní chomh hard sa bhearna idir na leictreoidí (approximately one-third the volume is occupied by particles) agus tá an sreabhadh agitated go bríomhar, tá go leor imbhuailtí idir cáithníní agus a mhuirearú is fearr is féidir a tharlaíonn go leanúnach le linn an crios scaradh. The counter-current flow induced by the oppositely moving belt sections and the continual re-charging and re-separation creates a countercurrent multistage separation within a single apparatus. This continuous charging and recharging of particles within the separator eliminate the need for any “charger” system prior to introducing material to the separator, thus removing a serious limitation on the capacity of electrostatic separation. Is é toradh an deighilteoir dhá shruth, a concentrate, agus iarmhair, gan sruth meánaigh. Tá an éifeachtacht an deighilteoir Tá sé léirithe go cothrom le thart ar trí chéim na deighilte saor-titim le meánaigh athchúrsáil.

figiúr 3: Leictreoid Bearna an STET Chreasa Deighilteoir

The STET separator has many process variables that enable optimization of the trade-off between product purity and recovery that is inherent in any Beneficiation process. The coarse adjustment is the feed port through which the feed is introduced to the separation chamber. The port furthest from the discharge hopper of the desired product gives the best grade but at the expense of a lower recovery. Tá coigeartú finer an luas an crios. The electrode gap, atá inchoigeartaithe idir 9 agus 18 mm, agus an voltas i bhfeidhm (± 4 go ± 10 kV) are also important variables. Is féidir leis an polaraíocht an leictreoidí a athrú a áiseanna i dheighilt ábhair áirithe. Pretreatment of feed material by precise control of trace moisture content (mar atá tomhaiste ag taiseachas coibhneasta beatha) is important to achieve optimum separation results. The addition of trace amounts of charge-modifying chemical agents can also aid in optimizing the process.

Mar a luadh thuas, the initial commercial application of the belt separator has been a separation of coal char from the glassy Aluminosilicate mineral from fly ash from coal-fired power plants. This technology is unique among electrostatic separators in its ability to separate fly ash, a bhfuil de ghnáth méid meán na gcáithníní níos lú ná 0.02 mm. The STET separator has also been proven to effectively separate magnesite from talc, halite from kieserite and sylvite, sileacáití ó Bart, and silicates from calcite.3 The mean particle size of all of these feed materials has been in the range of 0.02 agus 0.1mm. Samplaí de idirscarthaí le haghaidh ábhar éagsúla atá ar áireamh i Tábla 1.

Tábla 1 - idirscaradh mar shampla,

| Scaradh | Feed | Táirge | Aisghabháil |

|---|---|---|---|

| Calcium Carbonate - Sileacáití | 9.5% Acid Insols | <1% A.I. | 89% CaCO3 |

| talc - maignéisít | 58% talc | 95% talc | 77% talc |

| 88% talc | 82% talc | ||

| Kierserite + KCl - NaCl | 11.5% K2O | 27.1% K2O | 90% K2O |

| 12.2% kieserite | 31.8% kieserite | 94% kieserite | |

| 64.3% NaCl | 14.3% NaCl | 92% NaCl reject | |

| Fly Ash Mineral - Carbon | 6.3% carbon | 1.8% carbon | 88% mianraí |

| 11.2% carbon | 2.1% carbon | 84% mianraí | |

| 19.3% carbon | 2.9% carbon | 78% mianraí |

Go teoiriciúil, ós rud é ag brath mhuirearú gcáithníní ar an éifeacht triboelectric, aon dá mhianra a liberated ó gach ceann eile (seoltóir- seoltóir nó nonconductor-conductor) Is féidir a bheith scartha ag an modh seo. Áirítear ar iarratais féideartha eile maignéisít-Grianchloch, feldspar-Grianchloch, gaineamh mianraí, idirscarthaí potais mianraí eile, agus

idirscarthaí Phosphate-cailcít-shilice.

1 Bittner, J.D., Gasiorowski, S.A., Bush, T.W.,, Hrach, F.J., Separation technologies’ automated fly ash beneficiation process selected for new Korean power plant, Imeachtaí 2013 World of Coal Ash conference, aibreán 22-25, 2013. 2 Bittner, J.D., Hrach, F.J., Gasiorowski, S.A., Canellopoulus, L.A., Guicherd, H. Triboelectric belt separator for Beneficiation of fine minerals, SYMPHOS 2013 – 2nd International Symposium on Innovation and Technology for the Phosphate Industry. Lean ar aghaidh Innealtóireacht, Vol. 83 PP 122-129, 2014. 3 Bittner, J.D., Flynn, K.P., Hrach, F.J., iarratais Méadú i scaradh Triboelectric thirim mianraí, Imeachtaí an XXVII Idirnáisiúnta Mianra Próiseáil Comhdháil - IMPC 2014, Santiago, An tSile, Deireadh Fómhair 20 - 24, 2014.