Izberite jezik:

STET Triboelectrostatic separation has been used for the commercial beneficiation of coal combustion fly ash to produce a low carbon product for use as a cement replacement in concrete for nearly 20 years….

Download PDFF. Hrach, S. Gasiorowski, H.Guicherd

ST opreme & Tehnologije LLC (STET), 101 Hampton Avenue, Needham MA 02494 ZDA

CONFERENCE: Vietbuild Ho Chi Minh City-junij 2015

KLJUČNE BESEDE: Triboelectrostatic, Bogatenje, Dry Fly Ash, Carbon Separation ABSTRACT

STET Triboelectrostatic separation has been used for the commercial beneficiation of coal combustion fly ash to produce a low carbon product for use as a cement replacement in concrete for nearly twenty years. With 18 separators in 12 coal-fired power plants across the world, ST opreme & Tehnologija LLC (STET) patented electrostatic separator has been used to produce over 15 Million tonnes of low carbon product.

To date, commercial beneficiation of fly ash has been performed exclusively on dry “run of station” ash. STET’s electrostatic beneficiation technology reduces the carbon content of coal fly ash, producing consistent, low carbon ash for use as a substitute for cement. Fly ash with carbon levels up to 25% have been used to produce ash with a controlled carbon level of 2 ± 0.5%. A carbon-rich product is simultaneously produced to recover the fuel value of the carbon.

Uvod

Združenje ameriških premoga pepela (ACAA) letni pregled proizvodnje in uporabe premoga pepel poroča, da med 1966 in 2011, nad 2.3 billion short tons of fly ash have been produced by coal-fired utility boilers.1 Of this amount, Približno 625 milijonov ton so bili koristno uporabljeni, predvsem za proizvodnjo cementa in betona. Vendar, preostalih 1.7+ milijard ton najdemo predvsem na odlagališčih ali napolnjena ribniki zasega. While utilization rates for freshly generated fly ash have increased considerably over recent years, s trenutnimi stopnjami blizu 45%, Približno 40 million tons of fly ash continues to be disposed of annually. While utilization rates in Europe have been much higher than in the US, v nekaterih evropskih državah so bile shranjene tudi velike količine pepela muhe.. An excessive amount of unburned carbon in fly ash is the most common problem. The American Association of State Highway and Transportation Officials (AASHTO) and European Standards (EN 450 Category A) require that the amount of unburned carbon in fly ash, measured by loss on ignition (LOI) not exceed 5% by weight. Vendar, starting in the mid-1990s, installation of mandated NOx control equipment at coal-fired power plants increased the carbon (LOI) content of much of the previously marketable fly ash. Further requirements to reduce NOx and other power plant emissions have resulted in the contamination of fly ash with ammonia. As a consequence, while understanding the benefits of using fly ash in concrete continues to increase, the availability of suitable quality fly ash is decreasing. Processes to economically beneficiate off-quality fly ash are thus also of increasing interest to the power and concrete industries. STET has pioneered such processes for both carbon and ammonia removal from fly ash.

TECHNOLOGY OVERVIEW – FLY ASH CARBON SEPARATION

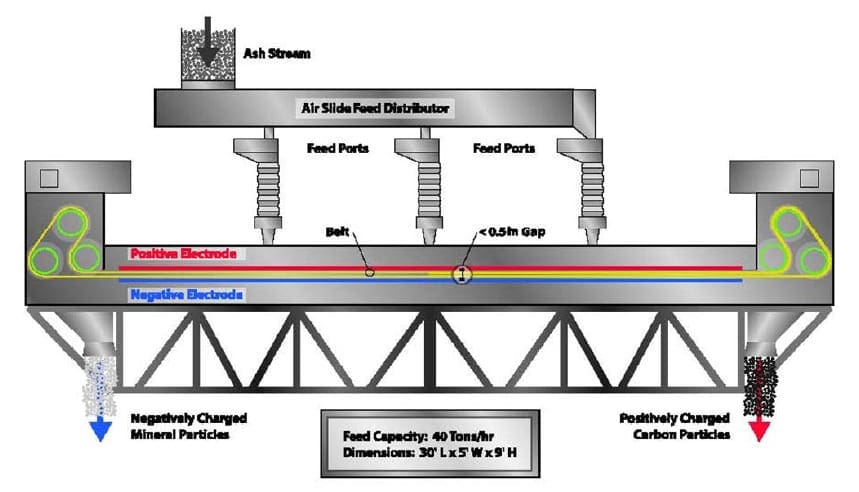

V separatorju ogljika STET (Slika 1), the material is fed into the thin gap between two parallel planar electrodes. The particles are triboelectrically charged by interparticle

Stik. Pozitivno nabiti ogljik in negativno nabiti mineralni (v sveže generiziranem pepelu, ki ni bil navlajen in sušen) privlačijo nasprotni elektrode. Delci se nato pometejo z neprekinjenim gibljivim trakom in se prenašajo v nasprotnih smereh.. Pas premakne delce, ki mejijo na vsako elektrodo proti nasprotni konci ločila. Visoka hitrost pasu omogoča tudi zelo visoke prepustne, do 36 ton na uro na enem ločevalniku. Majhna vrzel, high voltage field, countercurrent flow, vigorous particle-particle agitation and self-cleaning action of the belt on the electrodes are the critical features of the STET separator. Z nadzorovanjem različnih procesnih parametrov, kot je hitrost pasu, the feed point, in hitrost krme, proces STET proizvaja nizek pepel muhe LOI pri vsebnosti ogljika, ki je manjši od 1.5 za 4.5% iz pepela krme muha v loi od 4% do več kot 25%.

Slika. 1 STET Separator

Ločilo design je relativno preprosta in kompaktna. Stroj, zasnovan za obdelavo 36 tone na uro je približno 9 m (30 Ft.) dolgo, 1.5 m (5 Ft.) Širok, in 2.75 m (9 Ft.) Visoko. Pas in pripadajoči valji so edini gibajoči se deli. Elektrode so stacionarne in sestavljene iz ustrezno trajnega materiala. Pas je izdelan iz neprevodnih plastičnih. Poraba energije separatorja je približno 1 kilovatno uro na tono materiala, predelanega z večino moči, porabljene z dvema motoroma, ki vozita pas.

Postopek je popolnoma suh, requires no additional materials other than the fly ash and produces no wastewater or air emissions. Predelani materiali so sestavljeni iz muhi pepela, zmanjšanega vsebnosti ogljika na ravni, primerne za uporabo kot pozzolanska priseska v betonu, and a high carbon fraction useful as fuel. Uporaba obeh tokov izdelkov zagotavlja 100% rešitev za težave pri odstranjevanju pepela.

PREDELANA VREDNOST GORIVA VISOKOOKLJČNEGA PEPELA

In addition to the low carbon product for use in concrete, brand named ProAsh®, the STET separation process also recovers otherwise wasted unburned carbon in the form of carbon-rich fly ash, blagovno znamko EcoTherm™. EcoTherm™ has significant fuel value and can easily be returned to the electric power plant using the STET EcoTherm™ Return system to reduce the coal use at the plant. When EcoTherm™ is burned in the utility boiler, the energy from combustion is converted to high pressure /high-temperature steam and then to electricity at the same efficiency as coal, Običajno 35%. The conversion of the recovered thermal energy to electricity in ST Equipment & Technology LLC EcoTherm™ Return system is two to three times higher than that of the competitive technology where the energy is recovered as low-grade heat in the form of hot water which is circulated to the boiler feed water system. EcoTherm™ is also used as a source of silica and alumina in cement kilns, displacing the more expensive raw materials, such as shale or bauxite, which are used in cement production. Utilizing the high carbon EcoTherm™ ash either at a power plant or a cement kiln, maximizes the energy recovery from the delivered coal, zmanjšanje potrebe po minah in prevozu dodatnega goriva v objekte in naprave, ki.

STET's Talen Energy Brandon Shores, msppa r.d. Morrow, NBP Belledune, RWEnpower Didcot, EDF Energija West Burton, and RWEnpower Aberthaw fly ash plants, all include EcoTherm™ Return systems. The essential components of the system are presented in Figure 2.

Slika. 2 EcoTherm™ Return system

OBRATI ZA PREDELAVO PEPELA STET

Controlled low LOI fly ash is produced with STET’s technology at twelve power stations throughout the U.S., Kanada, the U.K., Poljska, in Republiko Korejo. ProAsh® fly ash

has been approved for use by over twenty state highway authorities, kot tudi številne druge specifikacijske agencije. ProAsh® je bil certificiran tudi v okviru Kanadskega združenja za standarde in EN 450:2005 standardov kakovosti v Evropi. Obrati za predelavo pepela, ki uporabljajo tehnologijo STET, so navedeni v tabeli 1.

Tabela 1. STET Commercial Operations

| Korist / Power Station | Lokacijo | Začetek Commercial Operacije | Facility Details |

|---|---|---|---|

| Duke Energy – Roxboro Station | Severna Karolina ZDA | September. 1997 | 2 Ločila |

| Talen energija - Brandon Shores Station | Maryland ZDA | Aprila 1999 | 2 Ločila 35,000 tona kupola za shranjevanje. Ecotherm™ Return 2008 |

| Škotska (Lafarge / Scottish Power Joint Venture) - Postaja longannet | Škotskem Uk | ČDO. 2002 | 1 Ločilo |

| Jacksonville Electric Authority - St. John's River Power Park, Fl | Florida ZDA | Maja 2003 | 2 Ločila Coal/Petcoke blends Ammonia Removal |

| South Mississippi Electric Power Authority R.D. Morrow Station | Mississippi ZDA | Jan. 2005 | 1 Ločilo Ecotherm™ Return |

| New Brunswick Power Company Belledune Station | New Brunswick, Kanada | Aprila 2005 | 1 Ločilo Coal/Petcoke Blends Ecotherm™ Return |

| RWE npower Didcot Station | Angliji Uk | Avgust 2005 | 1 Ločilo Ecotherm™ Return |

| Talen Energy Brunner Island Station | Pennsylvania ZDA | Decembra 2006 | 2 Ločila 40,000 Ton storage dome |

| Tampa električni co. postaja Big Bend | Florida ZDA | Aprila 2008 | 3 Ločila, dvojna podaja 25,000 Ton storage dome Ammonia Removal |

| RWE npower Aberthaw Station (Lafarge Cement UK) | Wales Uk | Septembra 2008 | 1 Ločilo Ammonia Removal Ecotherm™ Return |

| EDF Energija West Burton Station (Lafarge Cement Velika Britanija, Cemex (višek)) | Angliji Uk | Oktobra 2008 | 1 Ločilo Ecotherm™ Return |

| ZGP (Lafarge Cement Poljska / Ciech Janikosoda JV) | Poljska | Marca 2010 | 1 Ločilo |

| Korea South-East Power Yeongheung Units 5&6 | Južna Koreja | Septembra 2014 | 1 Ločilo Ecotherm™ Return |

| Lafarge Cement Poljska Warsaw | Poljska | 2016 | 1 Ločilo |

Sklepi

Maximizing the utilization of fly ash as a cement substitute in concrete production substantially reduces the carbon dioxide emissions associated with construction activity. Vendar, pollution control systems implemented by the coal-fired power stations have resulted in a reduction of available fly ash meeting concrete-grade specifications. Further degradation of fly ash quality is expected due to further reductions in allowable gas emissions. In order to avoid loss of this valuable resource of material for concrete production as well as reduction of greenhouse gas emissions associated with concrete construction, processes for restoring the quality of the fly ash in an economic and environmentally viable way are needed.

The beneficiation of fly ash with STET processes further increases the supply of this important material. The STET beneficiation processes continue to be the most extensively applied methods to upgrade otherwise unusable fly ash to high-value materials for cement replacement in concrete. Eighteen SETT carbon separators are currently in place with over 100 machine-years of operation.

ProAsh® has found wide acceptance in the concrete industry as a premium fly ash requiring far less monitoring of air entrainment requirements due to less LOI variability than other ashes. Returning the high-carbon concentrate from the STET process to the boiler at a power plant allows recovery of the recovered carbon fuel value at an efficiency similar to coal. STET offers economical means to recover ash for high-value use that would otherwise be landfilled. Electrostatic carbon separation and Ecotherm™ return to the boiler provide a modular solution to a utility’s fly ash needs. These processes can be implemented in phases, or as a single project.

Sklicevanja

[1] American Coal Ash Coal Combustion products and Use Statistics:

https://www.acaa-usa.org/Publications/Production-Use-Reports/