Animal feed quality has a significant impact on both animal health and farm margins. Done right, animal feed processing delivers uniform feed with consistent ingredients, keeping the line moving and cutting rework. The most helpful equipment functions as a coordinated line that operators can run every shift.

Why Flow and Equipment Choice Matter in Animal Feed Processing

Feed plants handle grains, protein meals, and byproducts that behave differently from lot to lot. Variation in grind, moisture, or foreign material can lead to digestive issues and lost output. Successful animal feed processing involves matching equipment and controls so that each step sets up the next. When sizing, mixing, forming, and finishing align, mills hit nutrition targets and avoid rework.

Core Equipment in Modern Animal Feed Processing

An efficient line assigns a clear job to each machine and ties steps together so status is visible while work is happening. Operators correct minor issues early, rather than chasing problems at packout.

Size Reduction: Choppers and Grinders

Choppers and grinders break whole material down to a steady, target size. An even grind helps animals digest feed and keeps later steps from separating. Sharp tools, matched screens, and a constant feed keep results consistent.

Mixing and Conditioning

Once sized, the ingredients are sent to the mixer for an even blend. Conditioning adds just enough heat or moisture for clean forming at the press or extruder. Lot tracking at this point makes any later issues easy to trace and correct.

Pelleting, Extrusion, Cooling

Forming equipment shapes the ratio and sets durability. Pellet mills and extruders can improve handling and raise digestibility when the formula and conditions are right. Coolers and dryers bring the product to storage-ready moisture, allowing it to flow and store safely. Stable forming and finishing reduce fines and returns, which protects line capacity.

Screening and Dust Control

Screens capture off-size products for rework before they reach the bin or bag. Dust control protects workers and limits cross-contamination. Cyclones and baghouses sized to the line help keep motors and instruments clean.

What a Feed Separator Does

A feed separator removes what doesn’t belong and organizes the remaining material so that the next step performs more efficiently. Mechanical screens remove oversized and too-fine particulates that cause bridging or poor flow.

Air classification uses air to separate lighter particles from heavier ones, preventing chaff and dust from diluting the nutrition. Advanced systems sort by what particles are made of, not just their size, to draw off a higher-protein portion or a clean fiber stream.

Dry Electrostatic Separation for Animal Feed

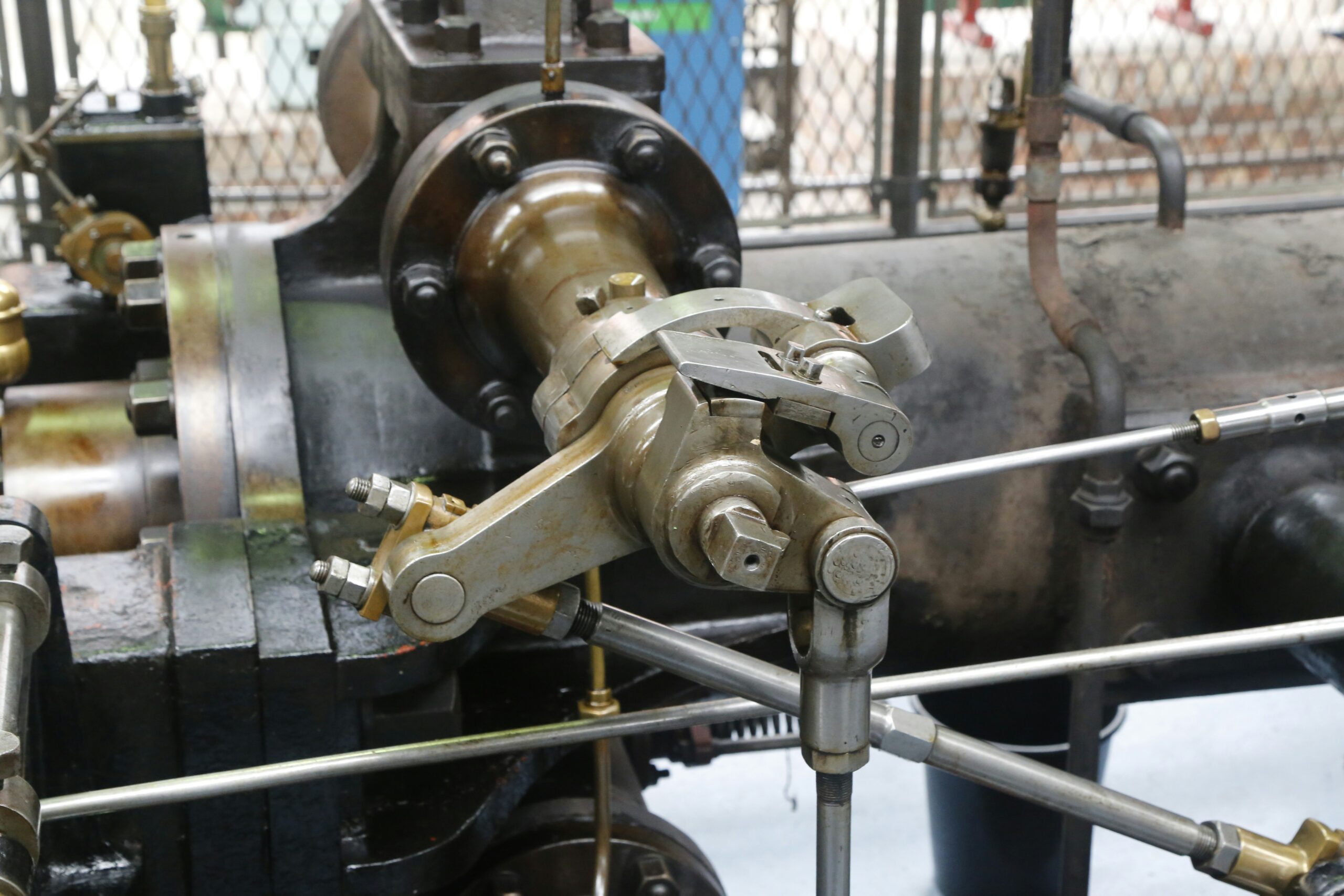

Dry electrostatic separation focuses on how particles charge and move in an electric field. In a triboelectrostatic system, particles come into contact with one another in a controlled zone and acquire opposite charges based on their surface chemistry.

The charged stream then enters an electric field, where it separates into distinct collection paths. The method remains dry and chemical-free, which eliminates the need for water handling and subsequent drying. Because it leverages inherent material properties, it can lift protein content in common feedstocks and concentrate fiber for diets that need it without changing the ingredient source.

Where Separation Creates Value

Separation creates value when it raises nutritional density or consistency without adding process burden. The most common wins involve directing fractions to the diets where they fit best and doing so with a dry method that avoids new bottlenecks.

- Oilseed meals, such as canola or sunflower, can be split so that a higher protein fraction supports monogastric diets, while the fiber-rich stream is better suited for ruminant rations.

- Byproducts, such as distillers’ grains, can be partially upgraded to a premium protein ingredient, while the remaining stream remains compatible with existing bins, conveyors, and packout systems.

- Dry routing eliminates slurry handling, evaporation, and effluent treatment, thereby shortening turnaround times and reducing utilities.

- Consistent fractions simplify formulation and purchasing because nutritionists can target fewer correction steps and smaller safety margins.

Practical Controls That Keep Results

Separation pays off only if crews can run it every shift. Practical controls focus on a few key readings, a stable feed rate, and scheduled fraction checks. Instrumentation should be easy to clean and durable around fines. When the separator’s status is shared on a dashboard with grinders, mixers, and packout, supervisors can see cause and effect in one place and act before the plant loses pace. The step becomes part of the line rather than an island.

Implementation Path That Works

A short, staged path keeps risk low and builds confidence. Each move should confirm material response, fit the floor, and protect uptime.

- Lab evaluation confirms that the feedstock responds to dry separation and sets target fraction specs.

- A slipstream pilot allows operators to feel the controls, check housekeeping, and verify product handling without interrupting the main line.

- Layout mapping protects traffic patterns, ensures dust collection tie-ins, and facilitates maintenance access, allowing daily work to proceed smoothly.

- A tight measure set guides decisions: protein at the bin, fines percentage, press throughput, and any quality checks tied to the finished ration.

- Scale-up training encompasses startup, routine checks, cleanliness, and safe shutdown procedures, ensuring the routine remains consistent through shift changes and planned stops.

Choose Equipment Built for Continuous Work

Systems should be able to tolerate variable feed and restart cleanly after changeovers. Choose a feed separator designed for continuous duty that fits existing equipment, eliminates tricky consumables, and uses parts that your team can easily replace. Pair it with consistent feeders, solid power, and simple guarding to keep production moving.

Talk With ST Equipment & Technology

ST Equipment & Technology supplies dry electrostatic separation to mills that want cleaner, higher-value streams without the need for additional water handling. For animal feed processing, the approach enhances protein where it matters and ensures a consistent product.

If your plant is exploring separation or working to stabilize quality with less waste, the team can evaluate your material, outline a pilot, and plan an integration that respects your current line. Reach out to discuss samples and a schedule that lands results without disrupting production.