Select Language:

ST Qalabka & Technology LLC ee (STET) SEPARATOR suunka Triboelectrostatic (Jaantuska 1) ayaa awood u leh soo bandhigay si loo farsameeyo Qurub ganaax ka 1995 kala carbon Unburned ka macdanta ash dhoobnayd ee Quwadda dhuxul-rideen ee North America, Europe and Asia to produce a concrete grade Pozzolan for use as a cement substitute. 1 Iyada oo imtixaanka warshad pilot, in-warshad mashaariicda tusidda iyo / ama hawlaha ganacsiga, STET’s separator has demonstrated Beneficiation of many minerals including potash, barite, calcite, iyo talc.2

Tan iyo danaha aasaasiga ah ee technology this ayaa awoodda si loo farsameeyo qayb ka yar 0.1 mm, soohdinta reer free-dayrta iyo durbaanka separators duudduuban caadiga ah, the upper particle size limit of STET’s current design has not been a focus of the development of the technology in the past. Si kastaba ha ahaatee, efforts are under way to increase it by design changes. STET hadda manufactures laba tirada la awoodaha magacaaban ah 40 iyo 23 tonne ton saacaddiiba.

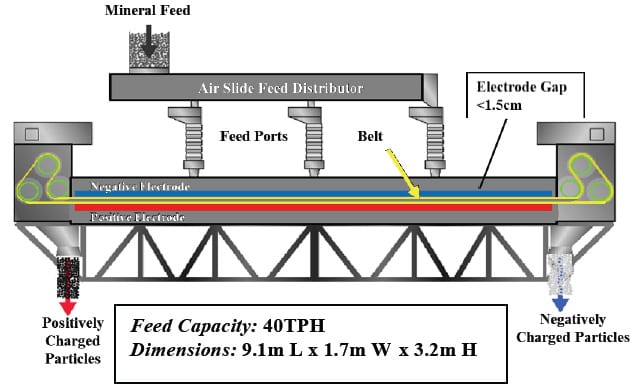

Jaantuska 1: ST Qalabka & Technology ee Triboelectric Belt SEPARATOR

The mabaadiida hawlgalka SEPARATOR ku STET waxaa lagu muujiyey Tirokoobyada 2 & 3. qayb ka ah waxaa lagu dalacayaa by saamaynta triboelectric iyada oo qayb-ka-qayb shilalka in qaybiyaha slide hawada feed iyo gudahood farqiga u dhexeeya elektaroodhada. danab ayaa codsatay on electrodes waxaa inoo dhexeeya ± 4 iyo ± 10kV qaraabo dhulka ku, siinaya wadarta farqiga danab of a 8 si ay u 20 kV. suunka, taas oo laga sameeyey caag ah non-qabashada, waa mesh a ballaaran leh oo ku saabsan 60% meesha furan. qayb ka ah si fudud u gudbin karaan furan ee suunka.

Jaantuska 2: Schematic of STET SEPARATOR

Capacity feed: 40TPH Cabirka: 9.1m L 3.2m x bixixo 1.7 W x H

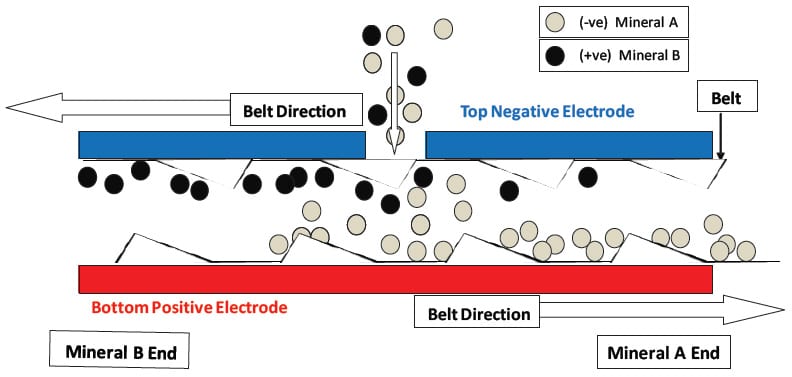

The flow patterns and particle-to-particle contact within the electrode gap that is established by the moving belt are key to the effectiveness of the separator. Marka galay farqiga u dhaxeeya electrodes galo ka qayb xun oo lagu eedeeyay waxaa soo jiitay by ciidamada beerta korontada u electrodes wanaagsan hoose. The Qurub wanaagsan eedeeyay waxaa soo jiitay in koronto ay si xun u eedeeyay top. xawaaraha suunka loop joogto ah waa variable ka 4 si ay u 20 m / s. The geometry of the belt cross-direction strands serves to sweep the particles of the electrodes moving them towards the proper end of the separator and back into the high shear zone between the oppositely moving sections of the belt. Maxaa yeelay, cufnaanta tirada walxaha waa sidaas sare gudahood farqiga u dhexeeya elektaroodhada (approximately one-third the volume is occupied by particles) iyo socodka waxaa si aada u xanaaqsan, waxaa jira shilalka badan oo u dhexeeya Qurub iyo xukun aan fiicnayn dhacdaa si joogto ah oo dhan zone kala. The counter-current flow induced by the oppositely moving belt sections and the continual re-charging and re-separation creates a countercurrent multistage separation within a single apparatus. This continuous charging and recharging of particles within the separator eliminate the need for any “charger” system prior to introducing material to the separator, thus removing a serious limitation on the capacity of electrostatic separation. wax soo saarka ee SEPARATOR tani waa laba durdurrada, a concentrate, Oo intii ka hadhay a, la'aan ah durdur middlings. oolnimada ee SEPARATOR this ayaa la sheegay inay u dhigmaan qiyaastii saddex marxaladood oo kala go'ida free-dayrta la middlings dib.

Jaantuska 3: Koronto Farqiga of STET Belt SEPARATOR

The STET separator has many process variables that enable optimization of the trade-off between product purity and recovery that is inherent in any Beneficiation process. The coarse adjustment is the feed port through which the feed is introduced to the separation chamber. The port furthest from the discharge hopper of the desired product gives the best grade but at the expense of a lower recovery. sixitaanka qaadhaan A waa xawaaraha suunka. The electrode gap, taas oo hagaajin karo oo u dhexeeya 9 iyo 18 mm, oo danab ku codsatay (± 4 ilaa ± 10 kV) are also important variables. polarity ee electrodes waxaa laga yaabaa in wax laga beddelo taas oo qalabka ku kala qalabka qaar ka mid ah. Pretreatment of feed material by precise control of trace moisture content (sida lagu qiyaasay feed qoyaan qaraabo) is important to achieve optimum separation results. The addition of trace amounts of charge-modifying chemical agents can also aid in optimizing the process.

Sida kor ku xusan, the initial commercial application of the belt separator has been a separation of coal char from the glassy Aluminosilicate mineral from fly ash from coal-fired power plants. This technology is unique among electrostatic separators in its ability to separate fly ash, kaas oo sida caadiga ah waxa uu leeyahay size walxaha mean a ka yar 0.02 mm. The STET separator has also been proven to effectively separate magnesite from talc, halite from kieserite and sylvite, silicates ka Bart, and silicates from calcite.3 The mean particle size of all of these feed materials has been in the range of 0.02 iyo 0.1mm. Tusaalooyinka kala qalabka dhowr ka mid yihiin Miis 1.

Miis 1 - kala Tusaale

| Kala | feed | Product | Recovery |

|---|---|---|---|

| Calcium Carbonate - Silicates | 9.5% Acid Insols | <1% A.I. | 89% CaCO3 |

| rusheyn kartaa - Magnesite | 58% rusheyn kartaa | 95% rusheyn kartaa | 77% rusheyn kartaa |

| 88% rusheyn kartaa | 82% rusheyn kartaa | ||

| Kierserite + KCl - NaCl | 11.5% K2O | 27.1% K2O | 90% K2O |

| 12.2% kieserite | 31.8% kieserite | 94% kieserite | |

| 64.3% NaCl | 14.3% NaCl | 92% NaCl reject | |

| Fly Ash Mineral - carbon | 6.3% carbon | 1.8% carbon | 88% macdanta |

| 11.2% carbon | 2.1% carbon | 84% macdanta | |

| 19.3% carbon | 2.9% carbon | 78% macdanta |

aragti, tan iyo xukun walxaha ku xiran tahay saameynta triboelectric, kasta oo laba macdanta in ay yihiin xoreeyay kasta oo kale oo (kaari- kaari ama nonconductor-kaari) la kala saari karaan by habkan. codsiyada kale ee ka iman kara waxaa ka mid ah magnesite-quartz, feldspar-quartz, sands macdanta, kala kale macdanta potash, iyo

kala Phosphate-calcite-silica.

1 Bittner, J.D., Gasiorowski, S.A., Bush, T.W.,, Hrach, F.J., Separation technologies’ automated fly ash beneficiation process selected for new Korean power plant, Talaaboda Guri ka mid ah 2013 World of Coal Ash conference, April 22-25, 2013. 2 Bittner, J.D., Hrach, F.J., Gasiorowski, S.A., Canellopoulus, L.A., Guicherd, H. Triboelectric belt separator for Beneficiation of fine minerals, SYMPHOS 2013 – 2nd International Symposium on Innovation and Technology for the Phosphate Industry. soco Engineering, vol. 83 PP 122-129, 2014. 3 Bittner, J.D., Flynn, K.P., Hrach, F.J., codsiyada Ballaarinta in separation qalalan Triboelectric of minerals, Talaaboda Guri ka mid ah XXVII International Macdanta Processing Congress - IMPC 2014, Santiago, Chile, Oct 20 - 24, 2014.