Fè chwa lang:

Kalsyom carbonate (kalke) se mineral ki pi lajman itilize nan papye a, plastik, pentire ak penti endistri tou de kom yon filler-ak akoz koule espesyal blan li yo-kom yon pigman kouch. Nan endistri papye a li vo atrave lemond pou klete segonde li yo ak karakteristik dispesyon limye, epi yo itilize kom yon filler pou fe opaque papye. Filler yo itilize nan mouye-fen papye a fe machin, ak kalsyom carbonate filler pemet pou papye a yo dwe klere ak lis. Kom yon extender, kalsyom carbonate ka reprezante kom anpil tankou 30% pa pwa nan pentire. Kalsyom carbonate tou te itilize lajman kom yon filler nan adezif, e mastik.

Kalsyom carbonate se kritik nan endistri a konstriksyon, toulede kom yon materyel bilding (pa egzanp. Marble), e kom yon materyel ki gen siman. Li kontribye nan fe nan motye itilize nan brik lyezon, blok konkre, Wòch, twati zona, konpoze kawotchou yo, e mozayik. Kalsyom carbonate decomposes pou fome dyoksid Kabon ak sitwon, yon materyel enpotan nan fe asye, ve, e papye. Akoz pwopriyete antiacid li yo, kalsyom carbonate yo itilize nan anviwonman endistriyel nan kondisyon likid neutralize nan tou de te ak dlo.

STET Dry Calcium Carbonate Beneficiation / Pierre:

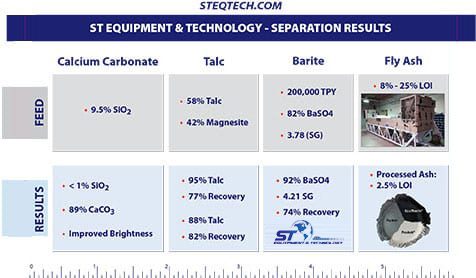

The STET separator has been successfully for the removal of quartz and other acid-insoluble contaminants from finely ground calcium carbonate used as a filler or whitening agent. Asid ensolib (LAVIL AYI) tes se yon metod estanda pou mezire kantite lajan endezirab contaminants nan kalsyom carbonate. Silicates, tankou kwats, Miche, e talk, tribo-charge strongly negative relative to carbonates and successful separations have been achieved on sources of calcium carbonate tested at the pilot-scale and in a demonstration plant. Improvement in product brightness is also achieved for many sources of calcium carbonate beneficiation as the tribo-electrostatic belt separation technology is also effective in removing trace amounts of dark contaminates such as graphite and metal sulfides. Monthly average results for a pilot-scale continuously operating separator processing calcium carbonate is shown below in the table. This demonstration plant used a continuously operating STET pilot-scale separator with average feed rate 10 ton pou chak le.

The STET separator has also been proven in removing silicates and other contaminants from cement rock limestone prior to calcination, pou yon ekstansyon pou lavi a ak maksimize rekiperasyon soti nan depo woch siman.

Kontakte nou jodi a pou aprann plis sou fason STET ka ede ak kalke ou / kalsyom operasyon pwosesis carbonate.

| Mwa | Proved. Klas manje (%LAVIL AYI) | Proved. Pwodwi klas (%LAVIL AYI) | Pwodwi Mas Sede (wt.%) | Kalsyòm Carbonate Rekiperasyon (%) | Lavil Ayi Reje pa- Pwodwi (%) |

|---|---|---|---|---|---|

| Mwa 1 | 3.3% | 0.6% | 86% | 89% | 84% |

| Mwa 2 | 3.7% | 0.6% | 89% | 92% | 87% |

| Mwa 3 | 4.1% | 0.6% | 89% | 92% | 88% |

| Mwa 4 | 4.0% | 0.7% | 89% | 92% | 84% |

| Mwa 5 | 4.7% | 0.6% | 89% | 93% | 89% |