Lingwa Agħżel:

STET Triboelectrostatic separation has been used for the commercial beneficiation of coal combustion fly ash to produce a low carbon product for use as a cement replacement in concrete for nearly 20 years….

Download PDFF. Rach, S. Gasiorowski, H.Guicherd

ST Tagħmir & Teknoloġiji LLC (STET), 101 Hampton Vjal, Needham MA 02494 USA

CONFERENCE: Vietbuild Ho Chi Minh City – June 2015

KEYWORDS: Triboelectrostatic, Beneficiation, Dry Fly Ash, Carbon Separation ABSTRACT

STET Triboelectrostatic separation has been used for the commercial beneficiation of coal combustion fly ash to produce a low carbon product for use as a cement replacement in concrete for nearly twenty years. With 18 separators in 12 coal-fired power plants across the world, ST Tagħmir & Technology LLC’s (STET) patented electrostatic separator has been used to produce over 15 Million tonnes of low carbon product.

To date, commercial beneficiation of fly ash has been performed exclusively on dry “run of station” ash. It-teknoloġija elettrostatika tal-benefiċjazzjoni tal-STET tnaqqas il-kontenut tal-karbonju tal-irmied li jtir il-faħam, producing consistent, irmied b'livell baxx ta' karbonju għall-użu bħala sostitut għas-siment. Fly ash with carbon levels up to 25% have been used to produce ash with a controlled carbon level of 2 ± 0.5%. A carbon-rich product is simultaneously produced to recover the fuel value of the carbon.

INTRODUZZJONI

The American Coal Ash Association (ACAA) annual survey of production and use of coal fly ash reports that between 1966 u l- 2011, Fuq 2.3 billion short tons of fly ash have been produced by coal-fired utility boilers.1 Of this amount, Madwar 625 million tons have been beneficially used, mostly for cement and concrete production. Madankollu, the remaining 1.7+ billion tons are primarily found in landfills or filled ponded impoundments. While utilization rates for freshly generated fly ash have increased considerably over recent years, with current rates near 45%, Madwar 40 million tons of fly ash continues to be disposed of annually. While utilization rates in Europe have been much higher than in the US, considerable volumes of fly ash have also been stored in landfills and impoundments in some European countries. Ammont eċċessiv ta 'karbonju mhux maħruq fl-irmied li jtir huwa l-iktar problema komuni. L-Assoċjazzjoni Amerikana tal-Awtostrada tal-Istat u l-Uffiċjali tat-Trasport (AASHTO) u l-Istandards Ewropej (EN 450 Kategorija A) jeħtieġu li l-ammont ta' karbonju mhux maħruq fl-irmied li jtir, imkejjel b'telf malli jkun qed jaqbad (LIĠI) ma jaqbżux 5% skont il-piż. Madankollu, starting in the mid-1990s, l-installazzjoni ta' tagħmir ta' kontroll tal-NOx b'mandat f'impjanti tal-enerġija li jaħdmu bil-faħam żiedet il-karbonju (LIĠI) kontenut ta' ħafna mill-irmied li jtir li qabel kien kummerċjabbli. Rekwiżiti ulterjuri biex jitnaqqsu l-NOx u emissjonijiet oħra tal-impjanti tal-enerġija rriżultaw fil-kontaminazzjoni tal-irmied li jtir bl-ammonja. B'konsegwenza ta' dan, il-mara x, while understanding the benefits of using fly ash in concrete continues to increase, id-disponibbiltà ta' rmied xieraq li jtir ta' kwalità qed jonqos. Il-proċessi għall-benefiċċju ekonomiku tal-irmied li jtir barra mill-kwalità huma għalhekk ukoll ta' interess dejjem akbar għall-industriji tal-enerġija u tal-konkrit. STET has pioneered such processes for both carbon and ammonia removal from fly ash.

TEKNOLOĠIJA ĦARSA ĠENERALI – IS-SEPARAZZJONI TAL-KARBONJU TAL-IRMIED LI JTIR

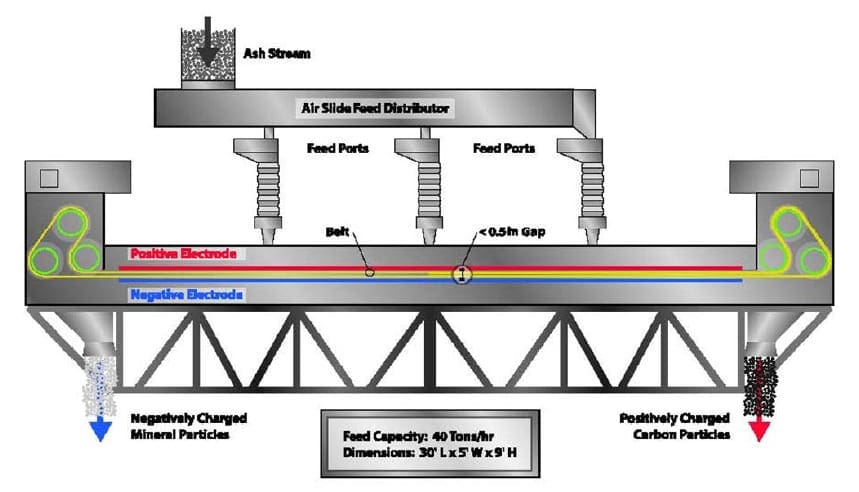

Fis-separatur tal-karbonju STET (Il-figura 1), the material is fed into the thin gap between two parallel planar electrodes. The particles are triboelectrically charged by interparticle

contact. The positively charged carbon and the negatively charged mineral (in freshly generated ash that has not been wetted and dried) huma attirati lejn elettrodi opposti. Il-partiċelli mbagħad jiġu mimsuħa minn ċinturin kontinwu li jiċċaqlaq u jitwasslu f'direzzjonijiet opposti. Iċ-ċintorin imexxi l-partiċelli maġenb kull elettrodu lejn truf opposti tas-separatur. Il-veloċità taċ-ċintorin għolja wkoll jippermetti produzzjoni għolja ħafna, sa 36 tunnellati fis-siegħa fuq separatur wieħed. Id-distakk żgħir, qasam ta 'vultaġġ għoli, countercurrent flow, aġitazzjoni vigoruża tal-partiċelli ta' partikuli u azzjoni ta' awto-tindif taċ-ċinturin fuq l-elettrodi huma l-karatteristiċi kritiċi tas-separatur STET. Billi jikkontrollaw parametri varji ta ' proċess, bħalma huma l-veloċità taċ-ċintorin, the feed point, u r-rata tal-għalf, il-proċess STET jipproduċi rmied li jtir LOI baxx f'kontenut ta' karbonju ta' inqas minn 1.5 biex 4.5% minn irmied li jtir fl-għalf li jvarja f'LOI minn 4% għal aktar 25%.

Fig. 1 STET Separator

Id-disinn tas-separatur huwa relattivament sempliċi u kompatt. Magna disinjata biex tipproċessa 36 tunnellati fis-siegħa hija bejn wieħed u ieħor 9 m (30 FT.) twil, 1.5 m (5 FT.) Wiesgħa, u l- 2.75 m (9 FT.) għoli. Il-belt u rombli assoċjati huma l-partijiet li jiċċaqalqu biss. L-elettrodi huma wieqfa u magħmula minn xi materjal dejjiemi kif jixraq. The belt is made of nonconductive plastic. The separator’s power consumption is about 1 kilowatt-sieg ħa għal kull tunnellata ta ' materjal ipproċessat bil-bi ċċa l-kbira tal-ener ġija kkunsmata minn żewġ muturi li jsuqu ċ-ċintorin.

Il-pro Ċess huwa kompletament niexef, requires no additional materials other than the fly ash and produces no wastewater or air emissions. Il-materjali rkuprati jikkonsistu f'irmied li jtir imnaqqas fil-kontenut tal-karbonju għal livelli adattati għall-użu bħala taħlita pozzolanika fil-konkrit, u frazzjoni għolja ta' karbonju utli bħala fjuwil. Użu ta ' żewġ nixxigħat prodott jipprovdi a 100% soluzzjoni għall-problemi ta ' rimi ta ' rmied.

RECOVERED FUEL VALUE OF HIGH-CARBON FLY ASH

In addition to the low carbon product for use in concrete, brand named ProAsh®, il-proċess ta' separazzjoni tal-STET jirkupra wkoll karbonju mhux maħruq mod ieħor fil-forma ta' rmied li jtir b'kontenut ta' karbonju, EkoTherm tad-ditta™. Eotherm™ għandu valur sinifikanti tal-fjuwil u jista 'jiġi rritornat faċilment fl-impjant tal-enerġija elettrika billi juża l-STET EcoTherm™ Return system to reduce the coal use at the plant. Meta EkoTherm™ jinħaraq fil-bojler tal-utilità, the energy from combustion is converted to high pressure /high-temperature steam and then to electricity at the same efficiency as coal, Tipikament 35%. The conversion of the recovered thermal energy to electricity in ST Equipment & Technology LLC EcoTherm™ Is-sistema tar-ritorn hija darbtejn sa tliet darbiet ogħla minn dik tat-teknoloġija kompetittiva fejn l-enerġija tiġi rkuprata bħala sħana ta' grad baxx fil-forma ta' ilma sħun li jiġi ċċirkolat lis-sistema tal-ilma tal-għalf tal-bojler. Eotherm™ is also used as a source of silica and alumina in cement kilns, displacing the more expensive raw materials, such as shale or bauxite, which are used in cement production. Użu tal-EkoTherm b'karbonju għoli™ irmied jew f'impjant tal-enerġija jew f'forn tas-siment, timmassimizza l-irkupru tal-enerġija mill-faħam ikkunsinnat, it-tnaqqis tal-ħtieġa li l-minjieri u t-trasport ta' fjuwil addizzjonali għall-faċilitajiet.

STET’s Talen Energy Brandon Shores, SMEPA R.D. Morrow, NBP Belledune, RWEnpower Didcot, EDF Energy West Burton, and RWEnpower Aberthaw fly ash plants, kollha jinkludu EcoTherm™ Sistemi ta' ritorn. Il-komponenti essenzjali tas-sistema huma ppreżentati fil-Figura 2.

Fig. 2 Eotherm™ Sistema ta' ritorn

FAĊILITAJIET GĦALL-IPPROĊESSAR TA' RMIED STET

Controlled low LOI fly ash is produced with STET’s technology at twelve power stations throughout the U.S., Kanada, ir-Renju Unit, Il-Polonja, u r-Repubblika tal-Korea. ProAsh® fly ash

has been approved for use by over twenty state highway authorities, l-aġenziji speċifikazzjoni oħra kif ukoll kemm. ProAsh® has also been certified under the Canadian Standards Association and EN 450:2005 standards ta ' kwalità fl-Ewropa. Faċilitajiet ta ' ipproċessar irmied bl-użu ta ' teknoloġija ta ' l-STET huma elenkati fit-tabella 1.

Tabella 1. Operazzjonijiet Kummerċjali STET

| L-utilità / Power Station | Il-post | Bidu ta ' l- Kummerċjali l-operazzjonijiet | Id-dettalji tal-faċilità |

|---|---|---|---|

| Duke Energy – Roxboro Station | Carolina tat-tramuntana USA | Sept. 1997 | 2 Separaturi |

| Enerġija Talen - Brandon Shores Station | Maryland USA | April 1999 | 2 Separaturi 35,000 koppla għall-ħżin tat-ton. Ecotherm™ Return 2008 |

| ScotAsh (Lafarge / Scottish Power Joint Venture) - Stazzjon longannet | Iskozja Renju unit | Ptlhb. 2002 | 1 Separatur |

| Awtorità Elettrika ta 'Jacksonville - San. Park tal-Qawwa tax-Xmara ta 'John, FL | Florida USA | jista ' 2003 | 2 Separaturi Coal/Petcoke blends Ammonia Removal |

| South Mississippi Electric Power Authority R.D. Morrow Station | Mississippi USA | Jan. 2005 | 1 Separatur Ecotherm™ Return |

| New Brunswick Power Company Belledune Station | New Brunswick, Kanada | April 2005 | 1 Separatur Coal/Petcoke Blends Ecotherm™ Return |

| RWE npower Didcot Station | Ingilterra Renju unit | awissu 2005 | 1 Separatur Ecotherm™ Return |

| Talen Energy Brunner Island Station | Pennsylvania USA | Diċembru 2006 | 2 Separaturi 40,000 Koppla tal-ħażna tat-ton |

| Ko Elettriku Tampa. Stazzjon tal-Liwja Kbira | Florida USA | April 2008 | 3 Separaturi, pass doppju 25,000 Koppla tal-ħażna tat-ton Ammonia Removal |

| RWE npower Aberthaw Station (Lafarge Cement UK) | Wales Renju unit | September 2008 | 1 Separatur Ammonia Removal Ecotherm™ Return |

| EDF Energy West Burton Station (Lafarge Siment Renju Unit, Cemex) | Ingilterra Renju unit | Ottubru 2008 | 1 Separatur Ecotherm™ Return |

| ZGP (Lafarge Siment Polonja / Ciech Janikosoda JV) | Il-Polonja | Marzu 2010 | 1 Separatur |

| Korea South-East Power Yeongheung Units 5&6 | Korea t'Isfel | September 2014 | 1 Separatur Ecotherm™ Return |

| Lafarge Siment Polonja Warsaw | Il-Polonja | 2016 | 1 Separatur |

CONCLUSIONS

Il-massimizzazzjoni tal-użu tal-irmied li jtir bħala sostitut tas-siment fil-produzzjoni tal-konkrit tnaqqas b'mod sostanzjali l-emissjonijiet tad-diossidu tal-karbonju assoċjati mal-attività tal-kostruzzjoni. Madankollu, pollution control systems implemented by the coal-fired power stations have resulted in a reduction of available fly ash meeting concrete-grade specifications. Further degradation of fly ash quality is expected due to further reductions in allowable gas emissions. In order to avoid loss of this valuable resource of material for concrete production as well as reduction of greenhouse gas emissions associated with concrete construction, huma meħtieġa proċessi għar-restawr tal-kwalità tal-irmied li jtir b'mod ekonomiku u ambjentalment vijabbli.

The beneficiation of fly ash with STET processes further increases the supply of this important material. The STET beneficiation processes continue to be the most extensively applied methods to upgrade otherwise unusable fly ash to high-value materials for cement replacement in concrete. Eighteen SETT carbon separators are currently in place with over 100 snin ta 'tħaddim ta' snin ta 'tħaddim.

ProAsh® has found wide acceptance in the concrete industry as a premium fly ash requiring far less monitoring of air entrainment requirements due to less LOI variability than other ashes. Returning the high-carbon concentrate from the STET process to the boiler at a power plant allows recovery of the recovered carbon fuel value at an efficiency similar to coal. STET offers economical means to recover ash for high-value use that would otherwise be landfilled. Electrostatic carbon separation and Ecotherm™ return to the boiler provide a modular solution to a utility’s fly ash needs. These processes can be implemented in phases, or as a single project.

REFERENZI

[1] American Coal Ash Coal Combustion products and Use Statistics:

https://www.acaa-usa.org/Publications/Production-Use-Reports/