Roghnaigh Teanga:

Kyle Flynn, Abhishek Gupta, Frank Hrach

Abstract

Léiríonn athbhreithniú ar an litríocht ábhartha uile atá curtha taighde suntasach déanta a chur i bhfeidhm leictreastatach

Teicnící deighilte a thriomú bia plandaí-bhunaithe granular (i.e., orgánach) ábhair. Tá sé seo forbairt luathaithe san am atá thart 10 - 20 blianta, with many researchers in Europe and the United States applying scaradh leictreastatach techniques to a wide variety of beneficiation challenges. Ón taighde, is léir go bhfuil modhanna leictreastatach an cumas a ghiniúint nua, táirgí plandaí níos airde-luach, nó a thairiscint rogha eile fliuch modhanna próiseála. Cé idirscarthaí spreagadh gráin arbhair, pulse and oilseed materials have been demonstrated at the laboratory and in some cases, pilot scale, the electrostatic systems used to demonstrate these results may not be suitable or cost-effective processing equipment to perform such separations on a commercial basis. Many electrostatic technologies are not suitable for process finely ground, low-density powders such as plant materials. ach, an Equipment ST & teicneolaíocht (STET) triboelectrostatic belt separator has the demonstrated capability to process fine particles from 500 - 1 m. The STET belt separator is a high-rate, industrially cruthaithe gléas próiseála d'fhéadfadh a bheith oiriúnach a thráchtálú na forbairtí is déanaí i bpróiseáil ábhar orgánach. Rinneadh tástáil ar an deighilteoir crios STET ar shampla de plúr cruithneachta ar fad agus fuarthas amach a bheith rathúil i bhaint an bran ón codán stáirse. Beidh tástáil amach anseo leis an deighilteoir STET a dhéanamh ar shamplaí bran cruithneacht, plúr coirce

agus de phulsanna nós soy agus lupine.

Keywords: Fine-leictreastatach, leictreastatach, Scaradh, codánúcháin, cruithneacht, grán, plúr, Fiber, próitéin, síolta ola, Pulses

Réamhrá

Electrostatic separation methods have been utilized for the past 50 years on the commercial-scale beneficiation of

industrial minerals and recycling of waste materials. Electrostatic beneficiation of dry granular plant-based food (i.e, orgánach) materials have been investigated for over 140 blianta, with the first patent for electrostatic separation of wheat flour middlings filled as early as 1880. [1] Electrostatic beneficiation allows for separations based on differences in surface chemistry (work function) or dielectric properties. In some instances, Ní bheadh na idirscarthaí indéanta ag baint úsáide as méid nó dlús idirscarthaí ina n-aonar. oibriú córais scaradh leictreastatach ar phrionsabail den chineál céanna. Go bhfuil gach córas scaradh leictreastatach córas chun iad a mhuirearú go leictreach na cáithníní, réimse leictreach a ghintear go seachtrach do dheighilt go dtarlóidh i, agus modh cáithníní iompar isteach agus amach ar an gléas scaradh. Is féidir le muirir leictreach tarlú trí mhodhanna amháin nó níos mó lena n-áirítear ionduchtúchán seoltaí, tribo-mhuirearú (leictriú teagmhála) agus ian nó Coróin mhuirearú. Electrostatic separation systems utilize at least one of these charging mechanisms. [2]

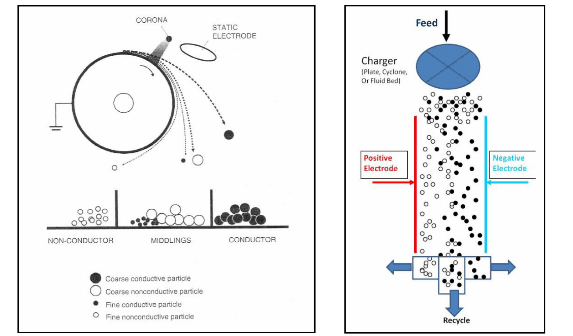

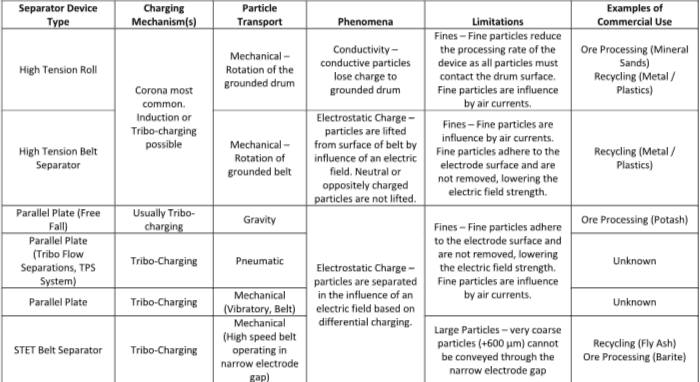

High tension roll electrostatic separation systems have been used in many industries and applications where one

the component is more electrically conductive than the others. Examples of applications for high tension roll separators include titanium bearing minerals separation, as well as recycling applications, for example sorting metal from plastic. There are multiple variations and geometries used for high tension roll systems, but in general, they operate on similar principles. Feed particles are charged negatively by an ionizing corona discharge. Feed particles are dispersed onto a rotating drum, where the drum is electrically grounded. The electrically conductive particles give up their charge upon contacting the surface of the grounded drum. The rotation of the drum causes the conductive particles to be thrown from the surface of the drum and deposited in the first product hopper. The non-conductive particles retain their electrical charge and are pinned to the surface of the drum. Eventually, the electrical charge on the non-conductive particles will dissipate, or the particles will be brushed from the drum after the drum has rotated so that the non-conductive particles are deposited in the non-conductive particle hopper. In some applications, a middlings hopper is placed between the conductive and non-conductive product hopper. The effectiveness of this type of separation device is generally limited to particles which are relatively coarse and/or have high specific gravity, due to the need for all particles to contact the surface of the drum. Freisin, particle flow dynamics is important as angular momentum is ultimately responsible for conveying the particles from the surface of the drum to the respective product hoppers. Fine particles and low-density particles are easily influenced by air currents and thus less likely to be thrown from the drum in a predictable area. [2] [3] [4]

The high tension belt separator is a variant of the high tension roll separator described above. Feed particles are dispersed evenly across the width of an electrically grounded conveyor belt. Particles are charged, usually by a negative corona, although other mechanisms of charging are possible. Again the conductive particles give their electrical charge up to the grounded conveyor belt, while the non-conductive particles retain their charge. The conductive particles fall off of the edge of the belt by gravity, while the charged non-conductive particles are “lifted” off of the surface of the belt by electrostatic forces. Again for the separation to be effective, each particle must contact the surface of the belt to allow for the conductive particles to give up their charge to the belt. Mar sin, only a single layer of particles can be conveyed by the separator at one time. As the particle size of the feed becomes smaller, the processing rate of the device is reduced. [5] [6]

Parallel plate electrostatic separators are typically based upon separating particles not on the basis of conductivity, but on differences in surface chemistry that allows for electrical charge transfer by frictional contact. Particles are electrically charged by vigorous contact with other particles, or with a third surface such as a metal or plastic will the desired tribo-charging properties. Materials that are electronegative (located on the negative end of the tribo-electric series) remove electrons from the tribo-charging surface and thus acquire a net negative charge. In contact, materials that are on the positive end of the tribo-electric series donate electrons and charge positively. The charged particles are then introduced into an electrical field generated between the two parallel plate electrodes by various transportation means (gravity, pneumatic, vibration). In the presence of the electric field, the charged particles move towards the oppositely charged electrodes and are collected at the corresponding product hoppers. Arís, a middlings fraction containing a mixture of particles may or may not be collected, depending on the configuration of the separation device. [4] [7]

figiúr 1: Léaráid de deighilteoir rolla teannas ard (D'fhág) agus plátaí comhthreomhara deighilteoir titim saor in aisce (ceart).

Tábla 1: Achoimre ar feistí scaradh leictreastatach a úsáidtear go coitianta.

Cás 1 - Cruithneacht agus Cruithneacht Bran beneficiation.

Is bran cruithneachta a trí-táirge de muilleoireacht cruithneachta traidisiúnta, a ionadaíonn 10-15% an grán cruithneachta. Is éard atá Bran Cruithneacht de shraitheanna seachtracha lena n-áirítear an pericarp, ceann, agus aleurone. Tá bran cruithneachta is mó de na micronutrients, snáithín, agus phytochemicals atá i gráin, a beidh sé taispeánta acu sochair sláinte atá teagmhálach don duine. [8] Significant interest in separating and beneficiating wheat bran has been reported. Historical interest in separating wheat bran was to improve the quality and the value of the flour product. ach, more recent interest has been reported in recovering valuable components from wheat bran.

in 1880, Thomas Osborne patented the first commercial electrostatic separator for removing bran from flour middlings. An deighilteoir comhdhéanta de rollaí brataithe le rubair chrua nó ábhar coibhéiseach a bhí féidir iad a mhuirearú go leictreach trí frictional tribo-mhuirearú le olann. Cé nach bhfuil cur síos, glactar leis na rollaí rubair a fuarthas lucht diúltach i gcoibhneas le olann, tagann sí le formhór sraith tribo-leictreacha. Na rollaí mhuirear leictreachas mheall ansin na cáithníní snáithín bran luchtaithe go deimhneach, iompar iad ar dhromchla an rolla go dtí go bhfuil na cáithníní snáithín pinned brushed ó dhromchla an rolla. seo (Glactar leis) Is mhuirearú dearfach na bran cruithneacht i gcoimhlint le torthaí a thuairiscigh daoine eile. Tugadh cúnamh Tribo-mhuirearú na cáithníní bran d'aer fluidizing isteach ag bun an gléas, a bhí an leas breise trína ndearnadh na cáithníní bran níos lú dlúth leis an dromchla, níos gaire don rollaí. [1]

in 1958 gur nochtadh gaireas do dheighilt leictreastatach bran agus inspeirm atá i meánaigh plúr i chomhdú paitinne ag Branstad ag obair ag General Mills. The device consisted of a parallel plate separator in which particles were conveyed between the two plates by vibration. Bran particles, charged by frictional contact with endosperm particles, were then lifted to the top electrode through perforations in the top electrode. [9]

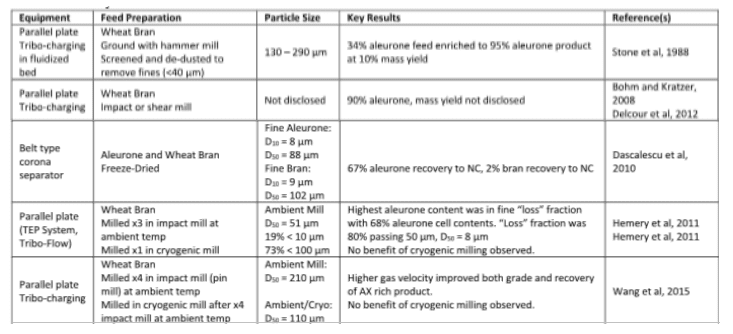

in 1988 an apparatus and process for recovering aleurone from commercial wheat bran was disclosed in a patent filing. Commercial wheat bran with a starting aleurone content of 34% was enriched to a concentrate of 95% at 10% mass yield (28% aleurone recovery) trí mheascán de mhuilleoireachta casúr, sizing le scagadh, elutriation aeir agus scaradh leictreastatach ag baint úsáide as plátaí comhthreomhara deighilteoir leictreastatach. gearradh Cáithníní san gléas elutriator aer, a bhfuil ról déach fíneálacha a bhaint (<40 m) by conveying, while simultaneously tribo-charging the aleurone particles positive (reporting to the negative electrode plate) and the pericarp/testa particles negative. The particle size of the bran mixture was carefully controlled by hammer milling and multi-level screening, to obtain a feed mostly sized in the 130 - 290 µm range. [10]

Recent work on recovering aleurone from wheat bran continues. in 2008, Buhler AG patented an electrostatic separation device for separating aleurone particles from shell particles made of commuted bran. One embodiment of the device consists of a rotor operating in a narrowly sized treatment area, which allows for particle-to-particle and particle-to-wall contact and subsequent tribo-charging. The charged particles are then conveyed mechanically into a separation vessel containing parallel plate electrodes. Particles fall through the separation vessel by gravity, as the differentially charged particles move toward the oppositely charged electrodes under the influence of the electric field. [11] When combined with proper sizing of the feed bran and mechanical sorting methods, aleurone concentrations of up to 90% have been reported. [12] [8]

figiúr 2: Macasamhail ó Hemery et al, 2007 [8].

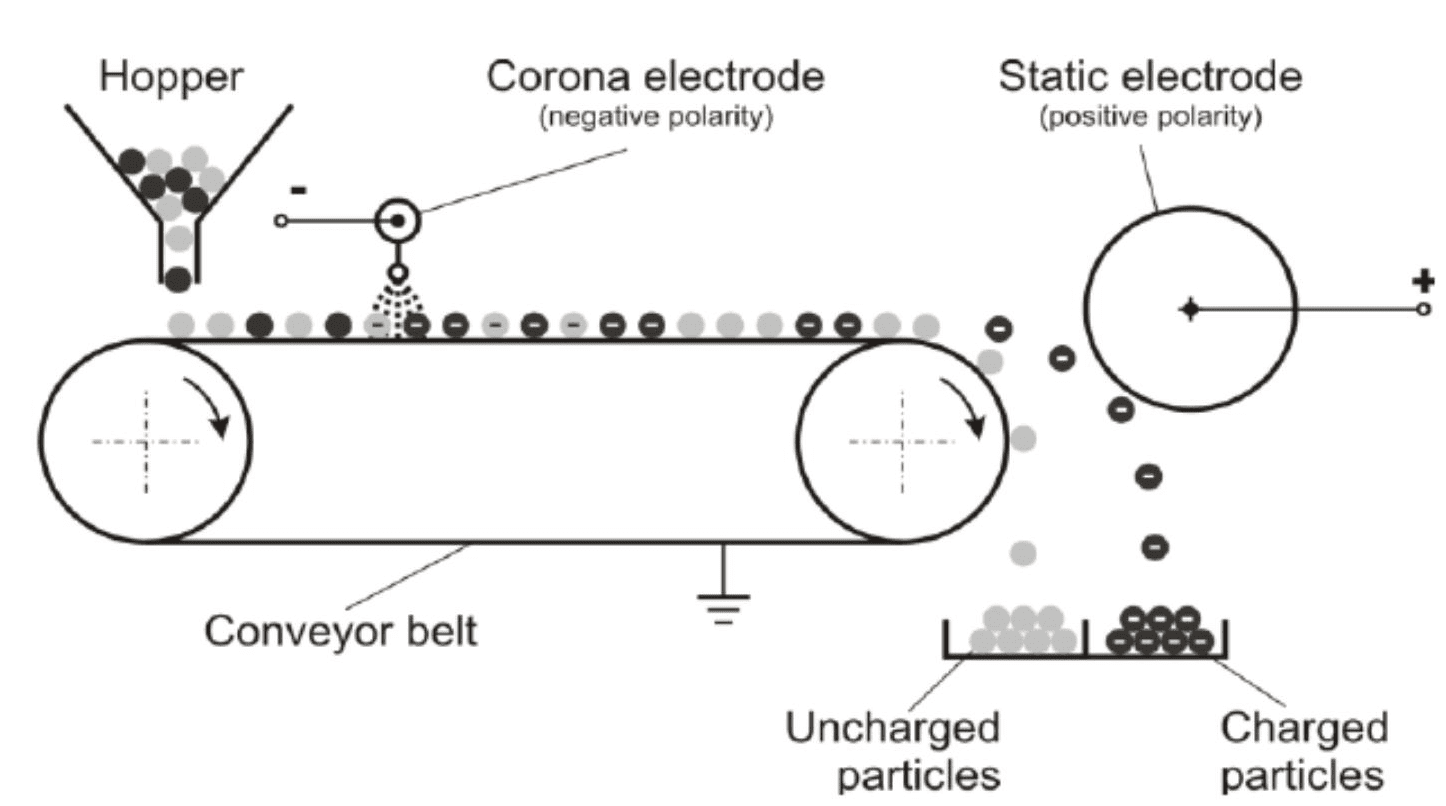

Tribo-mhuirearú agus rinneadh turgnaimh ar bran cruithneacht mhuirearú Coróin amach ag oibrithe ag an electrostatics Aonad Taighde ar na Meáin Scaipthe, Ollscoil Poitiers, Fhrainc i 2010. The researchers measured the surface charge and surface potential decay time on wheat bran with 10% moisture and lyophilized (freeze-dried) wheat bran. A separation test was performed on a sample of 50% freeze-dried wheat bran and 50% freeze-dried aleurone feed using a belt type corona electrostatic separator. (figiúr 3) Separation results for the laboratory scale corona separator indicated 67% of aleurone was recovered to the non-conductor hopper, while only 2% of the wheat bran reported to the non-conductor hopper. Tribo-charging experiments were also conducted with wheat bran and aleurone, but only to measure the specific surface charge [µC/g] generated on each fraction, as opposed to recovering products from an electrostatic separation. Both feed materials were charged using Teflon as the contact surface. Both wheat bran and aleurone are reported as charging positive relative to Teflon, which itself is very electronegative. The magnitude of the charge was found to depend on the operating pressures used on the tribo-charger, suggesting that higher turbulence leads to more contacts and more complete tribo-charging. [13]

figiúr 3: Reproduced from Dascalescu et al, 2010 [13]

in 2009, researchers evaluated the electrostatic charging properties of aleurone rich and pericarp rich feed materials. [14] in 2011 the researchers performed electrostatic separation testing on samples of finely ground wheat bran using a pilot scale electrostatic plate separator (TEP System, Tribo Flow Separations, Lexington, USA). The TEP System utilizes a charging line, i gcás ina bhfuil cáithníní beatha chuirtear isteach i sruth aer suaite comhbhrúite, agus haeroibritheach iúl tríd an líne a mhuirearú chuig an seomra scaradh. Na cáithníní tribo-ghearrann an cáithnín go teagmháil gcáithníní, chomh maith le teagmháil na gcáithníní leis an dromchla an líne muirearaithe. Léirigh torthaí a fhaightear trí an gCóras TEP go raibh deighilt leictreastatach éifeachtach in uasghrádú aleurone agus béite-glucan ábhar na bran cruithneacht. Interestingly, an codán den ábhar a fuarthas go go bhfuil an t-ábhar is airde cille aleurone, at 68%, bhí an fhíneáil an- (D50 = 8 m) codán a aisghabháil go ón fheadáin mhuirearú. Níl sé soiléir cén fáth go raibh an t-ábhar dírithe rogha, sa gaireas muirir, ach, a dhéanann sé in iúl gur féidir leis an cumas a phróiseáil aleurone t-ábhar cille cheangal teicnící leictreastatach atá in ann a phróiseáil púdair an-bhreá. ina theannta sin, Léirigh an obair seo go raibh ullmhúchán an beatha chun bran cruithneacht breithniú tábhachtach. Fuarthas amach go raibh samplaí d'ullmhaigh chrióigineach meilt i muileann casúr a dhealú chomh hiomlán (liberated) ná iad siúd talamh i muileann chineál tionchair ag teocht chomhthimpeallach. [15] [16]

figiúr 4: Macasamhail ó Hemery et al, 2011 [16]

obair le déanaí staidéar ar an tiúchan na n arabinoxylans ó bran cruithneacht trí mhodhanna leictreastatach. Na taighdeoirí úsáid deighilteoir scála saotharlainne leictreastatach comhdhéanta de feadán agus scaradh seomra mhuirearú ina bhfuil dhá leictreoidí plátaí comhthreomhara. Milled wheat bran was introduced into the charging tube and conveyed pneumatically into the separation chamber using compressed nitrogen. The turbulence and high gas velocity in the charging tube provided the particle contact needed for tribo-charging. The charged particles (products of the separation) were collected from the surface of the electrodes for analysis. Due to the vertical orientation of the electrodes a significant amount of material was not collected. This middlings fraction may be recycled for further processing in conventional electrostatics, ach, for the purposes of this experiment, material not collected on the electrodes was considered lost. The researchers reported an increase in both product grade (arabinoxylan content in the product) and separation efficiency as the conveying velocity increased. [17]

Recent efforts to beneficiate wheat bran using electrostatic methods are summarized below in Table 2.

Tábla 2: Summary of electrostatic methods evaluated to beneficiate wheat bran.

Cás 2 - Aisghabháil Próitéin ó Lúipín Plúr

Taighdeoirí ag an Próiseas Bia Grúpa Innealtóireacht i Wageningen, An Ísiltír, meastóireacht ar an bhféidearthacht a shaibhriú próitéine ag baint úsáide as pischineálaigh. Baineadh úsáid as Pea agus lupine plúr mar feeds d'éagsúlacht na teicnící saibhriú próitéine lena n-áirítear aicmiú aer in éineacht le scaradh leictreastatach. Bhí pea agus lupine síolta neamhchóireáilte meilte ar dtús go dtí thart ar 200 m. Feed materials for classification and electrostatic separation were subsequently milled using an impact type mill with an internal classifier (Hosokawa-Alpine ZPS50). Median particle size (D50) was reported as approximately 25 µm for the pea flour, and approximately 200 µm for the lupin flour, prior to air classification. Ar deireadh, a subset of each sample, pea and lupin flour, was then air classified (Hosokawa-Alpine ATP50). The feed to the electrostatic separator consisted of both untreated flours, as well as the course and fine product from air classification. [18]

The electrostatic separation device used during the experiments was a parallel plate type, with charging carried out via triboelectric charging in a 125 mm length charging tube, with particles conveyed pneumatically by compressed nitrogen. The device is similar in configuration to the device used by Wang et al (2015). [17] Electrostatic separation experiments were conducted on ground pea flour and lupin flour, chomh maith leis an gcúrsa agus fíneáil codáin de plúr pea agus plúr lupine fhaightear ó aicmiú aer. An plúr pea Léirigh gluaiseacht ach saorga próitéine le linn tástála leictreastatach. ach, an plúr lupine léirigh gluaiseacht shuntasach de próitéine sna trí sampla a tástáladh (meilte plúr - 35% próitéin, fíneálacha rangaithe de meilte - 45% próitéin, meilte garbh aicmithe - 29% próitéin). Táirgí mhórán próitéine de thart ar 60% Fuarthas ar an leictreoid bunaithe do gach ceann de na trí shampla lupine tástáladh. [18]

Cás 3 - Deireadh Snáithín ó Corn

Taighdeoirí ag an Roinn Talmhaíochta agus Innealtóireacht Bitheolaíochta, dhéantar Mississippi State University tástáil leictreastatach ar plúr coirce talamh, le cuspóir de chuid snáithín a bhaint. An gléas scaradh electrostatic comhdhéanta de crios conveyor le leictreoid diúltach a chur ag deireadh an iompair. Na cáithníní luchtaithe go deimhneach, cáithníní snáithín, sa chás seo, ardaíodh as an crios conveyor agus curtha in eagar isteach an dara dríodair. Na cáithníní neamh-snáithín thit amach ar an crios conveyor trí dhomhantarraingt agus cuireadh i dtaisce isteach sa chéad hopper táirge. Níl feidhm ag na húdair cur síos ar an gcaoi a bhfuil an t-mhuirearú leictreach i gcrích. Ba é an t-ábhar beatha a ghabhann leis an deighilteoir sách garbh, le méid a gcáithníní beatha ó 12 mogalra (1,532 m) chun 24 mogalra (704 m). Ní cosúil go bhfuil an undersize (<704 m) material was processed during this study. Each test condition was completed using 1 kg of feed material which was uniformly dispersed across the belt. [6]

figiúr 5: Macasamhail ó Pandya et al, 2013 [6]

Chríochnaigh an taighdeoirí Mississippi State tástáil scaradh leictreastatach ar an plúr coirce unscreened, the screened corn flour fractions and the fiber-rich fractions recovered from air classification. Electrostatic testing was not completed on the low-fiber streams recovered from air classification. Analysis of the results of the electrostatic separation is provided below:

Tábla 3: Results of fiber separation reproduced from Pandya et al, 2013 [6]

Cás 4 – Protein Concentration from Oilseeds

Oilseeds such as rapeseed (canola), sunflower, sesame, mustard, soybean-corn germ, and flaxseed generally contain a substantial amount of both protein and fiber. Processing technologies to remove the fiber, and thus increase the protein content, of oilseeds will become increasingly important as global demand for protein increases. [19] Recent work by researchers at the French National Institute for Agricultural Research examined ultrafine milling combined with electrostatic processing of sunflower seed meal, to concentrate protein. The feed sunflower meal samples were ground in an impact mill operating at ambient temperature to a particle size (scavenging dhá-pas) ar 69.5 m. Ba é an deighilteoir leictreastatach a úsáidtear chun tástáil gléas plátaí comhthreomhara áit a raibh an sásra muirearaithe atá bunscoile tribo-mhuirearú. Rinneadh an tribo-mhuirearú amach suas an sreabhadh na leictreoidí i líne tribo-mhuirearú, le cáithníní in iúl tríd an líne muirearaithe, agus leis na leictreoidí, via iompar aeroibrithe. Fuarthas go raibh Próitéin a ghearradh dearfach (ag tuairisciú don leictreoid diúltach) agus fuarthas an codán snáithín-saibhir a ghearradh diúltach. Fuarthas go raibh roghnachas Próitéin a bheith ard. Ba próitéin Feed 30.8%, leis an tomhais táirge mhórán próitéine 48.9% agus an próitéin laghdaithe (snáithín-saibhir) táirge a thomhas ach 5.1% próitéin. Ba aisghabháil Próitéin 93% leis an táirge dearfach. ceallalós, hemicelluloses, agus tomhaiseadh agus fuair lignin tuairisc a thabhairt don táirge luchtaithe go diúltach, os coinne de próitéine. [20]

Tábla 4: Torthaí an scaradh min síolta lus na gréine tógtha ó Barakat et al, 2015 [20]

in 2016, Cuireadh staidéar breise chun críche ag baint úsáide as talamh mín ráibe min síolta ola, nó cácaí ola ráibe (ROC), mar an bheatha ar phróiseas deighilte leictreastatach. Arís Rinneadh muilleoireacht ultrafine ag teocht chomhthimpeallach baint úsáide as gléas muileann scian (Retsch SM 100). An t-ábhar meilte, le méid na gcáithníní meánach (scavenging dhá-pas) tuairim is 90 m, Próiseáladh ag úsáid scála píolótach deighilteoir plátaí comhthreomhara (TEP System, Tribo Flow Separations). An Córas CTT úsáid as muirir triboelectric trí iompar aeir na gcáithníní trí líne muirir brú ard faoi choinníollacha suaite. Tástáil scaradh pas amháin leis an gCóras TEP mar thoradh ar an tiúchan suntasach próitéin, le próitéin beatha de 37%, leibhéal próitéin a táirge lucht deimhneach ar 47% agus leibhéal próitéin a táirge diúltach de 25%. Rinneadh céimeanna scaradh breise, deireadh thiar a tháirgeadh a táirge ar mhórán próitéine le 51% próitéin i ndiaidh 3 céimeanna scaradh i ndiaidh a. [21]

Tábla 5: Torthaí de ráibe scaradh min síolta ola atáirgeadh ó Basset et al, 2016 [21]

Plé

Léiríonn athbhreithniú ar an litríocht ábhartha uile atá curtha taighde suntasach déanta chun teicnící scaradh leictreastatach le haghaidh ábhar orgánach a fhorbairt. Tá an fhorbairt leanúnach nó fiú luathaithe san am atá thart 10 - 20 blianta, le go leor taighdeoirí san Eoraip agus sna Stáit Aontaithe a chur i bhfeidhm teicnící deighilte leictreastatach le raon leathan de dhúshláin beneficiation. Ón taighde, is léir go bhfuil modhanna leictreastatach an cumas a ghiniúint nua, táirgí plandaí luach níos airde, nó a thairiscint rogha eile fliuch modhanna próiseála.

Cé idirscarthaí grán arbhair a spreagadh, bíoga, agus tá ábhar síol ola léirithe ag an tsaotharlann agus i roinnt scála gcásanna píolótach, na córais leictreastatach a úsáidtear chun na torthaí a léiriú nach féidir a úsáid ar deireadh thiar mar an trealamh próiseála is oiriúnaí nó éifeachtaí ó thaobh costais chun idirscaradh sin ar bhonn tráchtála. Existing commercial electrostatic systems are most commonly used in separations of minerals, metals or plastics. Minerals and metals are both relatively dense materials with high specific gravity, as compared to plant materials. Even with the high specific gravity of minerals and metals, the effective particle size limitations for the drum roll and parallel plate electrostatic separators is relatively coarse, with few particles below 100 µm for example. Tá Plaistigh ar dhlús níos ísle ná an dá mianraí agus miotail ach is minic a phróiseáil ag mhéideanna cáithníní garbh, calóga mar shampla plaisteach. The introduction of fine particles creates operational difficulties for both high-tension roll and parallel plate separators. Fine, Tá cáithníní íseal-dlúis an-íogair do sruthanna aer, go háirithe i gcomparáid le mianraí agus miotal. difríochtaí beaga i sruthanna aer taobh istigh an gléas scaradh tionchar an cosán taistil na cáithníní fhíneáil, faoi réir iad a fórsaí seachas iad sin ba chúis leis an réimse leictreastatach.

Don chuid is mó Córais deighilteoir plátaí comhthreomhara, talamh agus íseal-dlúis cáithníní go mín a bhfuil táillí leictreastatach Bailítear ar na leictreoidí na deighilteoirí plátaí comhthreomhara. Mura gcuirfear na cáithníní leictreach ceangailte fíneáil as oifig ar bhonn leanúnach, an neart an réimse leictrigh agus éifeachtúlacht an degrade gléas. Obair na taighdeoirí ag an Próiseas Bia Innealtóireachta Grúpa Wageningen UR (Wang et al, 2015) took advantage of this phenomenon to collect samples off the surface of the electrodes of the parallel plate separator to analyze the products of the separation. Parallel plate separator systems, particularly those that rely upon gravity to convey particles through the electric field, have attempted to address this problem in several ways. Stone et al (1988) described a process in which fine particles were removed upstream of the electrostatic separator by air elutriation. [10] Others have reported maintaining a laminar stream of air flowing across the electrodes to prevent fine particles from being influenced by air currents. [22ach, maintaining laminar airflow becomes challenging as the separation device becomes larger, effectively limiting the processing capacity of such devices. Ultimately the particle size in which components are physically separate from other (present as discrete particles), will be the largest driver in determining the particle size at which processing must occur.

As mentioned previously, conventional electrostatic separation devices are limited in processing capacity, especially with low-density and finely ground powders such as plant materials. For high-tension drum and belt separation devices, the effectiveness is limited to particles that are relatively coarse and/or have high specific gravity, due to the need for all particles to contact the surface of the drum. As particles become smaller the processing rate is reduced. Parallel plate separators are further limited by the particle density that can be processed in the electrode zone. Particle loading must be relatively low to prevent space charge effects.

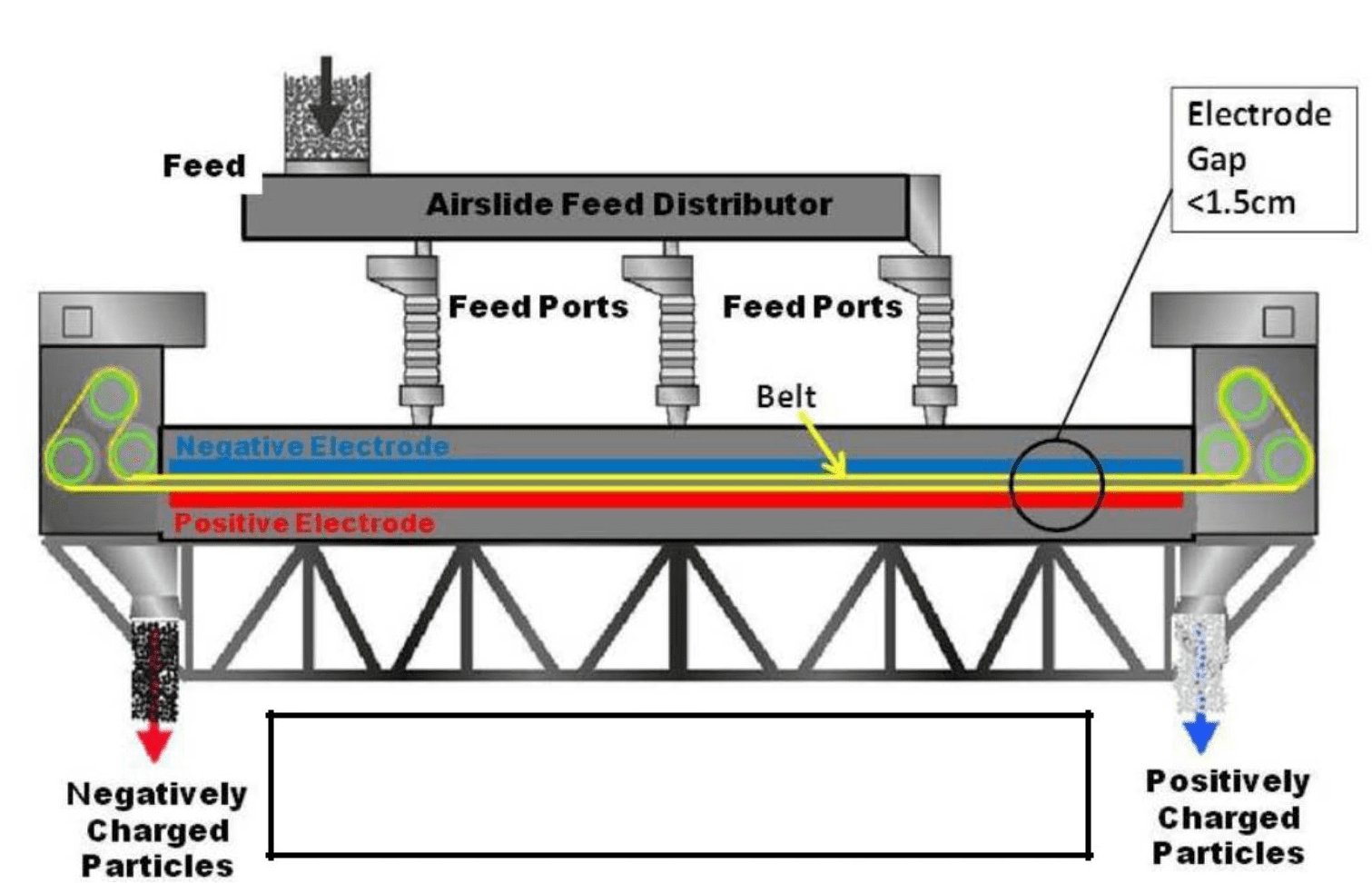

ST Trealamh & Technology Belt Separator

An Trealamh ST & teicneolaíocht (STET) deighilteoir crios triboelectrostatic Tá an cumas léirithe a phróiseáil cáithníní fíneáil ó 500 - 1 m. The STET separator is a parallel plate electrostatic separator, ach, the electrode plates are oriented horizontally as opposed to vertically as is the case in most parallel plate separators. (Féach Figiúr 6) ina theannta sin, the STET separator accomplishes the particle tribo-charging and conveying simultaneously by a high-speed open mesh conveyor belt. This feature allows for both a very high specific processing rate of feed, chomh maith leis an gcumas a phróiseáil púdair i bhfad níos míne ná feistí leictreastatach traidisiúnta. Tá an cineál feiste scartha ag feidhmiú tráchtála ó 1995 scaradh carbóin unburned ó mhianraí fuinseog eitilt (D50 tipiciúil thart 20 m) i stáisiúin chumhachta guail-fired. Tá an gléas scaradh leictreastatach freisin éiríonn beneficiating ábhair neamhorgánacha eile, lena n-áirítear mianraí, mar shampla carbónáit chailciam, talc, barite, agus Daoine eile.

Tá na sonraí bunúsacha an deighilteoir STET i bhFigiúr 7. The particles are charged by the triboelectric effect through particle-to-particle collisions within the gap between the electrodes. The applied voltage between the electrodes is between ±4 and ±10 kV relative to ground, giving a total voltage difference of 8 - 20 kV across a very narrow electrode gap of nominally 1.5 cm (0.6 orlach). Feed particles are introduced to the STET separator at one of three locations (Feed Ports) via a distributor air slide system with knife gate valves. The STET separator produces only two products, sruth na gcáithníní lucht diúltach a bailíodh ar an leictreoid atá luchtaithe go deimhneach, agus sruth na gcáithníní luchtaithe go deimhneach a bailíodh ar an leictreoid diúltach. Na táirgí atá in iúl do na hoppers faoi seach ag gach leibhéal an deighilteoir STET ag an crios deighilteoir agus a thabhairt amach as an deighilteoir trí dhomhantarraingt. Ní dhéanann an deighilteoir STET tháirgeadh meánaigh nó sruth athchúrsáil, cé go bhfoirmíochtaí pas il chun feabhas a chur ar íonachta táirge agus / nó aisghabháil is féidir a dhéanamh.

figiúr 6: STET Triboelectric Chreasa Deighilteoir

Cáithníní a in iúl tríd an bhearna leictreoid (crios scaradh) ag lúb leanúnach, crios mogalra oscailte. Feidhmíonn an crios ag luas ard, athróg ó 4 chun 20 m / s (13 - 65 ft / s). An geoiméadracht an crios ag freastal a sweep cáithníní fíneáil as an dromchla na leictreoidí, cosc carnadh na cáithníní fíneáil a degrade an fheidhmíocht agus voltas réimse na bhfeistí scaradh chineál thraidisiúnta saor-titim plátaí comhthreomhara. Freisin, Gineann an crios a fórsa ard, crios suaiteacht ard idir an dá leictreoidí, a chur chun cinn tribo-mhuirearú. Ceadaíonn an taisteal frith-reatha an crios deighilteoir do mhuirearú leanúnach agus ath-mhuirearú nó cáithníní laistigh den deighilteoir, deireadh leis an ngá atá le córas réamh-mhuirearú in aghaidh srutha ar an deighilteoir STET.

figiúr 7: Bunúsacha ar oibriú STET Chreasa Deighilteoir

Is é an deighilteoir STET ráta beatha ard, Córas próiseála cruthaithe ó thaobh na tráchtála. Is é an cumas próiseála uasta na deighilteoir STET den chuid is mó feidhm de chuid an ráta beatha toirtmhéadrach is féidir a chur in iúl tríd an bhearna leictreoid ag an crios deighilteoir STET. athróga eile, cosúil leis an luas an crios, an t-achar idir na leictreoidí agus an dlús aeraithe an púdar éifeacht ar an ráta beatha uasta, de ghnáth go pointe níos lú. I gcás réasúnta ábhair ard-dlúis, mar shampla, eitilt fuinseog, an ráta a phróiseáil uasta 42 orlach (106 cm) Is leithead leictreoid aonad scartha tráchtála thart 40 - 45 Tonna in aghaidh na huaire beatha. I gcás ábhar beatha níos lú dlúth, Is é an ráta beatha uasta níos ísle.

Tábla 6: Ráta beatha Neas uasta le haghaidh ábhar éagsúla próiseáilte le STET 42 orlach deighilteoir leictreastatach.

Is pléascanna Dust guais mhór i gráin agus oibríochtaí eile próiseála púdar orgánach. Is é an deighilteoir STET oiriúnach le haghaidh próiseála púdair inadhainte orgánacha, ach modhnuithe beag. Níl aon dromchlaí téite sa deighilteoir STET. Is iad na codanna ach amháin ag gluaiseacht an crios agus tiomáint rollóirí deighilteoir. Na imthacaí sorcóir atá suite taobh amuigh den sruth púdar ar an bhlaosc sheachtrach an aonaid. Dá bhrí sin, nach bhfuil siad i mbaol róthéamh / sparking sa sruth ábhartha. ina theannta sin, Is iad na bearings deighilteoir STET fáil le monarcha feistithe cumas tomhais teochta a bhrath bhfuil teip maith sula teocht contúirteach ard bainte. An crios deighilteoir agus córas tiomáint mbaineann aon riosca níos airde ná an innealra rothlach eile traidisiúnta. Na comhpháirteanna ardvoltais deighilteoir STET atá suite lasmuigh den sruth ábhar agus atá i hiatáin deannach-dhíonach. Tá fuinneamh uasta splanc thar an bhearna deighilteoir teoranta ag an dearadh de na comhpháirteanna ardvoltais. Is féidir le leibhéal breise sábháilteachta a thabhairt isteach trí purging nítrigin.

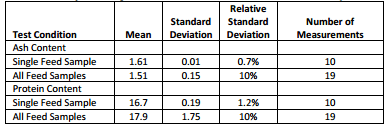

Iomlána Próiseáil Plúr cruithneachta ag STET Deighilteoir

Tá plúr cruithneachta ar fad a dhíorthaítear ó meilt an grán iomlán cruithneachta (bran, miocrób, agus inspeirm). fáil ar bhonn tráchtála, as an seilf, Ceannaíodh plúr cruithneachta ar fad lena n-úsáid mar ábhar tástála chun meastóireacht a dhéanamh ar an gcumas atá deighilteoir STET a bhaint as an bran snáithíneach agus miocrób ón codán endosperm stáirse plúr cruithneachta. Rinneadh anailís ar an sampla plúr cruithneachta ar fad ag STET roimh tosú an tástáil. Bhí scrúdú Ash ábhar ag ICC Caighdeánach 104 / 1 (900° C). tomhais fuinseog arís agus arís eile ar an sampla céanna, sampla beatha unseparated, thomhas 10 amanna, Fuarthas amach go raibh cion luaithe de 1.61%, diall caighdeánach de 0.01 agus diall caighdeánach coibhneasta 0.7%. Cuireadh anailís mhéid na gcáithníní i gcrích faoi díraonadh léasair ag baint úsáide as Mastersizer Malvern 3000 le gaireas scaipeadh tirim. Rinneadh anailís Próitéin baint úsáide as modh DUMAS, le N tapa Elementary mó ná nítrigin Anailíseoir / próitéin. Tá fachtóir coinbhéartachta N x 6.25 Baineadh úsáid as. Tá achoimre ar na hairíonna éagsúla an sampla plúr cruithneachta ar fad thíos. (Féach Tábla 7)

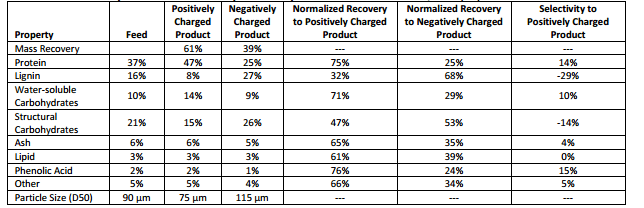

Tábla 7: Anailís ar beatha plúr cruithneachta ar fad ag STET

Fuarthas amach go raibh cion luatha agus ábhar próitéine a bheith an-athdhéanta nuair a dhéantar tástáil sa sampla céanna, ach Aithníodh inathraitheacht mhór idir na málaí iolraí de plúr cruithneachta ar fad a úsáidtear mar an sampla beatha. (Féach Tábla 8) Seo inathraitheacht samplach beatha mar thoradh ar roinnt scaip sna sonraí tástála.

Tábla 8: Anailís ar thorthaí tástála scaradh plúr cruithneachta ar fad le STET

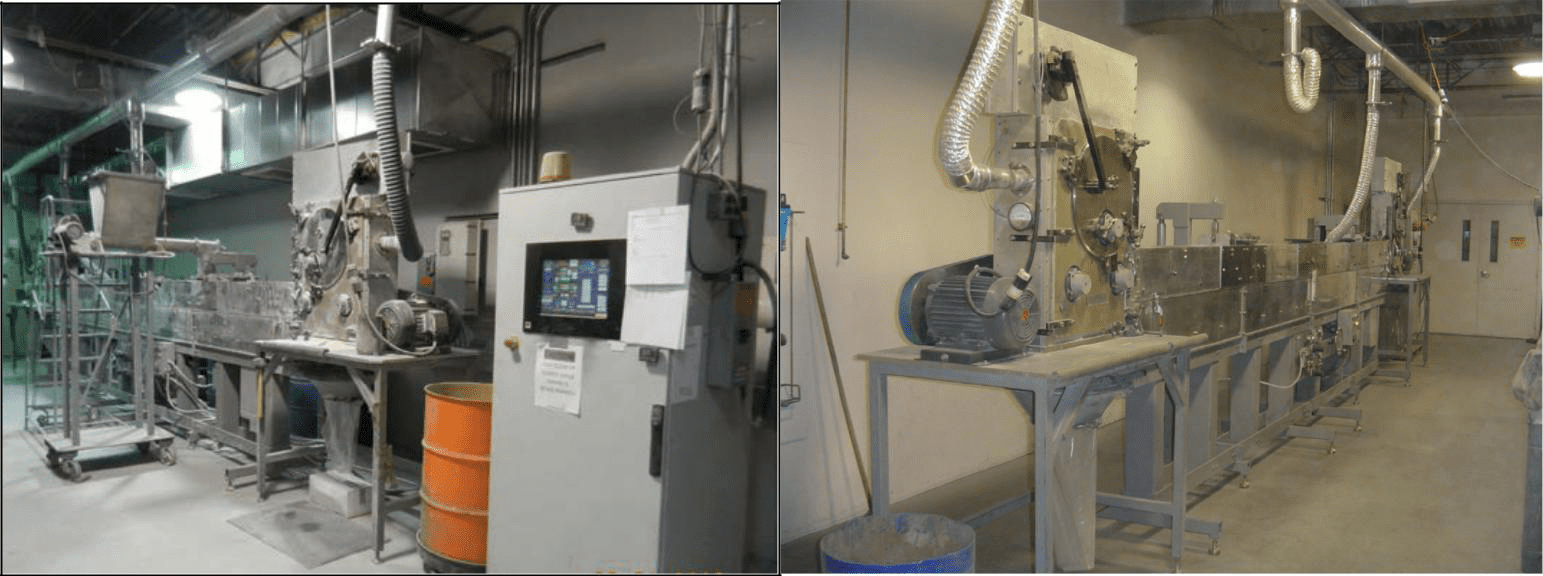

Tástáil scaradh leictreastatach den sampla plúr cruithneachta ar fad a bhí a sheoladh ar an Trealamh ST & teicneolaíocht (STET) saoráid monarcha treorach i Needham, Massachusetts. Tá monarcha treorach STET dhá deighilteoirí STET scála píolótach mar aon le trealamh coimhdeach a úsáidtear chun imscrúdú a dhéanamh ar an scaradh na n-ábhar ó fhoinsí iarrthóirí. Is iad na Deighilteoirí STET píolótach ar scála an fad céanna mar deighilteoir STET tráchtála, at 30 cosa (9.1 méadar) fada, ach, Is é an monarcha treorach deighilteoir leithead leictreoid amháin 6 orlach (150 mm), nó aon-seachtú leithead an deighilteoir STET mó tráchtála ar 42 orlach (1070 mm) leithead leictreoidí. Tá an acmhainn beatha an deighilteoir STET i gcomhréir leis an leithead an leictreoidí, dá bhrí sin,, is é an ráta beatha an deighilteoir monarcha treorach amháin seachtú an ráta beatha an t-aonad deighilteoir fairsinge tráchtála 42-orlach. Ba é an ráta beatha uasta le plúr cruithneachta ar fad 2.3 Tonna in aghaidh na huaire ag scála píolótach, a fhreagraíonn do 16 Tonna in aghaidh na huaire do na 42-orlach deighilteoir fairsinge tráchtála. I gcomparáid leis an scála ar a bhfuil an chuid is mó de na staidéir deighilte leictreastatach a bheith déanta go dtí seo, Rinneadh an tástáil deighilteoir STET amach ag ráta beatha i bhfad níos airde. Rinneadh tástáil i 10 KG (20 punt) tástálacha bhaisc, mar gheall ar na himpleachtaí praiticiúla a bhaineann sholáthar 2.3 Tonna in aghaidh na huaire beatha leanúnach. I gcás gach coinníoll tástála baisce, the products of the separation process were weighed to calculate the mass recovery. Subsamples from each test were collected and analyzed for ash content and protein content.

figiúr 8: STET Pilot Plant Separator.

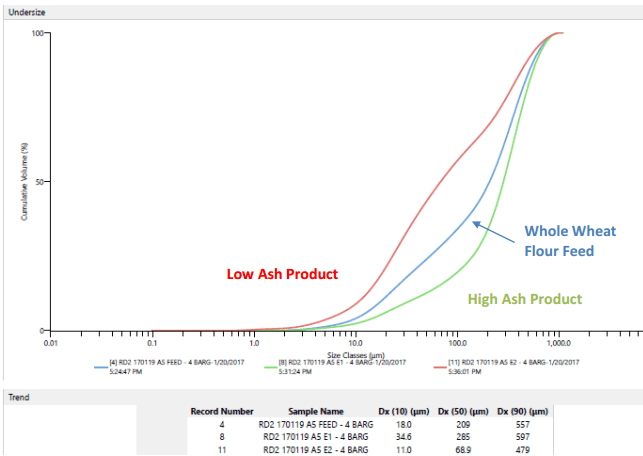

Particle size measurement of the whole wheat flour feed and two product samples is shown below in Figure 9.

figiúr 9: Particle size measurement of whole wheat flour feed, and the two separated product samples.

A picture of the recovered separation products is included below. (Féach Figiúr 10) A noticeable color shift was observed during the separation, which the high ash content product fraction considerably darker than the feed whole wheat flour sample.

figiúr 10: Typical products recovered from the STET separation process.

Ash content for all products from the separation process was measured. (Féach Figiúr 11)

figiúr 11: Ash content versus the mass recovery of low ash product for whole wheat flour separation tests by STET

Tástáil an deighilteoir leictreastatach STET le plúr cruithneachta ar fad léirigh gluaiseacht shuntasach na fuinseoige ard (bran) codán den eithne cruithneachta don leictreoid dearfach. Cuireadh an táirge fuinseog laghdaithe bailithe ina dhiaidh sin ar an leictreoid diúltach. Rinneadh tástáil ar scéim pas amháin, ach, is féidir a dhéanamh níos mó uasghrádú ceachtar de na táirgí scaradh ag feidhmiú céim scaradh eile. Beidh tástáil amach anseo leis an deighilteoir STET a dhéanamh ar shamplaí bran cruithneacht, chomh maith le plúr arbhar agus pischineálaigh nós Lúipín.

Conclúidí

Léiríonn athbhreithniú ar an litríocht ábhartha uile atá curtha taighde suntasach déanta chun teicnící scaradh leictreastatach le haghaidh ábhar orgánach a fhorbairt. Tá an fhorbairt leanúnach nó fiú luathaithe san am atá thart 10 - 20 blianta, le go leor taighdeoirí san Eoraip agus sna Stáit Aontaithe a chur i bhfeidhm teicnící deighilte leictreastatach le raon leathan de dhúshláin beneficiation. Ón taighde, is léir go bhfuil modhanna leictreastatach an cumas a ghiniúint nua, táirgí plandaí luach níos airde, nó a thairiscint rogha eile fliuch modhanna próiseála. Cé idirscarthaí de cruithneacht a spreagadh, arbhar agus ábhair phlanda lupine-bhunaithe a bheith léirithe ag an tsaotharlann agus i roinnt scála gcásanna píolótach, Ní féidir na córais leictreastatach a úsáidtear chun na torthaí a léiriú a bheith ar an trealamh is oiriúnaí nó éifeachtach ó thaobh costais phróiseála chun idirscaradh sin ar bhonn tráchtála. Many electrostatic technologies are not suitable for process finely ground, low-density powders such as plant materials. ach, an Equipment ST & teicneolaíocht (STET) triboelectrostatic belt separator has the demonstrated capability to process fine particles from 500 - 1 m ag rátaí arda. Is é an deighilteoir crios STET ráta ard, industrially cruthaithe gléas próiseála d'fhéadfadh a bheith oiriúnach a thráchtálú na forbairtí is déanaí i bpróiseáil ábhar plandaí. Rinneadh tástáil ar an deighilteoir crios STET ar shampla de plúr cruithneachta ar fad agus fuarthas amach a bheith rathúil i bhaint an bran ón codán stáirse. Beidh tástáil amach anseo leis an deighilteoir STET a dhéanamh ar shamplaí bran cruithneacht, chomh maith le plúr coirce agus de phulsanna nós soy agus lupine.

tagairtí

[1] T. B. Osborne, “Meánaigh-Purifier”. Stáit Aontaithe Mheiriceá Paitinne 224,719, 17 feabhra 1880.

[2] H. Manouchehri, K. Hanumantha Rao agus K. Forsberg, “Athbhreithniú ar mhodhanna deighilte leictreach – Cuid 1: ghnéithe bunúsacha,” mianraí & Próiseáil metallurgical, vol. 17, no. 1, pp. 23-36, 2000.

[3] J. Elder agus E. yan, “eForce – ghlúin nua de deighilteoir leictreastatach do thionscal mianraí gaineamh,” i gComhdháil Minerals Trom, Johannesburg, 2003.

[4] R. H. Perry agus D. W. Glas, Perry Chemical Engineers’ Lámhleabhar Seachtú Edition, Nua-Eabhrac: McGraw-Hill, 1997.

[5] S. Messal, R. Corondan, I. Chetan, R. Ouiddir, K. Medles agus L. dascalescu, “deighilteoir leictreastatach i gcás meascán micronized miotail agus plaisteach a thagann as leictreacha dramhaíola agus trealamh leictreonach,” Journal na Fisice, vol. 646, pp. 1-4, 2015.

[6] T. S. Pandya, R. Srinivasan agus C. P. Thompson, “Idirscaradh Fiber do Talún Corn Plúr Bain úsáid as an Modh leictreastatach,”Ceimic arbhair, vol. 90, no. 6, pp. 535-539, 2013.

[7] L. Brandaí, P. M. Beier, agus mé. Stahl, Scaradh leictreastatach, Weinheim: Wiley VCH Verlag GmbH & Co. KGaA, 2005.

[8] agus. Hemery, X. Rouau, V. Lullien-Pellerin, C. Barron agus J. Abecassis, “próiseas Tirim chun codáin cruithneacht agus táirgí a bhfuil cáilíocht chothaitheach feabhsaithe a fhorbairt,” Journal of Science Gránach, no. 46, pp. 327-347, 2007.

[9] W. A. Brastad agus E. C. Gear, “Modh agus Gaireas do leictreastatach Idirscaradh”. Stáit Aontaithe Mheiriceá Paitinne 2,848,108, 19 Lúnasa 1958.

[10] B. A. Cloch agus J. Minifie, “Aisghabháil Cealla Aleurone ó Bran Cruithneacht”. Stáit Aontaithe Mheiriceá Paitinne 4,746,073,24 Bealtaine 1988.

[11] A. Bohm agus A. scratch, “Modh don isolating Aleurone Particles”. Stáit Aontaithe Mheiriceá Paitinne 7,431,228, 7 Deireadh Fómhair 2008.

[12] J. A. Delcour, X. Rouau, C. M. Courtin, K. Poutanen agus R. Ranieri, “Teicneolaíochtaí maidir le saothrú níos fearr ar acmhainneacht sláinte chun cinn de ghránaigh,” Treochtaí in Eolaíocht Bhia & teicneolaíocht, pp. 1-9, 2012.

[13] L. dascalescu, C. dragan, M. Bilici, R. áilleacht, agus. Hemery agus X. Rouau, “Bunús leictreastatach le Scaradh na cruithneachta Bran Fíocháin,” Idirbhearta IEEE ar Iarratais Tionscail, vol. 46, no. 2, pp. 659-665, 2010.

[14] agus. Hemery, X. Rouau, C. dragan, R. Bilici agus L. dascalescu, “Airíonna leictreastatach bran cruithneacht agus a sraitheanna constitutive: Tionchar a imirt ar mhéid na gcáithníní, comhdhéanamh, agus cion taise,” Journal na hInnealtóireachta Bia, no. 93, pp. 114-124, 2009.

[15] agus. Hemery, M. Curnd, An. Holopainen, A.-M. lampaí, P. Lehtinen, V. piironen, A. Sadoudi agus X. Rouau, “Potential of dry fractionation of wheat bran for the development of food ingredients, part I: Influence of ultra-fine grinding,” Journal of Science Gránach, no. 53, pp. 1-8, 2011.

[16] agus. Hemery, An. Holopainen, A.-M. lampaí, P. Lehtinen, T. Nurmi, V. piironen, M. Edlemann and X. Rouau, “Potential of dry fractionation of wheat bran for the development of food ingredients, part II: Electrostatic separation of particles,” Journal of Science Gránach, no. 53, pp. 9-18, 2011.

[17] J. wang, E. Smits, R. M. Boom, agus M. A. Schutyser, “Arabinoxylans concentrates from wheat bran by electrostatic separation,” Journal na hInnealtóireachta Bia, no. 155, pp. 29-36, 2015.

[18] P. J. Pelgrom, J. wang, R. M. Boom, agus M. A. Schutyser, “Pre- and post-treatment enhance the protein enrichment from milling and air classification of legumes,” Journal na hInnealtóireachta Bia, no. 155, pp. 53-61, 2015.

[19] D. Chereau, P. Videcoq, C. Ruffieux, L. Pichon, J.-C. Motte, S. Belaid, J. Ventureira and M. Lopez, “Teaglaim de na teicneolaíochtaí atá ann cheana féin agus mhalairt ar síolta ola agus de phulsanna próitéiní in iarratais bia a chur chun cinn,” síolta ola & saillte Barraí agus Lipidí, vol. 23, no. 4, pp. 1-11, 2016.

[20] A. Barakat, F. Jerome agus X. Rouau, “A Platform Tirim le Scaradh na Próitéiní ó Bhithmhais-A bhfuil

polaisiúicrídí, lignin, agus Polyphenols,” ChemSusChem, vol. 8, pp. 1161-1166, 2015.

[21] C. Basset, S. Kedidi agus A. Barakat, “Chemical- agus Tuaslagóir-Saor Mechanophysical codánúchán na Bithmhais Spreagtha ag Tribo-leictreastatach Muirir: Próitéiní Scaradh agus lignin,” ACS Ceimic Inbhuanaithe & Innealtóireacht, vol. 4, pp. 4166-4173, 2016.

[22] J. M. Stencel, J. L. Schaefer, H. Ban, agus J. K. Neathery, “Apparatus and Method for Triboelectrostatic Separation”.Stáit Aontaithe Mheiriceá Paitinne 5,938,041, 17 Lúnasa 1999.