Fè chwa lang:

Barite se primè a, natirèlman rive, Baryòm ki gen baz minewo. Baryòm, nimewo atomik 56, ladann li yo, non soti nan moun lòt nasyon yo ak vle di se yon gwo. Barite se tou baryte. Pwensipal peyi yo nan ki depozisyon barite komèsyal ki aktyèlman te jwenn ki nan Etazini, Lachin, Zend ak Mawòk. Dansite anwo nan syèl la ak chimik inertness barite a fè l' yon pafè ineral pou aplikasyon nou dwe anpil.

Fòmil chimik pou barite se BaSO4. Li gen yon anwo nan syèl la gravite de 4.50 g/cm3. Dureté Mohs li se 3.0 pou 3.5. Barite, ki ka jwenn nan yon varyete koulè ki gen jòn, maron, Blan, Ble, Gray, oubyen menm san, sonje bagay gen yon vitreux pou pearly lustre.

Barite ka jwenn ansanm ak tou de ekla metalik ak nonmetallic mineral sou do. En ekonomikman solid pou fè ekstraksyon, barite dabitid bezwen prédominante materyèl nan yon depo. Ki kalite sou do kote li konn pa te jwenn yo gen venn nan janm, rès, ak avec. Venn nan janm ak rès depozisyon ki gen orijin hydrothermal, pandan depozisyon avec yo sédimentaires.

Pi gwo sou do nan Etazini te jwenn nan, Georgie, Missouri, Nevada ak Tennessee. Nan Kanada, ineral a te extrait nan teritwa Yukon, Nova Scotia ak Newfoundland. Nan Meksik, sou do barite te dekouvri nan Hermosillo, Pueblo, Monterrey ak Durango.

Majorite a akablan nan barite a ki se mined yo itilize pa endistri a petwol kom yon materyel weighting nan fomilasyon nan labou perçage. Barite ogmante presyon an idrostatik nan labou a perçage ki pemet li dedomaje pou zon segonde-presyon ki gen eksperyans pandan perçage. Ouse mineral la tou anpeche li soti nan zouti perçage domaje pandan perçage ak pemet li sevi kom yon gres. Ameriken Petwol Enstiti a (API) te etabli espesifikasyon pou itilize nan barite nan labou perçage.

Dry Barite Beneficiation

STET gen tou de echel Pilot ak pwosesis eksperyans komesyal barite yo retire gangue tankou silicates, fè, and alumina. Low-grade barite beneficiation with a specific gravity between 3.5 - 4.0 has been successfully upgraded using the STET process to product API-grade barite.

STET ka demontre ke pwosesis separasyon elektwostatik sek la ofri anpil avantaj sou metod tradisyonel mouye pwosesis (flotan) Enkli:

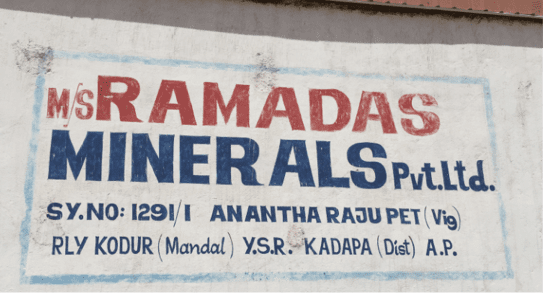

Deranje yon nouvo endistri se toujou yon defi. Sen ekipman & Teknoloji ak Ramadas mineral Pvt. Ltd. nan peyi Zend konprann defi sa a byen. Ramadas mineral kontakte STET pou fe tes nan yon barite klas ki ba / kwats echantiyon ki te pwodwi nan APMDC barite mwen nan Andhra Pradesh, End. Materyel la te yon pwodwi tailings klas ki ba soti nan pwosesis min lan. It contained too much silica to be sellable as a high SG barite product, and was being produced in large volumes. What was needed was a process to transform the mining waste to usable product. Wet processing (flotan) was one alternative technology being considered.

Testing at the STET pilot facility demonstrated excellent separation results for the barite powder. The STET separator was able to achieve the goal of +4.20 SG barite through a single separation step.

The STET separator was fit into the existing building, which was originally designed to house a flotation facility. The STET separator installation resulted in significant savings of space, in relation to the previously designed flotation facility. epi tou, a substantial reduction in capital and operating cost was realized.

Contact STET to learn more about dry processing of barite.