Teua lugha:

Muhtasari

SVifaa vya T & Teknolojia, LLC (STET) imeanzisha kujitenga na ukanda tribo electrostatic usindikaji mfumo ambayo hutoa sekta ya usindikaji madini njia beneficiate faini vifaa na teknolojia ya kavu kabisa. Tofauti na michakato mengine utengano electrostatic ambayo ni kawaida mdogo kwa chembe kubwa kuliko 75µm kwa ukubwa, Kitenganishi cha ukanda triboelectric ni walau inafaa kwa ajili ya mgawanyo wa nzuri sana (<1µm) kwa coarse kiasi (300µm) chembe na kote juu sana. Ukanda triboelectric kitenganishi teknolojia imekuwa kutumika kwa tofauti mbalimbali wa vifaa ikiwa ni pamoja na makaa ya mawe mwako kuruka majivu, calcite/quartz, Ulanga/magnesite, barite/quartz, na feldspar/quartz. Matokeo ya utengano ni iliyotolewa kuelezea tabia tribo ya kuchaji kwa madini Boksiti.

Utangulizi

Ukosefu wa upatikanaji wa maji safi ni kuwa sababu kuu kuathiri uwezekano wa miradi ya madini duniani kote. Kwa mujibu wa Hubert Fleming, Mkurugenzi wa zamani wa kimataifa wa maji ya Hatch, "Kati ya miradi yote ya madini duniani ambayo imesimamishwa au kupungua katika kipindi cha mwaka mmoja uliopita, imekuwa, katika karibu 100% ya kesi, Matokeo ya maji, either directly or indirectly”.1 Dry mineral processing methods offer a solution to this looming problem.

Njia kavu kama vile kujitenga kwa electrostatic zitaondoa haja ya maji safi, na kutoa uwezo wa kupunguza gharama. Electric separation methods that utilize contact, or tribo-electric, charging are particularity interesting because of their potential to separate a wide variety of mixtures containing conductive, insulating, and semi-conductive particles.

Tribo-electric charging occurs when discrete, dissimilar particles collide with one another, or with a third surface, resulting in a surface charge difference between the two particle types. The sign and magnitude of the charge difference depends partly on the difference in electron affinity (or work function) between the particle types. Utengano unaweza kisha kupatikana kutumia kutumika nje umeme shamba.

Mbinu ina itatumika viwandani katika free-fall wima aina vitenganishi. Katika free-fall vitenganishi, chembe kwanza kupata malipo, Kisha kuanguka na mvuto kupitia kifaa na kupinga electrodes ambazo zinatumika nguvu umeme shamba kupotosha kimelea chembe kulingana na ishara na ukubwa wa vitenganishi yao ya Free-fall charge.2 uso inaweza kuwa na ufanisi kwa ajili ya chembe coarse, lakini si ufanisi katika utunzaji chembe finer kuliko kuhusu 0.075 kwa 0.1 mm.3,4 mmoja wa maendeleo ya mpya wa anayechipuka utenganisho wa madini kavu ni kitenganishi ukanda tribo electrostatic. Teknolojia hii ameleta chembe ukubwa mbalimbali kwa chembe mazuri kuliko teknolojia ya utengano ya kawaida ya electrostatic, katika masafa ambapo tu ujenge imekuwa mafanikio katika siku za nyuma.

Utengano wa ukanda wa Tribo Electrostatic

Katika kitenganishi ukanda tribo electrostatic (Kielelezo 1 na Kielelezo 2), nyenzo ni kulishwa katika Mwanya mwembamba 0.9 – 1.5 cm kati ya mbili sambamba ndizi na electrodes. Chembe ni za kiumeme zinazoshtakiwa na mawasiliano ya mchanganyiko. Kwa mfano, katika kesi ya makaa ya mawe kuruka majivu, mchanganyiko wa chembe za kaboni na chembe za madini, kaboni inayotozwa vyema na madini yaliyoshtakiwa vibaya yanavutiwa na elektroni tofauti. Chembe ni kisha kufagiliwa na kuendelea kusonga wazi-matundu ukanda na kuwasilishwa katika maelekezo kinyume. Ukanda husonga chembe karibu na kila uchaguzi wakipanda kuelekea mwisho wa mgawanyiko. Shamba la umeme linahitaji tu kusonga chembe sehemu ndogo ya sentimita ili kuhamisha chembe kutoka kushoto-kusonga kwenye mkondo wa kulia. The counter current flow of the separating particles and continual triboelectric charging by carbon-mineral collisions provides for a multi-stage separation and results in excellent purity and recovery in a single-pass unit. Kasi ya ukanda wa juu pia inawezesha njia za juu sana, hadi 40 tani kwa saa kwenye kitenganishi kimoja. Kwa kudhibiti vigezo mbalimbali vya mchakato, kama vile kasi ya ukanda, kulisha pointi, pengo Electrode na kiwango cha kilishi, kifaa inazalisha kaboni chini kuruka majivu katika maudhui ya dioksidi ya 2 % ± 0.5% kutoka mlisho kuruka majivu kuanzia katika kaboni kutoka 4% zaidi kwa 30%.

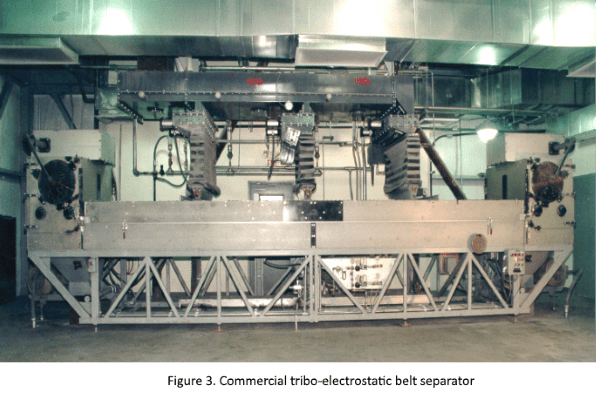

Sanifu kitenganishi ni rahisi. Ukanda na rollers kuhusishwa ni sehemu tu ya kusonga. Ya electrodes ni stationary na linajumuisha ya vifaa na muda mrefu ipasavyo. Ukanda wa ni alifanya ya plastiki vifaa vya. Kitenganishi electrode urefu ni takriban 6 mita za (20 futi.) na upana 1.25 mita za (4 futi.) kwa vitengo vya kibiashara Kilingo kamili. Matumizi ya nguvu ni chini ya 2 kilowati kwa tani moja ya vifaa vya kusindika na wengi wa nguvu zinazotumiwa na motors mbili kuendesha ukanda wa.

Mchakato ni kavu kabisa, inahitaji Hakuna vifaa vya ziada na inazalisha uzalishaji hakuna taka maji au hewa. Katika kesi ya kaboni kutoka utenganisho wa kuruka majivu, vifaa zinalipwa wajumbe wa kuruka majivu kupunguzwa katika maudhui ya kaboni kwa viwango vya kufaa kwa ajili ya matumizi kama admixture pozzolanic katika halisi, na sehemu ya kaboni ambayo inaweza kuchomwa katika mtambo wa uzalishaji umeme. Matumizi ya mito yote miwili ya bidhaa hutoa 100% ufumbuzi wa matatizo ya utupaji wa majivu. For mineral separations, processing bauxite for example, the separator provides a technology to reduce water usage, kupanua Hifadhi ya maisha na/au kupona na reprocess tailings.

The tribo-electrostatic belt separator is relatively compact. Mashine iliyoundwa kwa mchakato 40 tani kwa saa ni takriban 9.1 mita za (30 futi.) muda mrefu, 1.7 mita za (5.5 futi.) pana na 3.2 mita za (10.5 futi.) juu. Usawa unaohitajika wa mmea una mifumo ya kufikisha nyenzo kavu kwenda na kutoka kwa mtenganishi. Mkusanyiko wa mfumo inaruhusu kubadilika katika miundo ya ufungaji.

The tribo-electrostatic belt separation technology is robust and industrially proven, and was first applied industrially to the processing of coal combustion fly ash in 1995. Teknolojia ni bora katika kutenganisha chembe Carbon kutoka mwako kamili ya makaa ya mawe, kutoka Glassy aluminosilicate madini chembe katika Ash kuruka. Teknolojia imekuwa muhimu katika kuwezesha utoaji wa madini-tajiri kuruka Ash kama mbadala ya saruji katika uzalishaji halisi. Tangu 1995, juu ya 20,000,000 tonnes of fly ash has been processed by the 19 tribo-electrostatic belt separators installed in the USA, Kanada, UINGEREZA, Polandi, and South Korea. The industrial history of fly ash separation is listed in Jedwali 1.

Jedwali 1. Viwanda maombi ya ya makundi ya

| Matumizi / Kituo cha nishati | Mahali | Start of commercial operations | Facility details |

|---|---|---|---|

| Duke nishati – Roxboro Station | Kaskazini mwa Carolina | 1997 | 2 Vitenganishi |

| Nishati ya talen- Brandon fukwe | Maryland USA | 1999 | 2 Vitenganishi |

| Scotland nguvu- Longannet Station | Scotland | 2002 | 1 Kitenganishi |

| Ni. Johns mto Power Park | Florida | 2003 | 2 Vitenganishi |

| Kusini Mississippi Electric Power-R. D. Kesho | Mississippi USA | 2005 | 1 Kitenganishi |

| Mpya Brunswick nguvu-Belledune | Mpya Brunswick Canada | 2005 | 1 Kitenganishi |

| RSISI npower-Didcot stesheni | Uingereza | 2005 | 1 Kitenganishi |

| Talen nishati-Brunner kisiwa Station | Pennsylvania Marekani | 2006 | 2 Vitenganishi |

| Tampa Electric-Big bend stesheni | Florida | 2008 | 3 Vitenganishi two-pass scavenging |

| RSISI npower-Aberthaw stesheni | Wales Uingereza | 2008 | 1 Kitenganishi |

| EDF nishati-Magharibi Burton stesheni | Uingereza | 2008 | 1 Kitenganishi |

| ZGP (Lafarge saruji/Ciech Janikosoda JV) | Polandi | 2010 | 1 Kitenganishi |

| Korea Kusini- Yeongheung | Korea Kusini | 2014 | 1 Kitenganishi |

| PGNiG Termika-Sierkirki | Polandi | 2018 | 1 Kitenganishi |

| Taiheiyo saruji kampuni-Chichibu | Japani | 2018 | 1 Kitenganishi |

| Armstrong kuruka Ash- Saruji ya tai | Philippines | Ratibiwa 2019 | 1 Kitenganishi |

| Korea Kusini- Samcheonpo | Korea Kusini | Ratibiwa 2019 | 1 Kitenganishi |

Tribo-Electrostatic Separation of Bauxite Minerals

Vifaa vya ST & Teknolojia (STET) walifanya benchi Rekebisha kavu tribo electrostatic kujitenga kwa sampuli mbalimbali za madini Boksiti. Sampuli zimeorodheshwa chini katika Jedwali 2.

Jedwali 2. Sifa za sampuli wa Boksiti kupimwa kwa STET

| Description | Desired Product & Goals | |

|---|---|---|

| Sample 1 | ROM Bauxite | Al2O3 recovery Reduce SiO2, Fe2O3, TiO2 |

| Sample 2 | PLK (Partially Lateritized Khondalite) | Al2O3 recovery Reduce SiO2, Fe2O3, TiO2 |

| Sample 3 | Red Mud | Fe2O3 recovery Reduce SiO2, Al2O3, TiO2 |

| Sample 4 | ROM Bauxite Slimes | Al2O3 recovery Reduce SiO2, Fe2O3, TiO2 |

Muundo wa kemikali kwa ajili ya wote kilishi na kutengwa bidhaa sampuli kipimo na Fluorescence x-ray (XRF) kutumia mfumo wa WD-XRF. Matokeo ya uchambuzi wa kemikali kwa ajili ya sampuli kilishi zimeonyeshwa hapa chini katika Jedwali 3.

Jedwali 3. Sifa za kemikali za sampuli wa Boksiti kupimwa kwa STET

| Al2O3 wt.% | Fe2O3 wt.% | SiO2 wt.% | SiO2 wt.% | LOI wt.% | |

|---|---|---|---|---|---|

| Sample 1 | 43.7 | 25.9 | 3.9 | 2.3 | 23.6 |

| Sample 2 | 34.9 | 19.4 | 28.5 | 2.1 | 14.7 |

| Sample 3 | 19.0 | 52.1 | 6.7 | 4.9 | 11.1 |

| Sample 4 | 34.6 | 23.2 | 18.0 | 4.4 | 18.8 |

Ukubwa wa chembe kipimo na Leza chembe ukubwa upimaji kutumia usambazaji wa msimu wa kiangazi. Matokeo ya sampuli kilishi zimeonyeshwa hapa chini katika Jedwali 4.

Jedwali 4. Ukubwa wa chembe wa Boksiti sampuli kupimwa kwa STET

| D10 Micron | D50 Micron | D90 Micron | D90 Micron |

|

|---|---|---|---|---|

| Sample 1 | 2 | 19 | 73 | 118 |

| Sample 2 | 2 | 45 | 575 | 898 |

| Sample 3 | 1 | 27 | 212 | 325 |

| Sample 4 | 1 | 7 | 59 | 93 |

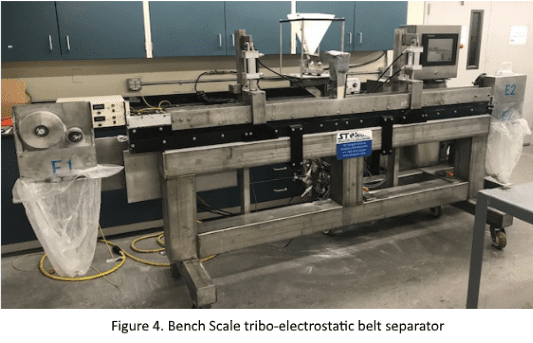

Sampuli walitenganishwa kutumia STET benchtop kitenganishi. Kitenganishi cha benchtop ni kutumika kwa ajili ya uchunguzi kwa ajili ya ushahidi ya kumshutumu tribo electrostatic na kuamua kama nyenzo ni mgombea mzuri kwa ajili ya electrostatic beneficiation. The primary difference between the benchtop separator and pilot-scale and commercial-scale separators is that the length of the benchtop separator is approximately 0.4 mara urefu wa vipimo vya majaribio na kiwango cha kibiashara. Kama ufanisi wa mgawanyiko ni kazi ya urefu wa uchaguzi wa wakipanda, uchunguzi wa kiwango cha benchi hauwezi kutumika kama mbadala kwa ajili ya kupima majaribio ya mtihani. Pilot-scale testing is necessary to determine the extent of the separation that the STET process can achieve, na kuamua kama STET mchakato unaweza kukutana bidhaa malengo chini kutokana na viwango vya kilishi. Badala yake, Kitenganishi benchtop hutumiwa na utawala wa nje vifaa vya mgombea ni uwezekano wa kuonyesha kujitenga yoyote muhimu katika kiwango cha kipimo cha majaribio. Matokeo kupatikana kwenye benchi wadogo itakuwa yasiyo na optimized, na utengano aliona ni chini ya ambayo ingekuwa aliona kwenye kitenganishi kibiashara na ukubwa wa STET.

Testing with the STET benchtop separator demonstrated significant movement of Al2O3 with the majority of the samples tested. In three of the four samples tested by STET, substantial movement of Al2O3 was observed. Zaidi ya hayo, the other major elements of Fe2O3, SiO2 and TiO2 demonstrated significant movement in most cases. In Sample 1, Sample 3 and Sample 4, the movement of loss on ignition (WA) followed movement of Al2O3. The movement of the major elements is shown below in Kielelezo 5.

Kitenganishi STET ni utaratibu kujitenga kimwili na selectively hutenganisha awamu ya madini kulingana na tribocharging, jambo uso. Shahada ambayo madini ni wanahusika na tribocharging ni katika baadhi ya kesi uwezo wa kuwa alitabiri kupitia mashauriano ya mfuatano triboelectric, lakini katika kesi ya ores ngumu ya madini, mara nyingi katika mazoezi lazima kubainishwa vitukio. Muhtasari wa sifa za tribocharging kwa ajili ya sampuli kupimwa huonyeshwa chini katika Jedwali 5.

Jedwali 5. Muhtasari wa tabia tribocharging kwa ajili ya mambo makubwa. POS = charged positive, NEG = charged negative.

| Al2O3 | Fe2O3 | SiO2 | TiO2 | WA | |

|---|---|---|---|---|---|

| Sample 1 | POS | NEG | NEG | NEG | POS |

| Sample 2 | NEG | POS | NEG | N/A | N/A |

| Sample 3 | POS | NEG | N/A | NEG | POS |

| Sample 4 | POS | N/A | NEG | NEG | POS |

Dry processing with the STET separator offers opportunities to generate value for bauxite and aluminium producers. The utilization of lower grade bauxite deposits may allow for lower mining costs by reducing stripping ratios and by reduced generation of tailings. Zaidi ya hayo, the pre-processing of bauxite ores by dry triboelectrostatic separation may result in improved economics of aluminium refining by supplying higher grades of bauxite to the refining process, or by reducing volumes of red mud generated. Zaidi ya hayo, higher aluminium content in red mud may allow for reprocessing. A summary of ideal characteristics for metallurgical grade bauxite is presented, as well as a summary of the benefit of the STET separator, below in Jedwali 6.

Jedwali 6. Summary of ideal characteristics for metallurgical grade bauxite.5

| Ideal Grade Characteristic | Impact if Inadequate | Observed with STET Separation |

|---|---|---|

| Low “reactive silica” (>1.5% - <3.0%) (kaolinite) | Increases caustic usage, a critical operating cost factor. | Reduction in total silica |

| High extractable alumina | Increases capital and operating costs for mining, processing and mud disposal. | Increase in alumina |

| Low organic carbon | Increases operating costs by reducing plant efficiency. | |

| Low boehmite (<3%) | Precludes low-temperature processing that can increase capital and operating costs. | |

| Low goethite (tolerable in a high-temperature plant or with high hematite) | Slows clarification, lowers product quality and increases alumina loss via mud circuit. | Reduction in total iron |

| Low moisture (can create nuisance dust if too low) | Increases capital costs (larger evaporation facility), fuel consumption, shipping costs. | |

| Iron content (ideally >5%-<15%) | Low iron can lower product quality. High iron dilutes alumina content of bauxite. | Reduction in total iron |

| Low quartz | Increases maintenance costs (pipe wear). Increases caustic usage in high-temperature plants. | Reduction in total silica |

| Low impurities and trace elements | Can lower process efficiency (sulfur, chlorine, calcium) and metal quality (gallium, zinc, vanadium, phosphorus). | |

| Soft and friable | Increases mining and grinding costs. | |

| Dissolves readily | Increases capital (larger digestion equipment) and operating costs. | |

| Low titania | Can increase caustic usage in high-temperature plants. | Reduction in titania |

| Low carbonates | Can require special processing. |

Conclusion

Tribo-electrostatic separation was demonstrated as an effective method for generating a high-grade bauxite ore for use in alumina production. Testing with the STET benchtop separator demonstrated significant movement of Al2O3 with the majority of the samples tested. In three of the four samples tested by STET, substantial movement of Al2O3 was observed. Zaidi ya hayo, the other major elements of Fe2O3, SiO2 and TiO2 demonstrated significant separation in most cases. Dry processing with the STET separator offers opportunities to generate value for bauxite and aluminium producers.

Marejeo

1. Blin, P & Dion-Ortega, A (2013) Juu na Kavu, Jarida la CIM, vol. 8, La. 4, Pp. 48-51.

2. Manouchehri, H, Hanumantha Roa, K, & Forssberg, K (2000), Mapitio ya Mbinu za Utenganishaji wa Umeme, Sehemu 1: Vipengele vya msingi, Madini & Usindikaji wa Metallurgical, vol. 17, La. 1 pp 23–36.

3. Manouchehri, H, Hanumantha Roa, K, & Forssberg, K (2000), Mapitio ya Mbinu za Utenganishaji wa Umeme, Sehemu 2: Mazingatio ya Vitendo, Madini & Usindikaji wa Metallurgical, vol. 17, La. 1 pp 139–166.

4. Ralston O. (1961) Electrostatic Separation of Mixed Granular Solids, Elsevier Publishing Company, out of print.

5. Kogel, Jessica Elzea; Trivedi, Nikhil C; Barker, James M; Krukowski, Stanley T.; Industrial Minerals and Rocks: Commodities, Markets, na inatumia toleo la 7, (2006), Ukurasa 237.