Izvēlieties valodu:

Barīta ir primārais, dabiskas izcelsmes, bārija balstīta minerāls. Bārija, atomu skaits 56, tās nosaukums cēlies no grieķu un nozīmē smago. Barīta ir arī pazīstams kā baryte. Kurā komerciālo barīta noguldījumus pašlaik atrast primāro valstis ir Amerikas Savienotās valstis, Ķīna, Indija un Maroka. Barīta ir augsta blīvuma un ķīmisko inertumu padara to ideālu minerālu daudzām lietojumprogrammām.

Barīta ķīmiskā formula ir BaSO4. Tas ir augsts īpatnējā 4.50 g/cm3. Tā Mosa cietības pakāpe ir 3.0 lai 3.5. Barītu, kurā var atrast dažādās krāsās, ieskaitot dzeltena, brūns, balta, zila, Grejs, vai pat bezkrāsainu, parasti ir stikla ar perlamutra spīduma.

Barīta var atrast kopā ar metāla un nonmetallic derīgo izrakteņu atradņu. Lai būtu ekonomiski dzīvotspējīgas izdalīšanai, barīta parasti vajadzētu būt dominējošais materiāls depozītu. Veidu noguldījumi, kur tas parasti atrodas arī vēnu, atlikusī, un noslāņota. Hidrotermālie izcelsmes vieta ir vēnu un atlikuma depozīti, lai gan noslāņota noguldījumi ir sedimentācijas.

Gruzijā ir konstatēts lielāko noguldījumu Amerikas Savienotajās valstīs, Missouri, Nevada un Tennessee. Kanāda, minerālu ir mīnēta, Yukon Territory, Nova Scotia un Newfoundland. Meksika, barīta noguldījumi ir atklāti Hermosillo, Pueblo, Monterreja un Durango.

The overwhelming majority of the barite that is mined is used by the petroleum industry as a weighting material in the formulation of drilling mud. Barite increases the hydrostatic pressure of the drilling mud allowing it to compensate for high-pressure zones experienced during drilling. The softness of the mineral also prevents it from damaging drilling tools during drilling and enables it to serve as a lubricant. The American Petroleum Institute (Api) has established specifications for the use of barite in drilling mud.

Dry Barite Beneficiation

STET has both pilot scale and commercial experience processing barite to remove gangue such as silicates, dzelzs, and alumina. Low-grade barite beneficiation with a specific gravity between 3.5 - 4.0 has been successfully upgraded using the STET process to product API-grade barite.

STET can demonstrate that the dry electrostatic separation process offers many advantages over traditional wet processing methods (flotācija) Ieskaitot:

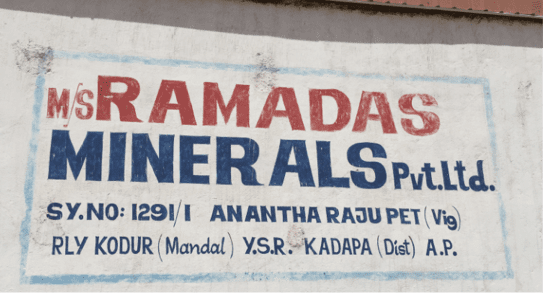

Disrupting a new industry is always a challenge. ST aprīkojums & Technology and Ramadas Minerals Pvt. Sia. in India understand this challenge well. Ramadas Minerals contacted STET to perform testing of a low grade barite / quartz sample produced at the APMDC barite mine in Andhra Pradesh, India. The material was a low grade tailings product from the mining process. It contained too much silica to be sellable as a high SG barite product, and was being produced in large volumes. What was needed was a process to transform the mining waste to usable product. Wet processing (flotācija) was one alternative technology being considered.

Testing at the STET pilot facility demonstrated excellent separation results for the barite powder. The STET separator was able to achieve the goal of +4.20 SG barite through a single separation step.

The STET separator was fit into the existing building, which was originally designed to house a flotation facility. The STET separator installation resulted in significant savings of space, in relation to the previously designed flotation facility. turklāt, a substantial reduction in capital and operating cost was realized.

Contact STET to learn more about dry processing of barite.