Mining New Value From Your Minerals

Add revenue streams with our water free particle separation technology

Your mineral ores contain potentially high-value products. We can help you unlock them efficiently and sustainably.

STET’s dry electrostatic separators are ideal for mineral separation—also called ore dressing, beneficiation, or mineral engineering.

You can be assured of the highest quality selective separation with our conductivity-based sorting. We can precisely separate different mineral types to achieve final products with superior purity and improved quality.

Extend the life of your mine or other mineral assets using our sustainable, water-free, and chemical-free process.

Calcium Carbonate

Limestone

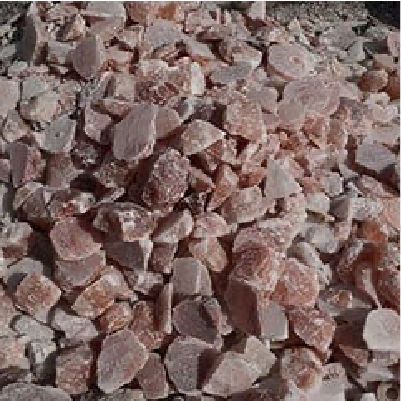

Barite

Talc

Magnesium Carbonate

Feldspar

Iron Ore

Bauxite

Potash

Phosphate Rock

Unlock Mineral Ore Potential with STET

The benefits of using STET dry electrostatic separators for minerals include:

- No water. No chemicals. You eliminate water usage, wastewater generation, and contamination of harmful chemicals.

- Wide range of particle sizes. Our dry electrostatic separators beneficiate minerals and metals from relatively coarse, at 600 microns, to very fine, at 1 to 2 micros.

- Continuous, high-rate, single-step process. With processing capacities of up to 40 tons per hour, the STET separator integrates seamlessly into existing workflows, providing adjustable control over product quality with user-friendly automation options.

- Reduced costs. Our completely dry electrostatic separation translates into lower operational costs, less energy consumption, minimal maintenance requirements, and reduced environmental remediation costs. And converting ores into concentrates increases the value of mined materials, making operations more economically sustainable.

- Easy to implement. Our compact equipment fits easily within your process layouts, and we make the permitting process simple.

- Durable and long-lasting. STET electrostatic separators have a long operational life, especially when compared to other types of mineral separation equipment.

The STET™ End-to-End Service Model

Putting our know-how to work for you

Evaluate

- Assess customer needs

- Sample testing

- Bench-scale testing

Trial

- Pilot plant trials (in-house at STET)

- Full-service lab testing

- Pilot plant of large sample

- Optimization of prep steps (milling, drying, deglomeration)

Design

- Confirm plant design through pilot plant trials

- Control system design

- Finalize plant design

- Estimate construction, production, and manufacturing costs

Build/Install

- Develop detailed engineering (typically done by a third-party specialist)

- Manufacturing of proprietary parts

- Construction of the plant

Optimize

- Deploy AI-driven Design of Experiment (DOE) techniques to fine-tune the system for maximum results

Ongoing Support

-

Maintenance program

-

Technical support

-

Scale-up as needed

-

Warehousing & inventory