Abstract

ST Equipment & Technology, LLC (STET) has developed a tribo-electrostatic belt separation processing system that provides the mineral processing industry a means to beneficiate fine materials with an entirely dry technology. In contrast to other electrostatic separation processes that are typically limited to particles greater than 75µm in size, the triboelectric belt separator is ideally suited for separation of very fine (<1µm) to moderately coarse (300µm) particles with very high throughput. The triboelectric belt separator technology has been used to separate a wide range of materials including coal combustion fly ash, calcite/quartz, talc/magnesite, barite/quartz, and feldspar/quartz. Separation results are presented describing the tribo-charging behavior for bauxite minerals.

Introduction

The lack of access to fresh water is becoming a major factor affecting the feasibility of mining projects around the world. According to Hubert Fleming, former global director for Hatch Water, “Of all the mining projects in the world that have either been stopped or slowed down over the past year, it has been, in almost 100% of the cases, a result of water, either directly or indirectly”.1 Dry mineral processing methods offer a solution to this looming problem.

Dry methods such as electrostatic separation will eliminate the need for fresh water, and offer the potential to reduce costs. Electric separation methods that utilize contact, or tribo-electric, charging are particularity interesting because of their potential to separate a wide variety of mixtures containing conductive, insulating, and semi-conductive particles.

Tribo-electric charging occurs when discrete, dissimilar particles collide with one another, or with a third surface, resulting in a surface charge difference between the two particle types. The sign and magnitude of the charge difference depends partly on the difference in electron affinity (or work function) between the particle types. Separation can then be achieved using an externally applied electric field.

The technique has been utilized industrially in vertical free-fall type separators. In free-fall separators, the particles first acquire charge, then fall by gravity through a device with opposing electrodes that apply a strong electric field to deflect the trajectory of the particles according to sign and magnitude of their surface charge.2 Free-fall separators can be effective for coarse particles, but are not effective at handling particles finer than about 0.075 to 0.1 mm.3,4 One of the most promising new developments in dry mineral separations is the tribo-electrostatic belt separator. This technology has extended the particle size range to finer particles than conventional electrostatic separation technologies, into the range where only flotation has been successful in the past.

Tribo-Electrostatic Belt Separation

In the tribo-electrostatic belt separator (Figure 1 and Figure 2), material is fed into the thin gap 0.9 – 1.5 cm between two parallel planar electrodes. The particles are triboelectrically charged by interparticle contact. For example, in the case of coal combustion fly ash, a mixture of carbon particles and mineral particles, the positively charged carbon and the negatively charged mineral are attracted to opposite electrodes. The particles are then swept up by a continuous moving open-mesh belt and conveyed in opposite directions. The belt moves the particles adjacent to each electrode toward opposite ends of the separator. The electric field need only move the particles a tiny fraction of a centimeter to move a particle from a left-moving to a right-moving stream. The counter current flow of the separating particles and continual triboelectric charging by carbon-mineral collisions provides for a multi-stage separation and results in excellent purity and recovery in a single-pass unit. The high belt speed also enables very high throughputs, up to 40 tonnes per hour on a single separator. By controlling various process parameters, such as belt speed, feed point, electrode gap and feed rate, the device produces low carbon fly ash at carbon contents of 2 % ± 0.5% from feed fly ashes ranging in carbon from 4% to over 30%.

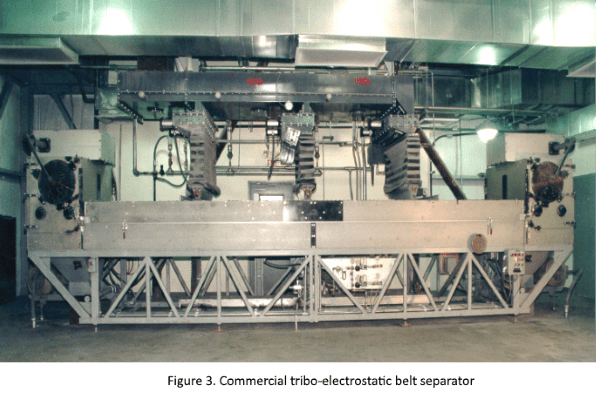

The separator design is relatively simple. The belt and associated rollers are the only moving parts. The electrodes are stationary and composed of an appropriately durable material. The belt is made of plastic material. The separator electrode length is approximately 6 meters (20 ft.) and the width 1.25 meters (4 ft.) for full size commercial units. The power consumption is less than 2 kilowatt-hour per tonne of material processed with most of the power consumed by two motors driving the belt.

The process is entirely dry, requires no additional materials and produces no waste water or air emissions. In the case of carbon from fly ash separations, the recovered materials consist of fly ash reduced in carbon content to levels suitable for use as a pozzolanic admixture in concrete, and a high carbon fraction which can be burned at the electricity generating plant. Utilization of both product streams provides a 100% solution to fly ash disposal problems. For mineral separations, processing bauxite for example, the separator provides a technology to reduce water usage, extend reserve life and/or recover and reprocess tailings.

The tribo-electrostatic belt separator is relatively compact. A machine designed to process 40 tonnes per hour is approximately 9.1 meters (30 ft.) long, 1.7 meters (5.5 ft.) wide and 3.2 meters (10.5 ft.) high. The required balance of plant consists of systems to convey dry material to and from the separator. The compactness of the system allows for flexibility in installation designs.

The tribo-electrostatic belt separation technology is robust and industrially proven, and was first applied industrially to the processing of coal combustion fly ash in 1995. The technology is effective in separating carbon particles from the incomplete combustion of coal, from the glassy aluminosilicate mineral particles in the fly ash. The technology has been instrumental in enabling recycle of the mineral-rich fly ash as a cement replacement in concrete production. Since 1995, over 20,000,000 tonnes of fly ash has been processed by the 19 tribo-electrostatic belt separators installed in the USA, Canada, UK, Poland, and South Korea. The industrial history of fly ash separation is listed in Table 1.

Table 1. Industrial application of tribo-electrostatic belt separation for fly ash

[table id=3 /]

Tribo-Electrostatic Separation of Bauxite Minerals

ST Equipment & Technology (STET) performed bench scale dry tribo-electrostatic separation testing on multiple samples of bauxite minerals. The samples are listed below in Table 2.

Table 2. Properties of bauxite samples tested by STET

[table id=4 /]

Chemical composition for all feed and separated product samples was measured by X-Ray Fluorescence (XRF) using a WD-XRF system. The results of the chemical analysis for the feed samples are shown below in Table 3.

Table 3. Chemical properties of bauxite samples tested by STET

[table id=5 /]

Particle size was measured by laser particle size measurement using dry pneumatic dispersion. The results for the feed samples are shown below in Table 4.

Table 4. Particle size of bauxite samples tested by STET

[table id=6 /]

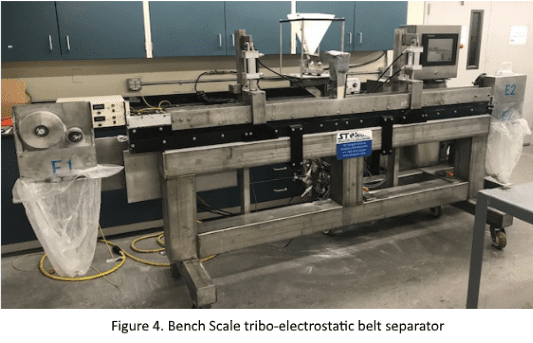

Samples were separated using the STET benchtop separator. The benchtop separator is used for screening for evidence of tribo-electrostatic charging and to determine if a material is a good candidate for electrostatic beneficiation. The primary difference between the benchtop separator and pilot-scale and commercial-scale separators is that the length of the benchtop separator is approximately 0.4 times the length of pilot-scale and commercial-scale units. As the separator efficiency is a function of the electrode length, bench-scale testing cannot be used as a substitute for pilot-scale testing. Pilot-scale testing is necessary to determine the extent of the separation that the STET process can achieve, and to determine if STET process can meet the product targets under given feed rates. Instead, the benchtop separator is used to rule out candidate materials that are unlikely to demonstrate any significant separation at the pilot-scale level. Results obtained on the bench-scale will be non-optimized, and the separation observed is less than which would be observed on a commercial sized STET separator.

Testing with the STET benchtop separator demonstrated significant movement of Al2O3 with the majority of the samples tested. In three of the four samples tested by STET, substantial movement of Al2O3 was observed. In addition, the other major elements of Fe2O3, SiO2 and TiO2 demonstrated significant movement in most cases. In Sample 1, Sample 3 and Sample 4, the movement of loss on ignition (LOI) followed movement of Al2O3. The movement of the major elements is shown below in Figure 5.

The STET separator is a physical separation process and selectively separates mineral phases based on tribocharging, a surface phenomenon. The degree to which minerals are susceptible to tribocharging is in some cases able to be predicted via consultation of a triboelectric series, but in the case of complex mineral ores, often in practice must be determined empirically. A summary of the tribocharging properties for the samples tested is shown below in Table 5.

Table 5. Summary of tribocharging behaviour for major elements. POS = charged positive, NEG = charged negative.

[table id=7 /]

Dry processing with the STET separator offers opportunities to generate value for bauxite and aluminium producers. The utilization of lower grade bauxite deposits may allow for lower mining costs by reducing stripping ratios and by reduced generation of tailings. In addition, the pre-processing of bauxite ores by dry triboelectrostatic separation may result in improved economics of aluminium refining by supplying higher grades of bauxite to the refining process, or by reducing volumes of red mud generated. In addition, higher aluminium content in red mud may allow for reprocessing. A summary of ideal characteristics for metallurgical grade bauxite is presented, as well as a summary of the benefit of the STET separator, below in Table 6.

Table 6. Summary of ideal characteristics for metallurgical grade bauxite.5

[table id=8 /]

Conclusion

Tribo-electrostatic separation was demonstrated as an effective method for generating a high-grade bauxite ore for use in alumina production. Testing with the STET benchtop separator demonstrated significant movement of Al2O3 with the majority of the samples tested. In three of the four samples tested by STET, substantial movement of Al2O3 was observed. In addition, the other major elements of Fe2O3, SiO2 and TiO2 demonstrated significant separation in most cases. Dry processing with the STET separator offers opportunities to generate value for bauxite and aluminium producers.

References

1. Blin, P & Dion-Ortega, A (2013) High and Dry, CIM Magazine, vol. 8, no. 4, pp. 48-51.

2. Manouchehri, H, Hanumantha Roa, K, & Forssberg, K (2000), Review of Electrical Separation Methods, Part 1: Fundamental aspects, Minerals & Metallurgical Processing, vol. 17, no. 1 pp 23–36.

3. Manouchehri, H, Hanumantha Roa, K, & Forssberg, K (2000), Review of Electrical Separation Methods, Part 2: Practical Considerations, Minerals & Metallurgical Processing, vol. 17, no. 1 pp 139–166.

4. Ralston O. (1961) Electrostatic Separation of Mixed Granular Solids, Elsevier Publishing Company, out of print.

5. Kogel, Jessica Elzea; Trivedi, Nikhil C; Barker, James M; Krukowski, Stanley T.; Industrial Minerals and Rocks: Commodities, Markets, and Uses 7th Edition, (2006), Page 237.