Tīpakohia Reo:

ST Taputapu & Hangarau LLC o (STET) whakawehe whitiki Triboelectrostatic (Figure 1) He te āheinga whakaatu ki te tukatuka matūriki pai i 1995 wehe waro Unburned i kohuke rere pungarehu i roto i te tipu te mana waro-pupuhi i roto i Amerika Te Tai Tokerau, Europe and Asia to produce a concrete grade Pozzolan for use as a cement substitute. 1 Na roto i paerata whakamātautau tipu, i roto i-whakato ngā mahi arumoni kaupapa whakaaturanga, me te / ranei, STET’s separator has demonstrated Beneficiation of many minerals including potash, barite, konupāhiko, me talc.2

Mai kua te moni tuatahi i roto i tenei hangarau tona kaha ki te tukatuka matūriki iti iho i te 0.1 mm, te rohe o tikanga whakawehe pukapuka noa-hinga me te pahū, the upper particle size limit of STET’s current design has not been a focus of the development of the technology in the past. Heoi, efforts are under way to increase it by design changes. STET tēnei wā manufactures rua rahi ki aravihi iti o 40 a 23 tone ngahuru ia haora.

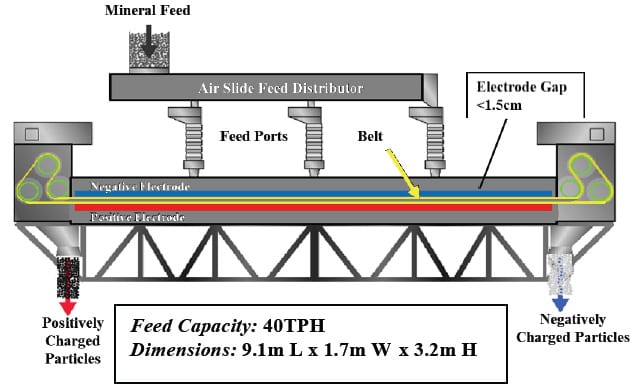

Figure 1: ST Taputapu & a Technology Triboelectric Belt Whakawehe

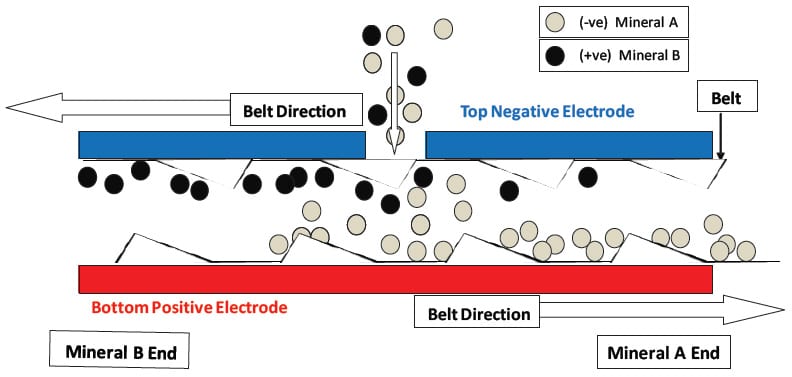

E whakaahua ana te mau parau tumu o te mahi o te kaiwehe STET i roto i Whika 2 & 3. E whakatupato ana te matūriki i te pānga triboelectric roto i matūriki-ki-korakora tukinga i roto i te whāngai distributor rangi kiriata me i roto i te āputa i waenganui i te electrodes. Te ngaohiko tono i runga i te electrodes ko waenganui i ± 4 me ± 10kV whanaunga ki whenua, hoatu he katoa rerekētanga ngaohiko o 8 ki 20 kV. Ko te whitiki, hanga e te o te kirihou whakahaere-kore, Ko te mata nui ki e pā ana ki 60% wāhi tuwhera. Ka taea e ngāwari te matūriki tika na waenganui i te tatau i roto i te whitiki.

Figure 2: Schematic o STET Whakawehe

Raukaha whāngai: 40TPH Ahu: 9.1m L x 1.7m W x 3.2m H

The flow patterns and particle-to-particle contact within the electrode gap that is established by the moving belt are key to the effectiveness of the separator. Ki runga ki te urunga ki te āputa i waenganui i te electrodes e ngā te matūriki tōraro whakatupato e te ope mara hiko ki te kawehiko pai raro. e ngā te matūriki pai whakatupato ki te kawehiko runga tōraro whakatupato. He tāupe i te tere o te whitiki koropiko tonu 4 ki 20 m / s. The geometry of the belt cross-direction strands serves to sweep the particles of the electrodes moving them towards the proper end of the separator and back into the high shear zone between the oppositely moving sections of the belt. No te mea he pera tiketike i roto i te āputa i waenganui i te electrodes te kiato tau matūriki (approximately one-third the volume is occupied by particles) a kei te kaha te puehu te rere, i reira e maha collisions i waenganui i ngā korakora, me te utu tino pai e tupu tonu puta noa i te rohe wehenga. The counter-current flow induced by the oppositely moving belt sections and the continual re-charging and re-separation creates a countercurrent multistage separation within a single apparatus. This continuous charging and recharging of particles within the separator eliminate the need for any “charger” system prior to introducing material to the separator, thus removing a serious limitation on the capacity of electrostatic separation. Ko te putanga o tenei whakawehe ko rua awa, a concentrate, me te toenga, kahore te awa middlings. Kua te tōtika o tenei whakawehe kua whakakitea ki te kia ōrite ki te āhua e toru ngā wāhanga o noa-hinga wehenga ki middlings tukurua.

Figure 3: Kawehiko Gap o STET Belt Whakawehe

The STET separator has many process variables that enable optimization of the trade-off between product purity and recovery that is inherent in any Beneficiation process. The coarse adjustment is the feed port through which the feed is introduced to the separation chamber. The port furthest from the discharge hopper of the desired product gives the best grade but at the expense of a lower recovery. He whakatikatika kaitahi ko te tere o te whitiki. The electrode gap, i te mea te whakarite i waenganui i 9 a 18 mm, me te ngaohiko tono (± 4 ki te ± 10 kV) are also important variables. kia puta ke ai te wehenga tawhiti o te electrodes i taonga i roto i te wehenga o te tahi mau rauemi. Pretreatment of feed material by precise control of trace moisture content (rite whanganga e kai haumākū whanaunga) is important to achieve optimum separation results. The addition of trace amounts of charge-modifying chemical agents can also aid in optimizing the process.

Ka rite ki kī i runga ake, the initial commercial application of the belt separator has been a separation of coal char from the glassy Aluminosilicate mineral from fly ash from coal-fired power plants. This technology is unique among electrostatic separators in its ability to separate fly ash, e te nuinga he rahi toharite matūriki iti iho i te 0.02 mm. The STET separator has also been proven to effectively separate magnesite from talc, halite from kieserite and sylvite, silicates i Bart, and silicates from calcite.3 The mean particle size of all of these feed materials has been in the range of 0.02 me 0.1mm. E ngā tauira o māvaé mo te maha ngā rauemi i roto i ripanga 1.

ripanga 1 - Whakawehenga Tauira

| wehenga | whāngai | hua | Whakaora |

|---|---|---|---|

| Whārangi konupūmā - Silicates | 9.5% Acid Insols | <1% A.I. | 89% CaCO3 |

| talc - Magnesite | 58% talc | 95% talc | 77% talc |

| 88% talc | 82% talc | ||

| Kierserite + KCl - NaCl | 11.5% K2O | 27.1% K2O | 90% K2O |

| 12.2% kieserite | 31.8% kieserite | 94% kieserite | |

| 64.3% NaCl | 14.3% NaCl | 92% NaCl reject | |

| Fly Ash Mineral - waro | 6.3% carbon | 1.8% carbon | 88% kohuke |

| 11.2% carbon | 2.1% carbon | 84% kohuke | |

| 19.3% carbon | 2.9% carbon | 78% kohuke |

I roto i te ariā, mai tei matūriki e mea ki runga ki te pānga triboelectric, tetahi kohuke e rua e kua mai i ia atu (kaiwhakahaere- kaiwhakahaere nonconductor-kaiwhakahaere ranei) Ka taea te wehea e tenei tikanga. Ētahi atu tono pea ngā magnesite-kiripaka, wherepāra-kiripaka, one kohuke, atu māvaé hopi kohuke, a

māvaé Phosphate-konupāhiko-takawai.

1 Bittner, J.D., Gasiorowski, S.A., Bush, T.W.,, Hrach, F.J., Separation technologies’ automated fly ash beneficiation process selected for new Korean power plant, whakahaerenga o 2013 World of Coal Ash conference, April 22-25, 2013. 2 Bittner, J.D., Hrach, F.J., Gasiorowski, S.A., Canellopoulus, L.A., Guicherd, H. Triboelectric belt separator for Beneficiation of fine minerals, SYMPHOS 2013 – 2nd International Symposium on Innovation and Technology for the Phosphate Industry. puta Engineering, Vol. 83 PP 122-129, 2014. 3 Bittner, J.D., Flynn, K.P., Hrach, F.J., Ki te whakanui koe tono i roto i te wehenga Triboelectric maroke o kohuke, Nga mahi o te maereraa International Mineral Processing Congress - IMPC 2014, Santiago, Chile, Oct 20 - 24, 2014.