Select Puo:

ST Helmets & Technology LLC e (STET) Triboelectrostatic lebanta kgaoganyo (Figure 1) o na le o ile a bontša bokgoni ho sebetsa likaroloana tse molemo tse tsoang 1995 arola Unburned k'habone tloha liminerale fofa molora ka dimela mashala-lelekoa matla Amerika Leboea, Europe and Asia to produce a concrete grade Pozzolan for use as a cement substitute. 1 Ka motsamaisi dimela etsa liteko, ka-semela diporojeke tse di pontšo le / kapa tshebetso khoebo, STET’s separator has demonstrated Beneficiation of many minerals including potash, barite, calcite, le talc.2

Ho tloha ka thahasello ka sehloohong ba ho theknoloji ena e bile matla a ho sebetsa likaroloana ka tlase ho 0.1 limilimithara, tekanyong ea tloaelehileng mahala-ho oa le moqomo moqolo separators, the upper particle size limit of STET’s current design has not been a focus of the development of the technology in the past. Leha ho le joalo, efforts are under way to increase it by design changes. STET jwale manufactures boholo bo tse peli le maikarabelong ipolela hore ba 40 le 23 meteriki tonne ka hora.

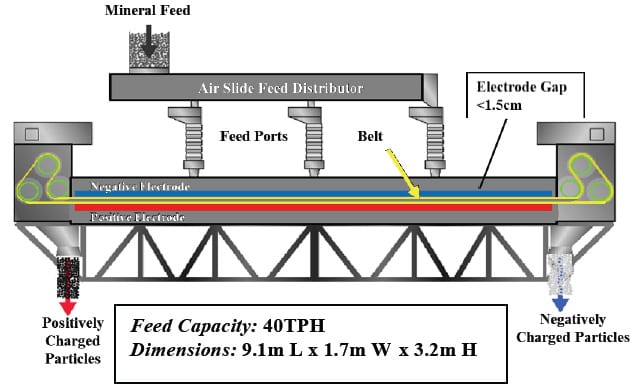

Figure 1: ST Helmets & Technology o Triboelectric lebanta la kgaoganyo

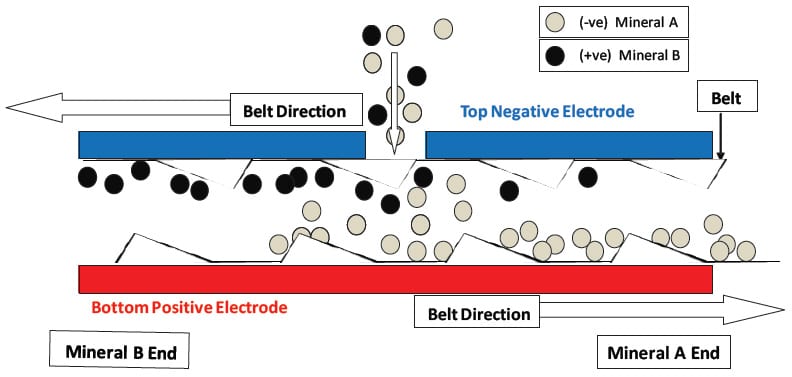

melao-motheo ea tshebetso ya kgaoganyo STET li bontšitsoe Figures 2 & 3. likaroloana a qosoa ke phello triboelectric ka phatsa-to-phatsa thulana ka moea slide iphepe distributor le ka hare ho lekhalo pakeng tsa li-electrode ho. The sebelisoa gagamalo ka li-electrode ke pakeng tsa ± 4 le ± 10kV amanang le ho fatše, ho fana ka kakaretso gagamalo phapang ea 8 ho 20 kV. lebanta, eo e entsoe ka polasetiki bao e seng khanna, ke letlooeng kgolo le ka 60% sebakeng bulehileng. likaroloana ho ka ba bonolo feta ho buleha ka lebanta la.

Figure 2: Tlhohlomiso tsa STET la kgaoganyo

Feed bokgoni: 40TPH litekanyo: 9.1limithara L: x 1.7m W: x 3.2m H

The flow patterns and particle-to-particle contact within the electrode gap that is established by the moving belt are key to the effectiveness of the separator. Holim 'a kena lekhalo pakeng tsa li-electrode ho le likaroloana hlonamisitsoe qosoa ba khahloa ke mabotho a motlakase tšimo ho li-electrode tlase positive,. The likaroloana sebele qosoa ba khahloa ke ho hlonamisitsoe qosoa eleketrode holimo. Lebelo la ho tswelang pele lebanta sekgoqetsane ke polygonal tswa 4 ho 20 Mof. The geometry of the belt cross-direction strands serves to sweep the particles of the electrodes moving them towards the proper end of the separator and back into the high shear zone between the oppositely moving sections of the belt. Hobane phatsa palo segokanyipalo ke kahoo e phahameng hara lekhalo pakeng tsa li-electrode ho (approximately one-third the volume is occupied by particles) le phallo e matla Halefang, ho na le thulana tse ngata pakeng tsa likaroloana le homolog tjhaja etsahalang tswelela pele ho pholletsa le libaka karohano. The counter-current flow induced by the oppositely moving belt sections and the continual re-charging and re-separation creates a countercurrent multistage separation within a single apparatus. This continuous charging and recharging of particles within the separator eliminate the need for any “charger” system prior to introducing material to the separator, thus removing a serious limitation on the capacity of electrostatic separation. The khumo ea kgaoganyo ena ke melapo e 'meli, a concentrate, le masalla, ntle le middlings le molapo. The ka bokgoni ba ho kgaoganyo ena e se e bontšitse hore ho ba lekana le hoo e ka bang tse tharo mekhahlelo ea bolokolohi-ho oa karohano le middlings recycle.

Figure 3: Eleketrode Gap tsa STET lebanta la kgaoganyo

The STET separator has many process variables that enable optimization of the trade-off between product purity and recovery that is inherent in any Beneficiation process. The coarse adjustment is the feed port through which the feed is introduced to the separation chamber. The port furthest from the discharge hopper of the desired product gives the best grade but at the expense of a lower recovery. A phetoho molemo ke lebelo la lebanta la. The electrode gap, eo ke fetolehang pakeng 9 le 18 limilimithara, le gagamalo sebediswa (± 4 ho ± 10 kV) are also important variables. The polarity tsa li-electrode ho ka 'na fetoloa tseo tse thusang ho ka karohano ya ba bang ba thepa. Pretreatment of feed material by precise control of trace moisture content (e le lekanngoa ka fepa ka a lekanyelitsoeng mongobo) is important to achieve optimum separation results. The addition of trace amounts of charge-modifying chemical agents can also aid in optimizing the process.

Joalokaha ho boletsoe ka holimo, the initial commercial application of the belt separator has been a separation of coal char from the glassy Aluminosilicate mineral from fly ash from coal-fired power plants. This technology is unique among electrostatic separators in its ability to separate fly ash, eo ka tloaelo ho na le bolela'ng ha phatsa boholo ka tlase ho 0.02 limilimithara. The STET separator has also been proven to effectively separate magnesite from talc, halite from kieserite and sylvite, silicates tloha Bart, and silicates from calcite.3 The mean particle size of all of these feed materials has been in the range of 0.02 le 0.1mm. Mehlala ea karohano ya thepa 'maloa li kenyelletsoa tafole 1.

tafole 1 - Mohlala karohano

| karohano | Feed | sehlahisoa | hlaphoheloa |

|---|---|---|---|

| k'halsiamo carbonate - Silicates | 9.5% Acid Insols | <1% A.I. | 89% CaCO3 |

| Talc - Magnesite | 58% talc | 95% talc | 77% talc |

| 88% talc | 82% talc | ||

| Kierserite + KCl - NaCl | 11.5% K2O | 27.1% K2O | 90% K2O |

| 12.2% kieserite | 31.8% kieserite | 94% kieserite | |

| 64.3% NaCl | 14.3% NaCl | 92% NaCl reject | |

| Fly Ash Mineral - k'habone | 6.3% carbon | 1.8% carbon | 88% matsoai |

| 11.2% carbon | 2.1% carbon | 84% matsoai | |

| 19.3% carbon | 2.9% carbon | 78% matsoai |

ka khopolo, kaha phatsa tjhaja itšetlehileng ka phello triboelectric, liminerale efe kapa efe e 'meli hore ba lokolloa e mong le tse ling tse (mokhanni- mokhanni kapa nonconductor-mokhanni) ka arohantsoe ke mokhoa ona. bokgoni ba dikopo tse ding kenyeletsa magnesite-quartz, feldspar-quartz, lehlabathe matsoai, tse ling tse karohano potash matsoai, le

karohano phosphate-calcite-silica.

1 Bittner, J.D., Gasiorowski, S.A., Bush, T.W.,, Hrach, F.J., Separation technologies’ automated fly ash beneficiation process selected for new Korean power plant, ditsamaiso tsa 2013 World of Coal Ash conference, Mmesa 22-25, 2013. 2 Bittner, J.D., Hrach, F.J., Gasiorowski, S.A., Canellopoulus, L.A., Guicherd, H. Triboelectric belt separator for Beneficiation of fine minerals, SYMPHOS 2013 – 2nd International Symposium on Innovation and Technology for the Phosphate Industry. tsoela pele Engineering, Vol. 83 maq 122-129, 2014. 3 Bittner, J.D., Flynn, K.P., Hrach, F.J., Atolosa dikopo ho omileng Triboelectric karohano oa liminerale, Ditsamaiso tsa XXVII International matsoai Processing Congress - IMPC 2014, Santiago, Chile, Oct 20 - 24, 2014.