Select Language:

ST-Búnaðurinn & tækni LLC (STET) tribo-electrostatic belti skiltákn is ideally suited for beneficiating very fine (<1Μm) í meðallagi gróft (500Μm) mineral particles, with very high throughput. Experimental findings demonstrated the capability of the STET separator to beneficiate bauxite samples by increasing available alumina while simultaneously reducing reactive and total silica. STET technology is presented as a method to upgrade and pre-concentrate bauxite deposits for use in alumina production. Dry processing with the STET separator will result in a reduction in operating costs of refinery due to lower consumption of caustic soda, savings in energy due to lower volume of inert oxides and a reduction in volume of alumina refinery residues (ARR or red mud). Að auki, the STET technology may offer alumina refiners other benefits including increased quarry reserves, extension of red mud disposal site life, and extended operating life of existing bauxite mines by improving quarry utilization and maximizing recovery. The water-free and chemical-free by-product produced by the STET process is usable for manufacture of cement in high volumes without pre-treatment, in contrast to red mud which has limited beneficial reuse.

1.0 Kynning

Ál framleiðsla er miðlæg mikilvægi fyrir námuvinnslu og málmsmíði iðnaður og grundvallaratriði fyrir ýmsum atvinnugreinum [1-2]. Meðan ál er algengasta málmeiningin sem finnst á jörðinni, í heildina um 8% af skornum jarðar, sem frumefni er það viðbragð og því kemur ekki fram náttúrulega [3]. Því, ál-ríkt Ore þarf að betrumbæta til að framleiða alumina og ál, sem leiðir til umtalsverðrar myndunar leifar [4]. As the quality of bauxite deposits globally decline, the generation of residue increases, posing challenges to the alumina and aluminum-making industry in terms of processing costs, costs of disposal and the impact on the environment [3].

Aðal upphafsefnið til hreinsunar á áli er báxít, helsta viðskiptauppspretta áls í heiminum [5]. Bauxite is an enriched aluminum hydroxide sedimentary rock, produced from the laterization and weathering of rocks rich in iron oxides, aluminum oxides, or both commonly containing quartz and clays like kaolin [3,6]. Bauxite rocks consists mostly of the aluminum minerals gibbsite (Al(Ó)3), boehmite (γ-AlO(Ó)) og útbreiðsla (α-AlO(Ó)) (Table 1), and is usually mixed with the two iron oxides goethite (FeO(Ó)) og hematít (Fe2O3), the aluminum clay mineral kaolinite, small amounts of anatase and/or titania (TiO2), ilmenite (FeTio3) and other impurities in minor or trace amounts [3,6,7].

The terms trihydrate and monohydrate are commonly used by industry to differentiate various types of bauxite. Bauxite that is totally or nearly all gibbsite bearing is called a trihydrate ore; if boehmite or diaspore are the dominant minerals it is referred to as monohydrate ore [3]. Mixtures of gibbsite and boehmite are common in all types of bauxites, boehmite and diaspore less common, and gibbsite and diaspore rare. Each type of bauxite ore presents its own challenges in terms of mineral processing and beneficiation for the generation of alumina [7,8].

Table 1. Chemical composition of Gibbsite, Boehmite and Diaspore [3].

| Chemical Composition | Gibbsite AL(Ó)3 or Al2O3.3H2O | Boehmite ALO(Ó) or Al2O3.H2O | Diaspore ALO(Ó) or Al2O3.H2O |

|---|---|---|---|

| Al2O3 WT | 65.35 | 84.97 | 84.98 |

| (Ó) WT | 34.65 | 15.03 | 15.02 |

Báxítinnstæður dreifast um allan heim, kemur aðallega fram á hitabeltis- eða heittempruðum svæðum [8]. Bauxite mining of both metallurgical and non-metallurgical grade ores is analogous to the mining of other industrial minerals. Normally, the beneficiation or treatment of bauxite is limited to crushing, sieving, washing, and drying of the crude ore [3]. Flotation has been employed for the upgrading of certain low-grade bauxite ores, however it has not proven highly selective at rejecting kaolinite, a major source of reactive silica especially in trihydrate bauxites [9].

The bulk of bauxite produced in the world is used as feed for manufacturing of alumina via the Bayer process, a wet-chemical caustic-leach method in which the Al_2 O_3 is dissolved out of the bauxite rock by using a caustic soda rich solution at elevated temperature and pressure [3,10,11]. Subsequently, the bulk of alumina is utilized as feed for the production of aluminum metal via the Hall-Héroult process, which involves electrolytic reduction of alumina in a bath of cryolite (Na3AlF6). It takes about 4-6 tons of dried bauxite to produce 2 t of alumina, which in turns yields 1 t of aluminum metal [3,11].

The Bayer process is initiated by mixing washed and finely ground bauxite with the leach solution. The resulting slurry containing 40-50% solids is then pressurized and heated with steam. At this step some of the alumina is dissolved and forms soluble sodium aluminate (NaAlO2), but due to the presence of reactive silica, a complex sodium aluminum silicate also precipitates which represents a loss of both alumina and soda. The resulting slurry is washed, and the residue generated (þ.e., red mud) is decanted. Sodium aluminate is then precipitated out as aluminum trihydrate (Al(Ó)3) through a seeding process. The resulting caustic soda solution is recirculated into the leach solution. Finally, the filtered and washed solid alumina trihydrate is fired or calcined to produce alumina [3,11].

Leaching temperatures may range from 105°C to 290°C and corresponding pressures range from 390 kPa to 1500 kPa. Lower temperatures ranges are used for bauxite in which nearly all the available alumina is present as gibbsite. The higher temperatures are required to digedepositsst bauxite having a large percentage of boehmite and diaspore. At temperatures of 140°C or less only gibbsite and kaolin groups are soluble in the caustic soda liquor and therefore such temperature is preferred for the processing of trihydrate alumina . At temperatures greater than 180°C alumina present as trihydrate and monohydrate are recoverable in solution and both clays and free quartz become reactive [3]. Operating conditions such as temperature, pressure and reagent dosage are influenced by the type of bauxite and therefore each alumina refinery is tailored to a specific type of bauxite ore. Tap á dýru orsakavaldandi gosi (Naoh) and the generation of red mud are both related to the quality of bauxite used in the refining process. Yfirleitt, the lower the Al_2 O_3 content of bauxite, því stærra rúmmál rauðrar leðju sem verður til, as the non-Al_2 O_3 phases are rejected as red mud. Að auki, the higher the kaolinite or reactive silica content of bauxite, því meira sem rauð leðja verður til [3,8].

High-grade bauxite contains up to 61% Al_2 O_3, and many operating bauxite deposits -typically referred as non-metallurgical grade- are well below this, stundum jafn lágt og 30-50% Al_2 O_3. Because the desired product is a high purity

Al_2 O_3, oxíðin sem eftir eru í báxítinu (Fe2O3, SiO2, TiO2, organic material) are separated from the Al_2 O_3 and rejected as alumina refinery residues (ARR) or red mud via the Bayer process. Yfirleitt, minni gæði báxítsins (þ.e., lower Al_2 O_3 content) the more red mud that is generated per ton of alumina product. Að auki, even some Al_2 O_3 bearing minerals, einkum kaolinite, produce undesirable side reactions during the refining process and lead to an increase in red mud generation, sem og tap á dýrum orsakavaldandi gosefnum, stór breytilegur kostnaður í báxíthreinsunarferlinu [3,6,8].

Rauð leðja eða ARR táknar stóra og áframhaldandi áskorun fyrir áliðnaðinn [12-14]. Rauð leðja inniheldur umtalsverðar leifar af orsakavaldandi efnaafgangi frá hreinsunarferlinu, og er mjög basískt, oft með sýrustig 10 - 13 [15]. It is generated in large volumes worldwide – according to the USGS, áætlað var að framleiðsla á súrál á heimsvísu væri 121 milljón tonn í 2016 [16]. This resulted in an estimated 150 milljón tonn af rauðri leðju sem myndaðist á sama tímabili [4]. Þrátt fyrir áframhaldandi rannsóknir, rauð leðja hefur nú fáar viðskiptalega hagkvæmar leiðir til gagnlegrar endurnotkunar. Talið er að mjög lítið af rauðri leðju sé gagnlega endurnýtt um allan heim [13-14]. Staðinn, the red mud is pumped from the alumina refinery into storage impoundments or landfills, þar sem það er geymt og vaktað með miklum tilkostnaði [3]. Þess vegna, both an economic and environmental argument can be made for improving the quality of bauxite prior to refining, in particular if such improvement can be done through low-energy physical separation techniques.

While proven reserves of bauxite are expected to last for many years, gæði varasjóðsins sem hægt er að nálgast efnahagslega minnkandi [1,3]. Fyrir hreinsiefni, sem eru í því að vinna úr báxíti til að búa til súrál, og að lokum álmálmur, þetta er áskorun með bæði fjárhagslegum og umhverfislegum afleiðingum

Dry methods such as electrostatic separation may be of interest of the bauxite industry for the pre-concentration of bauxite prior to the Bayer process. Electrostatic separation methods that utilize contact, eða tribo-rafmagns, charging is particularity interesting because of their potential to separate a wide variety of mixtures containing conductive, um einangrunarmeðferð, og parketagnir. Tribo-rafhleðslutengi á sér stað þegar misjafnt, er með eina aðra, eða með þriðjungi yfirborðs-, sem leiðir til þess að mismunur á yfirborðsmismun á tveimur tegundum. Formerki og stærðarmunur á mismunamismun fer eftir mismun í affinity (eða starfshlutfall) milli agagerðmanna. Aðskilnaðarkvíða er þá hægt að ná með því að nota utan að jafnaði rafmagns svæði.

Tæknin hefur verið að nýta iðnfræðilega í lóðrétta fríbyltugerð skilta. Í frjálsu falli skili, agnirnar öðlast fyrst gjald, then fall by gravity through a device with opposing electrodes that apply a strong electric field to deflect the trajectory of the particles according to sign and magnitude of their surface charge [18]. Free-fall separators can be effective for coarse particles but are not effective at handling particles finer than about 0.075 að 0.1 mm [19-20]. One of the most promising new developments in dry mineral separations is the tribo-electrostatic belt separator. Þessi tækni hefur aukið Kornastærð á bilinu til fínkornastærðar en hefðbundna raffasta aðskilnaðartækni, inn á svið þar sem aðeins flot hefur reynst vel á undanförnum.

Tribo-electrostatic separation utilizes electrical charge differences between materials produced by surface contact or triboelectric charging. In simplistic ways, when two materials are in contact, the material with a higher affinity for electros gains electrons thus changes negative, en efni með lægri rafeindasækni hleður jákvætt.

ST-Búnaðurinn & tækni (STET) tribo-electrostatic belt separator offers a novel beneficiation route to pre-concentrate bauxite ores. STET þurraðskilnaðarferlið býður báxítframleiðendum eða báxíthreinsiefnum tækifæri til að framkvæma uppfærslu á báxítgrýti fyrir Bayer til að bæta gæði. Þessi aðferð hefur marga kosti, Meðal: Lækkun rekstrarkostnaðar við súrálsframleiðslu vegna minni neyslu á orsakavaldandi gosi með því að draga úr inntaksviðbragðs kísils; savings in energy during refining due to lower volume of inert oxides (Fe2O3, TiO2, Non-reactive SiO2) inn með báxíti; smaller mass flow of bauxite to refinery and therefore less energy requirement to heat and pressurize; reduction in red mud generation volume (þ.e., rauð leðja til súrálshlutfalls) by removing reactive silica and inert oxide; og, tighter control over input bauxite quality which reduces process upsets and allows refiners to target ideal reactive silica level to maximize impurity rejection. Improved quality control over bauxite feed to refinery also maximizes uptime and productivity. Ennfremur, reduction in red mud volume translates into less treatment and disposal costs and better utilization of existing landfills.

The preprocessing of bauxite ore prior to the Bayer process may offer significant advantages in terms of processing and sales of tailings. Ólíkt rauðri leðju, halar úr þurru rafstöðuferli innihalda engin efni og tákna ekki langtímaábyrgð á umhverfisgeymslu. Ólíkt rauðri leðju, þurrar aukaafurðir/hala úr báxít forvinnslu er hægt að nýta í sementsframleiðslu þar sem engin krafa er um að fjarlægja natríumið, sem er skaðlegt fyrir sementsframleiðslu. In fact – bauxite is already a common raw material for Portland cement manufacturing. Extending operating life of existing bauxite mines may also be reached by improving quarry utilization and maximizing recovery.

2.0 Tilrauna

2.1 Efni

STET conducted pre-feasibility studies in over 15 different bauxite samples from different locations around the world using a bench-scale separator. Af þessum, 7 different samples were

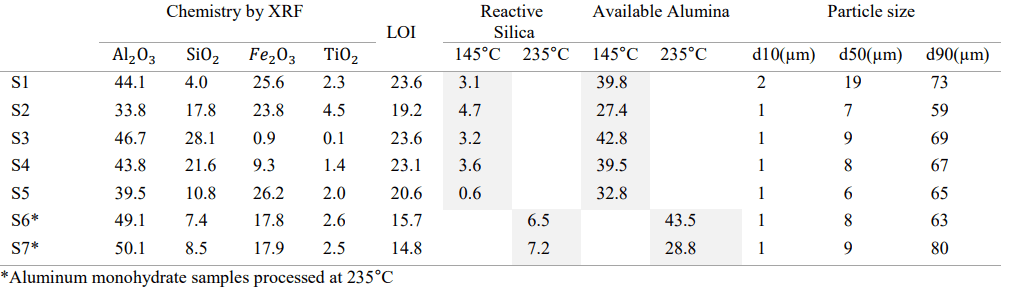

Table 2. Result of chemical analysis bauxite samples.

2.2 Aðferðir

Tilraunir voru gerðar með því að nota bekkur-mælikvarði tribo-rafstöðueiginleikar belti skilju, Hér á eftir vísað sem ' benchtop Skills '. Bekkjakerfi próf er fyrsta áfanga í þriggja fasa tækni innleiðingarferli (Sjá töflu 3) þar með mat á bekkjarkvarða, verkefnisstjórn um prófanir og auglýsing um útfærslu.

Kviðarholsskiltákn er notað til skimunar fyrir sönnun á tribo-rafföstum hleðslustraunum og til að ákvarða hvort efni er góður frambjóðandi til að fá raftruflanir til að. Helsti munur á hverju stykki búnaðar er sýndur í töflu 3. En búnaðurinn sem notaður er innan hvers áfanga er mismunandi eftir stærð, aðgerðarreglan er í grundvallaratriðum sú sama.

Table 3. Þriggja fasa innleiðingarferli með STET tribo-rafstöðueiginleikar belti aðskilinn tækni

| Áfanga | Notað fyrir: | Rafskaut Length cm | Type of Process |

|---|---|---|---|

| 1- Bench Scale Evaluation | Qualitative Evaluation | 250 | Runu |

| 2- Pilot Kvarði Testing | Quantitative evaluation | 610 | Runu |

| 3- Commercial Scale Implementation | Commercial Production | 610 | Samfelld |

As can be seen in Table 3, the main difference between the benchtop separator and pilot-scale and commercial-scale separators is that the length of the benchtop separator is approximately 0.4 sinnum lengd flugmódel-mælikvarða og atvinnuhúsnæði-mælikvarða einingar. Þar sem skilskilja skilvirkni er fall af lengd rafskautsins, ekki er hægt að nota próf á bekkpressu sem staðgengil fyrir prófanir á flugmanni. Prófanir á flugmálayfirvöldum eru nauðsynlegar til að ákvarða umfang aðskilnaðar sem STET-ferlið getur náð, og til að ákvarða hvort STET-ferlið getur uppfyllt afurðamarkmiðin undir gefnum matarhlutföllum. Staðinn, að viðmið skilríkjanna séu notuð til að útiloka framburðarefni sem ólíklegt er að geti sýnt fram á neinn marktækan aðskilnað á flugmannsstigi. Niðurstöður fengnar á bekkjarkvarðanum verða ekki til bjartsýni, og sá Aðskilnaður sem fram fer er minni en þar sem gæta yrði á viðskiptalega stór STET-skilmerki.

Testing at the pilot plant is necessary prior to commercial scale deployment, hins vegar, testing at the bench-scale is encouraged as the first phase of the implementation process for any given material. Enn fremur, in cases in which material availability is limited, the benchtop separator provides a useful tool for the screening of potential successful projects (þ.e., projects in which customer and industry quality targets can be met using STET technology).

2.2.1 STET Triboelectrostatic Belt Separator

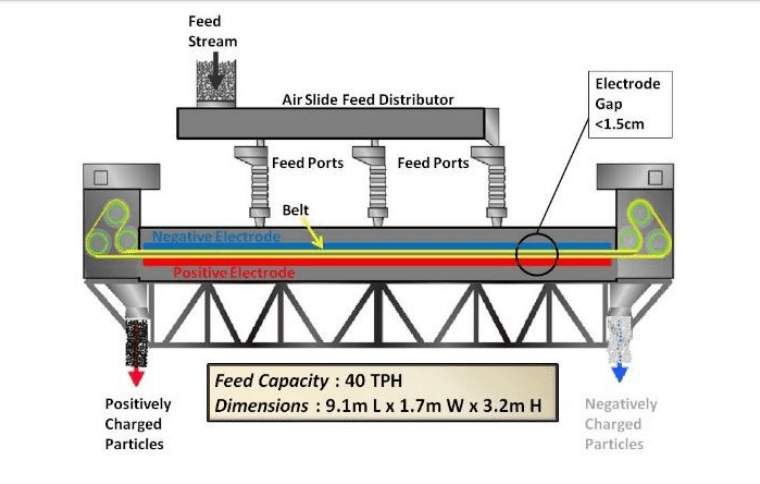

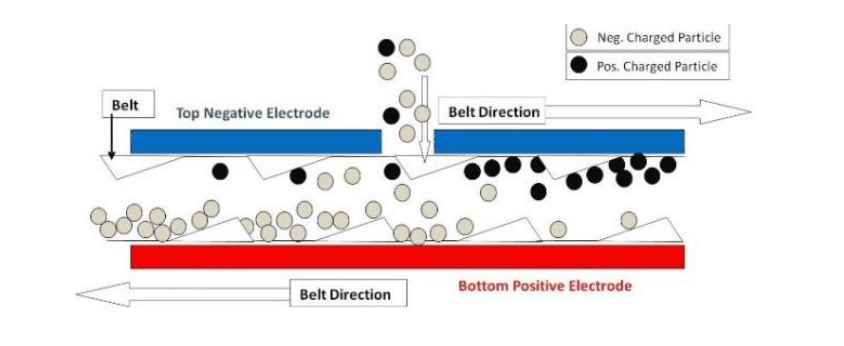

Í tribo-rafföst belti Skilrúm (Mynd 1 og mynd 2), efnið er fóðrað í þunnu Skarti 0.9 - 1.5 cm milli tveggja samsíða planar rafskaut. Þær agnir sem eru mjög hlaðnar með interagnið snertileysi. Til dæmis, in the case of a bauxite sample which main constituents are gibssite, kaolinite and quartz mineral particles, the positively charged (gibssite) and the negatively charged (kaolinite and quartz) eru dregnar saman á móti rafskaut. Þær agnir eru síðan sveipaðar upp með samfelldu Hreyfðu opnu möskvabelti og miðlað í gagnstæðar áttir. Beltið flytur agnir sem eru samliggjandi við hverja rafall í átt að gagnstæðum endum skiltisins. Á rafsviði þarf aðeins að færa agnir örlítið brot af centimetra til að færa ögn frá vinstrihreyfli yfir í hægri hreyfanlega straum. The counter current flow of the separating particles and continual triboelectric charging by particle collisions provides for a multi-stage separation and results in excellent purity and recovery in a single-pass unit. Hár beltahraði gerir einnig mjög mikil gegnumsnúningshraði, allt að 40 tonnum á klukkustund á einni skilvindu. Með því að stýra ýmsum ferlistikum, the device allows for optimization of mineral grade and recovery.

Mynd 1. Skýringarmynd af triboelectric beltaskilju

Aðgreining hönnunar er tiltölulega einföld. Beltið og tengd rollinum eru einu Hreyfðu hlutar. Rafskaut eru kyrrstætt og samsett úr viðeigandi varanlegum efnum. Beltið er úr plasti efni. Skilyrt raflengd er um það bil 6 Metra (20 Ft.) og breiddin 1.25 Metra (4 Ft.) viðskiptaeiningar í fullri stærð. Raforkunotkun er minni en 2 kílóvattstund á tonn af efni sem unnið er með mest af krafti sem neytt er af tveimur mótorum sem aka beltinu.

Mynd 2. Smáatriði aðskilnaðarsvæðis

Ferlið er algjörlega þurrt, krefst ekki viðbótarefna og framleiðir hvorki úrgangsvatn né loftpúða. For mineral separations the separator provides a technology to reduce water usage, lengja varalíf og / eða endurheimta og endurvinna halastjörnur.

Samningur kerfisins gerir ráð fyrir sveigjanleika í uppsetningarhönnun. The tribo-electrostatic belt separation technology is robust and industrially proven and was first applied industrially to the processing of coal combustion fly ash in 1997. Tæknin er árangursrík til að aðskilja kolefnisagnir frá ófullnægjandi brennslu kola, úr gleri álplötum steinefna í fljúgandi ösku. Tæknin hefur verið Instrumental í að gera endurvinnslu á steinefnaríkt fljót sem sementsbundin skipti í steypuframleiðslu.

Síðan 1995, Yfir 20 million tonnes of product fly ash have been processed by the STET separators installed in the USA. Iðnaðarsaga fluguöskuaðskilnaðar er skráð í töflu 4.

In minerals processing, the triboelectric belt separator technology has been used to separate a wide range of materials including calcite/quartz, talc/magnesite, og barít/kvars.

Mynd 3. Commercial tribo-electrostatic belt separator

Table 4. Industrial umsókn tribo-rafföst belti Skilrúm fyrir Fly Ash.

| Gagnsemi / rafstöð | Staðsetning | Upphaf atvinnustarfsemi | Upplýsingar um aðstöðu |

|---|---|---|---|

| Duke Energy – Roxboro-stöðin | Norður-Karólína Bandaríkin | 1997 | 2 Skiltákn |

| Talen orka- Brandon strendur | Maryland Bandaríkin | 1999 | 2 Skiltákn |

| Skoskt vald- Longannet-stöðin | Skotland Bretland | 2002 | 1 Skiltákn |

| Jacksonville rafmagns-St. Johns River Power Park | Flórída Bandaríkin | 2003 | 2 Skiltákn |

| Suður-Mississippi rafmagns -R.D. Morrow | Mississippi Bandaríkin | 2005 | 1 Skiltákn |

| Nýr Brunswick Power-Belledune | Nýja Brunswick Kanada | 2005 | 1 Skiltákn |

| RWE npower-Didcot stöðin | England Bretland | 2005 | 1 Skiltákn |

| Talen Energy-Brunner Island stöðin | Pennsylvanía Bandaríkin | 2006 | 2 Skiltákn |

| Tampa Electric-Big beygjustöðin | Flórída Bandaríkin | 2008 | 3 Skiltákn |

| RWE npower-Aberthaw-stöðin | Wales Bretland | 2008 | 1 Skiltákn |

| EDF Energy-West Burton stöðin | England Bretland | 2008 | 1 Skiltákn |

| ZGP (Lafarge sement /Ciech Janikosoda JV) | poland | 2010 | 1 Skiltákn |

| Kórea Suðausturveldi- Yeongheung | Suður-Kórea | 2014 | 1 Skiltákn |

| PGNiG Termika-Sierkirki | poland | 2018 | 1 Skiltákn |

| Taiheiyo sement fyrirtæki-Chichibu | Japan | 2018 | 1 Skiltákn |

| Armstrong fljúga aska- Örn sement | Filippseyjar | 2019 | 1 Skiltákn |

| Kórea Suðausturveldi- Samcheonpo | Suður-Kórea | 2019 | 1 Skiltákn |

2.2.2 Bench-scale testing

Standard process trials were performed around the specific goal to increase Al_2 O_3 concentration and to reduce the concentration of gangue minerals. Tests were conducted on the benchtop separator under batch conditions, with testing performed in duplicate to simulate steady state, and ensure that any possible carryover effect from the previous condition was not considered. Prior to each test, a small feed sub-sample was collected (designated as ‘Feed’). Upon setting all operation variables, the material was fed into the benchtop separator using an electric vibratory feeder through the center of the benchtop separator. Samples were collected at the end of each experiment and the weights of product end 1 (designated as ‘E1’) and product end 2 (designated as ‘E2’) were determined using a legal-for-trade counting scale. For bauxite samples, ‘E2’ corresponds to the bauxite-rich product. For each set of sub-samples (þ.e., Feed, E1 and E2) LOI, main oxides composition by XRF, reactive silica and available alumina was determined. XRD characterization was performed on selected sub-samples.

3.0 Results and Discussion

3.1. Samples Mineralogy

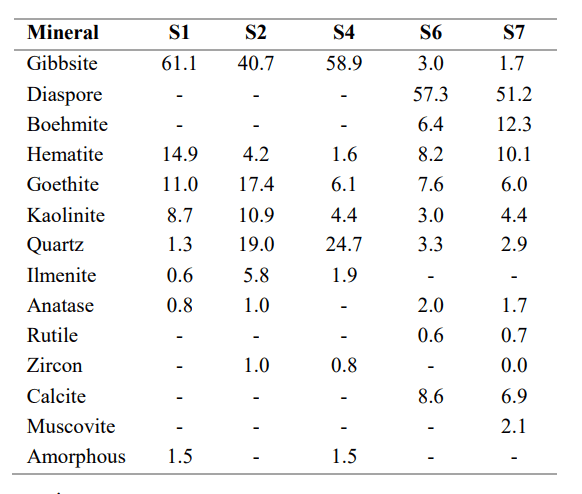

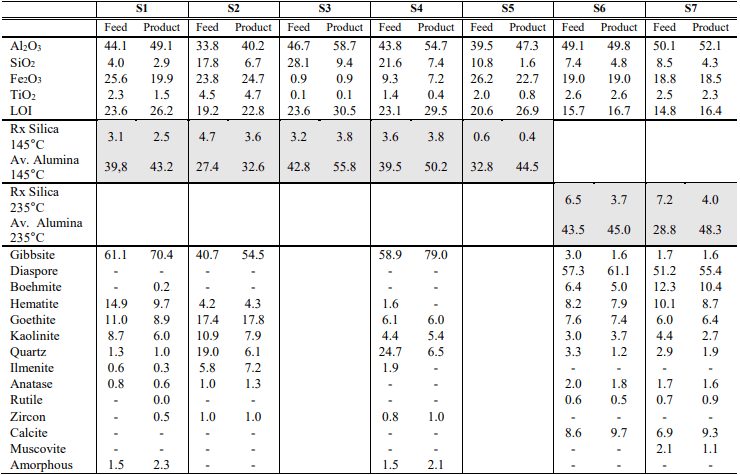

Results of the quantitative XRD analyses for feed samples are included in Table 5. The majority of the samples were primarily composed of gibbsite and varying amounts of goethite, hematite, kaolinite, and quartz. Ilmenite and anatase were also evident in minor amounts in the majority of the samples.

There was a change in the mineral composition for S6 and S7 as these feed samples were primarily composed of diaspore with minor amounts of calcite, hematite, goetite, boehmite, kaolinite, gibbsíða hjá, kvars, anatase, and rutile being detected. An amorphous phase was also detected in S1 and S4 and ranged from approximately 1 að 2 percent. This was probably due to either the presence of a smectite mineral, or non-crystalline material. Since this material could not be directly measured, results for these samples should be considered approximate.

3.2 Bench-scale experiments

A series of test runs were performed on each mineral sample aimed at maximizing Al2O3 and decreasing SiO_2 content. Species concentrating to the bauxite-rich product will be indicative of positive charging behavior. Results are shown in Table 6

Table 5. XRD analysis of feed samples.

Table 6. Summary Results.

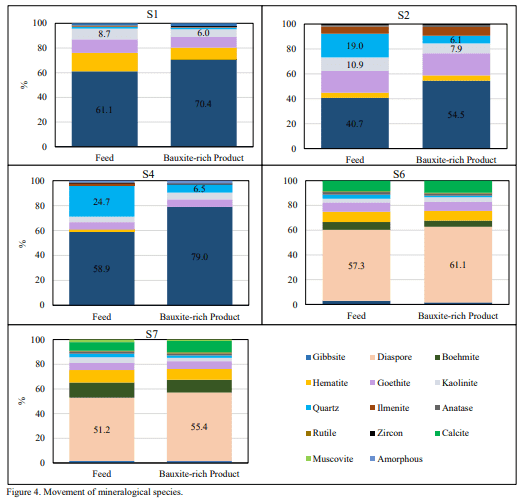

Testing with the STET benchtop separator demonstrated significant movement of Al2O3 for all samples. Separation of Al2O3 was observed for S1-5 which were mainly gibbsite, and also for S6-7 which were mainly diaspore. Að auki, aðrir helstu þættir Fe2O3, SiO2 og TiO2 sýndu fram á marktæka hreyfingu í flestum tilvikum. For all samples, hreyfingu taps á íkveikju (LOI) fylgt hreyfingu Al2O3. In terms of reactive silica and available alumina, for S1-5 which are nearly all gibbsite (aluminum trihydrate) values should be considered at 145°C while for S6-7 for which the dominant mineral is diaspore (aluminum monohydrate) values should be assessed at 235°C. For all samples testing with the STET benchtop separator demonstrated a substantial increase in available alumina and a significant reduction in reactive silica to product for both trihydrate and monohydrate bauxite samples. Movement of major mineral species was also observed and is graphically shown below in Figure 4.

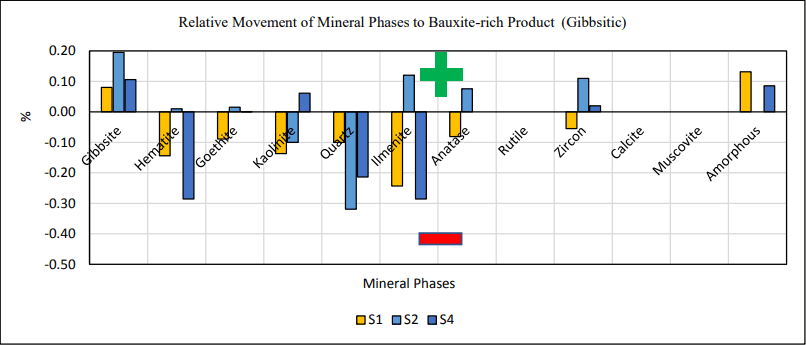

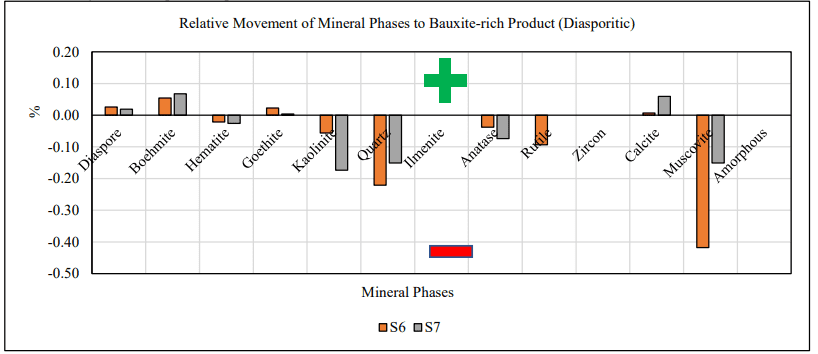

In terms of mineralogy, STET benchtop separator demonstrated concentration of the alumina bearing species gibbsite and diaspore to the bauxite-rich product while simultaneously rejecting other gangue species. Tölur 5 og 6 show selectivity of mineral phases to the bauxite-rich product for trihydrate and monohydrate samples, respectively. Selectivity was calculated as the difference between the mass deportment to product for each mineral species and the overall mass recovery to product. A positive selectivity is indicative of mineral concentration to the bauxite-rich product, and of an overall positive charging behavior. Contrary, a negative selectivity value is indicative of concentration to the bauxite-lean coproduct, and of an overall negative charging behavior.

For all trihydrate low-temperature samples (þ.e., S1, S2 and S4) kaolinite exhibited a negative charging behavior and concentrated to the bauxite-lean co-product while gibbsite concentrated to the bauxite-rich product (Mynd 5). For all monohydrate high-temperature samples (þ.e., S6 and S7) both reactive silica bearing minerals, kaolinite and quartz, exhibited a negative charging behavior. For the latter, diaspore and boehmite reported to the bauxite-rich product and exhibited a positive charging behavior (Mynd 6).

Mynd 5. Selectivity of mineral phases to product.

Mynd 6. Selectivity of mineral phases to product.

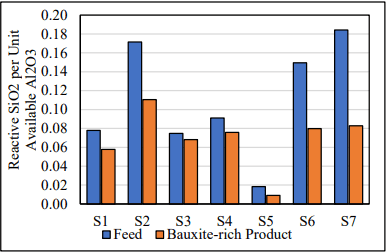

Measurements of available alumina and reactive silica demonstrate substantial movement. For low temperature bauxites (S1-S5), the amount of reactive silica present per unit of available alumina was reduced from 10-50% on a relative basis (Mynd 7). A similar reduction was observed in the high temperature bauxites (S6-S7) as can be seen in Figure 7.

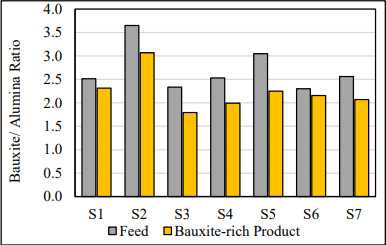

The bauxite to alumina ratio was calculated as the inverse of the available alumina. The bauxite to alumina ratio was decreased by between 8 - 26% in relative terms for all samples tested (Mynd 8). This is meaningful as it represents an equivalent reduction in mass flow of bauxite that needs to be fed to the Bayer process.

Mynd 7. Reactive SiO2 per unit of Available Al2O3

Mynd 8. Bauxite to Alumina ratio.

3.3 Discussion

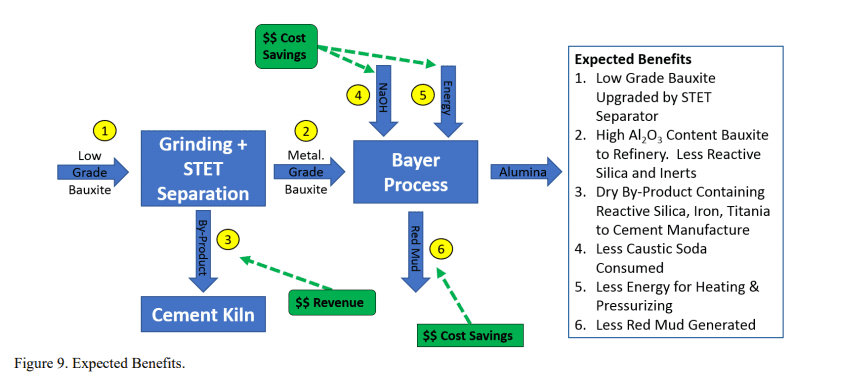

The experimental data demonstrates that the STET separator increased available Al2O3 while simultaneously reducing SiO_2 content. Mynd 9 presents a conceptual diagram of the expected benefits associated to the reduction of reactive silica and the increase of available alumina prior to the Bayer Process. The authors calculate that the financial benefit to an alumina refiner would be in the range of $15-30 USD per ton of alumina product. This reflects avoided cost from caustic soda lost to de-silicaton product (DSP), energy savings from reducing the input of bauxite to the refinery, reduction in red mud generation and a small revenue stream generated from selling the low-grade bauxite by-product to cement producers. Mynd 9 outlines the expected benefits of implementing STET triboelectrostatic technology as a mean to pre-concentrate bauxite ore prior the Bayer process.

Installation of the STET separation process for bauxite pre-processing could be performed either at the alumina refinery or the bauxite mine itself. þó, the STET process requires dry grinding of the bauxite ores prior to separation, to liberate the gangue, therefore the logistics of grinding and processing the bauxite at the refinery may be more straightforward.

As one option – the dry bauxite would be ground using well-established dry grinding technology, for example a vertical roller mill or impact mill. The finely ground bauxite would be separated by the STET process, with the high-alumina bauxite product sent to the alumina refinery. The installation of dry grinding would allow for the elimination of wet grinding traditionally used during the Bayer process. It is assumed that the operating cost of dry grinding would be roughly comparable to the operating cost of wet grinding, especially considering the wet grinding performed today is performed on a highly alkaline mixture, leading to considerable maintenance costs.

The dry low-grade bauxite co-product (tailings) from the separation process would be sold to cement manufacture as an alumina source. Bauxite is commonly added to cement manufacture, and the dry co-product, unlike red mud, does not contain sodium which would prevent its use in cement manufacture. This provides the refinery with a method of valorizing material that would otherwise exit the refining process as red mud, and would require long term storage, representing a cost.

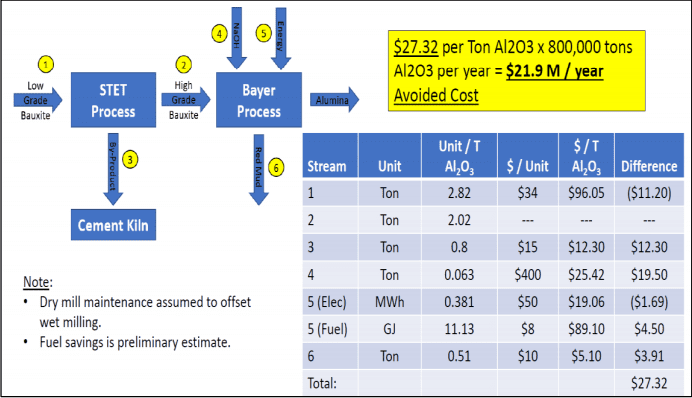

An operating cost calculation performed by the authors estimates a project benefit of $27 USD per ton of alumina, with the major impacts achieved through reduction in caustic soda, reduction in red mud, valorization of the co-product and fuel savings due to lower volume of bauxite to the refinery. Therefore an 800,000 ton per year refinery could expect a financial benefit of $21 M USD per year (See Figure 10). This analysis does not consider potential savings from reducing import or logistics costs of bauxite, which may further enhance the project return.

Mynd 10. Benefits of Reactive Silica Reduction and Available Alumina increase.

4.0 Conclusions

Í stuttu máli, þurrvinnsla með STET skiljunni býður upp á tækifæri til að skapa verðmæti fyrir báxítframleiðendur og hreinsiefni. Forvinnsla báxíts fyrir hreinsun mun draga úr efnakostnaði, lækka rúmmál rauðrar leðju sem myndast og lágmarka vinnsluuppnám. STET technology could allow bauxite processors to turn non-metallurgical grade into metallurgical grade bauxite – which could reduce need for imported bauxite and/or extend exiting quarry resource life. STET process could also be implemented to generate higher quality non-metallurgical grade and metallurgical grade bauxite, and cement grade bauxite by-products prior to the Bayer process.

The STET process requires little pre-treatment of the mineral and operates at high capacity – up to 40 tones per hour. Energy consumption is less than 2 kilowatt-hours per ton of material processed. Enn fremur, the STET process is a fully commercialized technology in minerals processing, and therefore does not require the development of new technology.

Tilvísanir

1. Bergsdal, Håvard, Anders H. Strømman, and Edgar G. Hertwich (2004), “The aluminium industry-environment, technology and production”.

2. Das, Subodh K., and Weimin Yin (2007), “The worldwide aluminum economy: The current state of the industry” JOM 59.11, Pp. 57-63.

3. Vincent G. Hill & Errol D. Sehnke (2006), “Bauxite”, in Industrial Minerals & Rocks: Vörur, Markaðir, and Uses, Society for Mining, Metallurgy and Exploration Inc., Englewood, CO, Pp. 227-261.

4. Evans, Ken (2016), “The history, challenges, and new developments in the management and use of bauxite residue”, Journal of Sustainable Metallurgy 2.4, Pp. 316-331

5. Gendron, Robin S., Mats Ingulstad, and Espen Storli (2013), “Aluminum ore: the political economy of the global bauxite industry”, UBC Press.

6. Hose, H. R. (2016), “Bauxite mineralogy”, Essential Readings in Light Metals, Springer, Cham, Pp. 21-29.

7. Authier-Martin, Monique, et al. (2001),”The mineralogy of bauxite for producing smelter-grade alumina”, JOM 53.12, Pp. 36-40.

8. Hill, V. G., and R. J. Robson (2016), “The classification of bauxites from the Bayer plant standpoint”, Essential Readings in Light Metals, Springer, Cham, Pp. 30-36.

9. Songqing, Gu (2016). “Chinese Bauxite and Its Influences on Alumina Production in China”, Essential Readings in Light Metals, Springer, Cham, Pp. 43-47.

10. Habashi, Fathi (2016) “A Hundred Years of the Bayer Process for Alumina Production” Essential Readings in Light Metals, Springer, Cham, Pp. 85-93.

11. Adamson, A. N., E. J. Bloore, and A. R. Carr (2016) “Basic principles of Bayer process design”, Essential Readings in Light Metals, Springer, Cham, Pp. 100-117.

12. Anich, Ivan, et al. (2016), “The Alumina Technology Roadmap”, Essential Readings in Light Metals. Springer, Cham, Pp. 94-99.

13. Liu, Wanchao, et al. (2014), “Environmental assessment, management and utilization of red mud in China”, Journal of Cleaner Production 84, Pp. 606-610.

14. Evans, Ken (2016), “The history, challenges, and new developments in the management and use of bauxite residue”, Journal of Sustainable Metallurgy 2.4, Pp. 316-331.

15. Liu, Yong, Chuxia Lin, and Yonggui Wu (2007), “Characterization of red mud derived from a combined Bayer Process and bauxite calcination method”, Journal of Hazardous materials 146.1-2, Pp. 255-261.

16. bandarískt. Geological Survey (USGS) (2018), “Bauxite and Alumina”, in Bauxite and Alumina Statistics and information.

17. Paramguru, R. K., P. C. Rath, and V. N. Misra (2004), “Trends in red mud utilization–a review”, Mineral Processing & Extractive Metall. Rev. 2, Pp. 1-29.

18. Manouchehri, H, Hanumantha Roa, K, & Forssberg, K (2000), “Review of Electrical Separation Methods, Hluti 1: Grundvallarþættir, steinefni & Metallurgical Processing”, Vol. 17, Nei. 1, Pp 23–36.

19. Manouchehri, H, Hanumantha Roa, K, & Forssberg, K (2000), “Review of Electrical Separation Methods, Hluti 2: Hagnýt atriði, steinefni & Metallurgical Processing”, Vol. 17, Nei. 1, pp 139–166.

20. Ralston O. (1961), Rafstöðuaðskilnaður blandaðra korna solids, Elsevier útgáfufyrirtæki, úr prentun.