Họrọ asụsụ:

The American Kol Ash Association (ACAA) kwa afọ e mere na nke mmepụta na ojiji nke coal ada uyi na-akọ na n'etiti 1966 na 2011, n'elu 2.3 ijeri obere tọn ada uyi na-emepụta site coal-chụọ n'ọrụ na ịba uru boilers. Of a ego, dị 625 nde tọn e bara uru na-eji, ukwuu n'ime ka simenti na ihe mmepụta. Otú ọ dị, nke fọdụrụ 1.7+ nde tọn na-isi hụrụ na landfills ma ọ bụ jupụtara ponded impoundments.

Triboelectrostatic Beneficiation nke Landfilled na Ponded ada uyi

Site Lewis Baker,Abhishek Gupta, Stephen Gasiorowski, na Frank Hrach

The American Kol Ash Association (ACAA) kwa afọ e mere na nke mmepụta na ojiji nke coal ada uyi na-akọ na n'etiti 1966 na 2011, n'elu 2.3 ijeri obere tọn ada uyi na-emepụta site coal-chụọ n'ọrụ na ịba uru boilers.1 Of a ego, dị 625 nde tọn e bara uru na-eji, ukwuu n'ime ka simenti na ihe mmepụta. Otú ọ dị, nke fọdụrụ 1.7+ nde tọn na-isi hụrụ na landfills ma ọ bụ jupụtara ponded impoundments. Mgbe eji ọnụego maka freshly eme ada uyi amụbawo nke ukwu n'elu-adịbeghị anya, na ugbu a udu nso 45%, dị 40 nde tọn ada uyi-anọgide na-ewekarị nke kwa afọ. Mgbe eji udu ke Europe ndidi nnọọ elu karịa nke United States, bukwanu mpịakọta nke ada uyi nakwa na e echekwara na landfills na impoundments na ụfọdụ mba Europe

na nso nso, mmasị na-agbake a na-ewekar ihe amụbawo, n'ụzọ ụfọdụ n'ihi ina elu-edu ada uyi maka ihe na simenti mmepụta n'oge a oge nke belata mmepụta dị ka coal-chụọ n'ọrụ ike ọgbọ belatara Europe na North America. Nchegbu banyere ogologo oge gburugburu ebe obibi mmetụta nke ndị dị otú ahụ landfills na-apostle utilities chọta bara uru iji ngwa a echekwara ash.

Ezie na ụfọdụ nke a echekwara ada uyi nwere ike kwesịrị ekwesị n'ihi na ọ bara uru iji dị ka ibido gwupụtatụrụla, ihe ka n'ọnụ ọgụgụ ga-achọ ụfọdụ nhazi izute àgwà ụkpụrụ maka simenti ma ọ bụ ihe mmepụta. N'ihi na ihe e a wetted aka njikwa na compaction izere airborne ájá ọgbọ, ihicha na deagglomeration bụ a dị mkpa a chọrọ n'aka ojiji na ihe n'ihi na ihe na-emepụta ga na-omume nke batching ada uyi ka a akọrọ, ezi ntụ ntụ. Otú ọ dị, emesi ndị chemical mejupụtara nke ash osobo nkọwa-ọtụtụ Ichi na carbon ọdịnaya, tụrụ ka ọnwụ na mgbanye (iWU)-bụ a ukwuu ịma aka. Dị ka ada uyi were amụbawo ke akpatre 20+ afọ, kacha "na-spec" ash e bara uru na-eji, na anya-quality ash ewekarị. N'ihi ya, LOI Mbelata ga-a chọrọ maka iji ọgụgụ ka ukwuu nke ada uyi recoverable si mmekọ impoundments.

Ezie na ndị ọzọ na-eme nnyocha ji combustion usoro na flotation Filiks maka LOI Mbelata Natara landfilled na ponded ada uyi, ST Equipment & Technologies (STET) hụrụ na ya pụrụ iche triboelectrostatic belt nkewa usoro, ogologo eji maka beneficiation nke freshly eme ada uyi, nwekwara irè na natara ash mgbe kwesịrị ekwesị ihicha na deagglomeration.

STET na-eme nnyocha na-anwale na triboelectrostatic nkewa omume nke Fikiere landfilled ash si ọtụtụ ada uyi landfills n'America na Europe. Nke a natara ash iche ukwuu N'otu aka ahụ freshly eme ash na otu ihe ijuanya dị iche: urughuru Nchaji e nwesịrị site na nke ọhụrụ ash, na carbon odori ọjọọ na ikwu na mineral.2 Ndị nnyocha ndị ọzọ nke electrostatic nkewa nke ada uyi carbon nwere kwukwara a phenomenon.3-5 The polarity nke STET triboelectrostatic separator nwere ike mfe ịgbanwe na-ekwe ka ojuju nke na-adịghị mma na ebubo carbon si Fikiere landfilled ada uyi na isi mmalite. Ọ dịghị pụrụ iche mgbanwe na separator imewe ma ọ bụ njikwa mkpa iji nabata ya phenomena

Na STET carbon separator (fig. 1), ihe a na nri n'ime mkpa ọdịiche n'etiti abụọ yiri planar electrodes. The ahụ na-triboelectrically boro ebubo site interparticle kọntaktị. The ghaghị ebubo carbon na-ezighị ezi na ebubo ịnweta (na freshly eme ash nke e wetted na Fikiere) na-dọtara na-abụghị electrodes. The ahụ na-ahụ kpochapụ elu site a na-aga n'ihu na-akpali akpali belt na ekekpepde na-abụghị ntụziaka. The belt na-akpali ndị ahụ n'akụkụ ọ bụla electrode n'ebe abụghị nsọtụ nke separator. The elu belt ọsọ na-enyere nnọọ elu throughputs ruo 36 ton kwa hour na a otu separator. The obere ọdịiche, elu-voltaji ubi, counter-ugbu a eruba, ike urughuru-urughuru n'ahụhụ, na-ehicha onwe edinam nke belt na electrodes bụ oké egwu atụmatụ nke STET separator. Site ịchịkwa dị iche iche usoro parameters, dị ka belt ọsọ, ndepụta na mgbe, na ndepụta ọnụego, na STET usoro arụpụta ala LOI ada uyi na carbon ọdịnaya nke na-erughị 1.5 ka 4.5% si oriri ada ntụ sitere na LOI si 4% karịrị 25%.

The separator imewe bụ dịtụ mfe na kọmpat. A igwe iji hazie 40 ton kwa hour bụ mkpokọta 30 ft (9 m) ogologo, 5 ft (1.5 m) obosara, na 9 ft (2.75 m) ogologo. The belt na metụtara rollers bụ naanị na-akpụ akpụ akụkụ. The electrodes bụ anyịnya na esịnede ihe n'ụzọ kwesịrị ekwesị inogide ihe. The belt ka nke nonconductive plastic. The separator ike oriri bụ banyere 1 kilowatt-hour kwa ton nke ihe onwunwe esichara na ọtụtụ ndị ike gwusia site abụọ Motors ụgbọala belt.

The usoro kpamkpam akọrọ, na-achọ ọ ọzọ ihe ndị ọzọ karịa nke ada uyi, ma na-amị dịghị n'efu mmiri ma ọ bụ ikuku anwuru. The natara ihe iso nke ada uyi ebelata ke carbon ọdịnaya etoju kwesịrị ekwesị maka dị ka a pozzolanic admixture na ihe, na a elu-carbon nta bara uru dị ka mmanụ ụgbọala. Iji ma ngwaahịa iyi na-enye a 100% ngwọta ofufe ash mkpofu nsogbu.

Anọ na isi mmalite nke ash e nwetara site landfills: Sample A si a ike osisi dị na United Kingdom na Samples B, C, na D si United States. All ndị a samples gụnyere ash si combustion nke bituminous coal site nnukwu mmekọ boilers. N'ihi Ngwakọta ihe onwunwe ke landfills, nweghị ozi ọzọ dị banyere kpọmkwem coal iyi ma ọ bụ combustion ọnọdụ.

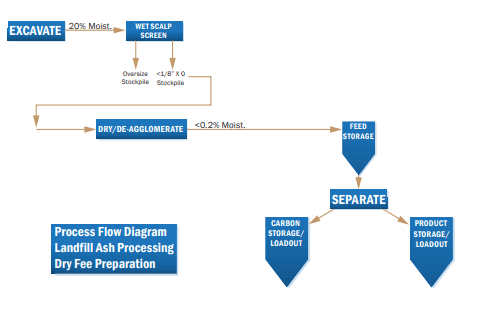

The samples dị ka natara site STET nwere n'etiti 15 na 27% mmiri, dị ka-ahụkarị nke landfilled ihe. The samples nakwa ẹdude mgbanwe ichekwa nnukwu >1/8 na. (3 mm) ihe. Iji kwadebe samples maka carbon nkewa, nnukwu irighiri e wepụrụ screening na samples mgbe Fikiere ma deagglomerated tupu carbon beneficiation. Ọtụtụ ụzọ maka ihicha / deagglomeration e inyocha na pilot ọnụ ọgụgụ na-ebuli n'ozuzu usoro. STET ahọrọwo ihe industrially pụtara oriri nhazi usoro na awade imekotaotuugbo ihicha na deagglomeration dị mkpa maka irè electrostatic nkewa. A general usoro flowchart na-adade ke Fig. 2.

Njirimara nke ihe atụ ndị a kwadebere dị mma n'ime oke nke ofufe ash enwetara ozugbo site na igwe ọkụ ọkụ nkịtị. The kasị mkpa Njirimara n'ihi na ma separator faili ntanetịime na ngwaahịa na-chịkọtara Isiokwu 2, tinyere Natara ngwaahịa.

STET separator nhazi Fikiere, landfilled ada uyi

Usoro eruba esereese

Carbon Mbelata ọnwụnwa iji STET triboelectric belt separator rụpụtara ezigbo mma mgbake nke ala-LOI ngwaahịa niile anọ landfill ada uyi na isi mmalite. Agbara odori nke carbon dị ka e kwuru na mbụ na-degrade nkewa n'ụzọ ọ bụla dị ka tụnyere nhazi ọhụrụ ash.

Njirimara nke ala-na-LOI ada uyi natara iji STET usoro maka ma freshly anakọtara ash si esi mmiri ọkụ na ntụ si gbakee site landfill A chịkọtara Isiokwu 1. The results na-egosi na ngwaahịa mma maka ProAsh® emepụta si landfilled ihe onwunwe bụ Ẹkot ngwaahịa na-emepụta si ọhụrụ ada uyi na isi mmalite.

Njirimara nke ProAsh site si agbapụtawo landfill ihe onwunwe na-tụnyere nke ProAsh emepụta si ọhụrụ ada uyi N'ịbụ mmekọ boilers si n'otu ebe. The esichara agbapụtawo ash osobo niile nkọwa nke ASTM C618 na AASHTO M 250 ụkpụrụ. Isiokwu 2 achikota onwu maka samples abụọ n'ime ndị isi mmalite egosi ntakịrị ihe dị iche n'etiti ọhụrụ na agbapụtawo ihe.

Ike mmepe nke a 20% nnọchi nke ala-na-LOI ada uyi na a ngwa agha nwere 600 lb / yd3 cementitious ihe (ahụ Isiokwu 3) gosiri ProAsh ngwaahịa ewepụtara landfilled ash amịghịkwa ogbunigwe ike iji tụnyere ogbunigwe na-emepụta na-eji ProAsh si ọhụrụ ada uyi emepụta n'otu ebe. The ọgwụgwụ ngwaahịa nke beneficiated agbapụtawo ash ga-akwado elu-ọgwụgwụ na-eji na ihe ụlọ ọrụ na-agbanwe agbanwe na nke ukwuu bara uru ọnọdụ ProAsh arụ ke ahịa ya eje ozi ugbu a.

The nnweta nke ala-na-eri eke gas na United States ewelite akụnụba nke ihicha Filiks, gụnyere ihicha nke wetted ada uyi si landfills. Isiokwu 4 achikota mmanụ ụgbọala na-akwụ ụgwọ maka arụmọrụ ke United States maka 15% na 20% mmiri ọdịnaya. Ahụkarị inefficiencies nke ihicha na-gụnyere ke gbakọọ ụkpụrụ. Akwụ ụgwọ na-dabeere na uka nke ihe onwunwe mgbe ihicha. The incremental-akwụ ụgwọ maka ihicha ada uyi maka STET triboelectrostatic nkewa nhazi na-dịtụ ala.

Ọbụna na mgbakwunye na nke oriri ihicha na-akwụ ụgwọ, na STET nkewa usoro awade a ala-na-eri, industrially nwapụtaworo na usoro maka LOI Mbelata landfilled ada uyi. The STET usoro maka agbapụtawo ada uyi bụ otu-na-atọ otu ọkara nke isi obodo-eri tụnyere combustion dabeere na usoro. The STET usoro maka agbapụtawo ada uyi na-nwere budata ala umu anwuru na gburugburu ebe obibi tụnyere combustion ma ọ bụ flotation dabeere na usoro. N'ihi na naanị ọzọ ikuku emission iyi ka ọkọlọtọ STET usoro echichi bụ eke gas-chụọ n'ọrụ draya, ikwe ọ ga-abụ nnọọ mfe.

| Nri sample ka separator | iWU, % | ProAsh iWU, % | ProAsh fineness, % +325 ntupu |

ProAsh uka mkpụrụ, % |

|---|---|---|---|---|

| Fresh A | 10.2 | 3.6 | 23 | 84 |

| Landfilled A | 11.1 | 3.6 | 20 | 80 |

| Fresh B | 5.3 | 2.0 | 13 | 86 |

| Landfilled B | 7.1 | 2.0 | 15 | 65 |

| Fresh C | 4.7 | 2.6 | 16 | 82 |

| Landfilled C | 5.7 | 2.5 | 23 | 72 |

| Landfilled D | 10.8 | 3.0 | 25 | 80 |

| ihe isi iyi | SiO2 | Al2O3 | Fe2O3 | CaO | MgO | K2O | Na2O | SO3 |

|---|---|---|---|---|---|---|---|---|

| Fresh B | 51.60 | 24.70 | 9.9 | 2.22 | 0.85 | 2.19 | 0.28 | 0.09 |

| Landfilled B | 50.40 | 25.00 | 9.3 | 3.04 | 0.85 | 2.41 | 0.21 | 0.11 |

| Fresh C | 47.7 | 23.4 | 10.8 | 5.6 | 1.0 | 1.9 | 1.1 | 0.03 |

| Landfilled C | 48.5 | 26.5 | 11.5 | 1.8 | 0.86 | 2.39 | 1.18 | 0.02 |

| 7-ụbọchị compressive ike, % nke ọhụrụ ash akara | 28-ụbọchị compressive ike, % nke ọhụrụ ash akara | |

|---|---|---|

| Fresh B | 100 | 100 |

| Landfilled B | 107 | 113 |

| Fresh C | 100 | 100 |

| Landfilled C | 97 | 99 |

| mmiri ọdịnaya, % | Okpomọkụ chọrọ KWhr / T mmiri ndabere | Ihicha eri / T akọrọ ndabere (eke gas na-eri $ 3,45 / mmBtu) |

| 15 | 165 | $ 2.28 |

| 20 | 217 | $ 3.19 |

Na mgbakwunye na ala-na-carbon ngwaahịa maka ojiji na concrete- ika-aha ya bụ ProAsh-na STET nkewa usoro nwekwara Recovers ma egbughị unburned carbon n'ụdị carbon-ọgaranya ada uyi, ewere EcoTherm™. EcoTherm nwere ịrịba mmanụ ụgbọala uru na ike mfe-laghachiri electric ike osisi iji STET EcoTherm Laghachi usoro iji belata coal ojiji na osisi. Mgbe EcoTherm na-akpọ ya na ịba uru ji esi mmiri ọkụ, ume site combustion na-ghọrọ ka elu-mgbali / elu-okpomọkụ uzuoku na mgbe ahụ ka ọkụ eletrik n'otu arụmọrụ dị ka coal, a na 35%. The akakabarede nke natara thermal ike ọkụ eletrik na STET EcoTherm Laghachi usoro bụ abụọ na atọ ugboro elu karịa nke asọmpi technology ebe ume natara dị ka ala-ọkwa okpomọkụ n'ụdị mmiri ọkụ, nke a na-ekesa na ji esi mmiri ọkụ oriri mmiri usoro. EcoTherm a na-eji dị ka isi iyi nke alumina na simenti kilns, displacing ndị ọzọ dị oké ọnụ bauxite, nke a na-emekarị-ebu anya. Iji elu-carbon EcoTherm ash ma na a ike osisi ma ọ bụ a cement n'ekwú ọkụ maximizes ume mgbake si napụta coal, mbenata mkpa egwupụtakwa na ibufe ọzọ mmanụ ụgbọala na ụlọ ọrụ.

STET si Talen Energy Brandon mben, SMEPA R.D. Morrow, NBP Belledune, RWEnpower Didcot, EDF Energy West Burton, RWEnpower Aberthaw, na Korea South-East Power ofufe ash osisi niile na-agụnye EcoTherm Laghachi usoro.

STET si nkewa usoro e ji mee commercially kemgbe 1995 maka ada uyi beneficiation na emewo site n'elu 20 nde tọn nke elu-edu ofufe ash maka ihe mmepụta. Na-achịkwa ala-LOI ProAsh a ugbu a na-emepụta na STET si technology na 12 ike ụgbọ ofụri United States, Canada, na United Alaeze, Poland, na Republic of Korea. ProAshfly ash e mma maka site karịa 20 ala okporo ụzọ ọchịchị, nakwa dị ka ọtụtụ ndị ọzọ na nkọwapụta ụlọ ọrụ. ProAsh nwekwara e gbaara n'okpuru Canadian Standards Association na EN 450:2005 àgwà ụkpụrụ na Europe. Ash nhazi ụlọ ọrụ iji STET technology na-depụtara na Isiokwu 5.

Mgbe kwesịrị ekwesị scalping nke nnukwu ihe onwunwe, ihicha, na deagglomeration, ofufe ash natara site na ịba uru osisi landfills nwere ike ebelata ke carbon ọdịnaya site na iji na azụmahịa STET triboelectric belt separator. Àgwà nke ada uyi ngwaahịa, ProAsh, na iji STET usoro na agbapụtawo landfill ihe, bụ Ẹkot ProAsh emepụta si ọhụrụ oriri ada uyi. The ProAsh ngwaahịa bụ nke ọma ruru eru ma pụtara na ihe mmepụta. The mgbake na beneficiation nke landfilled ash ga-enye a nọgidere na-enweta elu-edu ash maka ihe na-emepụta n'agbanyeghị belata mmepụta nke "ọhụrụ" ash ka coal-chụọ n'ọrụ utilities belata ọgbọ. Ọzọkwa, ike osisi na mkpa ka wepu ash si landfills izute na-agbanwe agbanwe gburugburu ebe obibi ụkpụrụ ga-enwe ike iji usoro ịgbanwe a n'efu ngwaahịa liability n'ime a bara uru akụrụngwa n'ihi ihe na-emepụta. The STET nkewa usoro na oriri preprocessing ngwá maka ihicha na deagglomerating landfilled ada uyi bụ ihe mara mma nhọrọ maka ash beneficiation na budata ala na-eri ma na ala umu anwuru tụnyere ndị ọzọ combustion- na flotation dabeere na usoro. ❖

1. American Kol Ash Kol combustion Ngwaahịa na Jiri Statistics, http://www.acaausa.org/Publications/Production-Use-Reports.

2. ST Esịtidem Report, Aug. 1995.

3. na, T. X.; Schaefer, J. L.; Ban, H.; Neathery, J. K.; na Stencel, J. M., "Akọrọ Beneficiation nhazi nke combustion ada uyi,"Ikpe nke DOE Conference on Unburned Carbon on Utility ada uyi, Pittsburgh, PA, Ka 19-20, 1998.

4. Baltrus, J. P.; Diehl, J. R.; Soong, Y.; na ájá, W., "Triboelectrostatic Nkewa nke ada uyi na n'Aka nloghachi,"Mmanụ, V. 81, 2002, p. 757-762.

5. Cangialosi, F.; Notarnicola, M.; Liberti, L.; na Stencel, J., "Otú Weathering na ada Ash n'Aka Nkesa n'oge Triboelectrostatic Beneficiation,"Journal of Hazardous Materials, V. 164, 2009, p. 683-688.

Lewis Baker bụ European nka na ụzụ Nkwado Manager maka ST Equipment & Technology (STET) dabeere na United Alaeze

Abhishek Gupta bụ a Usoro Engineer dabeere na STET pilot osisi na lab eweta na Needham, MA.

Stephen Gasiorowski bụ a Senior Research Scientist maka ST Equipment & Technology (STET) dabere na New Hampshire.

Frank Hrach bụ Vice President of Usoro Engineering dabeere na STET pilot osisi na lab eweta na Needham, MA.

| Utility na ike ojii | Location | Malite nke azụmahịa arụmọrụ | Facility nkọwa |

|---|---|---|---|

| Duke Energy-Roxboro Station | North Carolina | Sept. 1997 | 2 separators |

| Talen Energy-Brandon mben Station | Maryland | Apr. 1999 | 2 separators 35,000 ton nchekwa dome Ecotherm Lọghachinụ 2008 |

| ScotAsh (Lafarge / Scottish Power Joint Venture)-Longannet Station | Scotland, UK | Oct. 2002 | 1 separator |

| Jacksonville Electric Authority- St. Jọn River Power Park, FL | Florida | Ka 2003 | 2 separators Kol / petcoke ejikọta amonia mwepụ |

| South Mississippi Electric Power Authority R.D. Morrow Station | Mississippi | Jan. 2005 | 1 separator Ecotherm laghachi |

| New Brunswick Power Company Belledune Station | New Brunswick, Canada | Apr. 2005 | 1 separator Kol / petcoke ejikọta Ecotherm laghachi |

| RWE npower Didcot Station | England, The | Aug. 2005 | 1 separator Ecotherm laghachi |

| Talen Energy Brunner Island Station | Pennsylvania | Dec. 2006 | 2 separators 40,000 ton nchekwa dome |

| Tampa Electric Co. Big Bend Station | Florida | Apr. 2008 | 3 separators, abụọ ngafe 25,000 ton nchekwa dome amonia mwepụ |

| OF npower Aberthaw Station (Lafarge Cement UK) | Wales, UK | Sept. 2008 | 1 separator amonia mwepụ Ecotherm laghachi |

| EDF Energy West Burton Station (Lafarge Cement UK, Cemex) | England, UK | Oct. 2008 | 1 separator Ecotherm laghachi |

| ZGP (Lafarge Cement Poland / Ciech Janikosoda JV) | Poland | Mar. 2010 | 1 iche iche |

| Korea South-East Power Yeongheung Units 5&6 | South Korea | Sept. 2014 | 1 separator Ecotherm laghachi |

| PGNiG-Siekierki Termika | Poland | ndokwa 2016 | 1 separator Ecotherm laghachi |

| Na-mara ọkwa | Poland | ndokwa 2016 | 1 separator Ecotherm laghachi |