Select Language:

ST Equipment & Technology LLC has developed a process that removes ammonia from fly ash. Et processus repetit 100% of the fly ash treated and the resulting ash meets all specifications for use in Concrete. STET remotionem processus est ammoniaci spectare possit esse discretio sola aut cumulative cum comitatu scriptor technology ipsum. The carbon separation process is not affected by the presence of ammonia on the fly ash. This modular approach offers the lowest cost solution for treating otherwise unusable fly ash…

Download PDFTechnical Angelo Center

Ammonia removere a Fly Ash

J. Bittner, S. Gasiorowski, et F. Hrach

Sin Technologies, Press 101 Hampton Avenue, Needham, Massachusetts, USA

Abstract

Quod copia musca cinis available for use in Campaniae in rebus graviter potest impacted ab effectis species aeris normas quae de utilitate res plant. In specie agitur, reductiones in NOx mandavit,, particulata, itaque3 aerosol elit beneficium emissis quibus expectata requirere institutionem imperium opinationes intellegat quae forte uti ammoniaci spectare est reagens. Vestibulum in fine secundum gradum in unum precipitators ammoniaci, collectis ex musca fraxinus ammoniaci imprimis vehementissime Ammonium sulfate salium contaminari.

ST Equipment & Technology LLC (STET) processus developed a quo etiam removentur et ammoniaci spectare est ex musca cinis. Et processus repetit 100% per musca cinis tractata atque ad usus inde cinis Si obvium habueris omnibus in rebus cubits. ST’s ammonia removal process can be used alone or in combination with the company’s carbon separation technology. The carbon separation process is not affected by the presence of ammonia on the fly ash. Haec aditus praebet modularis erit solution infima sumptus enim aliter inutile ubi musca cinis.

ST duo ammoniaci spectare est removenda est a operating locus unus in USA et Europa. Levels ammoniaci spectare est ex musca cinis negligamus intacta inter variaverit 200 et 3000 NH medicamentum3 / kg, cinis (pars in mole per decies centena, vel etiam: ppm). S. prospere in processus est gradu ius iudiciumque suum in ammonia minus quam cinis 50 NH medicamentum3 / kg, cinis. Plus 500,000 talenta musca cinis est concretum misce venundati parati auctores remotionem processus ab ipfa ST ammoniaci spectare est scriptor.

Ammonia Contaminated Fly Ash

Quod copia musca cinis available for use in Campaniae in rebus graviter potest impacted ab effectis species aeris normas quae de utilitate res plant.1 In specie agitur, reductiones in NOx mandavit, , particulata, itaque3 aerosol elit beneficium emissis quibus expectata requirere institutionem imperium opinationes intellegat quae forte uti ammoniaci spectare est reagens. Depending on the level of ammonia present in the flue gas at the electrostatic precipitators, collectis ex musca fraxinus ammoniaci imprimis vehementissime Ammonium sulfate salium contaminari 1,2. For NOx control, the flue gas ammonia level will be set by the amount of ammonia “slip‿, i.e. unreacted ammonia present after the SCR or SNCR unit. Ad redigendum aut particulata3 aerosol emissiones, Vestibulum ante precipitators ammoniaci infunditur in fine versus in deposito et cinis. Deinde considerandum est, hoc contingit quod ita sit dependens3 contentus, fugere cinis contentus sulphuris, alkalinity per musca cinis, ammonia retrahitur, et cinis de LANUGO Gas, in loading.

The use of volare fraxinus in concrete requires that the fly ash have specific physical and chemical properties3. De proprietatibus pozzolanic activated cinis qui in definito per liberam creaturam highly alkaline calce calce ex hydratationis de catervas. When fly ash contains ammonia, this ammonia is liberated as a gas by the action of the highly alkaline solution of the concrete. The alkalinity shifts the equilibrium of ammonium ion in solution to molecular ammonia according to the following equation:

NH4+(aq) + O–(aq) ↔ NH3(aq) + II2Quod

The dissolved molecular ammonia is easily released from solution as free ammonia gas.

ST Equipment & Technology LLC 101 Hampton Avenue Needham, MA 02494 Tel: 781-972-2700

Technical Angelo Center

Ammonia is a strong smelling compound that carries the connotation of barnyards, manure and urine. A strong odor of ammonia is unacceptable to the concrete producer, the contractor working with the concrete, and the ultimate concrete user.4

The finished properties of the concrete are not adversely affected when using ammonia contaminated fly ash, but the odor is unacceptable, praecipue si sit in re vel sub terra spatia inclusum.5,6,7 Fretus speciali locum, inter quas tantum recens aer circulationem, ammonia odor inventa est admittendum cum usura musca cinis quibus non est 100 ut 200 medicamentum ex NH3 / kg (pars in mole per decies centena, vel etiam: ppm). Non dico ad difficultates occurrunt, fraxinum fugere contentus sit maior ammonia 100 ppm2,8.

autem, in praeter salis ammoniaci spectare possunt in plant consequuntur potentiam ad generationem per musca cinis ammoniaci spectare est contenta 200 ut 2500 ppm, est inconveniens usum in rebus reddita musca cinis.8 ita, reducing problems per aerem qualis est moderantum caeli emissiones Vis plantis augetur solidae atque perditio penes quaestio augetur Press2 emissiones a CONSERVATORIUM augendae productio moles concretum caementa in. Salis ammoniaci spectare est ex musca cinis remotionem adhiberi potest, ut sic ad casum definitum ac prodesse non perditio penes solidum utilitatem fugiendo, simul operante,, usor, et ultimum productum species atque augendae potentiae materiae dominus sumptus demisso, declarari possunt, reducendo environment et emissiones societatis maximum productio CONSERVATORIUM gasorum a.

Quod moles salis ammoniaci spectare Ammonium sales et in musca cinis moles salis ammoniaci spectare est ad praesens in LANUGO Gas. Quia unitas est typical opinio inolevit fabarum calculus per orientem calculus bitumen cum de summo valore heating 12,000 BTU / s (6667 kcal / kg), in fine Missae rationem proxime carbo Gas 8 ut 9.5. Cum cinis de carbo contentus est, 10%, et 80% cinis cineris de volatilibus carbone recreari (20% imo cinis est), LANUGO Gas / Ratio enim circa cinis 100. Vestibulum in specie ammonia si depositae vel fine versus in cineres adsorbed, proxime futurum in loco effusorum cinerum ammonia retrahitur 50 Vestibulum in fine Missae maior ratio in, e.g. ammoniaci spectare est “praetermisissent” autem 2 Volumen ex quo accideret ppm pinum 100 emptum / kg (ppm a secum.) ammoniaci spectare est. Mensuras ostendere quod ipsa sit recta necessitudo.9 Concentratio salis ammoniaci spectare est dependens musca cinis erit variabilis inter operating unitates in loco effusorum cinerum carbo contentus in imo cinis et usque in musca cinis Ratio etiam alia arcent.

Ammonia iniectio electrostatic precipitators (Nitro) Ad meliorem efficientiam et testans pluma commentum redigendum color potest ex hoc excelsum valde campester of ammonia per musca cinis. Ad levels 2500 ppm ammoniaci spectare ad talia inventa sunt in cinere systems. Emissum res nulla SNCR operari concentratione ammoniaci 5 ut 20 ppm, cinere et contaminati in planitiem 200 ut 1000 ppm ammoniaci spectare est. Ammoniaci spectare est lapsus ad maxime disposito, ut operate sunt SCR systems fere gradus, 2 uel 5 ppm, fretus speciali institutionem.10 fere, NH ad maiorem3/NONx ratio, maiorem autem nullax quod adeptus sit facere, inde lapsus ammoniaci spectare est ad altiorem. autem, ammoniaci spectare est lapsus major 2 ppm may result in ash-ammonia contents of greater than 100 ppm, in producendo unmarketable cinis.11 Multa potentia plantis, et in Japan in Germania operating disposito signa cf. 2 ppm pusillum vidit maximum labefactum emissum volat marketability de cinere.1,5 autem, SCR est quaedam sunt per orbem terrarum disposito 5 ppm ammoniaci spectare est lapsus. Labuntur altis gradibus operatio est maxime his partibus maior euentum 100 ppm salis ammoniaci spectare est in musca cinis.

Ammoniaci spectare est moderantum low campester est lapsus et reduces obturator et corrosio sunt decurrent atque armorum depositione propter sulfates Ammonium.1,10 Vitantes debita linamentis opus preheater caeli super hoc et expectantur esse magis est unitas operators sulphuris, ubi ardenti excelsis, US carbones incensi. ita, administratione eu ipsum tempus esse salis ammoniaci spectare est lapsus ad circumscribendam unitas magis quam petens ad planum ammoniaci spectare est ex musca cinis. effectus est

ST Equipment & Technology LLC 101 Hampton Avenue Needham, MA 02494 Tel: 781-972-2700

Technical Angelo Center

significans non potest esse quaestio, quae ad usus develops at some utilitatem locis cinere, fretus consilio et ex propria operatio egreditur de potestate systems.

De Processu STET

STET processus developed a quo etiam removentur et ammoniaci spectare est ex musca cinis.12 Et processus repetit 100% per musca cinis tractata atque ad usus inde cinis Si obvium habueris omnibus in rebus cubits. STET remotionem processus est ammoniaci spectare possit esse discretio sola aut cumulative cum comitatu scriptor technology ipsum. Quod ipsum processum expiationis non est affectus coram salis ammoniaci. Haec aditus praebet modularis erit solution infima sumptus enim aliter inutile ubi musca cinis.

Ammoniaci spectare est ad removendum est a Gas musca cinis, STET fundamental processus in eodem utetur quo eget reactionem ad quod ammoniaci spectare est ad casum definitum ac release. Liberation = salis ammoniaci spectare est ex musca cinis postulat ut ion Ammonium

–ammoniaci spectare est in aequilibrio, translata sit hypothetica salis ammoniaci spectare est per gratiam coram alcali. Non postulo additional insitam ferociam et cinere fugere alkalinity alcali. Pro cinere, minus alkaline, alcali serviet omne. Vilissimum est fons alcali cinis; (CAO). Ammonium sal salis ammoniaci spectare est tantumque liberat reactionem in calce valde favebat eget aequilibrium. In eget reactionem occurs cursim olim composita dissolvi.

Et reactionem altiore potest quam generativus:

(NH4)2QUOD4(s) + CAO(s) → 2NH3(g) + caso4(s) + II2Quod(g)

autem, vapor est impetus, fieri non potest solidorum esse reactionem satis humilis ac in Gas vel solidum tempus. Ammonium sulfate maxime solutum in aqua dissociat ammonium ions et iones sulfate.

(NH4)2QUOD4(aq) → 2NH4+(aq) + QUOD42-(aq)

Maxime calcis aqua instabilis aspirante, motum vulgo multum favere exothermic “macerata ascietur”, Calcium hydroxide hydrated calce, vel producendo.

CAOs +II2O → ca.(O)2(s)

Calx aqua solutum est parcus hydratisatus, Calcium hydroxide producendo ions.

quod(O)2(s) ↔ quod2+(aq) + 2 O–(aq)

Calcium sulfate, parce et solutum;, iones per fiunt available ut calcium et sicut fax inflammata hydrated calce, praecipitatio consumpti sunt principaliter calcium sulfate.

quod2+(aq) + QUOD42-(aq) → CaSO4(s)

denique, an equilibrium exists between ammonium ions and ammonia dissolved in water.

NH4+(aq) + O–(aq) ↔ NH3(aq) + II2Quod

ST Equipment & Technology LLC 101 Hampton Avenue Needham, MA 02494 Tel: 781-972-2700

Technical Angelo Center

The degree to which ammonium ions are converted to molecular ammonia is dependent on the pH of the aqueous system, higher pH’s favoring the formation of molecular ammonia. This equilibrium is well known.13

A key feature of the STET process is the use of a minimum quantity of water (1 ut 4%, typically 2%) and minimal quantities of alkali (< 2%). Large amounts of water are detrimental to the process, slowing the rate of ammonia release. The pH of the resulting ash / lime / water mixture should be greater than pH 10.0. Very small quantities of alkali are added to assure this pH, depending on the natural pH of the ash. Typically, minor quam 1% quod(O)2 is required, even with fly ash with naturally acidic pH. Calcium based alkalis are used which result in minimal alteration of the fly ash chemistry. The process is performed at ambient temperature.

Cum siccatio productum sumptus ad sumptus es: et alcali operating expensis major et major components sunt sizing ad ferventem similam et siccatio apparatu capitis sumptus est, diligenter mensuræ in usus tenui pro certis cinis est ut res oeconomica ad optimize processus.

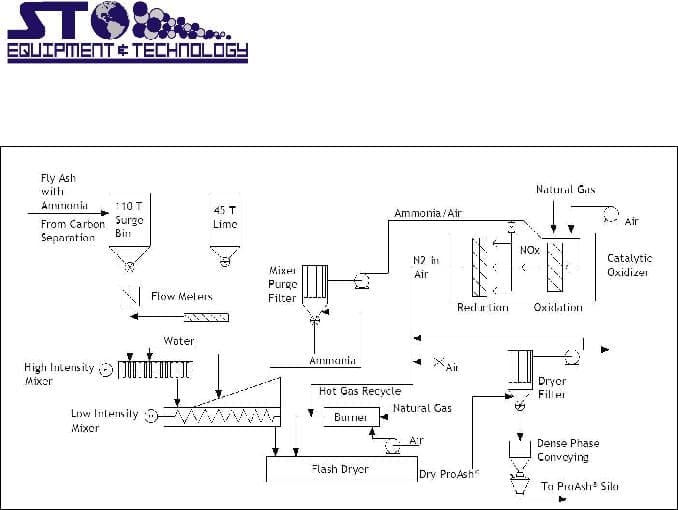

Processus in tabula pro fluxus STET continua operatio processus in in fi is presented 1. cinis, continentur in aqua conspiciuntur metered alcali in turpis. Admixtio aquae addita idemque dispersionem certificare alcali volatilis, magno intensionem turpis usus est:. Commorationis tempus turpis genus nimis, secundum ordinem unius. Totam evolutionis tempore gigni necesse ammoniaci statim dimisit autem 3 ut 4 Vestibulum lacus massa ut ex minutis molem de stercore Vestibulum ut lacus massa molem fraxinus.

Et dico bonum obtinere factam ab excessu magnitudine ammonia fraxinus, enim humilis intensionem fabrica talis ut turpis pug molendini adhibetur sicut secundarium. Quia nimis humidum contentus fraxinus, commotis per illum fluit a materia sicca pulverem turpis. Vestibulum ammoniaci et collecta sunt REDIVIVUS generans vel maximum Mixers celeritate conversa fiue unitas in duobus NITROGENIUM- Calcium gradu unitatis.

ST Equipment & Technology LLC 101 Hampton Avenue Needham, MA 02494 Tel: 781-972-2700

Technical Angelo Center

Figura 1: Ammonia STET remotionem processus fluere Diagram

Et exaruit deammoniated cinis est quam usquam in sicciora mico per materiam in aqua ad detrahere. Ex minima aquae addita, motus in aquis absumpti institutionis calcium sulfate hydratisatus solutum et in cinerem sulfate, aquam miscendam in humili gradu intensionis et iacturam, parum aquae siccius debet removeri. Hæc autem navitas demanda siccitates scaena, Regium,. Ultima temperaturis circa cinis 150quodF are adequate to produce a completely free-flowing, productum per musca cinis sub ASTM bene C continet in humorem 618 specificationem 3 apud. %.3

The first full-scale application of STET’s ammonia removal process began operating in 2003 at ST’s ash processing facility at the Jacksonville Electric Authority St. Johns River Power Park in Jacksonville, Florida. This commercial scale operation handles up to 40 tons per hour of contaminated ash, ammoniaci spectare est reducere contentus minus quam 30 ppm. Ammonia levels in the incoming fly ash varies from ~200 to 900 ppm. The process is very robust, resulting in 90+% ammonia removal under all trial settings, producing ash well below our target of maximum 50 ppm ammoniaci spectare est. Final moisture contents are <0.3%. Representative results are listed in Table 2. Plus 250,000 tons of ammonia-contaminated ash has been successfully processed at the Jacksonville facility.

ST Equipment & Technology LLC 101 Hampton Avenue Needham, MA 02494 Tel: 781-972-2700

Technical Angelo Center

Mensa 2: Ammoniaci spectare est typical commercial scale ratio results

|

Rate feed, |

Coepi Ammonia, |

Ammonia finalem, |

Aqua rate, |

rate aqua, |

|

tons / hr |

ppm |

ppm |

% de feed |

% de feed |

|

21 |

910 |

25 |

1.35 |

1.9 |

|

25 |

190 |

9 |

0.88 |

2.6 |

|

40 |

350 |

12 |

0.70 |

2.05 |

|

18 |

242 |

20 |

0.82 |

1.52 |

Big Subjicite cinis fugere a Statio Tampa, Florida quod contaminatum est ammoniaci spectare est ex infusione salis ammoniaci spectare est in potentia plant Esp systems to control sic beneficium emissis3 aerosol generatae iuxta imperium ratio NOx cf.. In alia potentia plantis, et inquinatus admixtus ammoniaci spectare est ex occurs SNCR NOx imperium et usum salis ammoniaci spectare est ad augendae particula collectio in ESP systems. In Big Subjicite, ammoniaci spectare est musca cinis levels si unitas lineamentum ammoniaci spectare est ex infusione range 750 ut 3360 ppm ammoniaci spectare est. Consequenter, per musca cinis vertuntur in animo esse tractata per productionem ammonia remotionem processus Sancti.

Magnus consilio installed Flecte remotionem processus STET ammoniaci (Figura 2) Secundum installation est plenus scale et includit multas depuratem. Material tractantem apparatu ut liceat melius est altior operatio ad rates. In siccitate ratio prior est downsized de consilio et de calidi vapores includit redivivus ad redigendum in altiore requisita de industria ratio. Denique, the ammonia released in the process is fed to a two-stage catalytic unit where the collected ammonia gas is converted into nitrogen. Calor generatur per liberorum capitum, hoc reactionem est ad supplementum industria postulant ipsa remittit ratio mico musca cinis. The use of the two-stage catalytic system results in minimal NOx emissions. Et processus repetit 100% per musca cinis tractata atque ad usus inde cinis Si obvium habueris omnibus in rebus cubits.

Hic non tractamus operatio scale usque ad commercial 52 tons per hour of contaminated ash, ammoniaci spectare est reducere contentus minus quam 75 mg / kg. The process is very robust, resulting in 97+% ammoniaci spectare remotionem, producing ash well below our target of maximum 100 mg / kg ammoniaci spectare est. Final moisture contents are <0.5%.

STET ammoniaci spectare est ad remotionem processus in processus operatio ad RWE Npower Aberthaw statione cinis facilities quia in the UK 2008. Aberthaw adiungit ammoniaci spectare est ad meliorem efficientiam cum Nitro collectio ammoniaci spectare est typical levels in loco effusorum cinerum 200 ppm et processus est disposito 500 ppm maximam.

ST Equipment & Technology LLC 101 Hampton Avenue Needham, MA 02494 Tel: 781-972-2700

Technical Angelo Center

Figura 2: Ammoniaci spectare est ad removenda Big Station NY, Tampa Florida

De piscium Product

Occurrit tellus eget fraxinum fugere ammoniaci humilitatem omnibus requisitis corporis C ASTM 618 et vexillum inde in cineres abit non sunt idem re proprietatibus subiecta ammoniaci spectare est ad remotionem processus. Mensa amet comparat rerum proprietates cum cinere e generans herbam loco effusorum cinerum reducendae content ammoniaci 250 emptum / k, ut 20 emptum / kg per processus continui Sancti. Calcium oxide rhoncus contentus nota servata est inde cinis 1.4 ut 12%. In addition ad Dei 1% quod(O)2 (0.75% in Cao) will result in Chymiam non minor mutationes in cinere, versus latiora variabilitate indi- viduum;.

Concretum probatio faciebat super his qui deammoniated cinis est optimum ostendit quod materia pozzolanic. Compressive viribus progressionem usura is cinis est ut bonum vel melius ab hoc fonte unammoniated cinis. Diu terminus concretus quoque possessiones habere optimum, inter melius resistendum corrosione, resistentia sulfate, chloride permeability, et fallere visco DECREMENTUM.

ST Equipment & Technology LLC 101 Hampton Avenue Needham, MA 02494 Tel: 781-972-2700

Technical Angelo Center

mensa mea: Fugere physica et chemica proprietates piscium.

|

|

C ASTM 618 specif icationem |

plant # 1 Properties cinis, typical |

plant # 1 Post remotionem cinis Ammonia |

|

|

Pennisetum purpureum |

|

|

|

|

|

siliconisque dioxide |

– |

55 – 61 % |

59.8 % |

|

|

Aluminium Oxide |

– |

15 – 25 % |

23.8 % |

|

|

ferrum cadmiae |

– |

5 – 10.9% |

7.35 |

|

|

summa (SiO2 + al2Quod3 + Fe2Quod3) |

70.0 mihi. |

78 – 91 % |

90.9 % |

|

|

Trioxide sulphuris |

5.0 max |

0.13 – 1.4% |

0.87% |

|

|

Calcium oxide |

– |

1.4 – 12 % |

1.79 % |

|

|

Humorem content |

3.0 max. |

0.0 – 0.3 % |

0.21% |

|

|

Damnum de Ignition |

6.0 max. |

0.7 – 2.6 % |

0.91% |

|

|

sodium cadmiae |

– |

0.1 – 0.7 |

0.14% |

|

|

kalium cadmiae |

– |

0.5 – 2.2% |

0.56% |

|

|

available alcalia (in2Quod) |

1.5 % max |

0.5 – 0.8% |

0.51% |

|

|

Corporalis test Results |

|

|

|

|

|

PULCHRITUDO, in retinuit #325 nihilum |

34% max. |

8 – 16% |

14% |

|

|

Actio viribus Index |

|

|

|

|

|

Ratio continere @ 7 diebus |

– |

81 – 95 % |

94.8% |

|

|

Ratio continere @ 28 diebus |

75% mihi. |

94 – 102% |

99.5% |

|

|

opus est aqua, % Imperii |

105% max. |

93 – 97% |

94.2% |

|

|

repraesentas incolumes:, autoclave Expansion |

0.8% max. |

-0.035 – 0.010 |

-0.033 |

|

|

DECREMENTUM aridam, Augere @ 28 Dies |

0.03% max. |

-0.01 – 0.010 |

-0.009 |

|

|

CRASSITUDO |

– |

2.35 – 2.45 |

2.36 |

|

summary

Quae decipi non quantum boni ex musca NOx vel particulatum cinerem resolvitur per rationes utilitas futura pendent arbitrio reducere velit NOx, emissiones et opacitatem testans pluma commentum materia particulata. autem, STET ammoniaci spectare est ad remotionem processus fieri nee expediri potest removere e ammonia contaminari cinis, quia materia productio valorem usus in singulis producendo magno. Eruit ergo ammoniaci spectare potest REDIVIVUS generating ut unitas ad Reutilization. This ammonia removal process can be installed as a stand-alone system or can be used in conjunction with STET’s successful fly ash carbon removal system.

1Stewart, B.R., Praeter intentionem effectus EPA scriptor recentes onerariam dominare Pinus halepensis, C., 1999 Conference on Selective Catalytic and Non-Catalytic Reduction for NOx control, May 1999, pp.9-10.

2Sloss, L. L., Hjalmarsson, A K,, atrium, H.N., Cicero, L.M., Lapis, D.K., Shareef, G.S., Emmel, C., Naebodi, M., Livengood, C.D., Markussen, J. Imperium Fact Book nitrogen oxides Technology, Data Vulgate Corporation, p. 94-95, 1992

3“Specification for Latin Coal Fly Ash et Rudis enim Campaniae aut calcinatum Naturalis usus in certam ac definitam formam lapidis permixtae corruptaeque”, C ASTM 618, Et Temptatione et American Societas Materials, Philadelphiae,, PA.

4majors, R.K., Hill, R., McMurry, R., Thoma, S., A Study of the Impact of Ammonia Injection on Marketable Fly Ash including Quality Control Procedures, C., 1999 Et electionem selectivam, in colloquium Catalytic Non Catalytic De reductione for nox imperium, May 1999, pp.11-13.

5Van der Brugghen, F.W., Gast, C.H., Van den Berg, J.W., Kuiper, W.H., Visser, R., Problemata occurrunt Per Ammonium Usus Fraxinum Vola contaminatum. C.: EPRI / EPA 1995 Communem Symposium in Statio Combustion NOx Control, May 16-19, 1995. Liber 4, Sessio 8A, p. 1-16.

6Van den Berg, J.W., Cornelissen, H.A.W. ,Effectus humilis NOx Technologies in Fuge Cinerum Quality, C.: 13th International Symposium de Usu et Procuratio Coal Combustionis Products, 1999, p. 29-1 – 29-11.

7Koch, H-J., Prenzel, H., Probat in Progressionibus Odoris in jactu Screedi Concreti – Usus NH *3-Fugite cinerem contaminatum, Concretum Precasting Planta et Technology, Volume 11, 1989 p. 72-75.

8Fisher, B.C., Blackstock, T. Cinere volantes Beneficiis processus utens in Ammonia expoliantes, 12th International Symposium de Coal Combustion By-Products Management and Use, 1997 p. 65-1 – 65-8.

ST Equipment & Technology LLC 101 Hampton Avenue Needham, MA 02494 Tel: 781-972-2700

Technical Angelo Center

9Larrimore, L., Dodgen, D., Monroe, L., Lactobacillus effectus salis ammoniaci spectare volutpat a feria IV Cinerum et remotionem methodis, C.: 13th International Symposium de Usu et Procuratio Coal Combustionis Products, 1999, p. 16-1 – 16-15.

10Imperium nitrogen cadmiae Emissions: De reductione Catalytic electionem selectivam, (cf.), Technology clean Coal, General Number Report 9. U.S. Energy Services Department of Company et Southern, Inc. July, 1997.

11O Connor, D., Larrimore, I., Dodgen, D., Monroe, L., Effectus Ammoniae-Substructio NOx reductio in Fly Cinerum: Triticum aestivum ammoniaci spectare est feria IV Cinerum, C., EPRI EPA-DOE, Utilitas `Combinatae quaevis Air pollutio Symposio Imperium: Et Symposii Mega, August, 1999, chartam # 16.

12Gasiorowski, S.A., et Hrach, F.J., Ammonia ad modum removere a Ammonia Contaminated Fly Ash, United States Patent 6,077,494, June 20, 2000.

13Thy, R.V., Russo, R.C., Cicero, C., Ammonia aquae Equilibrium – Tabulae Sentio Ammoniae Un-ionized, Iunctus Civitas Aliquam Donec, EPA-DC / 3-79-091, August, 1979.

ST Equipment & Technology LLC 101 Hampton Avenue Needham, MA 02494 Tel: 781-972-2700