زبان را انتخاب کنید:

STET Triboelectrostatic separation has been used for the commercial beneficiation of coal combustion fly ash to produce a low carbon product for use as a cement replacement in concrete for nearly 20 years….

دانلود PDFF. هراچ, S. گیرند Gasiorowski, H.Guicherd

ST تجهیزات & فن آوری های LLC (STET), 101 همپتون خیابان, نیدهام MA 02494 ایالات متحده آمریکا

CONFERENCE: Vietbuild شهر هوشی مین - ژوئن 2015

کلید واژه ها: Triboelectrostatic, بهره, Dry Fly Ash, Carbon Separation ABSTRACT

STET Triboelectrostatic separation has been used for the commercial beneficiation of coal combustion fly ash to produce a low carbon product for use as a cement replacement in concrete for nearly twenty years. With 18 separators in 12 coal-fired power plants across the world, ST تجهیزات & تکنولوژی LLC (STET) patented electrostatic separator has been used to produce over 15 Million tonnes of low carbon product.

To date, commercial beneficiation of fly ash has been performed exclusively on dry “run of station” ash. STET’s electrostatic beneficiation technology reduces the carbon content of coal fly ash, producing consistent, low carbon ash for use as a substitute for cement. Fly ash with carbon levels up to 25% have been used to produce ash with a controlled carbon level of 2 ± 0.5%. A carbon-rich product is simultaneously produced to recover the fuel value of the carbon.

مقدمه

انجمن خاکستر ذغال سنگ آمریکا (ACAA) بررسی سالانه از تولید و استفاده از زغال سنگ خاکستر گزارش می دهد که بین 1966 و 2011, روی 2.3 billion short tons of fly ash have been produced by coal-fired utility boilers.1 Of this amount, تقریبا 625 میلیون تن سودمند استفاده شده است, بیشتر برای سیمان و تولید بتن. با این حال, باقیمانده 1.7+ میلیارد تن در درجه اول در محل های دفن زباله پیدا شده است و یا پر impoundments ponded. While utilization rates for freshly generated fly ash have increased considerably over recent years, with current rates near 45%, تقریبا 40 million tons of fly ash continues to be disposed of annually. While utilization rates in Europe have been much higher than in the US, considerable volumes of fly ash have also been stored in landfills and impoundments in some European countries. An excessive amount of unburned carbon in fly ash is the most common problem. The American Association of State Highway and Transportation Officials (AASHTO) and European Standards (EN 450 Category A) require that the amount of unburned carbon in fly ash, measured by loss on ignition (قانون) not exceed 5% by weight. با این حال, starting in the mid-1990s, installation of mandated NOx control equipment at coal-fired power plants increased the carbon (قانون) content of much of the previously marketable fly ash. Further requirements to reduce NOx and other power plant emissions have resulted in the contamination of fly ash with ammonia. As a consequence, while understanding the benefits of using fly ash in concrete continues to increase, the availability of suitable quality fly ash is decreasing. Processes to economically beneficiate off-quality fly ash are thus also of increasing interest to the power and concrete industries. STET has pioneered such processes for both carbon and ammonia removal from fly ash.

TECHNOLOGY OVERVIEW – FLY ASH CARBON SEPARATION

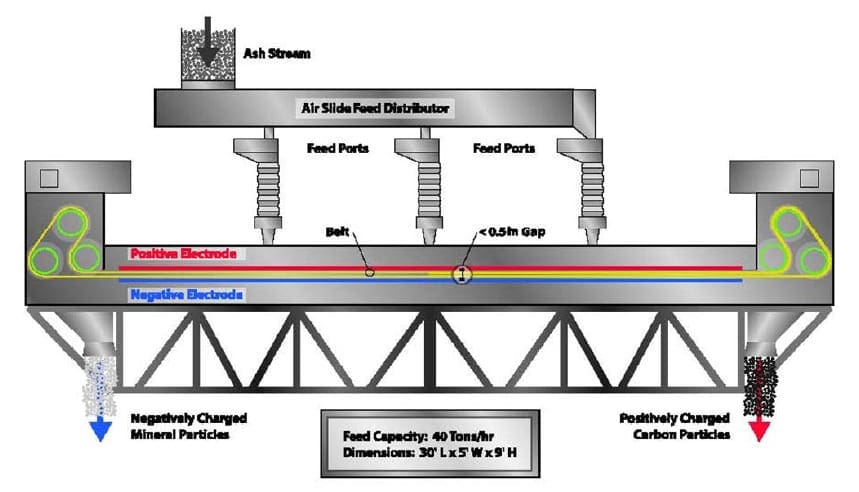

In the STET carbon separator (شکل 1), the material is fed into the thin gap between two parallel planar electrodes. The particles are triboelectrically charged by interparticle

contact. The positively charged carbon and the negatively charged mineral (in freshly generated ash that has not been wetted and dried) به مقابل الکترود جذب می شوند. The particles are then swept up by a continuous moving belt and conveyed in opposite directions. تسمه حرکت ذرات مجاور به هر الکترود به سمت انتهای مخالف جدا کننده. سرعت بالای تسمه همچنین قادر می سازد بسیار بالا throughputs, تا 36 تن در ساعت در یک جداکننده تکی. شکاف کوچک, high voltage field, countercurrent flow, vigorous particle-particle agitation and self-cleaning action of the belt on the electrodes are the critical features of the STET separator. توسط کنترل مراحل مختلف, مانند سرعت تسمه, the feed point, and feed rate, the STET process produces low LOI fly ash at carbon contents of less than 1.5 به 4.5% from feed fly ashes ranging in LOI from 4% به بیش از 25%.

انجیر. 1 STET Separator

طراحی جداکننده نسبتا ساده و جمع و جور است. ماشین طراحی شده برای پردازش 36 تن در هر ساعت در حدود 9 متر (30 مربع.) طولانی, 1.5 متر (5 مربع.) وسیع, و 2.75 متر (9 مربع.) بلند. کمربند و غلطک مرتبط هستند تنها قطعات متحرک. الکترود ثابت و متشکل از یک ماده مناسب با دوام. The belt is made of nonconductive plastic. The separator’s power consumption is about 1 کیلووات ساعت در هر تن از مواد پردازش با بسیاری از قدرت مصرف شده توسط دو موتور رانندگی کمربند.

فرایند کاملا خشک است, requires no additional materials other than the fly ash and produces no wastewater or air emissions. The recovered materials consist of fly ash reduced in carbon content to levels suitable for use as a pozzolanic admixture in concrete, and a high carbon fraction useful as fuel. استفاده از هر دو جریان محصول را فراهم می کند 100% راه حل برای مشکلات دفع خاکستر.

RECOVERED FUEL VALUE OF HIGH-CARBON FLY ASH

In addition to the low carbon product for use in concrete, brand named ProAsh®, the STET separation process also recovers otherwise wasted unburned carbon in the form of carbon-rich fly ash, branded EcoTherm™. EcoTherm™ has significant fuel value and can easily be returned to the electric power plant using the STET EcoTherm™ Return system to reduce the coal use at the plant. When EcoTherm™ is burned in the utility boiler, the energy from combustion is converted to high pressure /high-temperature steam and then to electricity at the same efficiency as coal, typically 35%. The conversion of the recovered thermal energy to electricity in ST Equipment & Technology LLC EcoTherm™ Return system is two to three times higher than that of the competitive technology where the energy is recovered as low-grade heat in the form of hot water which is circulated to the boiler feed water system. EcoTherm™ is also used as a source of silica and alumina in cement kilns, displacing the more expensive raw materials, such as shale or bauxite, which are used in cement production. Utilizing the high carbon EcoTherm™ ash either at a power plant or a cement kiln, maximizes the energy recovery from the delivered coal, reducing the need to mine and transport additional fuel to the facilities.

STET’s Talen Energy Brandon Shores, SMEPA R.D. فرداى, NBP Belledune, RWEnpower Didcot, EDF Energy West Burton, and RWEnpower Aberthaw fly ash plants, all include EcoTherm™ Return systems. The essential components of the system are presented in Figure 2.

انجیر. 2 EcoTherm™ Return system

STET ASH PROCESSING FACILITIES

Controlled low LOI fly ash is produced with STET’s technology at twelve power stations throughout the U.S., کانادا, the U.K., لهستان, جمهوری کره. ProAsh® fly ash

has been approved for use by over twenty state highway authorities, و همچنین بسیاری از سازمان های دیگر مشخصات. ® ProAsh نیز تحت استانداردهای کانادا انجمن گواهی شده است و EN 450:2005 استانداردهای کیفیت در اروپا. Ash processing facilities using STET technology are listed in Table 1.

جدول 1. STET Commercial Operations

| سودمند / Power Station | محل | شروع از تجاری عملیات | Facility Details |

|---|---|---|---|

| Duke Energy – Roxboro Station | North Carolina ایالات متحده آمریکا | Sept. 1997 | 2 جدا کننده |

| تالین انرژی - Brandon Shores Station | Maryland ایالات متحده آمریکا | آوریل 1999 | 2 جدا کننده 35,000 ton storage dome. Ecotherm™ Return 2008 |

| ScotAsh (Lafarge / Scottish Power Joint Venture) - ایستگاه longannet | Scotland بریتانیا | اکتبر. 2002 | 1 جدا کننده |

| Jacksonville Electric Authority - St. John’s River Power Park, Fl | Florida ایالات متحده آمریکا | ممکن است 2003 | 2 جدا کننده Coal/Petcoke blends Ammonia Removal |

| South Mississippi Electric Power Authority R.D. فرداى Station | Mississippi ایالات متحده آمریکا | ژانویه. 2005 | 1 جدا کننده Ecotherm™ Return |

| New Brunswick Power Company Belledune Station | New Brunswick, کانادا | آوریل 2005 | 1 جدا کننده Coal/Petcoke Blends Ecotherm™ Return |

| RWE npower Didcot Station | England بریتانیا | اوت 2005 | 1 جدا کننده Ecotherm™ Return |

| Talen Energy Brunner Island Station | Pennsylvania ایالات متحده آمریکا | دسامبر 2006 | 2 جدا کننده 40,000 Ton storage dome |

| Tampa Electric Co. Big Bend Station | Florida ایالات متحده آمریکا | آوریل 2008 | 3 جدا کننده, دو پاس 25,000 Ton storage dome Ammonia Removal |

| RWE npower Aberthaw Station (Lafarge Cement UK) | Wales بریتانیا | سپتامبر 2008 | 1 جدا کننده Ammonia Removal Ecotherm™ Return |

| EDF Energy West Burton Station (Lafarge Cement UK, Cemex) | England بریتانیا | اکتبر 2008 | 1 جدا کننده Ecotherm™ Return |

| ZGP (سیمان لیافج لهستان / سیچ جیانیکوسودا JV) | لهستان | مارس 2010 | 1 جدا کننده |

| Korea South-East Power Yeongheung Units 5&6 | کره جنوبی | سپتامبر 2014 | 1 جدا کننده Ecotherm™ Return |

| سیمان لیافج لهستان Warsaw | لهستان | 2016 | 1 جدا کننده |

CONCLUSIONS

Maximizing the utilization of fly ash as a cement substitute in concrete production substantially reduces the carbon dioxide emissions associated with construction activity. با این حال, pollution control systems implemented by the coal-fired power stations have resulted in a reduction of available fly ash meeting concrete-grade specifications. Further degradation of fly ash quality is expected due to further reductions in allowable gas emissions. In order to avoid loss of this valuable resource of material for concrete production as well as reduction of greenhouse gas emissions associated with concrete construction, processes for restoring the quality of the fly ash in an economic and environmentally viable way are needed.

The beneficiation of fly ash with STET processes further increases the supply of this important material. The STET beneficiation processes continue to be the most extensively applied methods to upgrade otherwise unusable fly ash to high-value materials for cement replacement in concrete. Eighteen SETT carbon separators are currently in place with over 100 machine-years of operation.

ProAsh® has found wide acceptance in the concrete industry as a premium fly ash requiring far less monitoring of air entrainment requirements due to less LOI variability than other ashes. Returning the high-carbon concentrate from the STET process to the boiler at a power plant allows recovery of the recovered carbon fuel value at an efficiency similar to coal. STET offers economical means to recover ash for high-value use that would otherwise be landfilled. Electrostatic carbon separation and Ecotherm™ return to the boiler provide a modular solution to a utility’s fly ash needs. These processes can be implemented in phases, or as a single project.

مراجع

[1] American Coal Ash Coal Combustion products and Use Statistics:

https://www.acaa-usa.org/Publications/Production-Use-Reports/