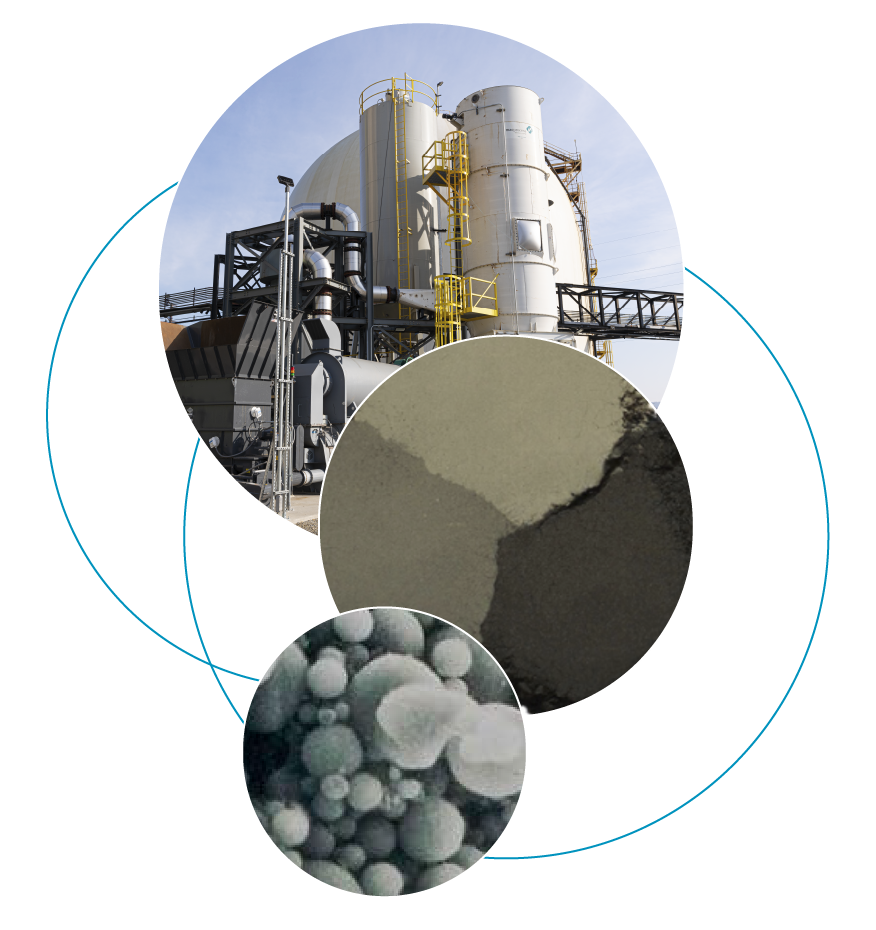

Application: Fly Ash

Turning Grey Fly Ash into Green

Recycle your fly ash and give it new purpose

As the energy industry moves from freshly generated ash to harvested ash, you need the best separation equipment to recover, harvest, and beneficiate fly ash to make it suitable for use in concrete.

Used commercially since 1995, our completely dry electrostatic separation process for pulverized coal (PC) fly ash beneficiation has generated over 20 million tons of high-quality fly ash for concrete production. Recycled fly ash is an environmentally friendly product used to create concrete with high strength, durability, workability, and reduced heat of hydration.

In use at 12 power stations throughout the United States, Canada, the United Kingdom, Poland, and the Republic of Korea, controlled low-LOI ProAsh® products generated with STET technology have been approved for use by more than 20 state highway authorities, as well as many other specification agencies.

Reasons to Believe

STET electrostatic separation achievements include:

- 25M tons of fly ash has been processed in our history.

- We have enabled the avoidance of >20M tons of CO2 emissions—equivalent to taking 4.3 million cars off the road for a year.

- We have enabled our customers to save over 8.5 billion gallons of water, which is more than 11,000 Olympic-sized swimming pools.

- ProAsh quality has been certified under the ASTM C618, CSA A3001-23 and EN 450.

-

ProAsh produced by our technology is used in some of the most demanding projects, including high rise buildings, bridges, tunnels, and other critical infrastructure.

Unlock Fly Ash Potential with STET

The benefits of using STET electrostatic separators for fly ash include:

- Fine particle capture. Our electrostatic separators capture fine fly ash particles down to sub-micron levels, to improve its viability for concrete production.

- No water. No chemicals. You eliminate water usage, wastewater generation, and contamination of harmful chemicals.

- Continuous, high-rate, single-step process. With processing capacities of up to 45 tons per hour, the STET separator integrates seamlessly into existing workflows, providing adjustable control over product quality with user-friendly automation options.

- Reduced costs. Our completely dry electrostatic separation translates into lower operational costs, less energy consumption, no landfill costs, and reduced environmental remediation costs. And the ability to use harvested fly ash is less expensive than raw materials, which lowers logistics costs.

- Revenue growth. Turn a waste product into a viable revenue stream

- End-to-end solution. From initial concept to fully permitted and supported plant, STET has all the technology, equipment, services, and support you need to optimize your fly ash business. We will even help market the products you generate!

The STET™ End-to-End Service Model

Putting our know-how to work for you

Evaluate

- Assess customer needs

- Sample testing

- Bench-scale testing

Trial

- Pilot plant trials (in-house at STET)

- Full-service lab testing

- Pilot plant of large sample

- Optimization of prep steps (milling, drying, deagglomeration)

- Market development

Design

- Confirm plant design through pilot plant trials

- Control system design

- Finalize plant design

- Estimate construction, production, and manufacturing costs

Build/Install

- Develop detailed engineering (typically done by a third-party specialist)

- Manufacturing of proprietary parts

- Construction of the plant

Optimize

- Rigorous statistics and design of experiments (DOE) based approach

Marketing and Ongoing Support

- Co-marketing programs of fly ash products

- Maintenance program

- Technical support

- Scale-up as needed

- Warehousing & inventory