L. Baker, A. Gupta, and S. Gasiorowski

ST Equipment & Technologies LLC, 101 Hampton Avenue, Needham MA 02494 USA

CONFERENCE: 2015 World of Coal Ash – (www.worldofcoalash.org)

KEYWORDS: Triboelectrostatic, Beneficiation, Fly Ash, Landfilled, Dried, Separation, Carbon

ABSTRACT

Triboelectrostatic separation has been used for the commercial beneficiation of coal combustion fly ash to produce a low carbon product for use as a cement replacement in concrete for nearly twenty years. With 18 separators in 12 coal-fired power plants across the world, ST Equipment & Technology LLC’s (STET) patented electrostatic separator has been used to produce over 15 Million tonnes of low carbon product.

To date, commercial beneficiation of fly ash has been performed exclusively on dry “run of station‿ ash. Recent environmental legislation has created, in certain markets, a need to supply beneficiated ash in times of low ash generation. This, coupled with a requirement in some locations to empty historical ash landfill sites, has created the need to develop a process to beneficiate historically landfilled ash.

Previous studies have shown that the exposure of fly ash to moisture, and subsequent drying influences the triboelectrostatic charging mechanism, with carbon and mineral particles charging in the opposite polarity to that experienced with run of station ash. Studies have been performed by the authors to determine the effect of moisture exposure on separation efficiency of several ashes that have been reclaimed from landfills and dried. Charge reversal was experienced following drying, but overall separation efficiency was achieved equivalent to that experienced with fresh run of station ash.

The effect of dried ash feed relative humidity on triboelectrostatic separation efficiency was examined, and sensitivity was greatly reduced compared to that experienced with run of station ash, lowering overall process costs.

INTRODUCTION

The American Coal Ash Association (ACAA) annual survey of production and use of coal fly ash reports that between 1966 and 2011, over 2.3 billion short tons of fly ash have been produced by coal-fired utility boilers.1 Of this amount approximately 625 million tons have been beneficially used, mostly for cement and concrete production. However, the remaining 1.7+ billion tons are primarily found in landfills or filled ponded

impoundments. While utilization rates for freshly generated fly ash have increased considerably over recent years, with current rates near 45%, approximately 40 million tons of fly ash continue to be disposed of annually. While utilization rates in Europe have been much higher than in the US, considerable volumes of fly ash have also been stored in landfills and impoundments in some European countries.

Recently, interest in recovering this disposed material has increased, partially due to the demand for high-quality fly ash for concrete and cement production during a period of reduced production as coal-fired power generation has decreased in Europe and North America. Concerns about the long-term environmental impact of such landfills are also prompting utilities to find beneficial use applications for this stored ash.

LAND FILLED ASH QUALITY AND REQUIRED BENEFICIATION

While some of this stored fly ash may be suitable for beneficial use as initially excavated, the vast majority will require some processing to meet quality standards for cement or concrete production. Since the material has been typically wetted to enable handling and compaction while avoiding airborne dust generation, drying will probably be a minimal requirement for use in concrete since concrete producers will want to continue the practice of batching fly ash as a dry powder. However, assuring the chemical composition of the ash meets specifications, most notably the carbon content measured as loss-on-ignition (LOI), is a greater challenge. As fly ash utilization has increased in the last 20+ years, most “in-spec‿ ash has been beneficially used, and the off-quality ash disposed. Thus, LOI reduction will be a requirement for utilizing the vast majority of fly ash recoverable from utility impoundments.

LOI REDUCTION BY TRIBOELECTRIC SEPARATION

While various workers have used combustion techniques and flotation processes for LOI reduction of recovered landfilled and ponded fly ash, ST Equipment & Technologies (STET) has found that its standard processing system, long used for beneficiation of freshly generated fly ash, is equally effective on recovered ash after suitable drying and deagglomeration at lower overall operating costs.

During the ramp-up to commercial application of the STET processing system for fly ash, STET researchers tested the separation of dried landfilled ash. This recovered ash separated very similarly to freshly generated ash with one surprising difference: the particle charging was reversed from that of fresh ash with the carbon charging negative in relation to the mineral.2 Other researchers of electrostatic separation of fly ash carbon have also observed this phenomena.3,4,5

TECHNOLOGY OVERVIEW – FLY ASH CARBON SEPARATION

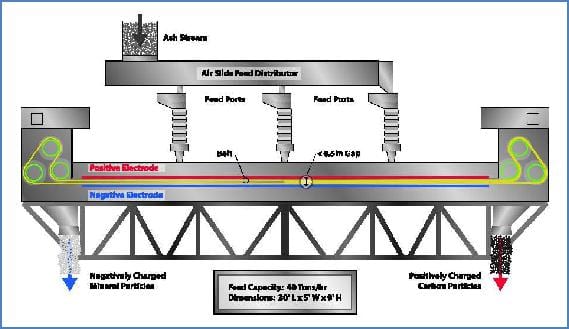

In the STET carbon separator (Figure 1), material is fed into the thin gap between two parallel planar electrodes. The particles are triboelectrically charged by interparticle contact. The positively charged carbon and the negatively charged mineral (in freshly generated ash that has not been wetted and dried) are attracted to opposite electrodes. The particles are then swept up by a continuous moving belt and conveyed in opposite directions. The belt moves the particles adjacent to each electrode toward opposite ends of the separator. The high belt speed also enables very high throughputs, up to 36 tonnes per hour on a single separator. The small gap, high voltage field, counter current flow, vigorous particle-particle agitation and self-cleaning action of the belt on the electrodes are the critical features of the STET separator. By controlling various process parameters, such as belt speed, feed point, and feed rate, the STET process produces low LOI fly ash at carbon contents of less than 1.5 to 4.5% from feed fly ashes ranging in LOI from 4% to over 25%.

Fig. 1 STET Separator

The separator design is relatively simple and compact. A machine designed to process 36 tonnes per hour is approximately 9 m (30 ft.) long, 1.5 m (5 ft.) wide, and 2.75 m (9 ft.) high. The belt and associated rollers are the only moving parts. The electrodes are stationary and composed of an appropriately durable material. The belt is made of non- conductive plastic. The separator’s power consumption is about 1 kilowatt-hour per tonne of material processed with most of the power consumed by two motors driving the belt.

The process is entirely dry, requires no additional materials other than the fly ash and produces no waste water or air emissions. The recovered materials consist of fly ash reduced in carbon content to levels suitable for use as a pozzolanic admixture in

concrete, and a high carbon fraction useful as fuel. Utilization of both product streams provides a 100% solution to fly ash disposal problems.

RECOVERED FUEL VALUE OF HIGH-CARBON FLY ASH

In addition to the low carbon product for use in concrete, brand named ProAsh®, the STET separation process also recovers otherwise wasted unburned carbon in the form of carbon-rich fly ash, branded EcoTherm™. EcoTherm™ has significant fuel value and can easily be returned to the electric power plant using the STET EcoTherm™ Return system to reduce the coal use at the plant. When EcoTherm™ is burned in the utility boiler, the energy from combustion is converted to high pressure / high temperature steam and then to electricity at the same efficiency as coal, typically 35%. The conversion of the recovered thermal energy to electricity in ST Equipment & Technology LLC EcoTherm™ Return system is two to three times higher than that of the competitive technology where the energy is recovered as low-grade heat in the form of hot water which is circulated to the boiler feed water system. EcoTherm™ is also used as a source of alumina in cement kilns, displacing the more expensive bauxite which is usually transported long distances. Utilizing the high carbon EcoTherm™ ash either at a power plant or a cement kiln, maximizes the energy recovery from the delivered coal, reducing the need to mine and transport additional fuel to the facilities.

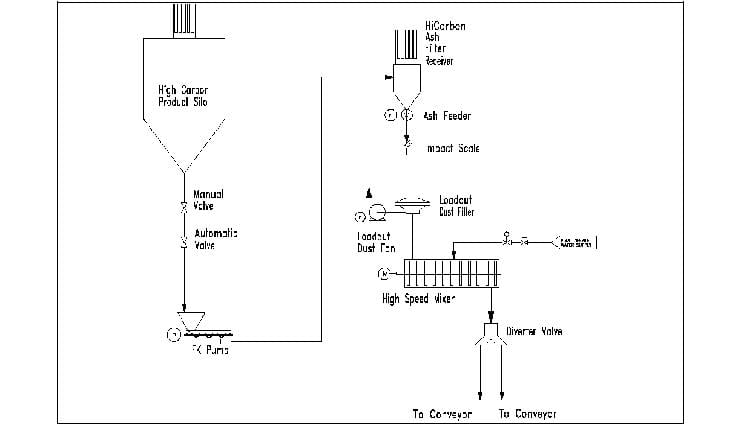

STET’s Raven Power Brandon Shores, SMEPA R.D. Morrow, NBP Belledune, RWEnpower Didcot, EDF Energy West Burton, and RWEnpower Aberthaw fly ash plants, all include EcoTherm™ Return systems. The essential components of the system are presented in Figure 2.

Fig. 2 EcoTherm™ Return system

STET ASH PROCESING FACILITIES

Controlled low LOI fly ash is produced with STET’s technology at twelve power stations throughout the U.S., Canada, the U.K., Poland, and Republic of Korea. ProAsh® fly ash has been approved for use by over twenty state highway authorities, as well as many other specification agencies. ProAsh® has also been certified under Canadian Standards Association and EN 450:2005 quality standards in Europe. Ash processing facilities using STET technology are listed in Table 1.

Table 1. STET Commercial Operations

|

Utility / Power Station |

Location |

Start of Commercial operations |

Facility Details |

|

Progress Energy – Roxboro Station |

North Carolina USA |

Sept. 1997 |

2 Separators |

|

Raven Power – Brandon Shores Station |

Maryland USA |

April 1999 |

2 Separators 35,000 ton storage dome. Ecotherm™ Return 2008 |

|

ScotAsh (Lafarge / Scottish Power Joint Venture) – Longannet Station |

Scotland UK |

Oct. 2002 |

1 Separator |

|

Jacksonville Electric Authority – St. John’s River Power Park,FL |

Florida USA |

May 2003 |

2 Separators Coal/Petcoke blends Ammonia Removal |

|

South Mississippi Electric Power Authority R.D. Morrow Station |

Mississippi USA |

Jan. 2005 |

1 Separator Ecotherm™ Return |

|

New Brunswick Power Company Belledune Station |

New Brunswick, Canada |

April 2005 |

1 Separator Coal/Petcoke Blends Ecotherm™ Return |

|

RWE npower Didcot Station |

England UK |

August 2005 |

1 Separator Ecotherm™ Return |

|

PPL Brunner Island Station |

Pennsylvania USA |

December 2006 |

2 Separators 40,000 Ton storage dome |

|

Tampa Electric Co. Big Bend Station |

Florida USA |

April 2008 |

3 Separators, double pass 25,000 Ton storage dome Ammonia Removal |

|

RWE npower Aberthaw Station (Lafarge Cement UK) |

Wales UK |

September 2008 |

1 Separator Ammonia Removal Ecotherm™ Return |

|

EDF Energy West Burton Station (Lafarge Cement UK, Cemex) |

England UK |

October 2008 |

1 Separator Ecotherm™ Return |

|

ZGP (Lafarge Cement Poland / Ciech Janikosoda JV) |

Poland |

March 2010 |

1 Separator |

|

Korea South-East Power Yeongheung Units 5&6 |

South Korea |

September 2014 |

1 Separator Ecotherm™ Return |

COAL ASH RECOVERED FROM LAND FILLS

Two sources of ash were obtained from landfills: sample A from a power plant located in

the United Kingdom and sample B: from the United States. Both these samples consisted of ash from the combustion of bituminous coal by large utility boilers. Due to the intermingling of material in the landfills, no further information is available concerning specific coal source or combustion conditions.

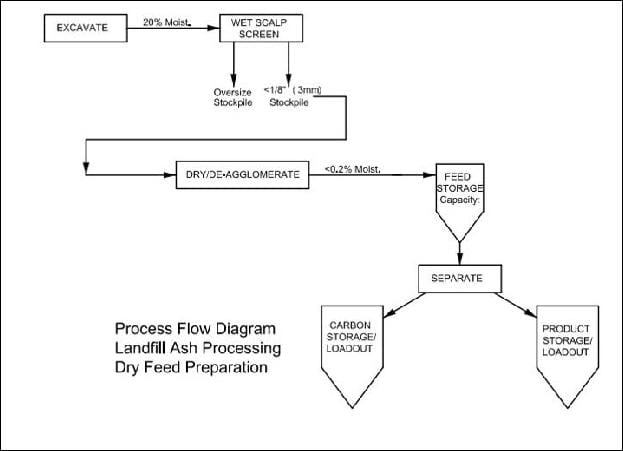

The samples as received by STET contained between 15% and 20% water as is typical for landfilled material. The samples also contained varying amounts of large >1/8 inch (~3 mm) material. To prepare the samples for carbon separation, the large debris was removed by screening and the samples then dried and deagglomerated prior to carbon beneficiation. Various methods for drying/deagglomeration are being evaluated in order to optimize the overall process. A general process flow sheet is presented in Figure 3.

Figure 3: Process flow sheet

The properties of the prepared samples were well within the range of fly ash obtained directly from normal utility boilers. The most relevant properties for both the separator feeds and products are summarized in Table 2 along with recovered product.

CARBON SEPARATION

Carbon reduction trials using the STET triboelectric belt separator resulted in very good recovery of low LOI product. The interesting phenomena observed was the reversal of charging of the carbon discussed above. While this behavior has been observed previously by STET and other researchers, the mechanism that changes the relative work functions and thus contact charging behavior of the material is not understood. One suggested mechanism is the redistribution of soluble ions on the mineral and

carbon particles, possibly further influenced by the pH of the aqueous solution on the ash4. Whatever the fundamental mechanism is, it does not appear to degrade the practical application of triboelectric separation to reduce the carbon content of the ash.

The properties of the low LOI fly ash recovered using the STET process for both freshly collected ash from the boiler and ash recovered from the landfill is summarized in Table

2.The results show that the STET process efficiency for the recovered landfill ash is within the range expected for ash freshly collected from the utility boiler.

Table 2: Properties of feed and recovered low-LOI ash.

|

Feed Sample to Separator |

LOI |

ProAsh LOI® |

ProAsh Fineness, %® +45 µm |

ProAsh® Mass Yield |

EcoTherm® High Carbon Product |

|

Fresh A |

10.2 % |

3.6 % |

23 % |

84 % |

39 % |

|

Landfill A |

9.8 % |

3.3 % |

20 % |

75 % |

28 % |

|

Fresh B |

5.3 % |

2.8 % |

17 % |

91 % |

28 % |

|

Landfill B |

6.9 % |

4.5 % |

24 % |

86 % |

26 % |

PROCESS ECONOMICS

In addition to the normal costs of the STET process, the cost of drying the recovered, high moisture content ash will increase the overall operating costs of the process. Table 3 summarizes the fuel costs for both operations in the USA and UK for 15% and 20% moisture contents. Typical inefficiencies of drying are included in the calculated values. Costs are based on the mass of material after drying.

Table 3: Drying costs on basis of dried mass.

| Moisture content | Heat Requirement KWhr/t | Drying cost / T dry basis UK | Drying cost / T dry basis US |

|---|---|---|---|

| Gas cost 0.027 £/kWhr | Gas cost $4.75 / mmBtu | ||

| 15 % | 165 | £ 5.24 | £ 1.94 |

| £ 8.48 | £ 3.14 | ||

| £ 6.73 | £ 2.49 | ||

| 20 % | 217 | £ 7.23 | £ 2.71 |

| £ 11.85 | £ 4.39 | ||

| £ 9.40 | £ 3.48 |

ASH CHEMISTRY AND PERFORMANCE IN CONCRETE

The properties of the low carbon ash generated from the dried landfill material were compared to that of freshly obtained ash to check the suitability for use in concrete production. The

following table summarizes the chemistry for samples from source B. Testing on source A material has not been completed.

Table 4: Ash Chemistry of low LOI ash.

|

Source B material |

SiO2 |

Al2O3 |

Fe2O3 |

CaO |

MgO |

K2O |

Na2O |

SO3 |

|

Fresh Production |

51.60 |

24.70 |

9.9 |

2.22 |

0.85 |

2.19 |

0.28 |

0.09 |

|

Landfilled |

50.40 |

25.00 |

9.3 |

3.04 |

0.85 |

2.41 |

0.21 |

0.11 |

Strength development of a 20% substitution of the low LOI fly ash in a mortar containing 600 lb / yd3 showed the material derived from landfilled ash performed somewhat better than material from fresh production. See Table 5 below.

Table 5: Compressive strength of mortar cubes.

|

|

7 day Compressive Strength PSI |

28 day Compressive Strength PSI |

|

Fresh |

3948 |

5185 |

|

Landfilled |

4254 |

5855 |

CONCLUSIONS

After suitable scalping of large material, drying, and deagglomeration, fly ash recovered from utility plant landfills can be reduced in carbon content using the commercialized STET triboelectric belt separator. The efficiency of the STET system is essentially equivalent for ashes obtained freshly from boiler operations and dried landfilled material. The separator product is suitable for use in concrete production without further beneficiation with nearly identical performance properties. The recovery and beneficiation of landfilled ash will provide a continuing supply of high quality ash for concrete producers in spite of the reduced production of “fresh‿ ash as coal-fired utilities reduce generation. Additionally, power plants that need to remove ash from landfills to meet changing environmental regulations will be able to utilize the process to alter a waste product liability into a valuable raw material for concrete producers.

REFERENCES

[1]American Coal Ash Coal Combustion products and Use Statistics: https://www.acaa-usa.org/Publications/Production-Use-Reports/

[2]ST internal report, August 1995.

[3]Li,T.X,. Schaefer, J.L., Ban, H., Neathery, J.K., and Stencel, J.M. Dry Beneficiation Processing of Combustion Fly Ash, Proceedings of the DOE Conference on Unburned Carbon on Utility Fly Ash, May 19 20, Pittsburgh, PA, 1998.

[4]Baltrus, J.P., Diehl, J.R., Soong, Y., Sands, W. Triboelectrostatic separation of fly ash and charge reversal, Fuel 81, (2002) pp.757-762.

[5]Cangialosi, F., Notarnicola, M., Liberti, L, Stencel, J. The role of weathering on fly ash charge distribution during triboelectrostatic beneficiation, Journal of Hazardous Materials, 164 (2009) pp.683-688.

Word to PDF Converter Converted By BCLTechnologies