Select Puo:

A.Gupta, k. Flynn le F. Hrach

ST Helmets & Technology, 101 Hampton Avenue, Needham, MA 02494, usa

inahaneloang

ST Helmets & Technology (STET) ke developer indonesia le moetsi oa triboelectrostatic lebanta oona tsamaisong karohano hore e fana ka liminerale indasteri tharollo ho beneficiate o motle matsoai tšepe ka ho sebelisa theknoloji ea omileng. The triboelectrostatic thekenoloji lebanta karohano 'nile la sebelisoa ka mokhoa oa thekiso ho arohana e mengata e fapaneng liminerale ho akarelletsa calcite / quartz, talc / magnesite, barite / quartz, le aluminosilicates / k'habone ka fofa molora. The phahameng bokgoni selotlolo boemo karohano finyelloa ka phatsa ho phatsa lefisa ho fella ka karohano e phahametse e bapisoa le e tloaelehileng mahala-ho oa triboelectrostatic kgaoganyo. Ke theknoloji ea omeletseng le ha a hloke tshebediso ya dikhemikhale tikoloho nahanela le metsi, kahoo ha ho na tsamaiso ea kalafo metsi litšila lia hlokahala ka tshebetso. Ka tlaleho ena, diphetho tsa e atlehileng motsamaisi dimela tekanyo e beneficiation teko tshwarwa ka motsoako oa zircon / rutile ka lehlabathe matsoai li hatisitsoe.

Keywords: liminerale, karohano omileng, triboelectrostatic tjhaja, lebanta kgaoganyo, lehlabathe matsoai, zircon, rutile

Selelekela

STET triboelectrostatic kgaoganyo utilizes se tšoane ka k'hemistri holim pakeng tsa likaroloana tsa lintho tse bonahalang fepa ka ho bopa ho se tšoane motlakase qoso. Ha tse pedi bokaholimo dissimilar ba rubbed khahlanong le mong ho e mong, qoso phetiso etsahala le lintho tse bonahalang le ka tlaase le elektrone e amana lahleheloa dieleketerone ho lintho tse bonahalang tse ka e phahameng le elektrone e amana ka tsela eo lefisa ntle 'me mpe ka ho latellana.

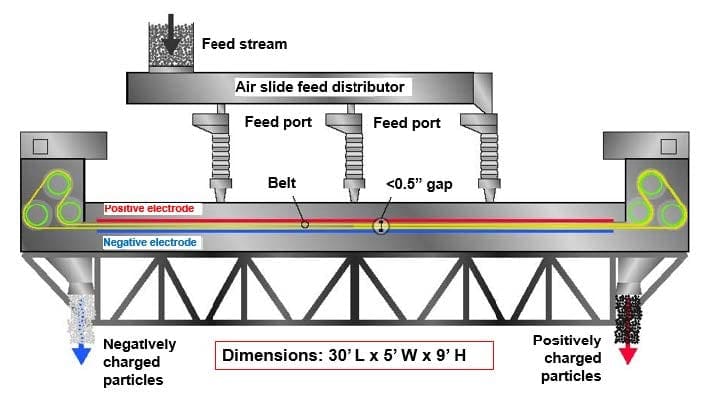

Ka STET triboelectrostatic lebanta kgaoganyo, lintho tse bonahalang fepa ka feptjoang ka lekhalo tšesaane pakeng tsa li-electrode tse peli e tšoanang. Ho na le e bulehileng-letlooeng lebanta fallela pakeng tsa li-electrode ho ka lebelo le phahameng, upto 65 maoto a / set lao, eaba ba etsa sekgoqetsane ho pota sete ya rollers ka lipheletsong bobeli (Figure 1). likaroloana li triboelectrically qosoa ke phatsa ea matla ho phatsa ho ikopanya le ba khahloa ke ho oppositely li-electrode qoso. Lebanta sweeps li-electrode le jarelang likaroloana fapaneng ho lipheletsong fapaneng kgaoganyo ho. The stats jwale phallo ea ho aroloa phatsa le tsoele pele triboelectric tjhaja ke phatsa ho thulana phatsa e fana ka bakeng sa selotlolo sethaleng omileng beneficiation thulaganyou e. Moralo kgaoganyo ke batlang le bonolo le le diseke ee. Bolelele ka kakaretso ke approx. 30 feat (9 limithara) le bophara 5 feat (1.5 limithara) bakeng sa e tletseng boholo unit trust khoebo.

STET lula ka ho etsa lipatlisiso le ntshetsopele laboratori ea setsing sa STET botekgeniki ka Needham, Massachusetts. setsing sena se akarelletsa ho STET motsamaisi semela le k'hemistri le laboratori eo, hammoho le moralo wa, ho etsa thepa le tšehetso botekgeniki mafapha bakeng sa ntshetsopele khoebo le ho etsa thepa libaka tsa STET e. Motsamaisi dimela Houses pedi fokoletse theko ea tekanyo e, separators STET hammoho le thepa ancillary sebediswa ho fuputsa diphetolo tsa tshebetso STET le ho hlahloba karohano ea fofa molora le liminerale mehloling nkgetheng.

Figure 1: STET triboelectrostatic kgaoganyo tlhohlomiso

matsoai lehlabathe

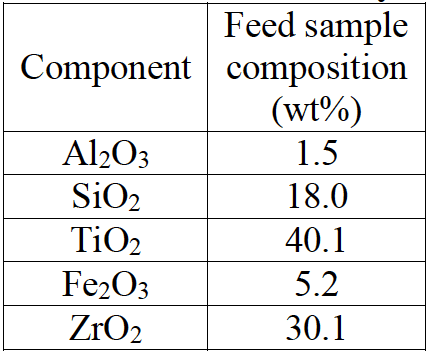

The diminerale ba rutile hana sampole e ne e hoo e ka bang 41% rutile, 33% zircon, 18% ilmenite le 8% liminerale tse ling. Sepheo e ne e le ho theha sebetsana maemo ho hlaphoheloa zircon tswa rutile hana sampole. STET khanna and analysis lik'hemik'hale sebelisa wavelength dispersive X-Ray khanyang (WD-XRF) ka fepa ka sampole le liphello (boetse maemong bakeng Loi) bontšoa ka tafole 1.

tafole 1: Elemental ho hlahloba matsoai lehlabathe sampole (dikarolo kgolo bontšoa)

mekhoa tloaelehileng bakeng sa beneficiating lehlabathe matsoai akarelletsa maqephe a rarahaneng phallo sebelisa dithulaganyo tse kang dithekeniki metsi matla a khoheli, matla a khoheli arohane le ho froth flotation (ref. 1,2) e nang le mefokolo ea bona. The a khoheli a karohano thulaganyou e hangata e isang karoloana middling eo hlokang ka ho lahla kapa botjha ha thepa morao ho fepa ka le molapo. Matla a khoheli karohano sebelisa rollers na likhaello tseo tse ling ka difaene sebetsa. The likaroloana o motle, esita le batho bao e seng matla a khoheli le tšekamelo ea ho theha coatings ka rolara ho, etsetsa tshebetso karohano thuso. STET kgaoganyo e hantle loketseng bakeng sa karohano ea thepa e ntle haholo le throughputs phahameng haholo. Metsi matla a khoheli le ho froth flotation dithulaganyo akarelletsa boima metsi lik'hemik'hale le tšebeliso ea metsi, le hloka litšila thulaganyou e kalafo metsi. Bakeng sa dikopo omileng ho qetela, e omisa mohato o lokela ho a phaella ka tlaase ho linoka tsa beneficiation mohato ka tsela eo e ntseng e eketseha ditjeo tsa ho sebelisa mehaho.

STET ya thekenoloji triboelectrostatic fana ka bokgoni ikhethang oa ho sebetsa le fepa ka ommeng, le tshebediso ya tlaase motlakase, ka tloaelo ho approx. 1 kWh / ton (ref. 3) le chelete e 'meli ntlafatswa melapo ka ka bofelo ba kgaoganyo le ha karoloana middling.

Results

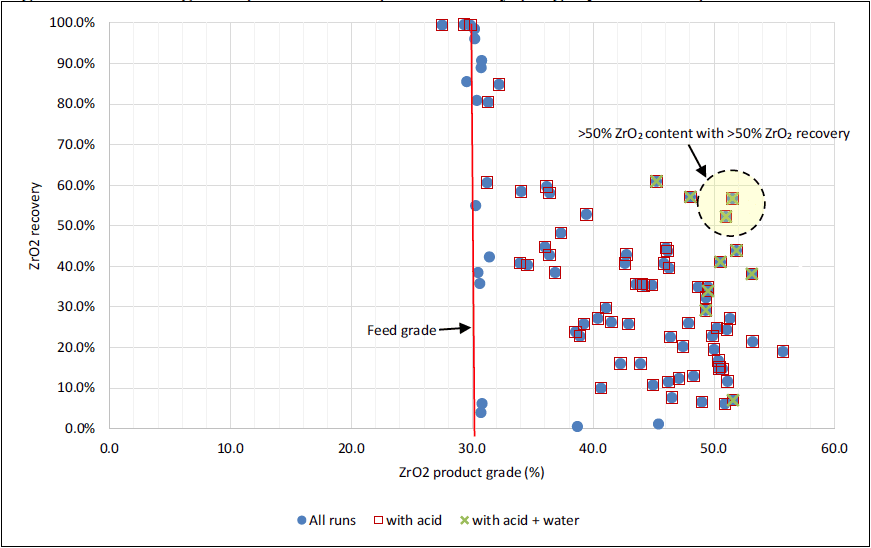

STET bontšitse bopaki ba tjhaja atlehang le karohano ea zircon le rutile likaroloana matsoai. E ile ea bonahala e doping ho fepa ka manya le ngata e nyenyane ea acid nkhang hamonate kapa aliphatic carboxylic (electrostatic mahlahana qoso conditioning) o ile a bontša Ntlafatso bohlokoa boitšoarong karohano. Figure 2 tlase bontša sehlahisoa sehlopheng (ZrO2 dikahare lekanya sebelisa WD-XRF) le ZrO2 hlaphoheloa ho sehlahisoa tsa balehela ho lona 'ohle tšoareloa STET motsamaisi dimela. E ka bone hore tlas'a maemo a optimized le fepa ka doped ka acid e nkhang hamonate carboxylic ka 2000 GM / ton litekanyetso li behoa 'me le mongobo, sehlahisoa limaraka tsa >50% ZrO2 khotsofalla >50% ZrO2 hlaphoheloa ho sehlahisoa ne fihlellwa (bona ya data a totobatsa). Karolelano ea ZrO2 dikahare tsa fepa ka e ne e le approx. 30%.

Figure 3 bontša ka sehlahisoa sehlopheng (TiO2 dikahare lekanya sebelisa WD-XRF) le TiO2 hlaphoheloa ho ka sehlahisoa tsa balehela ho lona 'ohle tšoareloa STET motsamaisi dimela. E ka bone hore tlas'a maemo a optimized le fepa ka doped ka acid e nkhang hamonate carboxylic le mongobo, ka sehlahisoa limaraka tsa >50% TiO2 khotsofalla >80% TiO2 hlaphoheloa ho ka sehlahisoa ne fihlellwa (bona ya data a totobatsa). Karolelano ea TiO2 dikahare tsa fepa ka e ne e le approx. 40%.

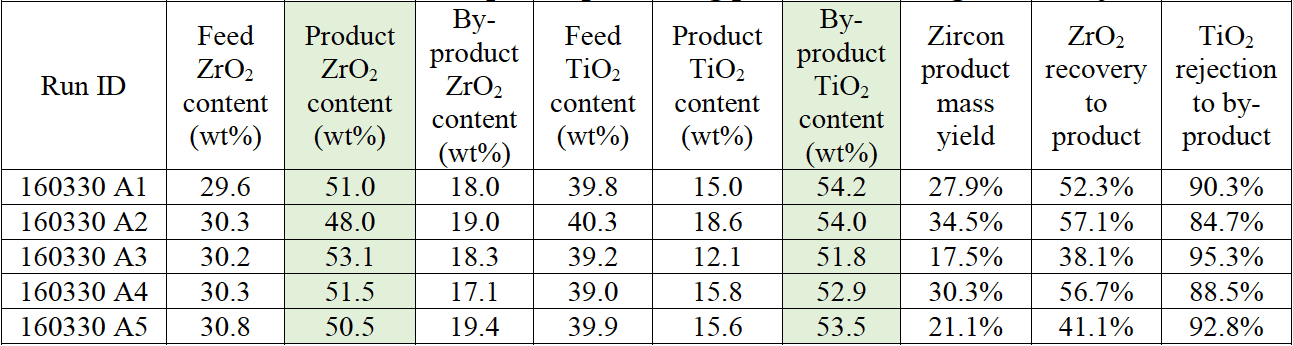

tafole 2 tlase bontša sephetho ho tswa balehela ho lona khanna tlas'a maemo optimized. STET ile a khona ho finyella >50% ZrO2 dikahare ka sehlahisoa le e ntlafetseng ya dikahare zircon beneficiating sa iphepe ka karolelano 30% ZrO2 dikahare. The rutile karoloana ya fepa ka e ne e bokella ka ka sehlahisoa, le >50% TiO2 dikahare beneficiating sa iphepe ka karolelano TiO2 dikahare approx. 40%. mosebetsi oa nakong e tlang o tla nahana ka go lekanyetsa diphetho karohano ka ho fokotsa litekanyetso li behoa ea qoso mahlahana conditioning.

Figure 2: Product sehlopheng (ZrO2 dikahare) v Le / s hlaphoheloa (diphetho fetisetsana le 'ngoe)

Figure 3: Ka sehlahisoa sehlopheng (dikahare TiO2) v Le / s hlaphoheloa (diphetho fetisetsana le 'ngoe)

tafole 2: Results fihlellwa tlas'a entsprechen homolog sebetsa sebelisa "rutile hana" iphepe

Qetello

E ka katleho ile a bontša hore STET triboelectrostatic lebanta kgaoganyo khonang ho katleho beneficiating ea zircon / rutile motsoako nang lehlabathe matsoai fepa, ka tsela eo, ho finyella ntlafatswa zircon le rutile dikahare ka sehlahiswa le ka sehlahisoa latellana. Lewa lena e fana ka e ka bolokang tjhelete, solofetsang mefuta e meng 'me ka mohlomong felisa dithekeniki sebetsa metsi. Ha ho hloka tšebeliso ea lik'hemik'hale tikoloho nahanela kapa metsi 'me ka tsela e sa hloka omisa ea lintho tse bonahalang tse ho qetela. The tshebediso ya matla bakeng sa ho kgaoganyo STET e tlaase, approx. 1 kWh / thane e le ea fepa ka lintho tse bonahalang sebetswa.

References

1. R.M. Tyler le R.C.A. Minnitt. A hlahloba ka boroa ho Sahara matsoai boima lehlabathe depositi: ama diporojeke tse di e ncha Afrika e ka boroa. Journal of le Institute ea morafo le Metallurgy South African, 89-100, March 2004.

2. V.G.K. Murty, D. Hriathod, S. Asokan le A. Chatterjee. Beneficiation la Indian boima matsoai Sands - Ba bang menyetla New Ho Khetholloa ka Tata Steel. Ditsamaiso tsa International thupelong ka Processing matsoai Technology, 2006.

3. J.D. Bittner, K.P. Flynn le F.J. Hrach, Atolosa Dikopo ka Dry Tribolectric arohana oa liminerale. Ditsamaiso tsa International matsoai Processing Congress, 2014.