Zabi Harshe:

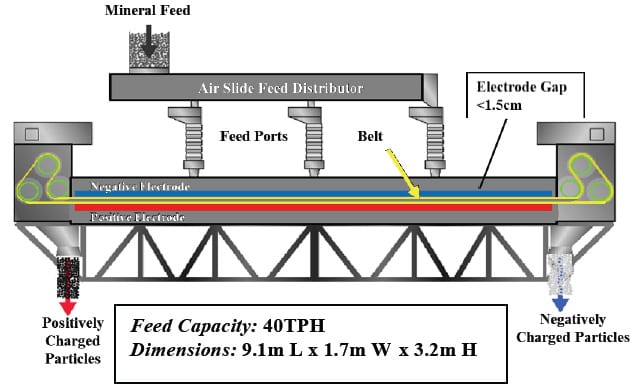

ST Boats & Technology LLC ta (STET) Triboelectrostatic bel SEPARATOR (Figure 1) yana da nuna damar aiwatar da lafiya barbashi daga 1995 raba Unburned carbon daga gardama ash ma'adanai a ci-kora ikon shuke-shuke, a Arewacin Amirka, Europe and Asia to produce a concrete grade Pozzolan for use as a cement substitute. 1 Ta hanyar matukin jirgi shuka gwaji, a-tsire zanga-zanga ayyukan da / ko kasuwanci ayyukan, STET’s separator has demonstrated Beneficiation of many minerals including potash, barite, calcite, kuma talc.2

Tun da farko ban sha'awa a cikin wannan fasahar ta kasance ta ikon aiwatar barbashi kasa da 0.1 mm, iyaka na al'ada free-fall da drum yi separators, the upper particle size limit of STET’s current design has not been a focus of the development of the technology in the past. Duk da haka, efforts are under way to increase it by design changes. STET a halin yanzu ƙera biyu masu girma dabam tare da maras karfin na 40 da kuma 23 tsarin awo tonne awa.

Figure 1: ST Boats & Technology ta Triboelectric Belt SEPARATOR

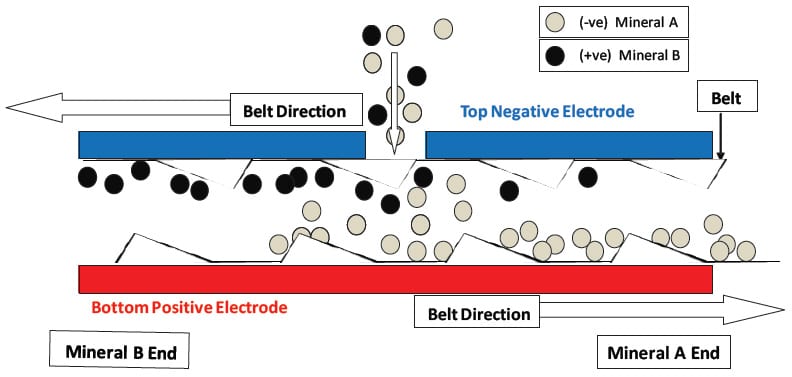

Ka'idojin aiki na STET SEPARATOR aka kwatanta a Figures 2 & 3. A barbashi an caje da triboelectric sakamako ta hanyar barbashi-to-barbashi collisions a cikin iska nunin feed rabawa da kuma a cikin rata tsakanin wayoyin. A amfani ƙarfin lantarki a kan wayoyin ne tsakanin ± 4 da kuma ± 10kV dangi zuwa ƙasa, bada wani total ƙarfin lantarki bambanci na 8 to 20 KV. A bel, wanda aka yi da wani maras gudanar da roba, ne babban raga tare da game 60% bude yanki. Barbashi iya wuce ta cikin takware a cikin bel.

Figure 2: Schematic na STET SEPARATOR

Hay Capacity: 40TPH Girma: 9.1m L x 1.7m W x 3.2m H

The flow patterns and particle-to-particle contact within the electrode gap that is established by the moving belt are key to the effectiveness of the separator. Bayan shigarwa a cikin rata tsakanin wayoyin da barnatar da cajin barbashi an janyo hankalin da lantarki filin sojojin zuwa kasa tabbatacce wayoyin. A gaskiya ma caje barbashi an janyo hankalin zuwa barnatar da cajin saman lantarki. Gudun da m madauki bel ne m daga 4 to 20 m / s. The geometry of the belt cross-direction strands serves to sweep the particles of the electrodes moving them towards the proper end of the separator and back into the high shear zone between the oppositely moving sections of the belt. Saboda barbashi yawan yawa ne don haka high cikin rata tsakanin wayoyin (approximately one-third the volume is occupied by particles) kuma ya kwarara da aka vigorously agitated, akwai mutane da yawa collisions tsakanin barbashi da kuma mafi kyau duka caji auku ci gaba cikin rabuwa zone. The counter-current flow induced by the oppositely moving belt sections and the continual re-charging and re-separation creates a countercurrent multistage separation within a single apparatus. This continuous charging and recharging of particles within the separator eliminate the need for any “charger” system prior to introducing material to the separator, thus removing a serious limitation on the capacity of electrostatic separation. The fitarwa na wannan SEPARATOR ne biyu qarqashinsu, a concentrate, kuma a saura, ba tare da wani middlings rafi. Yadda ya dace da wannan SEPARATOR an nuna su zama daidai kamar uku matakai na free-fall rabuwa da middlings maimaita.

Figure 3: Lantarki Gap na STET Belt SEPARATOR

The STET separator has many process variables that enable optimization of the trade-off between product purity and recovery that is inherent in any Beneficiation process. The coarse adjustment is the feed port through which the feed is introduced to the separation chamber. The port furthest from the discharge hopper of the desired product gives the best grade but at the expense of a lower recovery. A finer gyara ne gudun da bel. The electrode gap, wanda shi ne daidaitacce tsakanin 9 da kuma 18 mm, da kuma amfani da irin ƙarfin lantarki (± 4 zuwa ± 10 KV) are also important variables. A polarity na wayoyin iya canja wanda AIDS a cikin rabuwa da wasu kayan. Pretreatment of feed material by precise control of trace moisture content (auna feed zumunta zafi) is important to achieve optimum separation results. The addition of trace amounts of charge-modifying chemical agents can also aid in optimizing the process.

Kamar yadda ya bayyana a sama, the initial commercial application of the belt separator has been a separation of coal char from the glassy Aluminosilicate mineral from fly ash from coal-fired power plants. This technology is unique among electrostatic separators in its ability to separate fly ash, wanda yawanci yana nufin barbashi size kasa da 0.02 mm. The STET separator has also been proven to effectively separate magnesite from talc, halite from kieserite and sylvite, silicates daga Bart, and silicates from calcite.3 The mean particle size of all of these feed materials has been in the range of 0.02 da kuma 0.1mm. Misalan separations ga dama kayan ana kunshe a Table 1.

Table 1 - Misalin Separations

| rabuwa | Hay | Product | farfadowa da na'ura |

|---|---|---|---|

| alli carbonate - Silicates | 9.5% Acid Insols | <1% A.I. | 89% CaCO3 |

| talc - Magnesite | 58% talc | 95% talc | 77% talc |

| 88% talc | 82% talc | ||

| Kierserite + KCl - NaCl | 11.5% K2O | 27.1% K2O | 90% K2O |

| 12.2% kieserite | 31.8% kieserite | 94% kieserite | |

| 64.3% NaCl | 14.3% NaCl | 92% NaCl reject | |

| Fly Ash Mineral - carbon | 6.3% carbon | 1.8% carbon | 88% ma'adinai |

| 11.2% carbon | 2.1% carbon | 84% ma'adinai | |

| 19.3% carbon | 2.9% carbon | 78% ma'adinai |

a ka'idar, tun barbashi caji dogara a kan triboelectric sakamako, wani biyu ma'adanai cewa an sami 'yanci daga juna (shugaba- shugaba ko nonconductor-madugu) za a iya raba ta wannan hanya. Sauran m aikace-aikace hada magnesite-ma'adini, feldspar-ma'adini, ma'adinai Sands, wasu potash ma'adinai separations, da kuma

Phosphate-calcite-silica separations.

1 Bittner, J.D., Gasiorowski, S.A., Bush, T.W.,, Hrach, F.J., Separation technologies’ automated fly ash beneficiation process selected for new Korean power plant, aikace-aikace na 2013 World of Coal Ash conference, Afrilu 22-25, 2013. 2 Bittner, J.D., Hrach, F.J., Gasiorowski, S.A., Canellopoulus, L.A., Guicherd, H. Triboelectric belt separator for Beneficiation of fine minerals, SYMPHOS 2013 – 2nd International Symposium on Innovation and Technology for the Phosphate Industry. ci gaba Engineering, Vol. 83 PP 122-129, 2014. 3 Bittner, J.D., Flynn, K.P., Hrach, F.J., Fadada aikace-aikace a bushe Triboelectric rabuwa ma'adanai, Aikace-aikace na XXVII International Ma'adinai Processing Congress - IMPC 2014, Santiago, Chile, Oct 20 - 24, 2014.