Teua lugha:

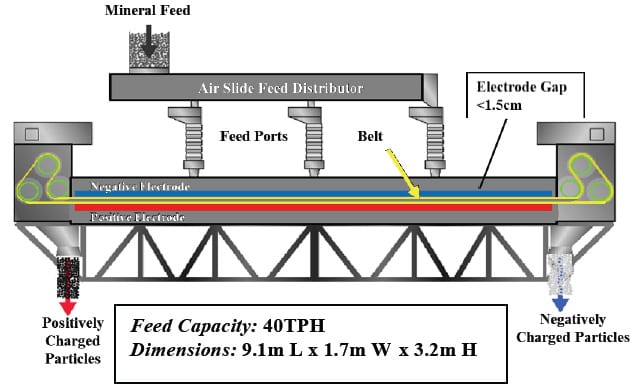

Vifaa vya ST & Teknolojia ya LLC (STET) Mgawanyiko wa ukanda wa (Kielelezo 1) ina uwezo walionyesha mchakato wa chembe nzuri kutoka 1995 separating Unburned carbon from fly ash minerals in coal-fired power plants in North America, Europe and Asia to produce a concrete grade Pozzolan for use as a cement substitute. 1 Kupitia majaribio ya mimea ya majaribio, Miradi ya maonyesho ya kupanda na / au shughuli za kibiashara, STET’s separator has demonstrated Beneficiation of many minerals including potash, barite, calcite, and talc.2

Since the primary interest in this technology has been its ability to process particles less than 0.1 mm, kikomo cha kawaida free-kuanguka na ngoma roll separators, the upper particle size limit of STET’s current design has not been a focus of the development of the technology in the past. Hata hivyo, efforts are under way to increase it by design changes. STET currently manufactures two sizes with nominal capacities of 40 na 23 metric tonne per hour.

Kielelezo 1: Vifaa vya ST & Technology’s Triboelectric Belt Separator

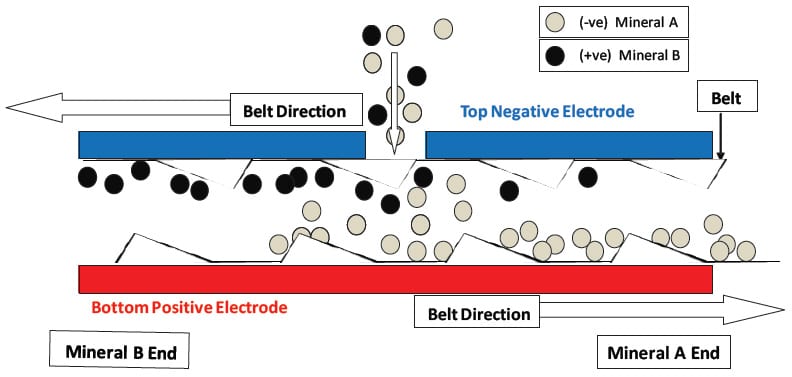

The principles of operation of the STET separator are illustrated in Figures 2 & 3. Chembe hizo zinashtakiwa na athari ya triboelectric kupitia mgongano wa chembe-to-particle katika msambazaji wa chakula cha slaidi ya hewa na ndani ya pengo kati ya electrodes. voltage iliyotumika kwenye electrodes ni kati ya ±4 na ±10kV jamaa na ardhi, giving a total voltage difference of 8 kwa 20 kV. Ukanda wa, ambayo imetengenezwa kwa plastiki isiyo ya kawaida, ni mesh kubwa na kuhusu 60% Eneo la wazi. The particles can easily pass through the openings in the belt.

Kielelezo 2: Schematic of STET Separator

Feed Capacity: 40TPH Dimensions: 9.1m L x 1.7m W x 3.2m H

The flow patterns and particle-to-particle contact within the electrode gap that is established by the moving belt are key to the effectiveness of the separator. Baada ya kuingia kwenye pengo kati ya electrodes chembe zilizochajiwa vibaya zinavutiwa na vikosi vya uwanja wa umeme kwa electrodes nzuri za chini. Chembe zilizochajiwa vyema zinavutiwa na electrode ya juu iliyoshtakiwa vibaya. Kasi ya ukanda wa kitanzi unaoendelea ni tofauti kutoka 4 kwa 20 m/s. The geometry of the belt cross-direction strands serves to sweep the particles of the electrodes moving them towards the proper end of the separator and back into the high shear zone between the oppositely moving sections of the belt. Kwa sababu wiani wa nambari ya chembe ni juu sana ndani ya pengo kati ya electrodes (approximately one-third the volume is occupied by particles) na mtiririko ni nguvu sana agitated, Kuna mgongano mwingi kati ya chembe na kuchaji bora hutokea kila wakati katika eneo la kujitenga. The counter-current flow induced by the oppositely moving belt sections and the continual re-charging and re-separation creates a countercurrent multistage separation within a single apparatus. This continuous charging and recharging of particles within the separator eliminate the need for any “charger” system prior to introducing material to the separator, thus removing a serious limitation on the capacity of electrostatic separation. Matokeo ya kitenganishi hiki ni mito miwili, a concentrate, and a residue, bila mpangilio Streams. Ufanisi wa kitenganishi hiki umeonyeshwa kuwa sawa na takriban hatua tatu za kujitenga kwa bure na middlings recycle.

Kielelezo 3: Electrode Gap of STET Belt Separator

The STET separator has many process variables that enable optimization of the trade-off between product purity and recovery that is inherent in any Beneficiation process. The coarse adjustment is the feed port through which the feed is introduced to the separation chamber. The port furthest from the discharge hopper of the desired product gives the best grade but at the expense of a lower recovery. A finer adjustment is the speed of the belt. The electrode gap, which is adjustable between 9 na 18 mm, and the applied voltage (±4 to ±10 kV) are also important variables. The polarity of the electrodes may be changed which aids in the separation of some materials. Pretreatment of feed material by precise control of trace moisture content (as measured by feed relative humidity) is important to achieve optimum separation results. The addition of trace amounts of charge-modifying chemical agents can also aid in optimizing the process.

Kama ilivyoelezwa hapo juu, the initial commercial application of the belt separator has been a separation of coal char from the glassy Aluminosilicate mineral from fly ash from coal-fired power plants. This technology is unique among electrostatic separators in its ability to separate fly ash, which typically has a mean particle size less than 0.02 mm. The STET separator has also been proven to effectively separate magnesite from talc, halite from kieserite and sylvite, silicates from Bart, and silicates from calcite.3 The mean particle size of all of these feed materials has been in the range of 0.02 and 0.1mm. Examples of separations for several materials are included in Jedwali 1.

Jedwali 1 – Example Separations

| Kujitenga | Kulisha | Bidhaa | Ufufuzi |

|---|---|---|---|

| Calcium Carbonate - Silicates | 9.5% Acid Insols | <1% A.I. | 89% CaCO3 |

| Ulanga - Magnesite | 58% Ulanga | 95% Ulanga | 77% Ulanga |

| 88% Ulanga | 82% Ulanga | ||

| Kierserite + KCl - NaCl | 11.5% K2O | 27.1% K2O | 90% K2O |

| 12.2% kieserite | 31.8% kieserite | 94% kieserite | |

| 64.3% NaCl | 14.3% NaCl | 92% NaCl reject | |

| Fly Ash Mineral - Carbon | 6.3% carbon | 1.8% carbon | 88% Madini |

| 11.2% carbon | 2.1% carbon | 84% Madini | |

| 19.3% carbon | 2.9% carbon | 78% Madini |

In theory, since particle charging depends upon the triboelectric effect, any two minerals that are liberated from each other (conductor- conductor or nonconductor-conductor) can be separated by this method. Other potential applications include magnesite-quartz, feldspar-quartz, mineral sands, other potash mineral separations, na

Phosphate-calcite-silica separations.

1 Bittner, J.D., Gasiorowski, S.A., Bush, T.W.,, Hrach, F.J., Separation technologies’ automated fly ash beneficiation process selected for new Korean power plant, Proceedings of 2013 World of Coal Ash conference, Aprili 22-25, 2013. 2 Bittner, J.D., Hrach, F.J., Gasiorowski, S.A., Canellopoulus, L.A., Guicherd, H. Triboelectric belt separator for Beneficiation of fine minerals, SYMPHOS 2013 – 2nd International Symposium on Innovation and Technology for the Phosphate Industry. Proceed Engineering, Vol. 83 PP 122-129, 2014. 3 Bittner, J.D., Flynn, K.P., Hrach, F.J., Expanding applications in dry Triboelectric separation of minerals, Proceedings of the XXVII International Mineral Processing Congress – IMPC 2014, Santiago, Chile, Oktoba 20 – 24, 2014.