Tīpakohia Reo:

Kyle Flynn, Abhishek Gupta, Frank Hrach

Abstract

Ko te arotakenga o ngā tuhinga hāngai e tohu ana kua whakaritea he rangahau nui hei hoatu ā-hiko

ngā pūkenga wehenga ki te kai ā-pūpū maroke (i.e., waro) rawa. Kua whakatere tēnei whanaketanga i mua 10 - 20 tau, with many researchers in Europe and the United States applying wehenga pateko techniques to a wide variety of beneficiation challenges. Mai i tēnei rangahau, Ko reira kitea e tikanga hiko i te pūmanawa ki te whakaputa hou, hua tipu teitei-uara, whakahere ranei he rerekē ki te maku tikanga tukatuka. Ahakoa e whakahauhau ana i ngā wehenga o te kākano kaiaka, pulse and oilseed materials have been demonstrated at the laboratory and in some cases, pilot scale, the electrostatic systems used to demonstrate these results may not be suitable or cost-effective processing equipment to perform such separations on a commercial basis. Many electrostatic technologies are not suitable for process finely ground, low-density powders such as plant materials. Heoi, te ST Taputapu & hangarau (STET) triboelectrostatic belt separator has the demonstrated capability to process fine particles from 500 - 1 μm. The STET belt separator is a high-rate, industrially proven processing device that may be suitable to commercialize the recent developments in organic material processing. The STET belt separator was tested on a sample of whole wheat flour and was found to be successful in removing the bran from the starch fraction. Future testing with the STET separator will be conducted on wheat bran samples, corn flour

and pulses such as soy and lupin.

kupumatua: Tribo-Electrostatic, Electrostatic, wehenga, Fractionation, Wheat, Grain, Flour, Fiber, Protein, Oilseeds, Pulses

Kupu Whakataki

Electrostatic separation methods have been utilized for the past 50 years on the commercial-scale beneficiation of

industrial minerals and recycling of waste materials. Electrostatic beneficiation of dry granular plant-based food (i.e, waro) materials have been investigated for over 140 tau, with the first patent for electrostatic separation of wheat flour middlings filled as early as 1880. [1] Electrostatic beneficiation allows for separations based on differences in surface chemistry (work function) or dielectric properties. In some instances, e kore e enei māvaé kia taea te whakamahi i te rahi kiato ranei māvaé anake. whakahaere pūnaha wehenga hiko i runga i te mau parau tumu ōrite. Kei roto ngā pūnaha wehenga hiko katoa he pūnaha ki electrically ako atu i te matūriki, he mara hiko waho hangaia mo te wehenga ki puta i roto i, me te tikanga o te tuku matūriki ki a i te pūrere wehenga. Ka taea e utu hiko puta i tetahi maha ranei tikanga tae atu whakaurutanga conductive, tribo-tohutohutia (Electrification whakapā) me te katote kurahauao ranei tohutohutia. Electrostatic separation systems utilize at least one of these charging mechanisms. [2]

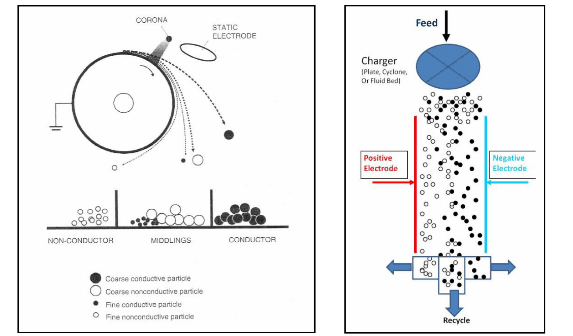

High tension roll electrostatic separation systems have been used in many industries and applications where one

the component is more electrically conductive than the others. Examples of applications for high tension roll separators include titanium bearing minerals separation, as well as recycling applications, for example sorting metal from plastic. There are multiple variations and geometries used for high tension roll systems, but in general, they operate on similar principles. Feed particles are charged negatively by an ionizing corona discharge. Feed particles are dispersed onto a rotating drum, where the drum is electrically grounded. The electrically conductive particles give up their charge upon contacting the surface of the grounded drum. The rotation of the drum causes the conductive particles to be thrown from the surface of the drum and deposited in the first product hopper. The non-conductive particles retain their electrical charge and are pinned to the surface of the drum. Eventually, the electrical charge on the non-conductive particles will dissipate, or the particles will be brushed from the drum after the drum has rotated so that the non-conductive particles are deposited in the non-conductive particle hopper. In some applications, a middlings hopper is placed between the conductive and non-conductive product hopper. Kei te tikanga whāiti te whai huatanga o tenei momo o te pūrere wehenga ki matūriki e he ngā pokepoke, me / whai mahara motuhake teitei ranei, e tika ana ki te hiahia mō ngā matūriki katoa ki te whakapā atu i te mata o te pahū. I tua atu, He nui rere matūriki akiaki rite torohaki koki ko te mutunga kawenga mō te tuku i te matūriki i te mata o te pahū ki te hoppers hua tēnā. matūriki pai me matūriki iti-kiato e ngāwari tākiekina e ngā hau, me te kupu iti pea ki te kia maka i te pahū i roto i te wāhi tonutia. [2] [3] [4]

Ko te whakawehe mānukanuka nui whitiki ko te kē o te whakawehe pukapuka mānukanuka teitei whakaahuatia i runga. E marara matūriki Feed whakanoho puta noa i te whanui o te nekeneke electrically tangata whenua. E whakatupato matūriki, te nuinga o e te kurahauao tōraro, ahakoa ka taea atu pūhanga o tohutohutia. Again the conductive particles give their electrical charge up to the grounded conveyor belt, while the non-conductive particles retain their charge. The conductive particles fall off of the edge of the belt by gravity, while the charged non-conductive particles are “lifted” off of the surface of the belt by electrostatic forces. Again for the separation to be effective, each particle must contact the surface of the belt to allow for the conductive particles to give up their charge to the belt. Na reira, anake e taea te kawea te paparanga kotahi o matūriki i te whakawehe i te kotahi wā. Ka rite ki te rahi o te matūriki o te kai riro iti, heke te auau tukatuka o te pūrere te. [5] [6]

Kei te nuinga hāngai pereti whakarara whakawehe hiko i runga i te kore wehe korakora i runga i te pūtake o te kawe ia, engari i runga i ngā rerekētanga i roto i te matū mata e taea hoki hiko tiaki whakawhiti i te whakapā waku. Kei te electrically whakatupato matūriki i te whakapā maia ki ētahi atu matūriki, or with a third surface such as a metal or plastic will the desired tribo-charging properties. Materials that are electronegative (located on the negative end of the tribo-electric series) remove electrons from the tribo-charging surface and thus acquire a net negative charge. In contact, materials that are on the positive end of the tribo-electric series donate electrons and charge positively. The charged particles are then introduced into an electrical field generated between the two parallel plate electrodes by various transportation means (gravity, pneumatic, vibration). In the presence of the electric field, the charged particles move towards the oppositely charged electrodes and are collected at the corresponding product hoppers. Again, a middlings fraction containing a mixture of particles may or may not be collected, depending on the configuration of the separation device. [4] [7]

Figure 1: Hoahoa o te pukapuka whakawehe mānukanuka tiketike (mahue) me te pereti whakarara whakawehe hinga noa (matau).

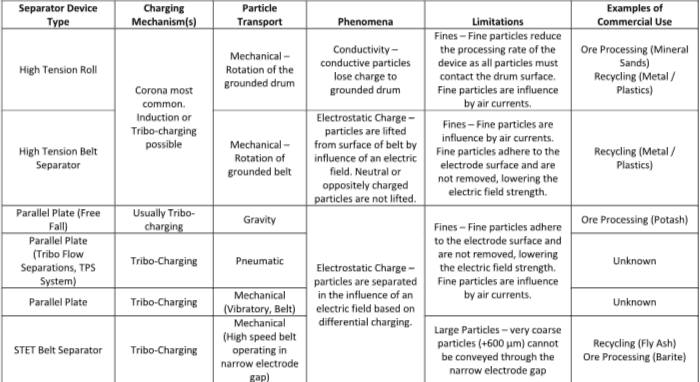

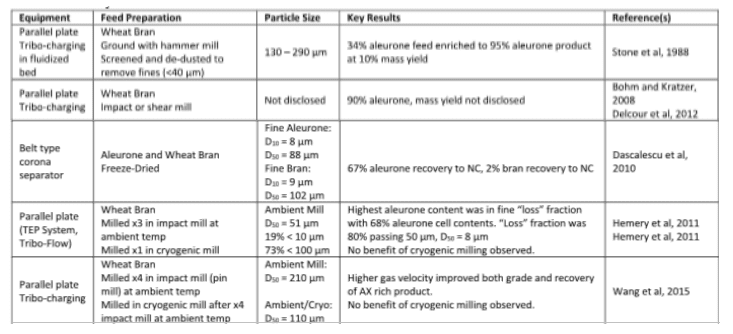

ripanga 1: Whakarāpopototanga o nuitia whakamahia ngā pūrere wehenga hiko.

Case 1 - Wheat ko Wheat Bran Beneficiation.

Wheat parani ko te i-hua o te mira witi tikanga, e tohu ana 10-15% o te witi witi. Kei Witi parani o te papa waho, tae atu i te pericarp, upoko, me aleurone. Kei witi parani te nuinga o nga micronutrients, muka, me phytochemicals roto i roto i te witi, e kua faaite hua hauora ki te tangata. [8] Significant interest in separating and beneficiating wheat bran has been reported. Historical interest in separating wheat bran was to improve the quality and the value of the flour product. Heoi, more recent interest has been reported in recovering valuable components from wheat bran.

I roto i 1880, Thomas Osborne patented the first commercial electrostatic separator for removing bran from flour middlings. The separator consisted of rolls coated with hard rubber or equivalent material which was capable of being electrically charged via frictional tribo-charging with wool. Although not described, it is assumed the rubber rolls acquired a negative charge relative to wool, consistent with most tribo-electric series. The electrically charged rolls then attracted the positively charged bran fiber particles, conveying them on the surface of the roll until the pinned fiber particles are brushed from the surface of the roll. tenei (assumed) positive charging of wheat bran is in conflict with results reported by others. Tribo-charging of the bran particles was assisted by fluidizing air introduced at the bottom of the device, which had the additional benefit of causing the less dense bran particles to the surface, closer to the rolls. [1]

I roto i 1958 an apparatus for electrostatic separation of bran and endosperm contained in flour middlings was disclosed in a patent filing by Branstad working at General Mills. Ko te pūrere ko tētahi whakawehe pereti whakarara i tukuna ai ngā korakora i waenganui i ngā pereti e rua mā te hawahawa. Ngā korakora Bran, i whakahikotia e te hoapā tau ki ngā korakora endosperm, Kātahi ka hikitia ki te hiko o runga mā ngā āhuatanga i roto i te hiko o runga. [9]

I roto i 1988 I whakaaturia tētahi mahi me tētahi tukanga mō te whakaora i te aleurone mai i te bran witi arumoni i roto i tētahi kōnae ārai. Ko te witi arumoni me te ihirangi tīmata o 34% i whakanuia ki te āta whakaaro o 95% ki 10% hua maha (28% whakaora aleurone) ma te pahekotanga o te mira hama, mā te whakamātau, wehenga hiko me te wehenga hiko mā te whakamahi i tētahi whakawehe hiko pereti whakarara. I whakahikotia ngā Particles i roto i te pūrere elutriator hau, he tūranga takirua tōna mo te tango i te whaina (<40 μm) mā te whakawhiti, i te wā kotahi e toru tekau mā toru nga korakora aleurone e pai ana (pūrongo ki te pereti hiko tōraro) ā, he tōraro ngā korakora pericarp/testa. I āta whakahaeretia te rahi korakora o te ranunga bran e te hama mira me te whakamātautau taumata-maha, kia whiwhi ai i tētahi whāngai i te nuinga o te wā i roto i te 130 - 290 awhe μm. [10]

Kei te haere tonu te mahi o nā tata nei ki te whakaora i te aleurone mai i te bran witi. I roto i 2008, I whakawāteatia e Buhler AG tētahi pūrere wehenga hiko mō te wehe i ngā korakora aleurone mai i ngā korakora anga i hangaia ki te bran haere. Ko tētahi whakatinanatanga o te pūrere ko tētahi rotor e mahi ana i tētahi wāhi rongoā whāiti, e āhei ai te korakora-ki-te-mata me te hoapā korakora-ki-te-tūtū me te tribo-charging o muri mai. Kātahi ka tukuna ngā korakora kua whakahikotia ki roto i tētahi oko wehenga e pupuri ana i ngā hiko pereti whakarara. E taka ana nga āhuatanga i roto i te oko wehenga ma te tō ā-papa, i te nekehanga o ngā korakora rerekē ki ngā hiko hiko i whakahikotia i raro i te mana o te āpure hiko. [11] Ina pahekotia ki te whakarahi tika o ngā aratuka kōmaka whāngai me ngā aratuka kōmaka pūkaha, ngā whakamōhiotanga aleurone tae atu ki 90% kua pūrongotia. [12] [8]

Figure 2: I whakaputaina mai i Hemery et al, 2007 [8].

I mahia e nga kaimahi i ngā hiko hiko o te Wae Rangahau Pāpāho i whakakorea e ngā kaimahi i ngā hiko o te Wae Rangahau Pāpāho i Whakakoretia, Te Whare Wānanga o Poitiers, Wīwī i 2010. I inetia e nga kairangahau te utu mata me te wā pirau mata i runga i te witi me 10% moke, kua oti te pīphil (whakatio) bran witi. I mahia he whakamātau wehenga i runga i te tauira o 50% riki witi whakatio, me 50% whāngai aleurone i te whakatio mā te whakamahi i tētahi momo tātua korona whakawehe hiko. (Figure 3) Ko ngā kitenga whakawehenga mō te whakawehe tauine taiwhanga kua tohua 67% o te aleurone i whakaorangia ki te hopper kore-kore, ahakoa ko ia anake 2% o te bran witi i pūrongotia ki te hopper kore-kore. I whakahaeretia hoki ngā whakamātautau tribo-charging ki te bran witi me te aleurone, engari hei ine anake i te utu mata tauwhāiti [μC/g] i hangā ki ia hautanga, ehara i te whakaora i ngā hua mai i tētahi wehenga hiko. I whakahikotia ngā rauemi whāngai e rua mā te whakamahi i te Teflon hei mata hoapā. E pūrongotia ana te bran witi me te aleurone hei whakahiko i te pānga tōrunga ki Teflon, he tino irahiko tērā. I kitea te nui o te utu i runga anō i nga pēhanga whakahaere e whakamahia ana i runga i te pūwhakahiko toru, whakaaro e arata'i arepurepuraa teitei ki atu hoapā me te oti atu tribo-utu. [13]

Figure 3: Tāruatia i Dascalescu et al, 2010 [13]

I roto i 2009, arotakea kairangahau te hiko ka tohutohutia ngā āhuatanga o te aleurone taonga, me te pericarp rauemi kai taonga. [14] I roto i 2011 whakamana nga kairangahau whakamātautau wehenga hiko i runga i ngā tauira o te parani witi tuki rawa te whakamahi i te tauine paerata paraharaha hiko whakawehe (Pänui o Pūnaha, Tribo Rere Whakawehenga, Lexington, USA). e faaohipahia te Pūnaha Pänui o te raina utu, te wahi e whakaurua matūriki kai ki te awa rangi kōpeke ririhau, a pneumatically kawea i roto i te raina e mea ki te ruma wehenga. E nga matūriki tribo whakatupato-e te korakora ki te matūriki whakapā, me te matūriki whakapā ki te mata o te raina e mea. Hua whiwhi ki te Pūnaha Pänui o faaite e he whai hua i roto i te whakahou aleurone me beta-glucan ihirangi o te parani witi wehenga hiko. mea faahiahia, te hautanga o te rauemi e i kitea ki roto i te teitei te ihirangi pūtau aleurone, ki 68%, ko te tino pai (D50 = 8 μm) hautanga e i ora ake i te ngongo ka tohutohutia. Ehara i te mea mārama he aha i preferentially hāngai tenei rauemi i roto i te taputapu utu, Heoi, e tohu i te reira e kia te kaha ki te tukatuka aleurone tirotiro pūtau rapu tikanga hiko e te hunga nehenehe o te tukatuka puehu rawa pai. I tua atu, whakaatu tenei mahi i he kai teuteu mo te parani witi te whakaaro nui. i kitea tauira rite e cryogenic huri i roto i te mira hama ki te kia iti rawa dissociated (tukua) atu i te hunga whenua i roto i te mira momo pānga i ambient pāmahana. [15] [16]

Figure 4: I whakaputaina mai i Hemery et al, 2011 [16]

ako mahi Tata te kukū o arabinoxylans i witi parani e tikanga hiko. whakamahi te kairangahau i te kaiwehe hiko tauine taiwhanga arā, o te ruma ka tohutohutia ngongo, me te wehenga kei roto e rua electrodes pereti whakarara. I whakaurua parani witi paräoa ki te ngongo tohutohutia ka tuku pneumatically ki te ruma wehenga mā te hauota kōpeke. Te arepurepuraa me hau nui tere i roto i te ngongo ka tohutohutia ngā te whakapā matūriki e hiahiatia ana mō te tribo-utu. Ko te matūriki i ako (hua o te wehenga) i kohia i te mata o te electrodes mō te tātari. Nā ki te takotoranga poutū o te electrodes kore te nui nui o te rauemi i kohia. kia hangarua tenei hautau middlings mō te tukatuka atu i roto i te electrostatics tikanga, Heoi, mo nga take o tenei whakamātau, rauemi e kore kohia i runga i te electrodes whakaaro i ngaro. korerotia nga kairangahau he hua i roto i rua kōeke hua (ihirangi arabinoxylan i roto i te hua) me te kakama wehenga rite te tere tuku nui haere. [17]

E whakarāpopoto tautooraa Tata ki te beneficiate parani witi te whakamahi i ngā tikanga hiko i raro i roto i Ripanga 2.

ripanga 2: Whakarāpopototanga o ngā tikanga hiko arotakea ki beneficiate parani witi.

Case 2 - Pūmua Whakaora i Lupin Flour

Ngā kaipūkaro i te Rōpū Pūkaha Tukanga Kai i Wageningen, Hōrana, i arotakea te kaha mo te whakakao pūmua mā te whakamahi i ngā waewae. I whakamahia te parāoa Pea me te lupin hei whāngai mō ngā momo pūkenga whakangahau pūmua tae atu ki te taunahatanga hau i whakakotahitia ki te wehenga hiko. I te tuatahi ka miratia ngā kākano pī me ngā kākano lupin, tata tonu ki te 200 μm. I muri iho ka miratia ngā rauemi whāngai mō te taunahatanga me te wehenga hiko mā te whakamahi i tētahi mira momo pānga ki tētahi taunaha ā-roto (Hosokawa-Alpine ZPS50). Rahi korakora pāpāho (d50) tata tonu te pūrongo 25 μm mo te parāoa pī, tata 200 μm mo te parāoa lupin, i mua i te taunahatanga hau. I te pae hopea, he huingaroto o ia tauira, parāoa pī me te lupin, kātahi ka whakawāteatia te hau (Hosokawa-Alpine ATP50). Ko te whāngai ki te whakawehe hiko, he parāoa kāore i te whakamahia, tae atu ki te akoranga me te hua pai mai i te taunahatanga hau. [18]

He momo pereti whakarara te pūrere wehenga hiko e whakamahia ana i te wā o ngā whakamātautau, me te whakahiko i mahia mā te whakahiko triboelectric i roto i tētahi 125 ngongo whakahiko roa mm, me ngā korakora i tukuna ā-ringatia e te hauota kōpeke. He ōrite te pūrere ki te whiringahora ki te pūrere e whakamahia ana e Wang et al (2015). [17] I whakahaeretia ngā whakamātautau wehenga hiko i runga i te parāoa pī whenua me te parāoa lupin, tae atu ki te akoranga me ngā hautanga pai o te parāoa pī me te parāoa lupine i whiwhi mai i te taunahatanga hau. I whakaaturia e te parāoa pī te nekehanga pūmua iti anake i te wā o te whakamātautau hiko. Heoi, faaite te paraoa rūpene kaupapa nui o te pūmua i roto i te katoa tauira e toru whakamatauria (paraoa paräoa - 35% pūmua, paräoa whaina whakarōpūtia - 45% pūmua, paräoa makaka whakarōpūtia - 29% pūmua). hua Pūmua-taonga o āhua 60% i ora ake i runga i te kawehiko tūāpapa mo ia o nga tauira rūpene toru whakamatauria. [18]

Case 3 - Tango muka i Kānga

Kairangahau i te Tari o Agricultural me Engineering koiora, whakamana Mississippi State University whakamātautau hiko i runga i paraoa witi whenua, ki te whāinga o te muka te tango i. Ko te pūrere wehenga hiko, he tātua kaikawe me tētahi hiko tōraro i whakatakotoria ki te mutunga o te kaikawe. Ngā korakora i whakahikotia tikatia, korakora tākaka, i tēnei take, I whakarewaina atu i te tātua kaikawe, a, ka kōmakatia ki roto i te hopper tuarua. I taka nga korakora kore-kore i te tātua kaikawe ma te tō ā-papa, ā, i whakatakotoria ki roto i te hopper hua tuatahi. Kāore ngā kaituhi e whakaahua he pēhea te whakahaere i te whakahiko hiko. He tino pai rawa atu nga rawa whāngai ki tēnei whakawehe, me ngā rahi korakora o te whāngai e tata ana mai i 12 mata (1,532 μm) ki 24 mata (704 μm). Te āhua nei kāore te rahi (<704 μm) I tukatukatia ngā rauemi i te wā o tēnei akoranga. Kua oti ia āhuatanga whakamātautau mā te whakamahi 1 kiro o nga rawa whāngai i marara ōrite puta noa i te tātua. [6]

Figure 5: I whakaputaina anō mai i Pandya et al, 2013 [6]

I oti i nga kaipūkaro o te Kāwanatanga o Mississippi te whakamātau i te wehenga hiko i runga i te parāoa kānga kāore i kitea, ngā hautanga parāoa kānga mata me ngā hautanga whai rawa i whakaorangia mai i te taunahatanga hau. Kāore i oti te whakamātau hiko i runga i ngā roma iti i whakaorangia mai i te taunahatanga hau. Ka tukuna ki raro nei te tātaritanga o ngā hua o te wehenga hiko:

ripanga 3: Ko ngā kitenga o te wehenga tākainga i hangaia anō mai i Pandya et al, 2013 [6]

Case 4 – Ko te ōritetanga o te hinu

Ngā hinu pēnei i te hīkaka (awa), Pua kōwhai, hāmoe, meke, germ germ, a, ko te nuinga o te wā, he nui tonu te pūmua me te tākaka. Tukatuka ana i ngā hangarau hei tango i te tākainga, ā, mā reira ka whakanui ake i te ihirangi pūmua, Ka nui haere te hira o ngā hinu i te nui o te tono pūmua o te ao whānui. [19] mahi Tata e kairangahau i te French National Institute mo Agricultural Research uiuia ultrafine mira ngā ki tukatuka hiko o te paraoa uri putirā, ki te aro pūmua. hurihia nga tauira kai kai putirā i roto i te mira pānga whakahaere i ambient pāmahana ki te rahi matūriki (D50) o 69.5 μm. Ko te whakawehe hiko whakamahia mo te whakamātautau i te pūrere pereti whakarara te wahi i te huarahi e mea tuatahi tribo-utu. kawea te tribo-e mea i roto i whakarunga o te electrodes i roto i te rārangi tribo-tohutohutia, ki matūriki kawea i roto i te raina utu, a ki te electrodes, mā waka whāhauhau. kitea Pūmua i ki atu tenei pai (pūrongo ki te kawehiko tōraro) ka kitea te hautanga muka-taonga i ki atu tenei tōraro. kitea Pūmua selectivity i ki kia tiketike. ko Whāngai pūmua 30.8%, ki te ruri hua pūmua-taonga 48.9% ka mauriora ki te pūmua (muka-taonga) hua ine anake 5.1% pūmua. ko whakaora Pūmua 93% ki te hua pai. cellulose, hemicelluloses, ā, i inetia te lignin, ā, i kitea he pūrongo ki te hua i whakahikotia kinotia, hangai i tērā o te pūmua. [20]

ripanga 4: Ko ngā kitenga o te wehenga kai kākano rā i hangaia anō mai i Barakat et al, 2015 [20]

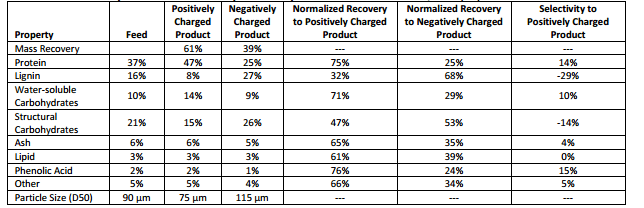

I roto i 2016, I oti tētahi akoranga tāpiri mā te whakamahi i te kai kākano hinu tino pai, keke hinu whakakōhuru rānei (ROC), hei whāngai ki tētahi tukanga wehenga hiko. Ano whakamana mira ultrafine i ambient pāmahana i te whakamahi i te pūrere mira maripi (Retsch SM 100). Ko te rauemi paräoa, ki te rahi matūriki waenga (D50) o āhua 90 μm, i tukatuka whakamahi i te tauine paerata paraharaha whakarara whakawehe (Pänui o Pūnaha, Tribo Rere Whakawehenga). e faaohipahia te Pūnaha Pänui o utu triboelectric i tuku whāhauhau o matūriki i roto i te raina e mea pēhanga teitei i raro i ngā āhuatanga ririhau. He whakamātautau haere wehenga kotahi ki te Pūnaha Pänui o hua i roto i te kukū nui o pūmua, ki te pūmua kai o 37%, he taumata pūmua hua kua whakahikotia tikatia o 47% me tētahi taumata pūmua hua kua whakahikotia tōrarotia o 25%. I mahia ētahi atu wāhanga wehenga, te mutunga whakaputa i te hua pūmua-taonga ki 51% pūmua i muri i 3 wāhanga wehenga ngā. [21]

ripanga 5: Hua o te rapeseed uri hinu wehenga kai tāruatia i Basset et al, 2016 [21]

Aparauraa

Arotake o te tuhinga e hāngai ana tohu e kua rangahau nui kua whakahaeretia ki te whakawhanake i ngā rautaki wehenga hiko mō rauemi organic. Kua tonu ara ranei tenei whanaketanga whakatere i roto i te mua 10 - 20 tau, me te tokomaha o ngā kaipūkaro i Uropi me Te Hononga o Amerika e hoatu ana i ngā pūkenga wehenga hiko ki ngā momo whakamātautau whānui o te whai hua. Mai i tēnei rangahau, Ko reira kitea e tikanga hiko i te pūmanawa ki te whakaputa hou, teitei hua tipu uara, whakahere ranei he rerekē ki te maku tikanga tukatuka.

Ahakoa akiaki i māvaé o pata totokore, ngātere, me ngā rauemi oilseed kua faaite i te taiwhanga, me i roto i te tahi mau tauine take whakamätau, te pūnaha hiko whakamahia ki te whakaatu i ēnei hua e kore te mutunga e mahi rite te taputapu tukatuka tino tika-utu whai hua ranei ki te mahi i taua māvaé i runga i te pūtake arumoni. Kei te tino nuitia arumoni ngā pūnaha hiko whakamahia i roto i māvaé o ngā kohuke, konganuku kirihou ranei. Kohuke me konganuku e rua rauemi āhua mātotoru ki mahara motuhake tiketike, he mea whakarite ki ngā rauemi tipu. Ahakoa ki te mahara motuhake tiketike o kohuke me konganuku, nga whāititanga rahi matūriki whai hua mo te pukapuka pahū me whakarara pereti whakawehe hiko ko ngā pokepoke,, ki torutoru matūriki i raro 100 μm mō te tauira. He kirihou o te mātotoru raro atu i rua kohuke me konganuku, engari e maha tukatuka i te rahi matūriki pokepoke, tawerewere rite kirihou mō te tauira. The introduction of fine particles creates operational difficulties for both high-tension roll and parallel plate separators. Utu, He tino tairongo ngā korakora kaha-iti ki ngā o nāianei hau, i runga anō i te whakataurite ki ngā kohuke me ngā konganuku. Ko ngā rerekētanga iti o te hau i roto i te pūrere wehenga ka pā ki te ara haere o ngā korakora pai, e herea ana rātau ki ngā tōpana atu i ērā i takea mai i te āpure pateko ā-hiko.

Mō te nuinga o ngā pūnaha whakawehe pereti whakarara, minita whenua me te iti-kiato matūriki e e electrostatically e kohia i runga i nga electrodes o te whakawehe pereti whakarara i ako. Ki te kore e enei matūriki pai electrically piri nekehia atu i runga i te pūtake tonu, te kaha mara hiko me te kakama o te haafaufaa pūrere. Ko te mahi o te kairangahau i te Tukanga Food Engineering Group Wageningen UR (Wang et al, 2015) ka mau painga o tenei āhuatanga ki te kohikohi i ngā tauira atu te mata o nga electrodes o te whakawehe pereti whakarara ki te tātari i te hua o te wehenga. pūnaha Whakawehe pereti whakarara, ngā hunga e whakawhirinaki ki runga ki te mahara ki te kawe i matūriki i roto i te mara hiko, Kua ngana ki te whakatutuki i tenei raruraru i roto i te maha ngā huarahi. Stone et al (1988) whakaahuatia te tukanga i roto i nei matūriki pai i nekehia atu whakarunga o te kaiwehe hiko i te rangi elutriation. [10] Kua korerotia etahi whakaū i te awa laminar o rangi e rerengia ana puta noa i te electrodes ki te ārai matūriki pai i te awe e ngā hau. [22Heoi, te pupuri i airflow laminar riro wero rite te pūrere wehenga riro nui, tōtika whāiti te kaha tukatuka o taua whakaaro. Te mutunga iho te rahi matūriki i roto i nei e wehe fakaesino i te tahi atu wāhanga (reira rite matūriki motuhake), ka waiho i te taraiwa nui i roto i te whakatau i te rahi matūriki i nei me tukatuka puta.

Ka rite ki whakahuatia i mua, E whāiti tikanga whakaaro wehenga hiko i roto i te kaha tukatuka, especially with low-density and finely ground powders such as plant materials. For high-tension drum and belt separation devices, he whāiti te mōtika ki ngā korakora e tino pai ana, ā, he tō ā-papa tino tauwhāiti rānei, e tika ana ki te hiahia mō ngā matūriki katoa ki te whakapā atu i te mata o te pahū. Ka rite ki riro iti matūriki heke te auau tukatuka te. E anō iti whakawehe pereti whakarara i te kiato matūriki e taea te tukatuka i roto i te rohe kawehiko. Me kia Matūriki uta āhua iti ki te ārai i ngā pānga tiaki wāhi.

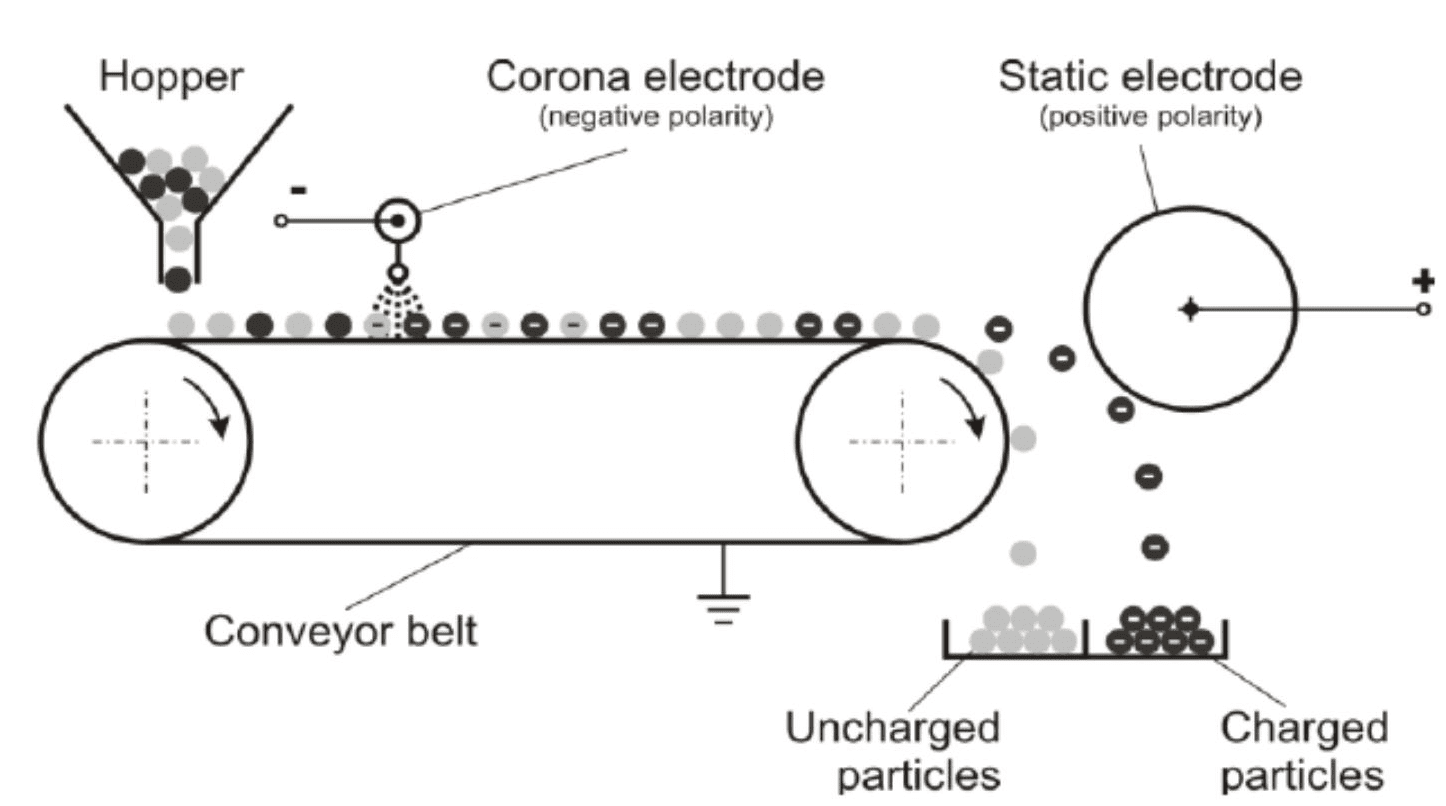

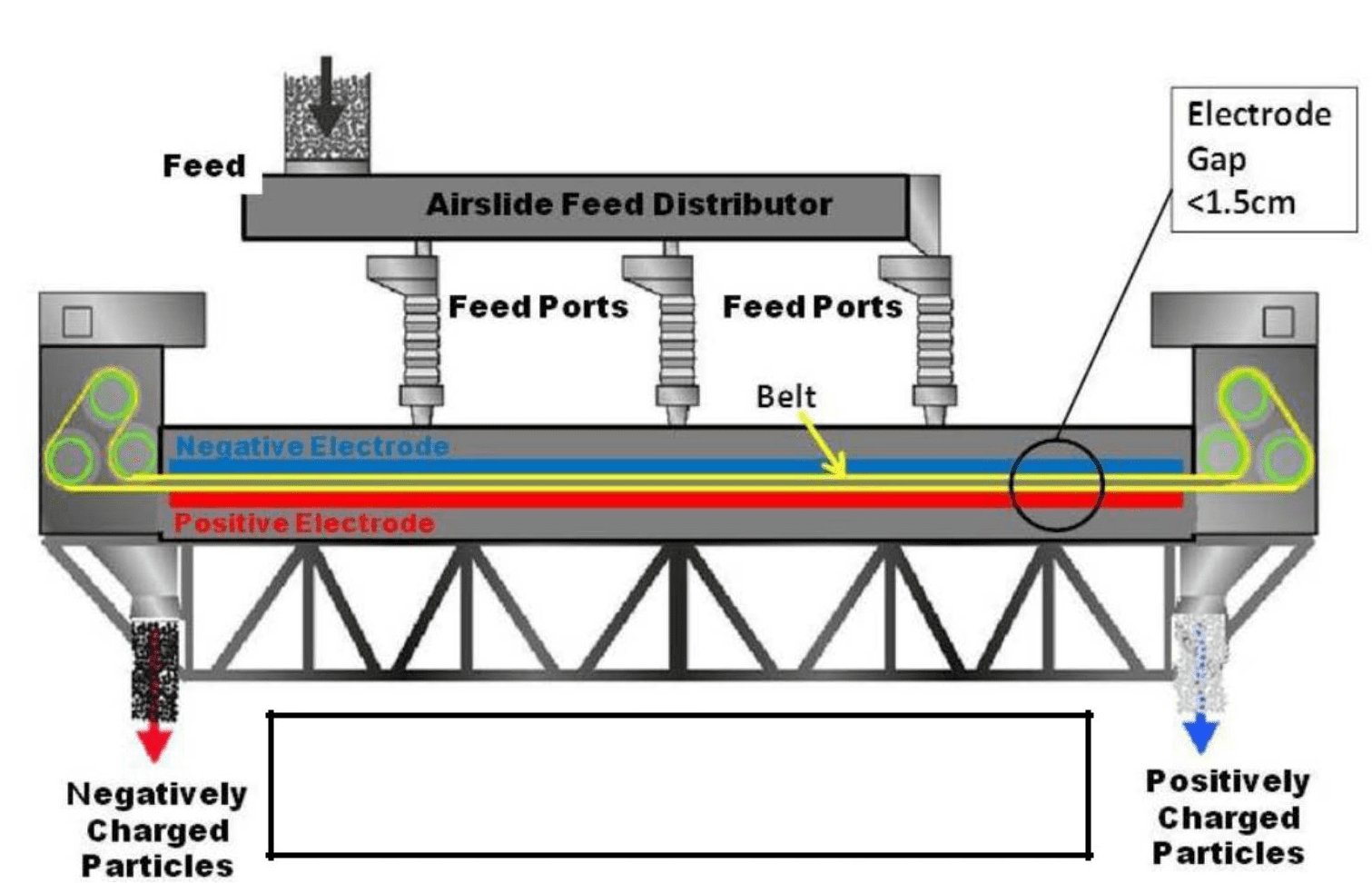

ST Taputapu & Hangarau Belt Whakawehe

Te ST Taputapu & hangarau (STET) whakawehe whitiki triboelectrostatic He te āheinga whakaatu ki te tukatuka matūriki pai i 500 - 1 μm. Ko te whakawehe STET ko te kaiwehe hiko pereti whakarara, Heoi, E hāngai te mau api kawehiko whakapae rite te ātete ki poutū ko te take i roto i te nuinga o ngā whakawehe pereti whakarara rite. (Tirohia te Figure 6) I tua atu, te kaiwehe STET oti te tribo-tohutohutia me tuku wā e te nui-tere tuwhera mata nekeneke matūriki. Tēnei āhuatanga e āhei hoki e rua he auau tukatuka motuhake tiketike rawa o te kai, me te ki te āheinga tukatuka nui kaitahi puehu atu pūrere hiko tikanga. Kua mahi arumoni tēnei momo pūrere wehenga mai i 1995 e wehe ana i te waro kāore i te tahuna i te rere kohuke (tata tonu ki te D50 20 μm) i roto i nga hiko waro. Kua momoho hoki tēnei pūrere wehenga hiko ki te whakaputa i ētahi atu rauemi ā-rōpū, tae atu ki ngā kohuke pēnei i te konupūmā pākawa waro, talc, barite, me ētahi atu.

Ko ngā taipitopito taketake o te whakawehe STET e whakaahuatia ana i Figure 7. E whakatupato ana te matūriki i te pānga triboelectric roto collisions matūriki-ki-matūriki i roto i te āputa i waenganui i te electrodes. Te ngaohiko tono i waenganui i te electrodes ko waenganui i ± 4 me ± 10 kV whanaunga ki whenua, hoatu he katoa rerekētanga ngaohiko o 8 - 20 kV puta noa te āputa kawehiko rawa kuiti o kīia ai 1.5 cm (0.6 inihi). E whakaurua matūriki Feed ki te whakawehe STET i tetahi o ngā wāhi e toru (Tauranga whāngai) mā te pūnaha distributor rangi kiriata ki vaolo kuwaha maripi. Ko te whakawehe STET hua e rua anake ngā hua, kohia he awa matūriki tōraro whakatupato i runga i te kawehiko pai whakatupato, ka kohia he awa matūriki pai whakatupato i runga i te kawehiko tōraro whakatupato. Kua kawea te hua ki te hoppers tēnā i ia pito o te STET kaiwhakawehe i te whitiki whakawehe me tuku atu o te whakawehe i te mahara. E kore e te whakawehe STET hua he middlings awa para ranei, ahakoa ki whirihoranga haere maha whakapai ake te viivii hua whakaora me / ranei e taea.

Figure 6: STET Triboelectric Belt Whakawehe

E kawea matūriki i roto i te āputa kawehiko (rohe wehenga) e te koropiko tonu, tuwhera whitiki mata. E whakahaerehia ana te whitiki i te tere tiketike, tāupe i 4 ki 20 m / s (13 - 65 ft / s). Ko te āhuahanga o te whitiki kaimahi ki te tahi i matūriki pai atu te mata o te electrodes, ārai i te haaputuputuraa o matūriki pai e haafaufaa i te mahi me te ngaohiko mara o noa-hinga pereti whakarara tuku iho ngā pūrere momo wehenga. I tua atu, te whitiki mahia he anake tiketike, rohe moveuveu tiketike i waenganui i nga electrodes e rua, whakatairanga tribo-utu. Ko te haere counter-o nāianei o te whitiki whakawehe taea hoki e mea tonu, me te re-e mea ranei matūriki i roto i te whakawehe, te whakakore i te hiahia mō te pūnaha mua tohutohutia-whakarunga o te whakawehe STET.

Figure 7: Fundamentals o mahi o STET Belt Whakawehe

Ko te whakawehe STET ko te auau whāngai tiketike, pūnaha tukatuka arumoni kï. Ko te nuinga te āheinga tukatuka mōrahi o te whakawehe STET he mahi o te auau kai rōrahi e taea te tuku i roto i te āputa kawehiko i te whitiki whakawehe STET. Ētahi atu taurangi, pērā i te tere o te whitiki, te tawhiti i waenganui i te electrodes me te kiato aerated o te paura whai te auau kai mōrahi, nuinga ki te whānuitanga iti. Hoki ngā rauemi tiketike-kiato āhua, hei tauira, rere pungarehu, te auau tukatuka mōrahi o te 42 inihi (106 cm) Ko te pakeke te whanui kawehiko wae wehenga arumoni 40 - 45 Taranata ia haora o te kai. Hoki ngā rauemi kai iti mātotoru, Ko raro te auau kai mōrahi.

ripanga 6: Āwhiwhi auau kai mōrahi mō te ngā rauemi tukatuka ki STET 42 inihi whakawehe hiko.

pahūtanga puehu ko te mōrearea nui i roto i te witi, me te tahi atu ngā mahi tukatuka paura organic. he pai hoki te tukatuka puehu organic combustible ki anake whakarerekētanga iti te whakawehe STET. E kore papa wera i roto i te whakawehe STET. Ko te wahi anake neke ko te whitiki, me te puku awa whakawehe. Kei te tū te ahunga takai i waho o te awa paura i runga i te anga waho o te kōwae. Na reira e kore e ratou he mōrea mō te pukā / sparking i roto i te awa rauemi. I tua atu, E wātea ana ki te wheketere e rite rawa āheinga pāmahana inenga ki te kitea e amo kore te ahunga STET whakawehe pai i mua i e tae pāmahana fakatu'utāmaki teitei. Ko te whitiki whakawehe me te pūnaha puku tū kahore mōrea ki runga ake i te tahi atu machinery E takahuri ana tikanga. Kei te tū hoki te STET whakawehe wae ngaohiko tiketike i waho o te awa rauemi me roto i roto i nohoanga puehu-raru. iti te pūngao mōrahi o te mura puta noa te āputa whakawehe e te hoahoa o nga wae ngaohiko tiketike. Ka taea te whakaurua tētahi taumata atu o te haumaru mā hauota tamâraa.

Whole Tukatuka Witi Flour e STET Whakawehe

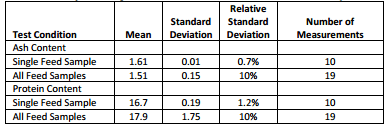

I ahu mai te paraoa witi katoa i huri i te witi katoa o te witi (parani, iroriki, me endosperm). arumoni wātea, atu-te-papa, I hokona katoatia te parāoa witi hei rawa whakamātautau hei arotake i te āheinga o te whakawehe STET hei tango i te bran fibrous me te germ mai i te hautanga o te parāoa witi. I tātaritia te tauira parāoa witi katoa e STET i mua i te tīmatanga o te whakamātautau. I whakamātauria ngā ihirangi Aha e icc Standard 104 / 1 (900° C). Ngā inenga rehu tukurua o te tauira ōrite, he tauira whāngai kāore i te whakaritea, ine 10 ngā wā, i kitea he ihirangi rehu o 1.61%, he ine mahora o 0.01 me te ine mahora pātahi o 0.7%. I oti te tātari rahi matūriki i taiaho ttara te whakamahi i te Malvern Mastersizer 3000 ki te purara taputapu maroke. whakahaere tātaritanga Pūmua i te whakamahi i te aratuka Dumas, ki te N tere Elementary nui hauota / pūmua analyzer. He take faafariuraa o N x 6.25 i whakamahia. Kua whakarāpopotohia nga āhuatanga ngā o te tauira paraoa witi katoa i raro. (Tirohia te Ripanga 7)

ripanga 7: Tātaritanga o katoa kai paraoa witi e STET

i kitea ihirangi pungarehu, me te ihirangi pūmua ki kia tino repeatable ka whakamatauria i roto i te tauira kotahi, engari tāutuhia nui rerekētanga i waenganui i te peke maha o te paraoa witi katoa whakamahia rite te tauira kai. (Tirohia te Ripanga 8) hua tenei kai tauira rerekētanga i roto i te tahi mau titari atu i roto i te raraunga whakamātautau.

ripanga 8: Tātaritanga o ngā hua wehenga whakamātautau o te paraoa witi katoa i te STET

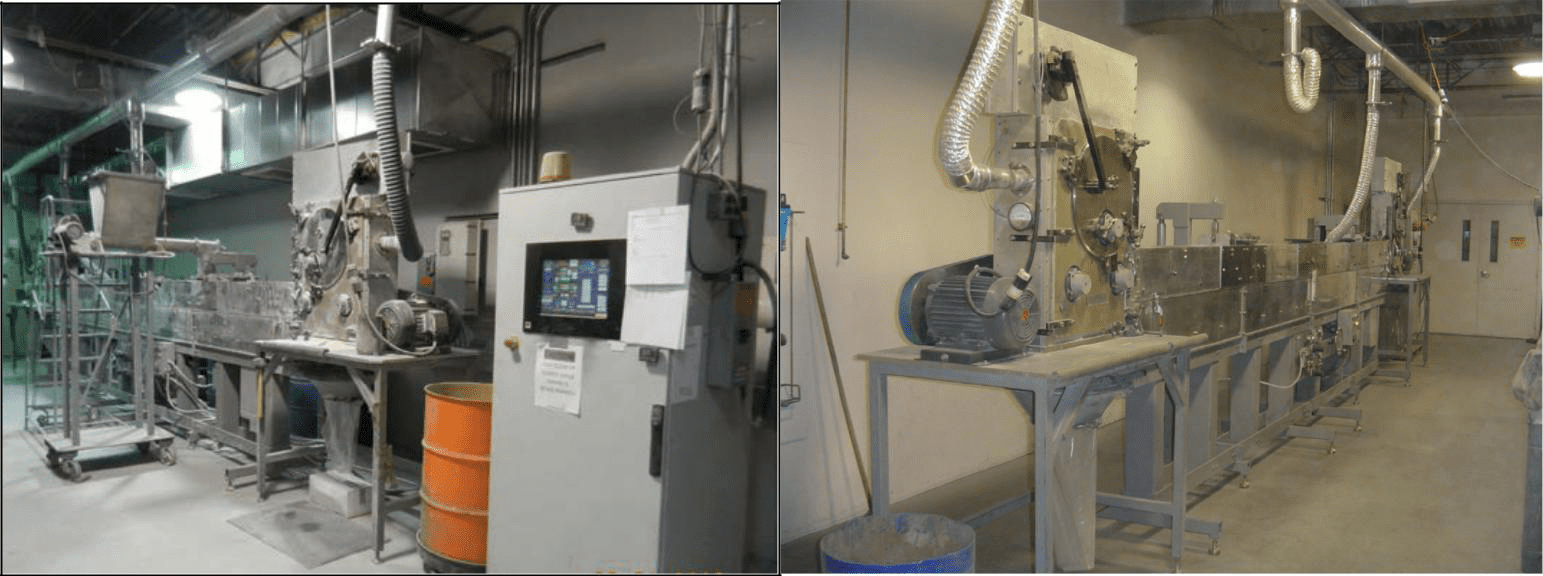

I whakamana whakamātautau wehenga hiko o te tauira paraoa witi katoa i te ST Taputapu & hangarau (STET) pairati wāhi tipu i roto i Needham, Massachusetts. Te tipu STET pairati kei rua whakawehe tauine pairati STET me taputapu āpiti whakamahia ki te tirotiro i te wehenga o ngā rauemi i ngā puna kaitono. Ko te whakawehe pairati-tauine STET ko te roa taua rite te whakawehe STET arumoni, ki 30 waewae (9.1 mita) roa, Heoi, Ko anake te pairati tipu whakawehe kawehiko whanui 6 inihi (150 mm), ranei tetahi-whitu o te whanui o te nui rawa whakawehe STET arumoni i 42 inihi (1070 mm) whānui kawehiko. Ko te tika hautanga ki te whanui o te electrodes te kaha kai o te whakawehe STET, reira, te auau kai o te whakawehe paerata tipu ko tetahi-whitu o te auau kai o te kōwae whakawehe arumoni whānui 42-inihi. Ko te auau whāngai mōrahi ki te paraoa katoa witi i 2.3 Taranata ia haora i tauine pairati, e hāngai ana ki 16 Taranata ia haora mo te 42-inihi whakawehe arumoni whānui. I roto i rite ki te tauine i ai te nuinga o nga akoranga wehenga hiko kua whakahaeretia ki te rā, kawea te whakamātautau STET whakawehe i roto i te tere whāngai tino teitei. i whakamana whakamatautau i 10 kg (20 pauna) whakamātautau puranga, e tika ana ki te whakaaro mahi o tuku 2.3 Taranata ia haora o te kai tonu. Hoki ia huru whakamātautau puranga, i paunatia nga hua o te tukanga wehenga ki te tātai i te whakaora papatipu. Subsamples i ia whakamātautau kohia i ka tātarihia mō te ihirangi pungarehu, me te ihirangi pūmua.

Figure 8: STET Pilot Plant Whakawehe.

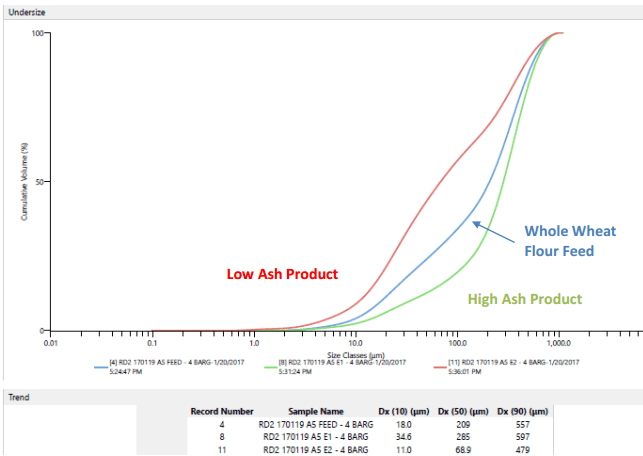

whakaaturia rahi matūriki inenga o te kai me ngā tauira hua paraoa witi katoa e rua kei te raro nei i roto i te Whakaahua 9.

Figure 9: inenga rahi matūriki o te kai paraoa katoa witi, me nga tauira hua e rua wehea.

Kei raro nei tētahi pikitia o ngā hua wehenga kua whakaorangia. (Tirohia te Figure 10) I kitea tētahi neke tae mōhiotia i te wā o te wehenga, e tino pouri ake ai te hautanga o te hua ihirangi rehu i te tauira parāoa witi katoa.

Figure 10: I whakaorangia ngā hua ā-rangi mai i te tukanga wehenga STET.

I inetia ngā ihirangi Aha mō ngā hua katoa mai i te tukanga wehenga. (Tirohia te Figure 11)

Figure 11: Ko te ihirangi o Aha me te whakaora maha o ngā hua rehu iti mō ngā whakamātautau wehenga parāoa witi katoa e STET

Whakamātautau o te kaiwehe hiko STET ki te paraoa witi katoa faaite kaupapa nui o te pungarehu tiketike (parani) hautanga o te pata witi ki te kawehiko pai. I muri kohia te hua pungarehu iti i runga i te kawehiko tōraro. I whakamana whakamatautau i runga i te kaupapa haere kotahi, Heoi, Ko reira taea ki te mahi i whakahoutanga atu o rānei o te hua wehenga mā te raveraa i te tahi atu atamira wehenga. Future testing with the STET separator will be conducted on wheat bran samples, me te paraoa witi me rēkiumu pērā i Lupin.

whakatau

Arotake o te tuhinga e hāngai ana tohu e kua rangahau nui kua whakahaeretia ki te whakawhanake i ngā rautaki wehenga hiko mō rauemi organic. Kua tonu ara ranei tenei whanaketanga whakatere i roto i te mua 10 - 20 tau, me te tokomaha o ngā kaipūkaro i Uropi me Te Hononga o Amerika e hoatu ana i ngā pūkenga wehenga hiko ki ngā momo whakamātautau whānui o te whai hua. Mai i tēnei rangahau, Ko reira kitea e tikanga hiko i te pūmanawa ki te whakaputa hou, teitei hua tipu uara, whakahere ranei he rerekē ki te maku tikanga tukatuka. Ahakoa akiaki i māvaé o witi, witi me ngā rauemi tipu e hāngai ana rūpene-kua faaite i te taiwhanga, me i roto i te tahi mau tauine take whakamätau, e kore ai te pūnaha hiko whakamahia ki te whakaatu i ēnei hua hei te taputapu tukatuka tino tika-utu whai hua ranei ki te mahi i taua māvaé i runga i te pūtake arumoni. Many electrostatic technologies are not suitable for process finely ground, low-density powders such as plant materials. Heoi, te ST Taputapu & hangarau (STET) triboelectrostatic belt separator has the demonstrated capability to process fine particles from 500 - 1 μm i reiti teitei. The STET belt separator is a high rate, industrially kï pūrere tukatuka e kia tika ki te hokohoko i te whanaketanga tata i roto i te tukatuka tipu. The STET belt separator was tested on a sample of whole wheat flour and was found to be successful in removing the bran from the starch fraction. Future testing with the STET separator will be conducted on wheat bran samples, me te paraoa witi me ngātere pērā i soy me rūpene.

Tohutoro

[1] T. B. Osborne, “Middlings-Purifier”. United States o Amerika Patent 224,719, 17 Hui-tanguru 1880.

[2] H. Manouchehri, K. Hanumantha Rao ko K. Forsberg, “Arotake o ngā tikanga wehenga hiko – wāhanga 1: āhuatanga taketake,” kohuke & Processing Metallurgical, vol. 17, kahore. 1, pp. 23-36, 2000.

[3] J. Elder ko E. yan, “eForce – whakatupuranga hōu o te kaiwehe hiko mo te ahumahi kohuke onepu,” i roto i te taumaha Minerals Conference, Johannesburg, 2003.

[4] R. H. Perry ko D. W. Green, a Perry Chemical Engineers’ Handbook Fitú Edition, New York: McGraw-Hill, 1997.

[5] S. Messal, R. Corondan, ahau. Chetan, R. Ouiddir, K. Medles ko L. dascalescu, “kaiwehe hiko mō ranunga micronized o konganuku me kirihou ahu i hiko koraha me te taputapu hiko,” Journal o Physics, vol. 646, pp. 1-4, 2015.

[6] T. S. Pandya, R. Srinivasan me C. P. Thompson, “He iti noa iho te fiber mō te whenua e pā ana ki te whakamahi i tētahi tikanga pateko hiko,”Matuhi Cereal, vol. 90, kahore. 6, pp. 535-539, 2013.

[7] L. rama, P. M. Beier, ko ahau hoki. Stahl, Separation hiko, Weinheim: Wiley VCH Verlag GmbH & Co. KGaa, 2005.

[8] A. Hemery, X. Rouau, V. Lullien-Pellerin, C. Barron me J. Abecassis, “Tukanga maroke hei hanga i ngā hautanga witi me ngā hua me te kounga kai whakarei,” Tuhitaka o te Pūtaiao Cereal, kahore. 46, pp. 327-347, 2007.

[9] W. He. Brastad me E. C. Gear, “Aratuka me te Mahi mō te Hekenga Hiko”. United States o Amerika Patent 2,848,108, 19 August 1958.

[10] B. He. Kohatu me J. Iti, “Whakaora o ngā Pūtau Aleurone mai i Wheat Bran”. United States o Amerika Patent 4,746,073,24 kia 1988.

[11] He. Bohm me A. raraku, “Aratuka mō te Whakatau i ngā Particles Aleurone”. United States o Amerika Patent 7,431,228, 7 nuku 2008.

[12] J. He. Delcour, X. Rouau, C. M. Kōti, K. Poutanen me R. Rāraniei, “Ngā hangarau mō te whakarei i te apo o te hauora o ngā kaiaka,” Ngā ia i te Pūtaiao Kai & hangarau, pp. 1-9, 2012.

[13] L. dascalescu, C. Tōkona, M. Bilici, R. Beleca, A. Hemery me X. Rouau, “Ko te āhua o te hiko mō te hekenga o ngā take o Wheat Bran,” Ngā Tauwhitinga IEEE mō ngā Taupānga Mahi, vol. 46, kahore. 2, pp. 659-665, 2010.

[14] A. Hemery, X. Rouau, C. Tōkona, R. Bilici me L. dascalescu, “Ngā āhuatanga pateko o te bran witi me ōna apa whai tikanga: Te āhuatanga o te rahi korakora, hanganga, me te ihirangi moisture,” Tuhitaka o te Pūkaha Kai, kahore. 93, pp. 114-124, 2009.

[15] A. Hemery, M. Manatiti, Ko te. Holopainen, A.-M. Lampi, P. Lehtinen, V. Piironen, He. Sadoudi me X. Rouau, “Pümanawa o fractionation maroke o te parani witi mo te whanaketanga o kai kai, wāhanga e ahau: Mana o te huri ultra-pai,” Tuhitaka o te Pūtaiao Cereal, kahore. 53, pp. 1-8, 2011.

[16] A. Hemery, Ko te. Holopainen, A.-M. Lampi, P. Lehtinen, T. tarutaru, V. Piironen, M. Edlemann ko X. Rouau, “Pümanawa o fractionation maroke o te parani witi mo te whanaketanga o kai kai, wāhanga II: wehenga hiko o matūriki,” Tuhitaka o te Pūtaiao Cereal, kahore. 53, pp. 9-18, 2011.

[17] J. Wang, E. Smits, R. M. Boom, ko M. He. Schutyser, “aro Arabinoxylans i parani witi i te wehenga hiko,” Tuhitaka o te Pūkaha Kai, kahore. 155, pp. 29-36, 2015.

[18] P. J. Pelgrom, J. Wang, R. M. Boom, ko M. He. Schutyser, “mua- me pou-maimoatanga whakarei i te haamaitairaa pūmua i mira, me te rangi whakarōpū o ngā rekiumu,” Tuhitaka o te Pūkaha Kai, kahore. 155, pp. 53-61, 2015.

[19] D. Chereau, P. Videcoq, C. Ruffieux, L. Pichon, J.-C. Motte, S. Belaid, J. Ventureira ko M. Lopez, “Te pahekotanga o ngā hangarau tīariari, whirinoa hoki hei whakatoko i ngā pūmua hinu me ngā pūmua mokowhiti i roto i ngā taupānga kai,” Oilseeds & ngā koko me ngā Lipids, vol. 23, kahore. 4, pp. 1-11, 2016.

[20] He. Parara, F. Ierome me X. Rouau, “He Pūhara Dry mō te hekenga o ngā Proteins mai i biomass-Containing

Ngā Polysaccharides, Lignin, me ngā Polyphenols,” ChemSusChem, vol. 8, pp. 1161-1166, 2015.

[21] C. Huinga, S. Kedidi me A. Parara, “Matū- me te hautanga mechanophysical koreutu o ngā Biomass i hangaia e Tribo-Electrostatic Charging: Ngā Proteins me te Lignin,” Matuhi Mārō ACS & Mātai pūhanga, vol. 4, pp. 4166-4173, 2016.

[22] J. M. Stencel, J. L. Schaefer, H. Ban, me J. K. Neathery, “Ngā Mahi me te Aratuka mō te Wehenga Triboelectrostatic”.United States o Amerika Patent 5,938,041, 17 August 1999.