Сайлагыз Тел:

Сент җиһазлар & Технологияләр " ҖЧҖ (НТОО) tribo-electrostatic belt separator technology allows for the beneficiation of fine mineral powders with an entirely dry technology at a high throughput. The STET separator is well suited for separation of very fine (<1мкм) чамасын грубый (500мкм) частицы, in contrast to other electrostatic separation processes that are typically limited to particles >75µm in size. STET has successfully beneficiated iron ore samples including run-of-mine ores, tailings and itabirite with iron feed contents ranging from 30-55%. Experimental findings indicate that low-grade iron ores can be upgraded to commercial grades (58-65% Фе) while simultaneously rejecting silica by using STET belt separator. Here, a compendium of experimental results and a preliminary study of potential applications for the STET technology for the iron industry are presented. The preliminary studies include high-level flowsheets and economic evaluations for selected applications. Challenges associated with the adoption of the technology and a comparison to currently available technologies for the processing of iron ore fines are also discussed.

1.0 Introduction

Iron ore is the fourth most common element in the earth’s crust and is essential for global economic development and steel manufacturing [1-2]. Iron ores have a wide range in chemical composition especially for Fe content and associated gangue minerals [1]. Major iron-bearing minerals are hematite, гетит, лимонит һәм магнетит [1,3] and the main contaminants in iron ores are 2 and Al2O3. Һәр чыганагы файдалы казылмалар бар, үз уникаль характеристика карата железу һәм жильные минералы урын алган, һәм шуңа күрә ул таләп итә башка да күп [4].

Modern processing circuits of iron bearing minerals may include gravimetric concentration, magnetic concentration, and flotation steps [1,3]. Әмма, modern circuits present challenges in terms of processing of iron ore fines and slimes [4-6]. Gravimetric techniques such as spirals are limited by particle size and are only deemed an efficient way of concentrating hematite and magnetite for the size fraction above 75μm [5]. Юеш һәм коры түбән арткан чорда, шуның өстендә урнашкан магнит сепарации (ЛИМС) techniques are used to process high-grade iron ores with strong magnetic properties such as magnetite while wet high-intensity magnetic separation is used to separate the iron bearing minerals with weak magnetic properties such as hematite from gangue minerals. Magnetic methods present challenges due to their requirement for the iron ore to be susceptible to magnetic fields [3]. Flotation is used to reduce the content of impurities in low-grade iron ores, but is limited by the cost of reagents, and the presence of silica, alumina-rich slimes and carbonate minerals [4,6]. In the absence of further downstream processing for the reject streams the fine iron rejects will end up disposed in a tailings dam [2].

Tailings disposal and processing of iron fines have become crucial for environmental preservation and recovery of iron valuables, димәк, and therefore the processing of iron ore tailings and fines in the mining industry has grown in importance[7].

Әмма, the processing of iron tailings and fines remains challenging via traditional flowcharts and therefore alternative beneficiation technologies such as tribo-electrostatic separation which is less restrictive in terms of the ore mineralogy and particle size may become of interest. Dry electrostatic processing of iron ore presents an opportunity to reduce costs and wet tailings generation associated with traditional gravimetric, flotation and wet magnetic separation circuits.

STET has developed a separation process that enables efficient separation of fly ash and minerals according to their response when exposed to a specific electric field. The technology has been applied successfully to the fly ash industry and the industrial minerals industry; and STET is currently exploring other market openings where their separators could offer a competitive advantage. One of the targeted markets is the upgrading of fine iron ore.

STET has performed exploratory studies with several iron ores and experimental results to date have demonstrated that low-grade iron ore fines can be upgraded by means of STET tribo-electrostatic belt separator. The STET dry electrostatic separation process offers many advantages over traditional wet processing methods, including the ability to recover fine and ultra-fine iron that would otherwise be lost to tailings if processing with existing technology. Моннан тыш,, the technology requires no water consumption, which results in the elimination of pumping, thickening and drying, as well as any costs and risks associated with water treatment and disposal; no wet tailings disposal – recent high-profile failures of tailings dams have highlighted the long-term risk of storing wet tailings; һәм, no chemical additional required, which therefore negates the ongoing expense of reagents and simplifies permitting.

Iron ore is an industry with a dynamic that is different from the other base metals. This is due to its fluctuating market, билгеләнгән гаять зур җитештерү күләмнәре һәм тиешле чыгымнар буларак, капитальную, шулай ук операционную яклар [8] шулай ук булмау, үзәк обменных үзәкләре кебек Лондонская биржасы металл. Бу-китерә, зур керемнәр, алар возможны, кайчан бәясе взлетает өскә таба һәм бритва тонкая маржа, кайчан обстоятельства начаррак. Бу сәбәпләренең берсе зур җитештерү күләмнәре һәм басым түбән уртача җитештерү затратах.

Here, results of a screening study of the iron ore industry developed by STET and Soutex is presented in order to identify niches in which the STET technology could offer an economic advantage in comparison to more conventional technologies. Soutex is a minerals processing and metallurgy consultancy and has experience designing, optimizing and operating various iron ore concentration processes, with an understanding of the CAPEX, OPEX as well as the marketing aspects of the iron ore industry. For this study, Soutex provided its expertise in evaluating potential applications for triboelectrostatic separation in iron ore. Soutex’ scope included flowsheet development and order of magnitude study-level capital and operating cost estimates. This paper explores three of the most promising applications found, on a technical and economical level. These three applications were identified as: Upgrading of iron ore fines in the Australian DSO mining; scavenging of fine iron concentrate in hematite/magnetite concentrators; һәм, reprocessing of rich-Fe tailings from Brazilians operations.

2.0 STET Triboelectrostatic Belt Separator

Экспериментлар үткәрелгән кулланып, лаборатор Трибо-электростатический сепаратор поясы . Bench-scale testing is the first phase of a three-phase technology implementation process including bench-scale evaluation, тәҗрибә-сәнәгать сынауларын һәм сәнәгый кулланышка кертү. Сепаратор настольная өчен кулланыла скрининг өчен булуы Трибо-электростатический өлкәннәр өчен билгеләргә, әгәр дә материал булып тора, яхшы кандидат өчен электростатического баету. Төп тамгасын һәр берәмлек җиһаз түбәндә таблица формасында күрсәтелгән 1. Кулланганда җиһазлар кысаларында һәр этапта төрлечә күләме буенча, эш принцибы асылда шул ук.

STET has evaluated several iron ore samples at bench scale and significant movement of iron and rejection of silicates has been observed (См. Таблицасын 2). Experimental conditions were selected so that an iron recovery vs. iron increase curve could be drawn and later be used as input for an operating economic model

Таблица 2. Bench-scale results on different iron ores

| Exp | Ашатырга Fe wt.% | Продукт Fe wt.% | Absolute Fe Increase % | Фе Яңадан торгызу % | Ѕіо2 Rejection % | D10 (мкм) | Д50 (мкм) | D90 (мкм) |

|---|---|---|---|---|---|---|---|---|

| 1 | 39.2 | 50.6 | 11.4 | 91.5 | 63.9 | 5 | 23 | 59 |

| 2 | 39.4 | 60.5 | 21.1 | 50.8 | 96.0 | 5 | 23 | 59 |

| 3 | 30.1 | 48.0 | 17.9 | 70.6 | 84.6 | 1 | 18 | 114 |

| 4 | 29.9 | 54.2 | 24.3 | 56.4 | 93.7 | 1 | 18 | 114 |

| 5 | 47.0 | 50.2 | 3.2 | 96.6 | 35.3 | 17 | 62 | 165 |

| 6 | 21.9 | 48.9 | 27.0 | 41.2 | 96.6 | 17 | 62 | 165 |

| 7 | 47.6 | 60.4 | 12.8 | 85.1 | 96.9 | 17 | 62 | 165 |

| 8 | 35.1 | 44.9 | 9.8 | 89.0 | 54.2 | 3 | 61 | 165 |

| 9 | 19.7 | 37.4 | 17.7 | 76.0 | 56.8 | 5 | 103 | 275 |

| 10 | 54.5 | 62.5 | 8.0 | 86.3 | 77.7 | 5 | 77 | 772 |

| 11 | 54.6 | 66.5 | 11.9 | 82.8 | 95.6 | 8 | 45 | 179 |

(See Section 3.0, Дөге. 4). Additional experimental results showing separation results on iron ore samples using STET technology are presented in a previous publication by STET on iron ore processing [9].

Таблица 1. Өч этапта процессын кертү файдаланып, СТЕТ Трибо-электростатическая технология ленточного сепаратора .

| Phase | Used For: | Electrode Length | Type of Process |

|---|---|---|---|

| 1- Bench Scale Evaluation | Qualitative Evaluation | 250см | Batch |

| 2- Pilot Scale Тест | Quantitative evaluation | 610см | Batch |

| 3- Коммерция Scale | Коммерция Production | 610см | Continuous |

Күрәсең таблицасында 1, төп аерма арасындагы сепаратором кыр һәм эксперименталь һәм сәнәгать сепараторов булып тора, ягъни озынлыгы сепаратора настольная тәшкил итә, якынча 0.4 тапкыр озынлыгы пилот һәм сәнәгать җайланмалары. Ничек нәтиҗәлелеген сепаратора бәйле длины электрода , стендовые сынаулар да булырга мөмкин материаллары сыйфатында алыштыру өчен тәҗрибә-сәнәгать сынауларын. Pilot-scale testing is necessary to determine the extent of the separation that the STET process can achieve at commercial scale, һәм билгеләү өчен, әгәр процессы СТЕТ очратырга мөмкин продукт максатка каршындагы заданных скоростях бирү . Due to the difference in active separation length from bench scale to pilot scale, results typically improve at pilot scale.

2.1 Operation Principle

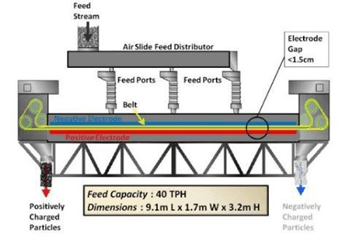

Бу Трибо-электростатический сепаратор поясы (see Figure 1 һәм дөге. 2), материал бирелә " тонком зазоре 0.9 – 1.5 см арасында ике параллельными плоскими электродами.

Частицы triboelectrically, взимаемые межчастичного бәйләнеш. Мәсәлән, in the case of an iron sample comprising mainly hematite and quartz mineral particles, the positively charged (hematite) and the negatively

Частицы triboelectrically, взимаемые межчастичного бәйләнеш. Мәсәлән, in the case of an iron sample comprising mainly hematite and quartz mineral particles, the positively charged (hematite) and the negatively

charged (кварцевые) җәлеп итә к противоположным электродам. Аннары частицы заметенного өзлексез хәрәкәт ачык сетка пояс һәм колесниковка, шул противоположных юнәлешләре. Пояс двигает частицы янында һәр электрода бу противоположных концах сепаратора. The counter current flow of the separating particles and continual triboelectric charging by particle-particle collisions provides for a multi-stage separation and results in excellent purity and recovery in a single-pass unit. The belt allows for processing on fine and ultra-fine particles including particles smaller than 20µm, by providing a method to continuously clean the surface of the electrodes and remove the fine particles, which would otherwise adhere to the surface of the electrodes. The high belt speed also enables throughputs up to 40 tonnes per hour on a single separator by continuously conveying material out of the separator. Аша контроль төрле параметрлары процессын , the device allows for optimization of mineral grade and recovery.

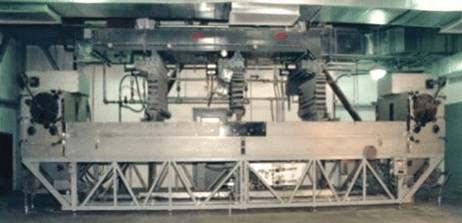

Төзелеш исә сепаратора булып, чагыштырмача гади генә кебек. Поясы һәм бәйле роликлар булып автоспорт движущимися өлешләре. The electrodes are stationary and composed of a highly durable material. The belt is a consumable part which requires infrequent but periodic replacement, a process which is able to be completed by a single operator in only 45 минут. Озынлыгы электрода сепаратора тәшкил итә, приблизительно 6 метрдан (20 футов.) ә киңлеге 1.25 метрдан (4 футов.) өчен тулы күләмен коммерция бүлекләре (see Figure 3). Кереме энергиясе азрак 2 kWh per tonne of material processed with most of the power consumed by two motors driving the belt.

Процесс тулысынча коры, таләп итми, өстәмә материаллар да җитештерә суларны яки атмосферага . For mineral separation the separator provides a technology to reduce water usage, киңәйтергә запасы тормыш һәм/яки торгызу һәм кабат үткәрелгән эшкәртү хвостов.

Процесс тулысынча коры, таләп итми, өстәмә материаллар да җитештерә суларны яки атмосферага . For mineral separation the separator provides a technology to reduce water usage, киңәйтергә запасы тормыш һәм/яки торгызу һәм кабат үткәрелгән эшкәртү хвостов.

Компактность системасын тәэмин итә гибкость " конструкцияләр урнаштыру . The tribo-electrostatic belt separation technology is robust and industrially proven and was first applied industrially to the processing of coal combustion fly ash in 1995. Технология нәтиҗәле бу бүлекчәсе частиц углерод нче неполного яну күмер, нче стекловидные алюмосиликатные минераль частицы " пепел. Технология мөһим роль уйный, тәэмин итү, эшкәртү, минераль золы уноса буларак алыштыру цемент җитештерүдә бетон.

Шулай 1995, өчен 20 million tonnes of product fly ash have been processed by the STET separators installed in the USA. The industrial history of fly ash STET separation is listed in Table 3.

In minerals processing, the triboelectric belt separator technology has been used to separate a wide range of materials including calcite/quartz, тальк/магнезитовые, һәм барит/кварц.

Таблица 3. Сәнәгый куллану Трибо-электростатической сепарации пояс өчен пепла

| Утилита / электростанция | Урнашуы | Start of commercial операциясе | Объект детальләрен |

|---|---|---|---|

| Герцог Энергиясе – Станция Роксборо | Төньяк Каролина, АКШ | 1997 | 2 Сепараторы |

| Тален Энергиясе- Брэндон Буенда | Мэриленд, АКШ | 1999 | 2 Сепараторы |

| Шотландские Хакимияте- Станциясе Longannet | Шотландия Бөекбритания | 2002 | 1 Сепаратор |

| Электрический Джексонвилл-Иске. Johns River Power Park | Флорид АКШ | 2003 | 2 Сепараторы |

| South Mississippi Electric Power -R.D. Морроу | Миссисипи, АКШ | 2005 | 1 Сепаратор |

| Яңа Хакимият Белән Belledune Брансуик | Нью-Брансуик Канада | 2005 | 1 Сепаратор |

| Компания RWE гсостояние-Дидкот вокзалы | Англия Бөекбритания | 2005 | 1 Сепаратор |

| Talen Energy-Brunner Island Station | Пенсильвания, АКШ | 2006 | 2 Сепараторы |

| Тампа Электрический-Зур Станциясе Согнуть | Флорид АКШ | 2008 | 3 Сепараторы |

| Компания RWE гсостояние-отель aberthaw вокзалы | Уэльс Бөекбритания | 2008 | 1 Сепаратор |

| ЭДФ Энерджи-Көнбатыш станциясе Бертон | Англия Бөекбритания | 2008 | 1 Сепаратор |

| Тагын да күбрәк ләззәт (Lafarge Cement /Ciech Janikosoda JV) | Польша | 2010 | 1 Сепаратор |

| Корея Егәрлек Көньяк-Көнчыгыш - Yeongheung | Көньяк Корея | 2014 | 1 Сепаратор |

| PGNiG Termika-Sierkirki | Польша | 2018 | 1 Сепаратор |

| Taiheiyo Cement Company-Chichibu | Япония | 2018 | 1 Сепаратор |

| Armstrong Fly Ash- Eagle Cement | Филиппин | 2019 | 1 Сепаратор |

| Корея Егәрлек Көньяк-Көнчыгыш - Samcheonpo | Көньяк Корея | 2019 | 1 Сепаратор |

3.0 Methodology

Three (3) cases have been identified for further evaluation and are processed through an order of magnitude study-level economic and risk/opportunity review. The evaluation is based on the potential gain an operator would perceive by incorporating STET’s technology into their plant’s flowsheet.

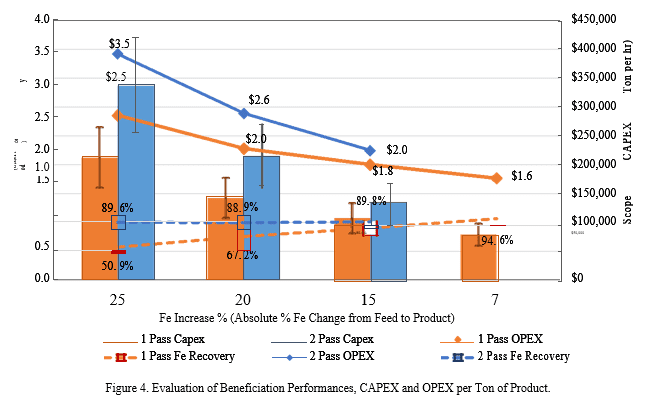

Performance of the STET separator is estimated according to bench scale tests performed (См. Таблицасын 2). The data gathered with various iron ores allowed the calibration of a recovery model which was used to predict the recovery for the three (3) case studies. Дөге. 4 illustrates the outcome of the model in terms of performances and costs. The iron recovery is indicated directly on the bars, against the iron beneficiation in %Fe. In the bench scale testing, a single pass through the STET was tested as well as a two-pass flowsheet. Two-pass flowsheets involve the scavenging of the rougher tails, therefore increasing the recovery substantially. Әмма, this involves additional STET machines and therefore higher costs. The error bars over the CAPEX bars indicate CAPEX price variation depending on project size. The unitary CAPEX figures decrease with project size. As an example, for the typical ore tested with a two-pass flowsheet, an increase of 15% in iron grade (мин.е. нче 50% Fe to 65% Фе) would predict an iron recovery of 90%. Lower iron recoveries are voluntarily used in the following case studies in order to consider the inherent loss of recovery when producing higher grade iron ore concentrates.

For each case study, a flowsheet is presented at an order of magnitude level and only the main equipment is shown in order to support economical evaluation. For each flowsheet, the economics are estimated under the following categories: Capital expense (CAPEX); Operating expense (Эксплуатация чыгымнары); һәм, Revenue. At this screening stage, the level of accuracy for each category is at the “order of magnitude” (± 50%).

Main equipment CAPEX is estimated using internal databases (Provided by Soutex) and equipment quotes when available. Factors were then determined to establish the cost of both direct and indirect costs. STET specific CAPEX values also include secondary equipment and controls, justifying a lower factorization for installation and construction for this piece of equipment. The OPEX estimation is composed of maintenance, manpower, power and consumable costs. The technical elements provided by the process flowsheet support the cost evaluation both in terms of CAPEX and OPEX, and cost elements related to the installation and use of STET tribo-electrostatic belt separator were estimated using STET database of completed projects and iron ore bench scale test work.

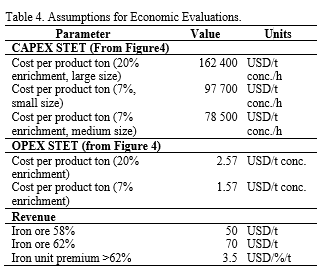

Саннар кулланыла торган түбәндәге оценках чыгымнарны алынган бер рәсеме 4. As an example, өчен типичной руды испытанной белән двухпроходным концентрацией арту 15% in iron grade (мин.е. нче 50% Fe to 65% Фе) төшәчәк якынча шулай 135 000$ тоннасы / сәг татарстанда капиталь затратах һәм 2$ / т OPEX (тонна железного концентрата). Чөнки бу задумано ничек скрининговое өйрәнү, карар саклап консервативность карата бәя кую продукциягә һәм анализ чувствительности карата ахыргы марке һәм бәядән продукт. Ноябрьгә булган мәгълүматларга караганда, 2019, 62% Диңгез тимер руда торгует тирәсендә 80USD/t, бик югары волатильностью.

The premium on iron ore unit concentrate is also very volatile and depends on many factors such as contaminants and the needs from a specific customer. The price difference between 65% iron and 62% iron is constantly changing in time. " 2016, the difference was minimal (around 1 $/t/%Fe) but in 2017-2018, the premium climbed close to 10 $/t/%Fe. At the time of this writing, it is currently around 3 $/t/%Fe [10]. Таблица 4 shows selected design criteria used for the costing estimation.

Таблица 4. Assumptions for Economic Evaluations.

The payback time is estimated from the first year of production. For each project, an additional two (2) years should be considered for the construction. The cash flow values (expenses and revenue) are discounted from the beginning of the construction.

The payback time is estimated from the first year of production. For each project, an additional two (2) years should be considered for the construction. The cash flow values (expenses and revenue) are discounted from the beginning of the construction.

4.0 Beneficiation process in a DSO dry operation

Direct shipping ore (DSO) projects produce the biggest volume of iron ore in the world, primarily feeding the Chinese market and most of the volume comes from Western Australia (WA) and Brazil. " 2017, the volume of iron ore produced in WA exceeded 800 million tons and Brazil’s volume was around 350 million tons [11]. The beneficiation processes are very simple, consisting mostly of crushing, washing and classifying [12].

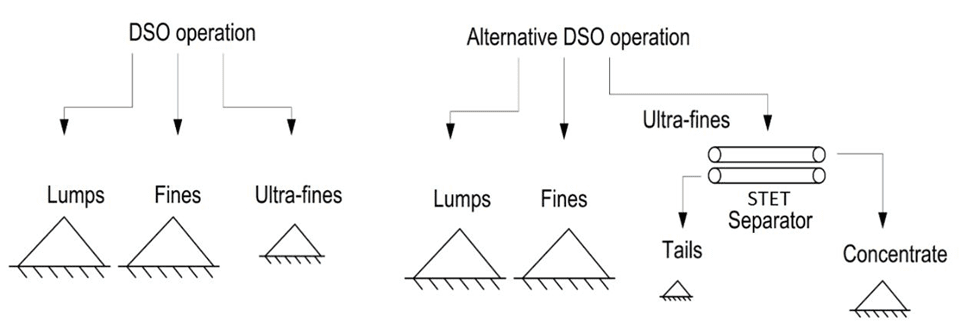

Beneficiation of ultra-fines to generate a 65% Fe concentrate is an opportunity for the DSO market. The approach taken for evaluating the STET technology benefits for DSO projects is a trade-off between producing existing low-grade iron ultra-fines and an alternative of producing a product with added value after STET beneficiation. The flowsheet proposed (Дөге. 5) considers a fictional DSO operation in WA that would currently export among its products ultra-fines at 58% Фе. The alternative would concentrate the ultra-fines in order to increase the value of final product. Таблица 5 presents some of the design criteria and the high-level mass balance used in the estimation of revenue. The orebody in terms of grade and capacity does not represent an existing project but rather a typical DSO project in terms of size and production.

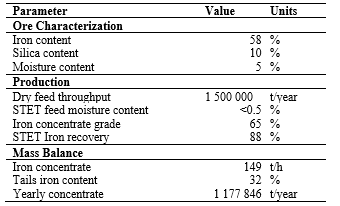

Таблица 5. Ультратонкие критерийлары проектлау обогатительной фабрикасы DSO һәм балансы масса.

Дөге. 5. Чагыштыру, технологик схемаларын системасында DSO trade-off

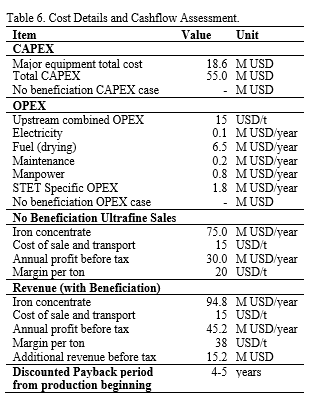

Таблица 6 тәкъдим ителгән капитальные кертемнәр югары дәрәҗәдәге, Операция һәм предполагаемые керемнәр. Бәяләү капиталь чыгымнарны үз эченә ала добавление яңа выделенной системасын загрузки (силосохранилище loadout һәм йөкләнеш автомобиле), шулай ук системасы STET. Өчен бәяләү өчен возвратность тәкъдим ителгән технологик схемаларын, икътисади анализ үткәрелә тирәсендә уртак тел табылды арасында уңайдан баету һәм продажей низкосортного продукт. Эшендә турында обогащении, the volume is reduced but the premium on iron units increases the sale price significantly. In the OPEX, an estimation is provided for the upstream ore processing (чыгару, crushing, classifying and handling).

Despite reducing the volume significantly, the return is interesting given the premium on high grade iron ore concentrate. The return calculation is highly dependent on this premium, which has been increasing in the last few years due to environmental issues. As demonstrated above (Таблица 6), the economic attractiveness of such a project is highly dependent on the price difference between 58% iron and 65% iron. In this current evaluation, this price premium was 30.5 $/t, which reflects approximately the current market situation. Әмма, this price premium has historically ranged from 15 – 50 $/t.

5.0 Scavenging Process in a Gravity

Separation Plant

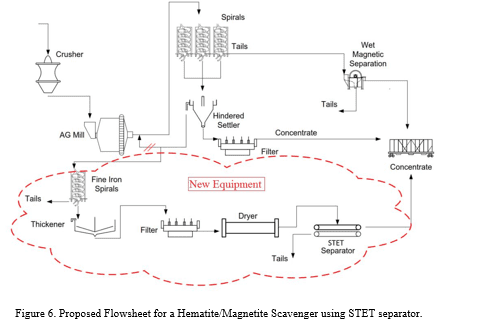

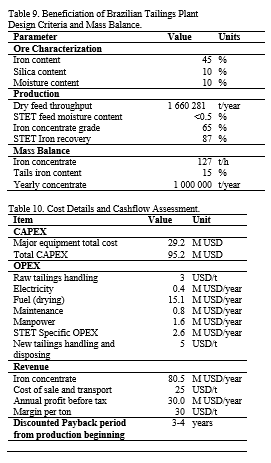

Iron concentrators in the North America region use gravity concentration which is an efficient way of concentrating hematite and magnetite, especially for the size fraction above 75μm [5,13]. Hematite/magnetite plants in this region typically use spirals as the primary separation process and also incorporate Low Intensity Magnetic Separation steps (ЛИМС). A common issue across hematite/magnetite plants is the recovery of fine iron as the iron tailings amounts often reach levels as high as 20%. The main challenge is related to fine hematite, as the fine iron can hardly be recovered by spirals and is impervious to LIMS used to recover fine magnetite. Аермалы буларак,, the STET separator is highly effective at separating fine particles, including particles below 20µm microns where LIMS and spirals are less effective. Шуңа күрә, the overflow from a cleaner hydrosizer (hindered settler) feeding scavenger spirals is a good fit for STET technology. The proposed flowsheet is presented in Figure 6.

In this configuration, the red dash line highlights new equipment within an existing plant. Under the proposed flowsheet, instead of being recirculated, the hindered settler overflow would be processed by scavenging spirals operating at different conditions than rougher spirals. A fine iron concentrate could be produced and dried. The dried concentrate would then be directed to the STET separator in order to produce a final concentrate of salable grade. The fine product could be marketed separately or together with remaining concentrator production.

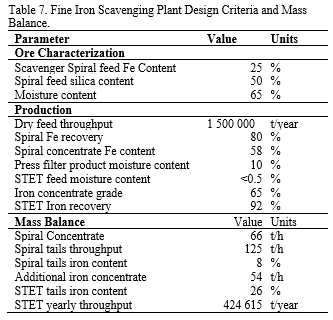

Таблица 7 presents the design criteria and the high-level mass balance used in the estimation of revenue.

Таблица 8 тәкъдим ителгән капитальные кертемнәр югары дәрәҗәдәге, Операция һәм предполагаемые керемнәр.

This analysis indicates that the return of implementing a scavenging circuit involving STET technology is attractive and warrants further consideration.

Another advantage of drying the fine iron concentrate when comparing to competing technologies is the associated benefit resulting from material handling following concentration. Very fine wet concentrate is problematic regarding filtering, handling and transport. Freezing problems in trains and fluxing in boats renders the drying of very fine concentrate sometimes mandatory. STET embedded drying could therefore become advantageous.

6.0 Beneficiation of Brazilian Tailings

Deposit

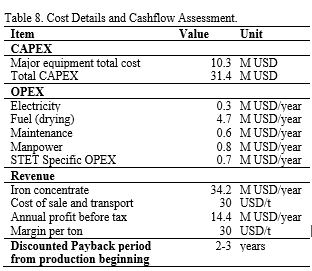

Beneficiation of fine tailings appears as a value-added application for processors to valorize the STET technology, as the resource is finely ground and available for low cost. While iron ore tailings deposits bearing high levels of iron are present in many places, locations where the logistics are simple should be privileged for further evaluation. Brazilian deposits containing high Fe grades and strategically located near existing transport infrastructure could represent a good opportunity for processors to benefit from the implementation of STET tribo-electrostatic technology. The flowsheet proposed (Дөге. 7) considers a fictional Fe-rich Brazilian tailings operation in which STET technology would be the only beneficiation process.

Beneficiation of fine tailings appears as a value-added application for processors to valorize the STET technology, as the resource is finely ground and available for low cost. While iron ore tailings deposits bearing high levels of iron are present in many places, locations where the logistics are simple should be privileged for further evaluation. Brazilian deposits containing high Fe grades and strategically located near existing transport infrastructure could represent a good opportunity for processors to benefit from the implementation of STET tribo-electrostatic technology. The flowsheet proposed (Дөге. 7) considers a fictional Fe-rich Brazilian tailings operation in which STET technology would be the only beneficiation process.

The deposit is considered to be large enough to provide decades of feed at a yearly rate of 1.5 M ton/year. For this scenario, the feed ore is already finely ground with a D50 of ~50µm and the ore would need to be shoveled, transported and then dried before tribo-electrostatic beneficiation. The concentrate would then be loaded on trains/ships and the new tailings would be stockpiled in a new facility.

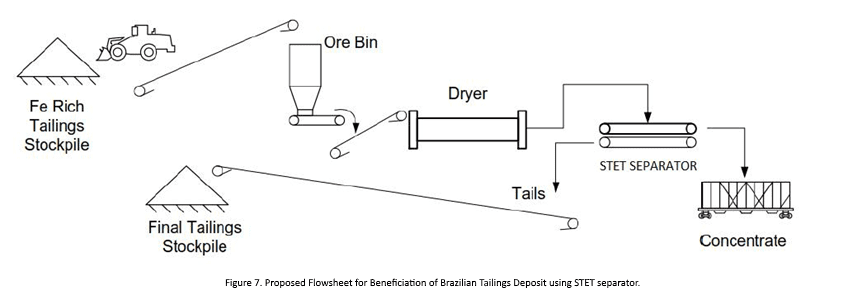

Таблица 9 presents the design criteria and high-level mass balance used in the estimation of revenue. Таблица 10 тәкъдим ителгән капитальные кертемнәр югары дәрәҗәдәге, Операция һәм предполагаемые керемнәр.

As demonstrated in Table 10, the return of implementing STET technology for the beneficiation of Brazilian tailings is attractive. Моннан тыш,, from an environmental standpoint the proposed flowsheet is also beneficial insomuch as the beneficiation of dry tailings would reduce tailings size and surface and would also reduce the risks associated with wet tailings disposal.

As demonstrated in Table 10, the return of implementing STET technology for the beneficiation of Brazilian tailings is attractive. Моннан тыш,, from an environmental standpoint the proposed flowsheet is also beneficial insomuch as the beneficiation of dry tailings would reduce tailings size and surface and would also reduce the risks associated with wet tailings disposal.

7.0 Discussion and Recommendations

The STET separator has been successfully demonstrated at bench scale to separate fine iron ore, therefore offering processors a novel method to recover fines that would otherwise be difficult to process to sellable grades with existing technologies.

The flowsheets evaluated by STET and Soutex are examples of iron ore processing which may benefit from dry triboelectrostatic separation. The three (3) developed flowsheets presented in this study are not exclusive and other alternatives should be considered. This preliminary study indicates that scavenging processes involving low drying costs, DSO operations and tailings beneficiation have a good chance of commercial success.

Another advantage in dry processing is on the tailings storage – which are currently stored in huge tailings ponds – as dry tailings would have the advantage of eliminating an important environmental risk. Recent and well publicized tailings dam failures highlight the need for tailings management.

The inputs to this study used to calculate iron ore grade and recovery were bench scale separation results using iron ore samples from multiple regions. Әмма, the mineralogy and liberation characteristics of each ore is unique, therefore customer iron ore samples should be evaluated at bench or pilot scale. In a next step of development, the three flowsheets evaluated in this paper should be studied in further detail.

Ниһаять, other technologies are currently under study for fine iron recovery such as WHIMS, Jigs and reflux classifiers. It is already known that many wet separation processes become inefficient for particles under 45μm and therefore STET technology might have an advantage in the very fine range, as STET has seen good performances with feed as fine as 1μm. A formal trade-off study comparing the cited technologies with STET should be conducted, which would include performance assessment, capacity, cost, һ. б.. In that way the best niche for STET could be highlighted and refined.

Сылтамалар

1. Лу, Л. (Эд.) (2015), “Тимер Руды: Минералогия, Эшкәртү һәм экологик тотрыклылыгын", Эльзевир.

2. Феррейра, Х., & Лейти, М. Г. П. (2015), "Тормыш циклы өйрәнү буенча бәяләү чыгару, тимер руд", Journal of cleaner production, 108, ПП. 1081-1091.

3. Филиппова, Л. О, Северова, " . В., & Филиппова, Мин. " . (2014), "Күзәтү баету тимер руд ярдәмендә кире катионной флотации", International journal of mineral processing, 127, ПП. 62-69.

4. Саху, Х., Рат, Белән. С., РАО, Д. С., Мишра, Б. К., & Дас, Б. (2016), "Ролен кремнезема һәм глинозема бу флотации тимер руд", Халыкара журналы эшкәртү минерального чимал , 148, ПП. 83-91.

5. Bazin, Claude, һ. б (2014), “Size recovery curves of minerals in industrial spirals for processing iron oxide ores.” Файдалы Казылмалар Инженерлык 65, ПП 115-123.

6. " , Х., Ван, Ю., Вэнь, С., Кисђтђ, М., Кояш, С., Инь, У., & Кисђтђ, Г. (2016), "Эффект карбонатных минераллар бу кварц тәртибе каршындагы флотации шартларында кире анионной флотации тимер руд", Халыкара журналы эшкәртү минерального чимал , 152, ПП. 1-6.

7. Әйе Силва, Ф. Л., Араужу, Ф. Г. С., Тейшейра, М. П., Гомеш, Р., & Фон Крюгер, Ф. Л. (2014), "Тикшеренү утильләштерү һәм эшкәртү койрыклар баю тимер руд җитештерү өчен керамика", Ceramics International, 40(10), ПП. 16085-16089.

8. Bielitza, Marc P. (2012), “Prospects for the 2020 Iron Ore Market. Quantitative Analysis of Market Dynamics and Risk Mitigation Strategies” Books, Rainer Hampp Verlag, edition 1, number 9783866186798, Jan-Jun.

9. Rojas-Mendoza, Л. Ф. Грач, К. Flynn and A. Гупта. (2019), “Dry beneficiation of low-grade iron ore fines using a tribo-electric belt separator”, In Proceedings of SME Annual Conference & Expo and CMA 121st National Western Mining Conference Denver, Colorado – February 24-27, 2019.

10. China Iron Ore Spot Price Index (CSI). Retrieved from http://www.custeel.com/en/price.jsp

11. АКШ. Geological Survey (USGS) (2018), “Iron Ore”, in Iron Ore Statistics and information.

12. Jankovic, Ә. (2015), “Developments in iron ore comminution and classification technologies. Тимер Руды. протоколы HTTP://dx.doi.org/10.1016/B978-1-78242-156-6.00008-3.

Elsevier Ltd.

13. Richards, Р. Г., һ. б. (2000), “Gravity separation of ultra-fine (− 0.1 мм) minerals using spiral separators.” Файдалы Казылмалар Инженерлык 13.1, ПП. 65-77.