Select Puo:

Kyle Flynn, Katrina Saahil, Frank Hrach

inahaneloang

Tlhahlobo ea lingoliloeng tse amehang e bontša hore lipatlisiso tsa bohlokoa li entsoe ho sebelisa electrostatically

mekhoa ea ho arohana ho omisa lijo tse entsoeng ka limela tse nang le granular (i.e., manyolo) lisebelisoa. Nts'etsopele ena e potlakile nakong e fetileng 10 - 20 lilemo tse, with many researchers in Europe and the United States applying electrostatic karohano techniques to a wide variety of beneficiation challenges. Ho tsoa patlisisong ena, ho hlakile hore mekhoa electrostatic na le monyetla oa ho hlahisa e ncha, lihlahisoa godimo-boleng dimela, kapa fana ka ya mefuta e meng ho kolobisa mekhoa sebetsa. Le hoja e khothatsa karohano ea lijo-thollo lijo-thollo, pulse and oilseed materials have been demonstrated at the laboratory and in some cases, pilot scale, litsamaiso electrostatic sebelisoa ho bontša liphetho tsena ka 'na se ke ua se loketseng kapa e ka bolokang tjhelete thepa e lokisa ho phetha karohano joalo ka motheo oa khoebo. theknoloji e ngata electrostatic ha a loketse bakeng sa thulaganyou e khabeloa fatše, tlase segokanyipalo powders kang thepa ea dimela. Leha ho le joalo, le ST Helmets & Technology (STET) triboelectrostatic lebanta kgaoganyo o na le o ile a bontša bokgoni ho sebetsa likaroloana tse molemo tse tsoang 500 - 1 μm. The STET belt separator is a high-rate, sesebediswa sa ho sebetsa se netefaditsweng ke diindasteri se ka bang se loketse ho etsa kgwebo dintlafatso tsa moraorao tsa ho sebetsa ha dintho tse phelang. The STET lebanta separator e ile ea lekoa ka sampole ea phofo ea koro 'me ho ile ha fumanoa hore e atlehile ho tlosa bran ho tloha karoloana ea starch.. Teko ea nako e tlang le searohanyi sa STET e tla etsoa ka lisampole tsa bran ea koro, phofo ea poone

le li-pulse tse kang soya le lupine.

Keywords: Tribo-Electrostatic, Motlakase, karohano, Karohano, Koro, Lijo-thollo, Phofo, Fiber, Protheine, Lipeo tsa oli, Pulse

Selelekela

Mekhoa ea karohano ea electrostatic e 'nile ea sebelisoa nakong e fetileng 50 lilemo tsa ho rua molemo ka tekanyo ea khoebo ea

lirafshoa tsa indasteri le ho sebelisoa hape ha litšila. Electrostatic beneficiation ea lijo tse omeletseng tse nang le granular tse thehiloeng ho semela (i.e, manyolo) lisebelisoa li 'nile tsa batlisisoa ka nako e telele 140 lilemo tse, le patent ea pele bakeng sa karohano ea electrostatic ea middlings ea phofo ea koro e tlatsitsoeng esale pele 1880. [1] Electrostatic beneficiation e lumella karohano ho latela phapang ea k'hemistri e holimo (mosebetsi oa mosebetsi) kapa thepa ea dielectric. Maemong a mang, karohano tsena e ne e ke ke ha khoneha ho sebelisa karohano boholo kapa segokanyipalo feela. Mekhoa ea karohano ea electrostatic e sebetsa ka melao-motheo e tšoanang. Litsamaiso tsohle tsa karohano ea electrostatic li na le sistimi ea ho tjhaja likaroloana ka motlakase, sebaka sa motlakase se hlahisoang ka ntle bakeng sa karohano ho etsahala ho, le mokgoa wa ho tsamaisa dikarolwana ho kena le ho ntsha sesebediswa sa karohano. Ho tjhaja motlakase ho ka etsahala ka mekhoa e le 'ngoe kapa tse ngata ho kenyelletsa le conductive induction, tribo-lefisa (ho kenya motlakase) le ho tjhaja ion kapa corona. Mekhoa ea karohano ea motlakase e sebelisa bonyane e 'ngoe ea mekhoa ena ea ho tjhaja. [2]

Phahameng tsitsipano moqolo electrostatic karohano litsamaiso li 'nile tsa sebelisoa liindasteri tse ngata le dikopo moo e mong

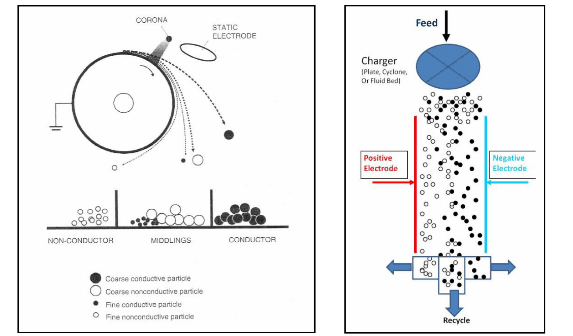

karolo e tsamaisana le motlakase ho feta tse ling. Mehlala ea likopo tsa li-separators tse phahameng tsa tsitsipano li kenyelletsa karohano ea liminerale tse nang le titanium, hammoho le lisebelisoa tsa ho tsosolosa, mohlala ho hlopha tšepe ho tloha polasetiki. Ho na le liphapang tse ngata le li-geometri tse sebelisoang bakeng sa litsamaiso tse phahameng tsa tsitsipano, empa ka kakaretso, ba sebetsa ka melao-motheo e tšoanang. Likaroloana tsa phepelo li lefisoa hampe ke ho tsoa ha ionizing corona. Likaroloana tsa phepelo li qhalakanngoa holim'a moropa o potolohang, moo moqomo o tiisitsoeng ka motlakase. Likaroloana tse tsamaisang motlakase li fana ka tefiso ea tsona ha li kopana le bokaholimo ba moropa o theohileng fatše. Ho potoloha ha moropa ho etsa hore likaroloana tsa conductive li lahleloe ho tsoa holim'a moropa ebe li kenngoa ka har'a hopper ea sehlahisoa sa pele.. Likaroloana tse se nang conductive li boloka tefiso ea tsona ea motlakase 'me li kenngoa ka holim'a moropa. Qetellong, tefiso ea motlakase holim'a likaroloana tse se nang conductive li tla fela, kapa likaroloana li tla hlatsuoa ho tloha moqomong ka mor'a hore moropa o pota-potiloe e le hore likaroloana tse seng tsa conductive li kenngoe ka har'a "non-conductive particle hopper".. Lisebelisoa tse ling, hopper ea middlings e behoa pakeng tsa sehlahiswa se conductive le se sa conductive. Katleho ea mofuta ona oa sesebelisoa sa karohano hangata e lekanyelitsoe ho likaroloana tse batlang li le mahoashe le/kapa tse nang le matla a khoheli a khethehileng., ka lebaka la tlhokeho ya hore makumane ohle a kopane le bokahodimo ba moropa. Holim'a moo, particle flow dynamics ke ea bohlokoa kaha matla a angular a qetella a ikarabella bakeng sa ho fetisa likaroloana ho tloha holim'a moropa ho ea ho li-hopper tsa lihlahisoa tse fapaneng.. Likaroloana tse ntle le likaroloana tse tlase-tlase li susumetsoa habonolo ke maqhubu a moea 'me kahoo ha ho bonolo hore li lahleloe ho tloha moqomong sebakeng se ka tsejoang esale pele.. [2] [3] [4]

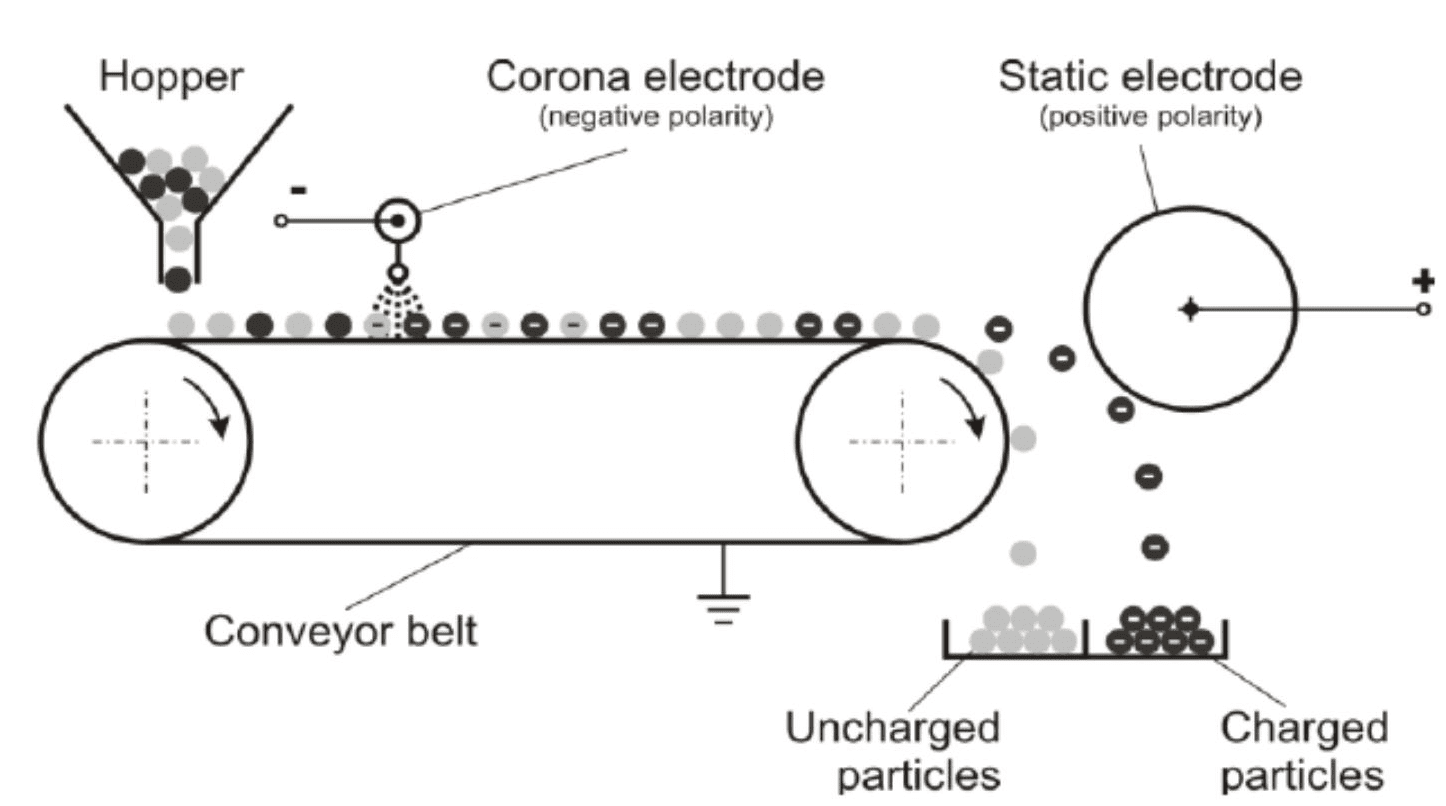

Sepharoli se phahameng sa lebanta la tsitsipano ke mofuta o fapaneng oa karohano e phahameng ea tsitsipano e hlalositsoeng ka holimo. likaroloana Feed ba qhalakantsoeng evenly ho pholletsa le bophara ya pellet motheo o tiileng conveyor lebanta. Likaroloana tse qosoa, hangata ke Corona mpe, le hoja mekgwa tse ling tsa lefisa lia khoneha. Hape le likaroloana conductive fa qoso bona motlakase ho fihlela ho sa motheo o tiileng conveyor lebanta, ha a ntse a likaroloana bao e seng conductive boloke qoso bona. The likaroloana conductive oela theoha la bohale ba lebanta ke matla a khoheli, ha a ntse a qosoa likaroloana bao e seng conductive ke "tlosoa" theoha ba holim 'a lebanta ka mabotho a electrostatic. Hape bakeng sa karohano ho atleha, e mong le e phatsa lokela ikopanya holim 'a lebanta ho lumella bakeng sa likaroloana conductive ho tela qoso ea bona ea ho lebanta la. Ka lebaka leo,, feela mokato le 'ngoe ea likaroloana ka fetisoa ka kgaoganyo le ka nako e' ngoe. E le phatsa boholo ba fepa ka e ba nyenyane, Sekhahla sebetsa sesebediswa e fokotsehile. [5] [6]

Parallel plate electrostatic separators hangata e thehiloe holim'a ho arola likaroloana eseng motheong oa conductivity, empa ka liphapang tsa k'hemistri e ka holimo e lumellang phetiso ea tefiso ea motlakase ka ho kopana ha likhohlano. Likaroloana li qosoa ka motlakase ka ho kopana ka matla le likaroloana tse ling, kapa ka bokaholimo ba boraro joalo ka tšepe kapa polasetiki e tla ba le thepa e lakatsehang ea tribo-charging. Lisebelisoa tse sebelisang motlakase (teng pheletsong e mpe ea letoto la tribo-motlakase) tlosa dieleketerone ho tswa ho tribo-charging holim 'me kahoo fumana letlooa qoso e mpe. Ho kopana, lisebelisoa tse qetellong e ntle ea letoto la tribo-motlakase li fana ka lielektrone 'me li lefisa hantle. Likaroloana tse qosoang li kenngoa sebakeng sa motlakase se hlahisoang lipakeng tsa li-electrode tse peli tse tšoanang ka mekhoa e fapaneng ea lipalangoang. (matla a khoheli, moea oa moea, thothomelo). Boteng ba sebaka sa motlakase, likaroloana tse qosoang li ea ho li-electrode tse qosoang ka tsela e fapaneng 'me li bokelloa ho li-hopper tsa lihlahisoa tse tsamaellanang. Hape, karoloana e mahareng e nang le motsoako oa makumane e ka bokelloa kapa ha ea bokelloa, ho itšetlehile ka tlhophiso ea sesebelisoa sa karohano. [4] [7]

Figure 1: Setšoantšo sa moqolo o phahameng oa khatello ea maikutlo (letsetsoa) le poleiti e bapileng e sa lefelloeng ea ho oa (hantle).

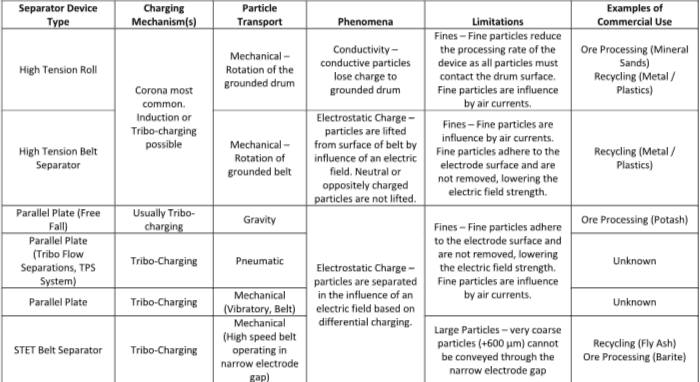

tafole 1: Kakaretso ea lisebelisoa tse atisang ho sebelisoa tsa karohano ea electrostatic.

Nyeoe 1 – Melemo ea Makala a Koro le Koro.

Lehlaka la koro ke sehlahisoa sa ho siloa ha koro ho tloaelehileng, emelang 10-15% ea tlhaka ea koro. Koro ea koro e na le likarolo tse ka ntle ho kenyeletsa le pericarp, testa, le aleurone. Koro ea koro e na le boholo ba micronutrients, faeba, le li-phytochemicals tse ka har'a lijo-thollo, tse bontšitseng melemo ea bophelo bo botle ho batho. [8] Thahasello e kholo ea ho arola le ho rua molemo matlapeng a koro ho tlalehiloe. Thahasello ea histori ea ho arola bran ea koro e ne e le ho ntlafatsa boleng le boleng ba sehlahisoa sa phofo. Leha ho le joalo, thahasello e eketsehileng tsa morao tjena e se e ile ea tlaleha ka ho hlaphoheloa dikarolo ea bohlokoa ho matlapi a korong koro.

ka 1880, Thomas Osborne patented pele khoebo electrostatic kgaoganyo bakeng sa ho tlosa matlapi a korong tloha middlings phofo. The kgaoganyo ne e ena le le meqolong e tlotsitsoeng le rabara e thata kapa lintho tse bonahalang lekanang eo e ne e le ba nang le bokhoni ba ho pellet qosoa ka tsela frictional tribo-lefisa ka ulu. Le hoja e se ho hlalositsoe, e nahana le meqolong e le rabara fumana qoso mpe amanang le ho boea, tsela e lumellanang le ho fetisisa tribo-motlakase letoto lena. The le meqolong e pellet qosoa ebe hapa sebele qosoa matlapi a korong faeba likaroloana, ho fetisa bona holim 'a moqolo ho fihlela Pinned faeba likaroloana tse brushed ho tloha holim' a moqolo le. sena (nahana) positive, tjhaja ea matlapi a korong koro e hananang le sephetho tlalehile ka ho ba bang. Tribo-tjhaja ea likaroloana le matlapi a korong ile a thusoa ke fluidizing moea hlahiswa qetellong ea sesebediswa, e neng molemong eketsehileng ba ho baka le ka tlaase ho moo le letšo-letšo matlapi a korong likaroloana ho holim'a metsi, haufi le le meqolong e le. [1]

ka 1958 sesebelisoa sa karohano ea "electrostatic" ea bran le endosperm e fumanehang ka har'a li-middlings tsa phofo li ile tsa senoloa ha Branstad a sebetsa ho General Mills.. Mochine ona o ne o e-na le searohanyi sa poleiti e bapileng eo ho eona likaroloana li neng li fetisoa pakeng tsa lipoleiti tse peli ka ho thothomela.. Likaroloana tsa lekala, e qosoa ka ho hohlana le likaroloana tsa endosperm, li ile tsa phahamisetsoa ho eleketrode e kaholimo ka li-perforations tse kaholimo ho eleketrode. [9]

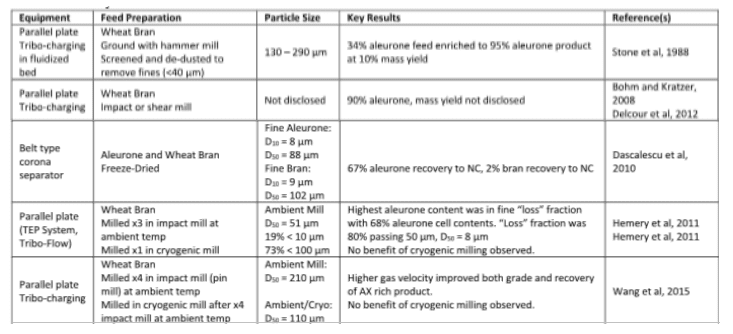

ka 1988 e sethusathuto le thulaganyo ho lopolla aleurone tloha khoebo matlapi a korong koro ile a senola ka litokelo tsa molao filing. Commercial koro matlapi a korong le qalang aleurone dikahare tsa 34% o ne a ruisa ho mamelisisa ya 95% ka 10% lihlahisoa boima (28% aleurone hlaphoheloa) ke motswako wa hamore siloa, moleposelekanyi ke screening, moea elutriation le electrostatic karohano sebelisa e tšoanang le poleiti electrostatic kgaoganyo. Likaroloana li ile tsa qosoa ka sesebediswa moea elutriator, eo e na le karolo e kopanetsoe ea ho tlosa difaene (<40 μm) ka ho fetisa, ha ka nako e le 'ngoe tribo-charging ea aleurone particles positive (ho tlaleha ho poleiti ea electrode e mpe) le likaroloana tsa pericarp/testa tse mpe. Boholo ba karoloana ea motsoako oa bran bo ne bo laoloa ka hloko ke ho sila ha hamore le ho hlahloba maemo a mangata, ho fumana phepelo e boholo bo boholo ka ho 130 - 290 µm sebaka. [10]

Mosebetsi oa morao-rao oa ho khutlisa aleurone ho tsoa ho bran ea koro o ntse o tsoela pele. ka 2008, Buhler AG e na le tokelo ea molao ea sesebelisoa sa karohano ea electrostatic bakeng sa ho arola likaroloana tsa aleurone ho tsoa ho likhetla tse entsoeng ka bran e fetotsoeng.. Sebopeho se le seng sa sesebelisoa se na le rotor e sebetsang sebakeng se senyenyane sa phekolo, e lumellang hore ho kopane le karoloana-to-particle le phatsa-to-bota le ho tjhaja tribo e latelang. Likaroloana tse qosoang li fetisetsoa ka mochini ka har'a seketsoana sa karohano se nang le li-electrode tsa parallel plate.. Likaroloana li oela ka sekepeng sa karohano ka matla a khoheli, ha likaroloana tse fapaneng tse fapaneng li ea ho li-electrode tse fapaneng ka tlas'a tšusumetso ea lebala la motlakase.. [11] Ha e kopantsoe le boholo bo nepahetseng ba bran ea phepelo le mekhoa ea ho hlopha ka mochini, aleurone concentrations ho fihlela ho 90% li tlalehiloe. [12] [8]

Figure 2: Ikatisa tloha Hemery et al a, 2007 [8].

Tribo-lefisa le Corona lefisa liteko ka matlapi a korong koro li ne li etsoa ke basebetsi ba ka Electrostatics ba qhalakantsoeng Media Unit Research, University of Poitiers, France ka 2010. Bafuputsi ba lekanya qoso holim 'me holim' nang bola nako ka matlapi a korong koro le 10% mongobo le lyophilized (hatsele-omisitsoeng) matlapi a korong koro. A teko karohano ile a etsa ka sa sampole ea 50% hatsele-omisitsoeng koro matlapi a korong le 50% hatsele-omisitsoeng aleurone fepa ka sebelisa lebanta mofuta Corona electrostatic kgaoganyo. (Figure 3) Karohano diphetho tsa kgaoganyo laboratori ea tekanyo e Corona bontša 67% ea aleurone ile a hlaphoheloa ka ho batho bao e seng mokhanni Hopper, ha feela 2% ea matlapi a korong koro tlalehile ho bao e seng mokhanni Hopper. Tribo-lefisa liteko li ile tsa boela khanneloa matlapi a korong koro le aleurone, empa feela ho lekanya itseng qoso holim [μC / g,] generated ka e mong le e karoloana, ho fapana hlaphoheloa lihlahisoa ho tloha ea karohano electrostatic. thepa bobeli fepa ka li ile tsa qosoa sebelisa Teflon ka holim 'ho ikopanya. Bobeli ba koro le aleurone li tlalehoa li lefisa tefiso e ntle ho Teflon, eo ka boyona e nang le motlakase haholo. Boholo ba tefiso bo ile ba fumanoa bo itšetlehile ka likhatello tsa ts'ebetso tse sebelisoang ho tribo-charger, ho fana ka maikutlo a hore moferefere o phahameng o lebisa ho mabitso a mangata le ho tjhaja tribo ka ho feletseng. [13]

Figure 3: E hlahisitsoe ho tsoa ho Dascalescu et al, 2010 [13]

ka 2009, bafuputsi ba ile ba lekola thepa ea ho tjhaja ka motlakase ea aleurone e ruileng le lisebelisoa tse ruileng tsa pericarp. [14] ka 2011 bafuputsi ba ile ba etsa tlhahlobo ea karohano ea electrostatic ho lisampole tsa mokoallo oa koro o fatše hamonate ba sebelisa sekhetho sa sefofane sa motlakase. (Sistimi ea TEP, Likarohano tsa Phallo ea Tribo, Lexington, usa). TEP System e sebelisa mohala oa ho tjhaja, moo makumane a phepelo a hlahiswang ka hara moya o moferefere o hatelletsoeng, le ho fetisoa ka pneumatically ka mohala oa ho tjhaja ho ea phaposing ea karohano. The likaroloana ba tribo-qosoa ke phatsa ho kopana le phatsa, mmoho le ho kopana le karoloana le bokahodimo ba mohala wa ho tjhaja. Results fumana le System tep xuong la bontša hore electrostatic karohano ne a atleha ho ntlafatsa aleurone le beta-glucan dikahare tsa matlapi a korong koro. Ho thahasellisang ke hore, le karoloana ea lintho tse bonahalang hore ile a fumanoa a ho na le phahameng ka ho fetisisa aleurone seleng e dikahare, ka 68%, e ne e le e ntle haholo (D50 = 8 μm) karoloana e ileng ea hlaphoheloa ho tswa tube lefisa. Ho ke ke ha e hlakileng hore na ke hobane'ng boitsebiso boo ile preferentially concentrated sethusathuto ho tjhaja, Leha ho le joalo, ha bontša hore ho khona ho sebetsa litaba tse ka hare li-cell aleurone ka 'na hloka dithekeniki electrostatic hore ba ka khona ho e lokisa ntle haholo powders. Ho feta moo, mosebetsi ona o ile a bontša hore fepa ka ho lokisetsa bakeng sa matlapi a korong koro e ne e le ho nahanela bohlokoa. Disampole lokisitsoeng ke cryogenic sila ka hamore leloala li fumanoe ho ka tlaase ho moo ka ho feletseng dissociated (lokolotsoeng) ho feta ba fatše ka tshusumetso mofuta leloala ka mocheso ambient. [15] [16]

Figure 4: Ikatisa tloha Hemery et al a, 2011 [16]

mosebetsi oa morao tjena o ile a ithuta ho tsepamisa mohopolo oa arabinoxylans tloha koro matlapi a korong ke mekhoa electrostatic. Bafuputsi ba sebelisoa e le laboratori ea tekanyo e electrostatic kgaoganyo e entsoeng ka ka lethopo le karohano lefisa kamoreng e nang le e tšoanang le tse peli poleiti li-electrode. Siloa koro matlapi a korong ile hlahiswa ka tube lefisa le fetisoa pneumatically kenye ka kamoreng e karohano sebelisa petetswa naetrojene. The loebehlanang le khase phahameng lebelo ka tube lefisa fane ka phatsa ikopanye le hlokahala bakeng sa tribo-tjhaja. Likaroloana tse qosoang (lihlahisoa tsa karohano) li ile tsa bokelloa ho tloha holim'a li-electrode bakeng sa tlhahlobo. Ka lebaka la mokhoa o otlolohileng oa li-electrode palo e kholo ea thepa ha ea ka ea bokelloa. Karolo ena ea li-middlings e ka sebelisoa hape bakeng sa ts'ebetso e tsoelang pele ho li-electrostatics tse tloaelehileng, Leha ho le joalo, molemong oa teko ena, lintho tse sa bokelloang holim'a li-electrode li ne li nkoa li lahlehile. Bafuputsi ba tlalehile keketseho ea boemo ba lihlahisoa ka bobeli (dikahare tsa arabinoxylan sehlahisoa) le katleho ea karohano ha lebelo la ho tsamaisa le ntse le eketseha. [17]

Boiteko ba morao-rao ba ho rua molemo matla a koro ho sebelisa mekhoa ea electrostatic e akaretsoa ka tlase ho Lethathamo 2.

tafole 2: Kakaretso ea mekhoa ea electrostatic e hlahlobiloeng ho ruisa matla a koro.

Nyeoe 2 - Pholiso ea Protheine e tsoang ho Lupine Flour

Bafuputsi ba Sehlopheng sa Boenjiniere sa Lijo sa Wageningen, Netherlands, e ile ea hlahloba monyetla oa ho matlafatsa protheine ka ho sebelisa limela tsa linaoa. Erekisi le lupine phofo li ne li sebelisoa e le fepa a sa tšoaneng ea mekhoa protheine matlafatso ho akarelletsa tlhophiso moea ho kopantswe le karohano electrostatic. Untreated erekisi le lupine dipeo ba ne ba pele siloa ho hoo e ka bang 200 μm. Feed thepa tlhophiso le electrostatic karohano ne o ile siloa sebelisa ama mofuta leloala le e classifier hare (Hosokawa-Alpine ZPS50). Bohare phatsa boholo (d50) e ile ea tlaleha ka hoo e ka bang 25 μm bakeng sa phofo erekisi, le hoo e ka bang 200 μm bakeng sa phofo lupine, pele ho sehlopha sa moea. Qetellong, karolo e nyane ea sampole ka 'ngoe, erekisi le phofo ea lupine, ka nako eo e ne e khetholloa ka moea (Hosokawa-Alpine ATP50). Phepelo ea separator ea electrostatic e ne e e-na le liforomo tse peli tse sa phekoloang, hammoho le thupelo le sehlahisoa se setle ho tsoa ho sehlopha sa moea. [18]

Sesebelisoa sa karohano ea electrostatic se sebelisitsoeng nakong ea liteko e ne e le mofuta oa poleiti e bapileng, ka tjhaja e etsoang ka triboelectric tjhaja ka 125 tube e tjhajang bolelele ba mm, e nang le likaroloana tse fetisoang ka moea ka naetrojene e petelitsoeng. sesebediswa ke tshwanang ka phetolo ho sesebediswa sebelisoa ke Wang et al a (2015). [17] Electrostatic liteko karohano ne a khanna ka phofo fatše erekisi le phofo lupine, hammoho le tsela e le bo botle le likaroloana tsa phofo erekisi le phofo lupine fumaneha tlhophiso moea. The phofo erekisi bontša feela tse nyenyane motsamao oa protheine nakong liteko electrostatic. Leha ho le joalo, phofo lupine bontša mokhatlo oa bohlokoa oa protheine ka disampole tsohle tse tharo lekoa (siloa phofo - 35% protheine, siloa classified difaene - 45% protheine, siloa classified mahoashe - 29% protheine). Lihlahisoa tse nang le protheine tse ka bang 60% li ile tsa fumanoa ka eleketrode fatše bakeng sa e 'ngoe le e 'ngoe ea lisampole tse tharo tsa lupine tse lekiloeng. [18]

Nyeoe 3 - Ho tlosoa ha Fiber ho Poone

Bafuputsi Lefapheng la Temo le Boenjineri ba Likokoana-hloko, Mississippi State University e ile ea etsa tlhahlobo ea electrostatic ka phofo ea poone e fatše, ka sepheo sa ho tlosa fiber. Sesebelisoa sa karohano sa electrostatic se ne se e-na le lebanta la conveyor le electrode e mpe e behiloeng qetellong ea conveyor.. Likaroloana tse chehiloeng hantle, likaroloana tsa fiber, boemong bona, li ile tsa ntšoa lebantang la conveyor 'me tsa hlophisoa hore e be hopper ea bobeli. Likaroloana tse se nang fiber li ile tsa oela ho tloha lebantang la conveyor ka matla a khoheli 'me tsa kenngoa ka har'a hopper ea pele ea sehlahisoa.. Bangoli ha ba hlalose hore na ho tjhaja motlakase ho etsoa joang. Lintho tse fepang karohano ena li ne li batla li le mahoashe, e nang le likaroloana tsa lijo tse tsoang ho 12 letlooeng (1,532 μm) ho 24 letlooeng (704 μm). Ha ho bonahale e le undersize (<704 μm) litaba li ile tsa sebetsoa nakong ea thuto ena. Boemo bo bong le bo bong ba teko bo phethiloe ho sebelisoa 1 lik'hilograma tsa lijo tse neng li qhalakantsoe ka mokhoa o ts'oanang lebanta. [6]

Figure 5: E hlahisitsoe ho tsoa Pandya et al, 2013 [6]

Bafuputsi ba Naha ea Mississippi ba qetile tlhahlobo ea karohano ea motlakase holim'a phofo ea poone e sa hloekisoang, likaroloana tsa phofo ea poone e hlahlobiloeng le likaroloana tse nang le fiber tse ngata tse fumanoeng ho tsoa ho sehlopha sa moea. Teko ea electrostatic ha ea phethoa melapong ea fiber e tlase e fumanoeng ho tsoa ho sehlopha sa moea. Tlhahlobo ea liphetho tsa karohano ea electrostatic e fanoe ka tlase:

tafole 3: Liphetho tsa karohano ea fiber tse hlahisitsoeng hape ho tsoa Pandya et al, 2013 [6]

Nyeoe 4 – Protein Concentration from Oilseeds

Lipeo tsa oli tse kang rapeseed (canola), soneblomo, sesame, mosetareta, kokoana-hloko ea soya, 'me flaxseed ka kakaretso e na le palo e kholo ea liprotheine le fiber. Mekhoa ea ho sebetsa ea ho tlosa fiber, 'me kahoo eketsa protheine, Lipeo tsa oli li tla ba tsa bohlokoa le ho feta ha tlhoko ea lefats'e ea protheine e eketseha. [19] Mosebetsi oa morao-rao oa bafuputsi Setsing sa Sechaba sa Fora sa Lipatlisiso tsa Temo o ile oa hlahloba ho siloa ha ultrafine ho kopantsoe le ts'ebetso ea electrostatic ea lijo tsa peo ea soneblomo., ho tsepamisa maikutlo ho protheine. The iphepe sonobolomo disampole lijo li ne li fatše ka tshusumetso leloala sebetsa ka mocheso ambient ho boholo phatsa (D50) ya 69.5 μm. The kgaoganyo electrostatic sebediswa bakeng sa liteko e ne e le e tšoanang le poleiti sesebediswa moo mathomo tjhaja mochine ne tribo-tjhaja. The tribo-tjhaja ile atlehe nyolosa tsa li-electrode ho ka mola tribo-lefisa, le likaroloana fetisoang ka mola tjhaja, le ho li-electrode ho, ka tsela lipalangoang pneumatici. Protein ile a fumanoa a ho lefisa positive, (ho tlaleha ho eleketrode mpe) le faeba e ngata karoloana ile a fumanoa a ho lefisa hlonamisitsoe. Protein selectivity ile a fumanoa a hore e be bo phahameng. Feed protheine e ne 30.8%, le protheine e ngata sehlahisoa lekanya 48.9% le protheine ha mo qeta (faeba e ngata) sehlahisoa lekanya feela 5.1% protheine. Protein hlaphoheloa ne 93% ho sehlahisoa positive,. selulose, hemicelluloses, le lignin ne lekanya 'me ba fumana ho tlaleha ho sehlahisoa hlonamisitsoe qosoa, thoko ho ea protheine. [20]

tafole 4: Diphetho tsa sonobolomo peo lijo karohano ikatisa tloha Barakat et al a, 2015 [20]

ka 2016, boithuto bo bong bo ile ba phethoa ho sebelisoa lijo tsa peō ea oli ea rapeseed, kapa likuku tsa oli ea rapeseed (ROC), joalo ka phepelo ea tšebetso ea karohano ea electrostatic. Hape ho siloa ha ultrafine ka mocheso o tikolohong ho ile ha etsoa ka sesebelisoa sa leloala la thipa (Retsch SM 100). Thepa e sililoeng, e nang le boholo bo mahareng (D50) ea hoo e ka bang 90 μm, e ne e sebetswa ka ho sebedisa searohanyi sa pilot scale parallel plate separator (Sistimi ea TEP, Likarohano tsa Phallo ea Tribo). Sistimi ea TEP e sebelisa ho tjhaja ha triboelectric ka ho tsamaisa likaroloana tsa moea ka har'a mohala o phahameng oa khatello tlas'a maemo a moferefere.. Teko e le 'ngoe ea karohano ea liphase tse nang le Sisteme ea TEP e felletse ka bongata bo boholo ba protheine, e nang le protheine ea phepo ea 37%, ka sebele qosoa sehlahisoa protheine boemo ba 47% le hlonamisitsoe qosoa sehlahisoa protheine boemo ba 25%. Tlatsetso mekhahlelo karohano ne o phethile, qetellong hlahisa protheine e ngata sehlahisoa le 51% protheine ka mor'a 3 mekhahlelo karohano latellanang. [21]

tafole 5: Diphetho tsa rapeseed oli peo lijo karohano ikatisa tloha Basset et al a, 2016 [21]

puisano

Tlhahlobo ea lingoliloeng e loketseng e bontšang hore ho etsa lipatlisiso bohlokoa e se e etsoa ho ntshetsa pele dithekeniki electrostatic karohano ya thepa manyolo. Tsoelo-pele ena e tsoetse pele kapa e bile e potlakile nakong e fetileng 10 - 20 lilemo tse, le bafuputsi ba bangata ba Europe le United States ba sebelisa mekhoa ea karohano ea electrostatic ho mathata a mangata a fapaneng a molemo.. Ho tsoa patlisisong ena, ho hlakile hore mekhoa ea electrostatic e na le monyetla oa ho hlahisa tse ncha, lihlahisoa phahame boleng dimela, kapa fana ka ya mefuta e meng ho kolobisa mekhoa sebetsa.

Le hoja e khothatsa karohano ea lijo-thollo lijo-thollo, pulses, le lisebelisoa tsa peo ea oli li bontšitsoe laboratoring le maemong a mang sekala sa liteko, litsamaiso electrostatic sebelisoa ho bontša liphetho tsena ka 'na qetellong ke la sebeletsa e le thepa e loketse ho fetisisa kapa e ka bolokang tjhelete e lokisa ho phetha karohano joalo ka motheo oa khoebo. O teng tsamaiso ea khoebo electrostatic ba ho fetisisa e atisa ho sebelisoa ka karohano oa liminerale, tšepe kapa dipolasetiki. Le liminerale le lirafshoa tse bobeli thepa e batlang e le letšo-letšo le matla a khoheli se phahameng e itseng, e le bapisoa le thepa dimela. Esita le phahameng matla a khoheli e itseng ea le liminerale le tšepe, mefokolo ea boholo ba karoloana e sebetsang bakeng sa moqomo le li-parallel plate electrostatic separators e batla e le mahoashe., e nang le likaroloana tse fokolang ka tlase 100 µm mohlala. Plastiki e na le letsoalo le tlase ho feta liminerale le tšepe empa hangata e sebelisoa ka boholo bo mahoashe., joalo ka li-flakes tsa polasetiki, mohlala. The introduction of fine particles creates operational difficulties for both high-tension roll and parallel plate separators. Hantle, likaroloana tse tlaase-tlaase li utloa bohloko haholo ho maqhubu a moea, haholo ha ho bapisoa le lirafshoa le tšepe. Phapang e nyane ea maqhubu a moea ka har'a sesebelisoa sa karohano e ama tsela ea ho tsamaea ea likaroloana tse ntle, beha hore ba mabotho a mang ho ao a bakoa ke tšimo electrostatic.

Bakeng sa tsamaiso ea ho fetisisa e tšoanang le poleiti kgaoganyo, khabeloa fatše le tlase segokanyipalo likaroloana tse electrostatically qosoa bokelloa ka li-electrode tsa separators tšoanang le poleiti. Ha tsena e metle likaroloana pellet khomaretse ha ba tlosoa ka thōko ea kamehla, le matla a motlakase tšimo le bokgoni ba sesebelisoa degrade. Mosebetsi oa bafuputsi ka ho Process Lijo Engineering Group Wageningen Ure (Wang et al a, 2015) o ile a nka monyetla ka ketsahalo ena ho bokella disampole theoha holim 'a li-electrode ea tšoanang le kgaoganyo poleiti ho sekaseka lihlahisoa tsa karohano ho. E tšoanang le poleiti tsamaiso ea kgaoganyo, haholo-holo ba hore u itšetlehe ka matla a khoheli ho fetisa likaroloana ka tšimo ea motlakase, ba ile a leka ho rarolla bothata bona ka litsela tse ngata. Stone et al a (1988) o ile a hlalosa tshebetso oo likaroloana e metle li ne li tlosoa nyolosa ba kgaoganyo electrostatic ke moea elutriation. [10] Batho ba bang ba tlalehile boloka laminar kemisong ea moea phallang ka mose li-electrode ho thibela likaroloana tse molemo tse tsoang ho susumetsoa ke maqhubu moea. [22Leha ho le joalo, boloka laminar moea o phaphamatsang fetoha thata e le sesebelisoa karohano fetoha kholoanyane, katleho fokotsa ho sebetsa matla a disebedisweng tse joalo. Qetellong phatsa boholo oo dikarolo di meleng arohile tse ling (joale e le likaroloana discrete), e tla ba mokhanni kholo ka ho fetisisa ka ho beha phatsa boholo eaba sebetsa Etlare.

Joalokaha ho boletsoe pejana, tloaelehileng electrostatic disebediswsa karohano li felle feela ka ho ba le mothamo sebetsa, especially with low-density and finely ground powders such as plant materials. For high-tension drum and belt separation devices, katleho e lekanyelitsoe ho likaroloana tse batlang li le mahoashe le / kapa tse nang le matla a khoheli a khethehileng, ka lebaka la tlhokeho ya hore makumane ohle a kopane le bokahodimo ba moropa. E le likaroloana ba nyenyane ka tekanyo e lokisa e fokotsehile. E tšoanang le separators poleiti ba ka ho eketsehileng lekanyetsoeng ke nako e phatsa segokanyipalo e ka sebetswa ka libaka eleketrode. Ho roala likaroloana ho tlameha ho ba tlase ho thibela litlamorao tsa tefiso ea sebaka.

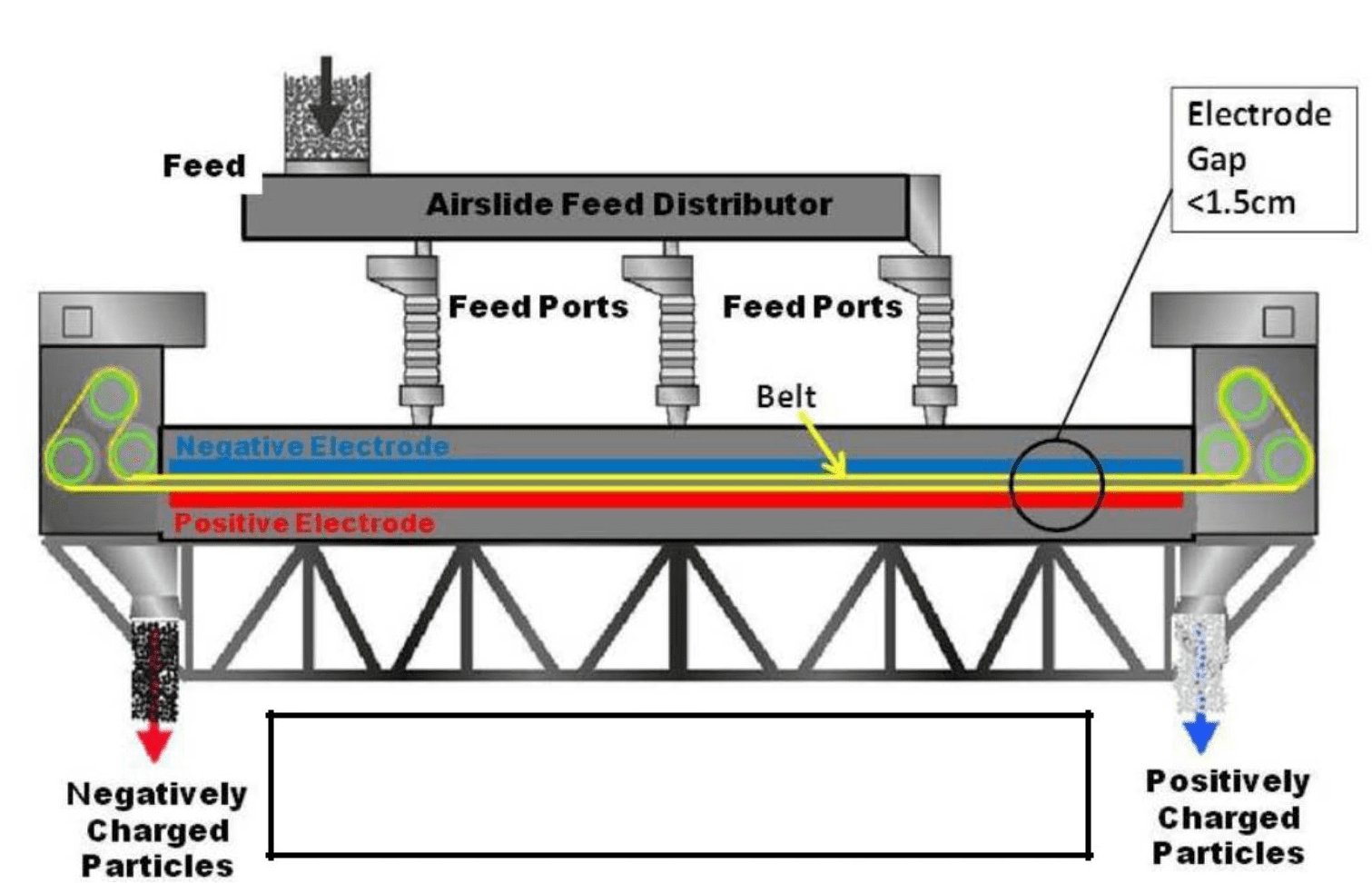

ST Helmets & Theknoloji Belt Separator

The ST Helmets & Technology (STET) triboelectrostatic lebanta kgaoganyo o na le o ile a bontša bokgoni ho sebetsa likaroloana tse molemo tse tsoang 500 - 1 μm. The STET separator ke parallel poleiti electrostatic separator, Leha ho le joalo, lipoleiti tsa li-electrode li lebisitsoe ka holimo ho fapana le ho ea holimo joalo ka ha ho le joalo ho li-separators tse ngata tse bapileng.. (sheba Figure 6) Ho feta moo, le STET kgaoganyo finyelloang ka phatsa tribo-lefisa le ho fetisa ka nako ke e phahameng-lebelo bulehileng letlooeng conveyor lebanta. Tsobotsi ena lumella bobeli e phahameng haholo sekhahla itseng e lokisa ya fepa ka, hammoho le bokgoni ba ho sebetsa powders molemo haholo ho feta le disebediswa tse tloaelehileng electrostatic. mofuta ona wa sesebediswa karohano e bile sebetsa khoebo ho tloha 1995 arola unburned k'habone tloha fofa liminerale molora (tloaelehileng D50 hoo e ka bang 20 μm) limeleng mashala-lelekoa matla. Sena electrostatic karohano sesebediswa o boetse o atlehile ho beneficiating thepa e 'ngoe inorganic, ho akarelletsa le liminerale tse kang k'halsiamo carbonate, talc, barite, le ba bang.

Lintlha tsa motheo tsa kgaoganyo STET li bontšitsoe Figure 7. likaroloana a qosoa ke phello triboelectric ka thulana phatsa-to-phatsa hara lekhalo pakeng tsa li-electrode ho. The gagamalo sebelisoa pakeng tsa li-electrode ke pakeng tsa ± 4 le tse 10 ± kV amanang le ho fatše, ho fana ka kakaretso gagamalo phapang ea 8 - 20 kV ka mose ho lekhalo le moqotetsane haholo la eleketrode ea ka lebitso 1.5 cm (0.6 lisenthimithara). Likaroloana tsa phepelo li hlahisoa ho karohano ea STET sebakeng se seng sa libaka tse tharo (Fepa Ports) ka mochini o tsamaisang li-slide tsa moea o nang le li-valve tsa heke ea thipa. The STET karohano hlahisa lihlahisoa tse peli feela, phatsa e nang le qoso e mpe e bokelletsoeng holim'a electrode e nang le qoso e ntle, le phatsa e nang le qoso e ntle e bokelletsoeng holim'a electrode e nang le qoso e mpe. Lihlahisoa li fetisetsoa ho li-hoppers tse fapaneng pheletsong e 'ngoe le e' ngoe ea karohano ea STET ka lebanta la karohano 'me li fetisetsoa ka ntle ho karohano ka matla a khoheli.. The STET karohano ha hlahisa middlings kapa recycle molapo, le hoja mekhoa e mengata ea ho feta ho ntlafatsa bohloeki ba sehlahisoa le / kapa ho hlaphoheloa ho khoneha.

Figure 6: STET Triboelectric Belt Separator

Likaroloana tse fetisoang ka lekhalo eleketrode (libaka karohano) ke sekgoqetsane tsoelang pele, bulehileng letlooeng lebanta. Lebanta sebetsang ka phahameng lebelo, polygonal tswa 4 ho 20 Mof (13 - 65 feat / s). The le geometry ba lebanta le sebeletsa ho fiela likaroloana o motle theoha holim 'a li-electrode ho, ho thibela ho bokella likaroloana tse ntle tseo degrade tshebetso le gagamalo tšimo wa marena mahala-ho oa e tšoanang le poleiti disebediswsa mofuta karohano. Holim'a moo, lebanta la etsa chelete e fetisisang phahameng, phahameng libaka loebehlanang pakeng tsa li-electrode ho ba babeli, kgothaletsa tribo-tjhaja. The stats-hona joale ho tsamaea ba lebanta kgaoganyo dumella tjhaja tswelang pele mme botjha tjhaja kapa likaroloana hara kgaoganyo ho, ho felisa ho hlokahala hore tsamaiso ea pele ho lefisa nyolosa ba kgaoganyo STET.

Figure 7: Metheo e ya tshebetso ya STET lebanta la kgaoganyo

The STET kgaoganyo ke phahameng sekhahla iphepe, ka mokhoa oa thekiso proven tsamaiso e khopo e lokisa. The lebetsoeng le e lokisa bokgoni ba kgaoganyo STET ke hangata mosebetsi oa volumetric sekhahla fepa ka e ka fetisoang ka lekhalo eleketrode ke STET kgaoganyo lebanta. Liphetoho tse ling, joalo ka lebelo la lebanta, sebaka se pakeng tsa li-electrode le segokanyipalo aerated ea phello phofo palo e kahodimodimo fepa ka lebelo, hangata ho isa tekanyong e nyane. Bakeng sa lisebelisoa tse batlang li le ngata haholo, ka mohlala, fofa molora, tekanyo e phahameng ea ts'ebetso ea a 42 intshi (106 cm) eleketrode bophara khoebo karohano yuniti ke hoo e ka bang 40 - 45 Lithane ka hora ea lijo. Bakeng sa lisebelisoa tse fokolang tsa phepo, boholo ba sekhahla sa phepelo se tlase.

tafole 6: Sekhahla sa phepelo e ka bang boholo ba lisebelisoa tse fapaneng tse sebetsitsoeng ka STET 42 inch electrostatic separator.

Dust ho phatloha ke kotsi e khōlō ea lijo-thollo le ho tse ling tse phofo manyolo tshebetso sebetsa. The STET kgaoganyo ke a loketse bakeng sa sebetsana combustible powders manyolo ka diphetolo nyenyane feela. Ha ho na bokaholimo halefile ka kgaoganyo STET. Likarolo feela ho fallela ke kgaoganyo lebanta le drive rollers. dibering The rolara leng teng ntle ho kemisong phofo ka khetla Link ea unit trust e. Ka lebaka leo, ba ne ba ha e kotsi ho overheating / sparking kemisong tse bonahalang. Ho feta moo, li-bearings tsa STET li fumaneha ka matla a fektheri a kenyellelitsoeng mocheso ho lemoha ho hloleha ho beha hantle pele mocheso o kotsi o fihla.. Lebanta la ho arola le tsamaiso ea koloi ha li na kotsi e kholo ho feta mechine e meng e tloaelehileng e potolohang. Likarolo tsa karohano tsa STET tse phahameng tsa motlakase li boetse li fumaneha ka ntle ho molapo oa lintho tse bonahalang 'me li fumaneha ka matlung a nang le lerole.. Matla a palo e kahodimodimo ea tlhase e ka mose ho lekhalo kgaoganyo e felle feela ka ho moralo la metsoako e phahameng gagamalo. Boemo bo eketsehileng tsa polokeho ka hlahiswa ka tsela naetrojene purging.

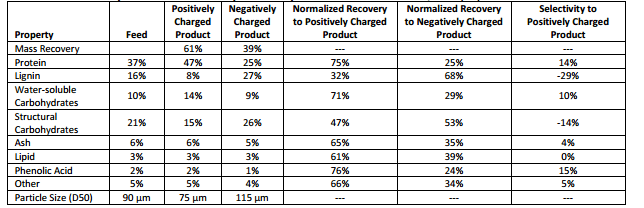

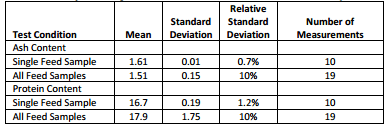

Whole Wheat Flour Processing ke STET la kgaoganyo

Whole phofo koro le tsoa ho sila lijo-thollo tsohle tsa koro (matlapi a korong, kokoana-hloko, le endosperm). ka mokhoa oa thekiso e fumanehang, e felile rakeng, phofo e feletseng ea koro e ile ea rekoa bakeng sa ho sebelisoa e le lisebelisoa tsa teko ho hlahloba bokhoni ba karohano ea STET ea ho tlosa bran ea fibrous le kokoana-hloko ho tloha karolong e 'ngoe ea endosperm ea starchy ea phofo ea koro.. Sample eohle ea phofo ea koro e ile ea hlahlojoa ke STET pele ho qala tlhahlobo. Litaba tsa molora li ile tsa lekoa ke ICC Standard 104 / 1 (900° C). Litekanyo tse phetoang tsa molora tsa sampole e tšoanang, sampole ya phepelo e sa arohanang, lekantsoeng 10 linako, li fumanoe li na le litaba tsa molora oa 1.61%, kheloha e tloaelehileng ea 0.01 le kheloha e lekanyelitsoeng ea maemo a 0.7%. Phatsa boholo and analysis e ile ea phethoa ka mong bang laser diffraction sebelisa Malvern Mastersizer 3000 le sethusathuto omileng hasana. and analysis protheine ile a khanna ho sebelisa mokhoa Dumas, ka mathomo ka potlako N feta naetrojene / protheine semanolli. A ho sokoloha le palokatiso ya N x, 6.25 e ne e sebelisetsoa. The thepa e sa tšoaneng ea kaofela phofo koro sampole di akaretsa tlase. (sheba Lethathamo 7)

tafole 7: Ho hlahloba bohle ba phofo koro fepa ka ke STET

Ash dikahare le dikahare protheine ile a fumanoa ho repeatable haholo ha lekoa ka sampole e tšoanang, empa phapang e khōlō e ile ea tsejoa pakeng tsa mekotla e mengata ea phofo ea koro e sebelisoang e le mohlala oa lijo. (sheba Lethathamo 8) Phapang ea sampole ena ea phepelo e bakile ho hasana ho itseng ho data ea liteko.

tafole 8: Tlhahlobo ea liphetho tsa tlhahlobo ea karohano ea phofo ea koro e felletseng ka STET

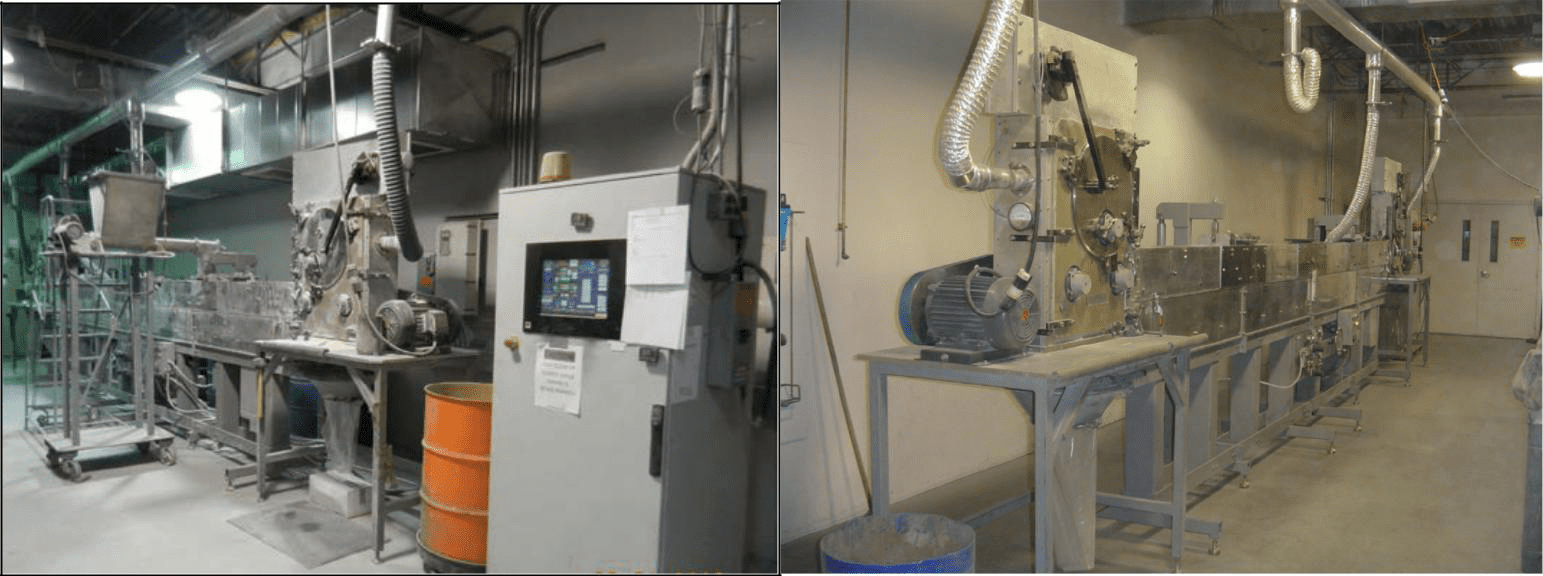

Teko ea karohano ea motlakase ea sampole eohle ea phofo ea koro e ile ea etsoa Setsing sa ST & Technology (STET) setsi sa lifofane sa Needham, Massachusetts. Semela sa liteko sa STET se na le li-separators tse peli tsa liteko tsa STET hammoho le lisebelisoa tse tlatselletsang tse sebelisoang ho batlisisa karohano ea thepa ho tsoa mehloling ea bonkgetheng.. The pilot-scale STET separators ke bolelele bo lekanang le separator ea STET ea khoebo, ka 30 maoto (9.1 limithara tse) nako e telele, Leha ho le joalo, sefofane sa sefofane karohano eleketrode bophara ke feela 6 lisenthimithara (150 limilimithara), kapa karolo ea bosupa ea bophara ba kholo ka ho fetisisa khoebo STET karohano ka 42 lisenthimithara (1070 limilimithara) bophara ba electrode. Bokhoni ba ho fepa ba karohano ea STET bo lekana ka ho toba le bophara ba li-electrode, ka hona, Sekhahla fepa ka tsa kgaoganyo motsamaisi dimela ke e 'ngoe-ea bosupa ka tekanyo fepa ka tsa 42 lisenthimithara lohle khoebo kgaoganyo unit trust. The lebetsoeng le fepa ka sekhahla le phofo kaofela koro e ne e le 2.3 Boima ba lithane tse ka hora ka motsamaisi tekanyo e, eo e tšoana le 16 Boima ba lithane tse ka hora bakeng sa 42 lisenthimithara lohle kgaoganyo khoebo. Ha ho bapisoa ho tekanyo e le moo ba boholo ba lithuto tsa electrostatic karohano di khanna ho letsatsi, ho etsa liteko STET kgaoganyo ile phethahatsoa ka lebelo haholo e phahameng iphepe. Testing ile etsoa 10 kg (20 ponto) liteko methaka, ka lebaka la ho nahanelwa ea sebetsang oa fa 2.3 Boima ba lithane tse ka hora ya fepa ka tswelela pele. Bakeng sa e mong le e boemo ba teko methaka, lihlahisoa tsa tshebetso karohano ne boima ho a bale le boima hlaphoheloa. Subsamples le e mong le teko ba ne ba bokella le ho hlahloba bakeng sa molora dikahare le dikahare protheine.

Figure 8: STET Pilot Plant la kgaoganyo.

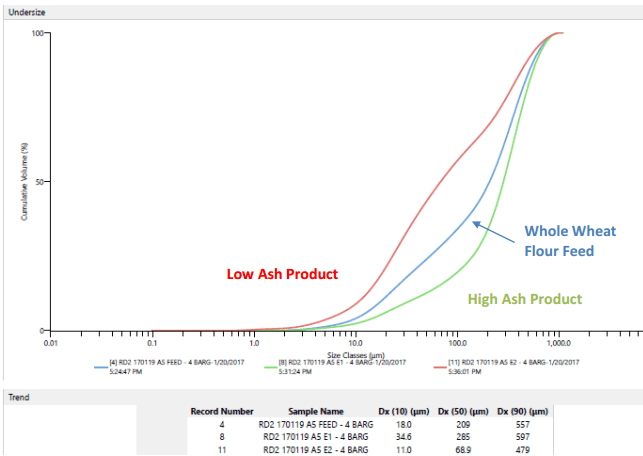

Phatsa boholo tekanyo ea kaofela phofo koro fepa ka le disampole sehlahisoa tse peli e bontšitsoeng tlaase mona ka Figure 9.

Figure 9: Phatsa boholo tekanyo ea kakaretso koro fepa ka phofo, me bao ba babeli disampole arohane sehlahisoa.

Setshwantsho sa lihlahisoa hlaphoheloa karohano e kenyelelitsoe tlase. (sheba Figure 10) A bonahala 'mala battlefield ile a hlokomela nakong karohano ya, eo ea phahameng molora dikahare sehlahisoa karoloana le leso kudu haholo ho feta fepa ka kakaretso koro phofo sampole.

Figure 10: lihlahisoa tloaelehileng hlaphoheloa ho tswa ho STET thulaganyou e karohano.

Ash dikahare tsa lihlahisoa tsohle ho tswa ho tshebetso karohano ile lekanya. (sheba Figure 11)

Figure 11: Ash dikahare e bapisiwa le hlaphoheloe boima ba sehlahiswa tlaase molora bakeng sa bohle ba phofo koro karohano liteko ke STET

Testing a STET electrostatic kgaoganyo ka kakaretso phofo koro bontša mokhatlo oa bohlokoa oa molora phahameng (matlapi a korong) karoloana ya khenele koro ho eleketrode positive,. The fokotswa molora sehlahisoa ile hamorao bokella ka eleketrode mpe. Testing ile a etsa ka morero le 'ngoe fetisetsana, Leha ho le joalo, ho ka etsahala ho etsa malebela ho eketsehileng ka lihlahisoa karohano ka ho etsa sethaleng e mong karohano. Teko ea nako e tlang le searohanyi sa STET e tla etsoa ka lisampole tsa bran ea koro, hammoho le phofo poone le legumes kang Lupine.

Nahanisisa

Tlhahlobo ea lingoliloeng e loketseng e bontšang hore ho etsa lipatlisiso bohlokoa e se e etsoa ho ntshetsa pele dithekeniki electrostatic karohano ya thepa manyolo. Tsoelo-pele ena e tsoetse pele kapa e bile e potlakile nakong e fetileng 10 - 20 lilemo tse, le bafuputsi ba bangata ba Europe le United States ba sebelisa mekhoa ea karohano ea electrostatic ho mathata a mangata a fapaneng a molemo.. Ho tsoa patlisisong ena, ho hlakile hore mekhoa electrostatic na le monyetla oa ho hlahisa e ncha, lihlahisoa phahame boleng dimela, kapa fana ka ya mefuta e meng ho kolobisa mekhoa sebetsa. Leha ho kgothaletsa karohano ea koro, poone le dimela thepa lupine thehiloeng di a bontša ka laboratoring le ka ba bang ba tekanyo e Maemong a motsamaisi, litsamaiso electrostatic sebelisoa ho bontša liphetho tsena ka 'na ha e-ba se loketseng ho fetisisa kapa e ka bolokang tjhelete thepa e lokisa ho phetha karohano joalo ka motheo oa khoebo. theknoloji e ngata electrostatic ha a loketse bakeng sa thulaganyou e khabeloa fatše, tlase segokanyipalo powders kang thepa ea dimela. Leha ho le joalo, le ST Helmets & Technology (STET) triboelectrostatic lebanta kgaoganyo o na le o ile a bontša bokgoni ho sebetsa likaroloana tse molemo tse tsoang 500 - 1 μm ka lebelo le phahameng. The STET lebanta kgaoganyo ke palo e phahameng, industrially proven sebetsa sesebediswa hore e ka ba se loketseng ho commercialize liketsahalo tsa morao tjena ka sebetsa dimela tse bonahalang. The STET lebanta separator e ile ea lekoa ka sampole ea phofo ea koro 'me ho ile ha fumanoa hore e atlehile ho tlosa bran ho tloha karoloana ea starch.. Teko ea nako e tlang le searohanyi sa STET e tla etsoa ka lisampole tsa bran ea koro, hammoho le phofo poone le linaoa tse kang soya le lupine.

References

[1] T. B. Osborne, “Middlings-Purifier”. United States of America Patent 224,719, 17 February 1880.

[2] H. Manouchehri, k. Hanumantha Rao and K. Forsberg, “Tlhahlobo ea mekhoa ea karohano ea motlakase – Karolo 1: likarolo tse ka sehloohong,” liminerale & Processing Metallurgical, volume. 17, ha ho na. 1, maq. 23-36, 2000.

[3] J. Moholo le E. Yan, “eForce – Moloko o mocha ka ho fetisisa oa karohano ea motlakase bakeng sa indasteri ea lehlabathe la liminerale,” Sebokeng sa Liminerale tse Boima, Johannesburg, 2003.

[4] R. H. Perry le D. w. Botala, Baenjiniere ba Lik'hemik'hale ba Perry’ Bukana ea Seventh Edition, New york: McGraw-Hill, 1997.

[5] S. Molaetsa, R. moqhaka, ke. Chetan, R. Ouiddir, k. Medles le L. Dascalescu, “Electrostatic separator bakeng sa metsoako ea micronized ea tšepe le polasetiki e tsoang litšila tsa lisebelisoa tsa motlakase le tsa elektroniki.,” Journal of Physics, volume. 646, maq. 1-4, 2015.

[6] T. S. Pandya, R. Srinivasan le C. P. Thompson, “Faeba arohana bakeng Ground Corn Flour sebelisa e Electrostatic Method,”lijo-thollo k'hemistri, volume. 90, ha ho na. 6, maq. 535-539, 2013.

[7] L. Brands, P. M. Beier, 'me ke. Stahl, Electrostatic arohana, Weinheim: Wiley VCH Verlag GmbH & Co. KGaA, 2005.

[8] le. Hemery, X. Rouau, V. Lullien-Pellerin, C. Barron le J. Abecassis, “thulaganyou e Dry ho ntshetsa pele koro dikotwana le lihlahisoa le ntlafatsoa phepo e nepahetseng boleng,” Journal of thollo Saense, ha ho na. 46, maq. 327-347, 2007.

[9] w. A. Brastad le E. C. Gear, “Mokhoa le didiriswa tse di tlwaeditsweng bakeng Electrostatic arohana”. United States of America Patent 2,848,108, 19 Phato 1958.

[10] B. A. Lejoe le J. Minifie, “Hlaphoheloa tsa Lisele Aleurone tloha Wheat tsa matlapi a korong”. United States of America Patent 4,746,073,24 E se eka 1988.

[11] A. Boehm le A. mengoapo, “Mokhoa bakeng sa ho itšehla Aleurone likaroloana”. United States of America Patent 7,431,228, 7 Mphalane 2008.

[12] J. A. Delcour, X. Rouau, C. M. Courtin, k. Poutanen le R. Ranieri, “Technologies bakeng sa hanyapetsoa ntlafatsoa tsa bokgoni ba tsa bophelo bo botle-kgothaletsa ea lijo-thollo,” Trends ka Lijo Saense & Technology, maq. 1-9, 2012.

[13] L. Dascalescu, C. Dragan, M. Bilici, R. botle, le. Hemery le X. Rouau, “Electrostatic Motheo tsa arohana ea Koro tsa matlapi a korong lisele,” Ditransekshene IEEE ka Dikopo Industry, volume. 46, ha ho na. 2, maq. 659-665, 2010.

[14] le. Hemery, X. Rouau, C. Dragan, R. Bilici le L. Dascalescu, “Electrostatic thepa ea matlapi a korong koro le le dikarolo tsa lona constitutive: Tšusumetso ea phatsa boholo, sebopeho, le dikahare mongobo,” Journal of Lijo Engineering, ha ho na. 93, maq. 114-124, 2009.

[15] le. Hemery, M. Curnd, The. Holopainen, A.-M. mabone, P. Lehtinen, V. piironen, A. Sadoudi le X. Rouau, “Ba fractionation omileng ea matlapi a korong koro bakeng sa ntshetsopele ya metsoako ea lijo, karolo ke: Tšusumetso ea sila marang-o motle,” Journal of thollo Saense, ha ho na. 53, maq. 1-8, 2011.

[16] le. Hemery, The. Holopainen, A.-M. mabone, P. Lehtinen, T. joang bo, V. piironen, M. Edlemann le X. Rouau, “Ba fractionation omileng ea matlapi a korong koro bakeng sa ntshetsopele ya metsoako ea lijo, karolo II: Electrostatic karohano ya likaroloana,” Journal of thollo Saense, ha ho na. 53, maq. 9-18, 2011.

[17] J. Wang, E. Smits, R. M. Boom, le M. A. Schutyser, “Arabinoxylans concentrates tloha matlapi a korong koro ke karohano electrostatic,” Journal of Lijo Engineering, ha ho na. 155, maq. 29-36, 2015.

[18] P. J. Pelgrom, J. Wang, R. M. Boom, le M. A. Schutyser, “Pele- le poso-kalafo ntlafatsa protheine matlafatso ho tswa ho sila le moea tlhophiso ea legumes,” Journal of Lijo Engineering, ha ho na. 155, maq. 53-61, 2015.

[19] D. Chereau, P. Videcoq, C. Ruffieux, L. Pichon, J.-C. Motte, S. Belaid, J. Ventureira le M. Lopez, “Motsoako oa theknoloji e badileng le mefuta e meng ho kgothaletsa oilseeds le linaoa liprotheine ka dikopo lijo,” Lipeo tsa oli & mafura Lijalo le Lipids, volume. 23, ha ho na. 4, maq. 1-11, 2016.

[20] A. Barakat, F. Jerome le X. Rouau, “Sethala Dry tsa arohana liprotheine tloha Biomass-E Nang

Polysaccharides, Lignin, le Polyphenols,” ChemSusChem, volume. 8, maq. 1161-1166, 2015.

[21] C. Basset, S. Kedidi le A. Barakat, “lik'hemik'hale- le Solvent-Free Mechanophysical Fractionation tsa Biomass hlohlelletsoa ke Tribo-Electrostatic tjhaja: Karohano liprotheine le Lignin,” ACS ntshetsopele e tshwarellang ya k'hemistri & Engineering, volume. 4, maq. 4166-4173, 2016.

[22] J. M. Stencel, J. L. Schaefer, H. Ban, le J. k. Neathery, “Sethusathuto le Method tsa arohana Triboelectrostatic”.United States of America Patent 5,938,041, 17 Phato 1999.