Họrọ asụsụ:

Abstract

ST Equipment & Technology, LLC (STET) azụlitewo a tribo-electrostatic belt nkewa nhazi usoro na-enye ịnweta nhazi ụlọ ọrụ a iji beneficiate ezi ihe na ihe kpamkpam akọrọ technology. N'ụzọ dị iche na ndị ọzọ electrostatic nkewa Filiks na na-a-ejedebeghị na ahụ ukwuu karịa 75μm na size, na triboelectric belt separator kwesịrị ruru eru maka nkewa nke nnọọ mma (<1μm) ka moderately Ntụ (300μm) ahụ na dị nnọọ elu throughput. The triboelectric belt separator technology e ji mee ikewapụ a dịgasị iche iche nke ihe gụnyere coal combustion ada uyi, calcite / quartz, talc / magnesite, barite / quartz, na feldspar / quartz. Nkewa pụta na-n'ihu na-akọwa tribo-odori omume maka bauxite minerals.

Okwu Mmalite

The enweghị ohere ọhụrụ mmiri na-aghọ a ihe bụ isi na-emetụta ndị feasibility nke na Ngwuputa oru gburugburu ụwa. Dị ka Hubert Fleming, mbụ zuru ụwa ọnụ director maka imu nwa Water, "Of niile Ngwuputa oru na ụwa na ma e kwụsịrị ma ọ bụ kwụsịlata afo gara-aga, ọ dịla, fọrọ nke nta 100% nke ikpe, a n'ihi nke mmiri, ma ozugbo ma ọ bụ n'ụzọ ".1 kpọrọ nkụ ịnweta nhazi ụzọ na-enye ihe ngwọta a na-eru nsogbu.

Akọrọ ụzọ ndị dị otú ahụ dị ka electrostatic nkewa ga-ewepụ mkpa maka ọhụrụ mmiri, na-enye ndị nwere iji belata-akwụ ụgwọ. Electric nkewa si na ahu nagide kọntaktị, ma ọ bụ tribo-electric, Nchaji bụ particularity akpali n'ihi na ha nwere iji ikewapụ a dịgasị iche iche nke mixtures nwere conductive, egbochi ihe, na ọkara conductive ahụ.

Tribo-electric Nchaji na-adị mgbe pụrụ iche, dissimilar ahụ ikukota na onye ọzọ, ma ọ bụ na a atọ n'elu, n'ihi na a elu ụgwọ dị iche n'etiti abụọ urughuru ụdị. The ịrịba ama na ịdị ukwuu nke ihe-ndebe ihe dị iche na-adabere obere na ihe dị iche na elektrọn mmekọrita (ma ọ bụ ọrụ ọrụ) n'etiti urughuru ụdị. Nkewa nwere ike mgbe ahụ ga-enweta na-eji ihe externally etinyere electric ubi.

Usoro a tinye n'ọrụ industrially na vetikal free-ọdịda ụdị separators. Na free-ọdịda separators, ahụ ụzọ nweta ụgwọ, mgbe da site ike ndọda site a ngwaọrụ eguzogide electrodes na-emetụta a ike electric ubi ka kụchapụ na trajectory nke ahụ dị ka ihe ịrịba ama na ịdị ukwuu nke ha n'elu charge.2 Free-ọdịda separators nwere ike ịdị irè maka ntụ ahụ, ma na-adịghị irè na njikwa ahụ mma karịa banyere 0.075 ka 0.1 mm.3,4 Otu n'ime ndị kasị ekwe ọhụrụ tolite na akọrọ ịnweta nkewa bụ tribo-electrostatic belt separator. Nke a technology ka akp urughuru size nso ka mma ahụ ka ot electrostatic nkewa teknụzụ, n'ime nso ebe naanị flotation kemgbe ihe ịga nke ọma n'oge gara aga.

Tribo-Electrostatic echebe Nkewa

Na tribo-electrostatic belt separator (Ọgụgụ 1 na Ọgụgụ 2), ihe a na nri n'ime mkpa ọdịiche 0.9 - 1.5 cm n'etiti abụọ yiri planar electrodes. The ahụ na-triboelectrically boro ebubo site interparticle kọntaktị. Ọmụmaatụ, na ikpe nke coal combustion ada uyi, a ngwakọta nke carbon ahụ na ịnweta ahụ, na ghaghị ebubo carbon na-ezighị ezi na ebubo ịnweta na-dọtara na-abụghị electrodes. The ahụ na-ahụ kpochapụ elu site a na-aga n'ihu na-akpụ akpụ na-emeghe-ntupu belt na ekekpepde na-abụghị ntụziaka. The belt na-akpali ndị ahụ n'akụkụ ọ bụla electrode n'ebe abụghị nsọtụ nke separator. The electric ubi ekwesịghị naanị akpali ahụ a obere nta nke a sentimita ịkwaga a urughuru si a ekpe-akpụ akpụ na a nri-akpali akpali stream. The counter ugbu a eruba nke kewara ahụ na nọgide triboelectric Nchaji site carbon-ịnweta collisions enye maka a multi-ogbo nkewa na utịp ke magburu onwe-adị ọcha na mgbake na a otu-ngafe unit. The elu belt ọsọ na-enyere nnọọ elu throughputs, ruo 40 ise kwa hour na a otu separator. Site ịchịkwa dị iche iche usoro parameters, dị ka belt ọsọ, ndepụta na mgbe, electrode ọdịiche na ndepụta ọnụego, ngwaọrụ arụpụta ala carbon ada uyi na carbon ọdịnaya nke 2 % ± 0.5% si oriri ada ntụ sitere na carbon si 4% karịrị 30%.

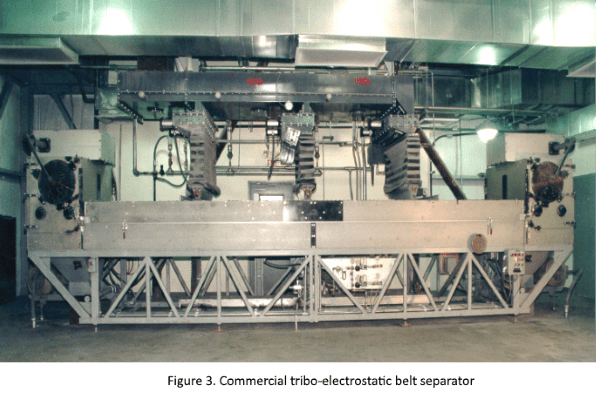

The separator imewe bụ dịtụ mfe. The belt na metụtara rollers bụ naanị na-akpụ akpụ akụkụ. The electrodes bụ anyịnya na esịnede ihe n'ụzọ kwesịrị ekwesị inogide ihe. The belt ka nke plastic ihe. The separator electrode ogologo bụ mkpokọta 6 mita (20 ft.) na obosara 1.25 mita (4 ft.) maka zuru size azụmahịa nkeji. The ike oriri bụ ihe na-erughị 2 kilowatt-hour kwa tonne nke ihe onwunwe esichara na ọtụtụ ndị ike gwusia site abụọ Motors ụgbọala belt.

The usoro kpamkpam akọrọ, na-achọ ọ ọzọ ihe ma na-amị dịghị n'efu mmiri ma ọ bụ ikuku anwuru. Na ikpe nke carbon si ada uyi nkewa, na natara ihe iso nke ada uyi ebelata ke carbon ọdịnaya etoju kwesịrị ekwesị maka dị ka a pozzolanic admixture na ihe, na a elu carbon nta nke nwere ike ọkụ na ọkụ eletrik-amụba osisi. Itinye n'ọrụ nke ma ngwaahịa iyi na-enye a 100% ngwọta ofufe ash mkpofu nsogbu. N'ihi na ịnweta nkewa, nhazi bauxite ihe atụ, na separator enye a technology iji belata mmiri ojiji, ịgbatị idobere ndụ na / ma ọ bụ naghachi na reprocess tailings.

The tribo-electrostatic belt separator dịtụ kọmpat. A igwe iji hazie 40 ise kwa hour bụ mkpokọta 9.1 mita (30 ft.) ogologo, 1.7 mita (5.5 ft.) obosara na 3.2 mita (10.5 ft.) elu. The chọrọ itule nke osisi mejupụtara usoro ime akọrọ ihe onwunwe ma si na separator. The compactness nke usoro na-enye ohere maka mgbanwe na echichi aghụghọ.

The tribo-electrostatic belt nkewa technology bụ siri ike na industrially pụtara, na mbụ etinyere industrially na nhazi nke coal combustion ada uyi na 1995. The technology bụ irè kewara carbon ahụ si na-ezughị ezu combustion nke coal, si yiri enyo aluminosilicate ịnweta ahụ na ada uyi. The technology kemgbe instrumental na eme egweri nke ịnweta-ọgaranya ada uyi ka a cement nnọchi na ihe mmepụta. ebe ọ bụ na 1995, n'elu 20,000,000 ise ada uyi e esichara site 19 tribo-electrostatic belt separators arụnyere na USA, Canada, UK, Poland, na South Korea. The ulo oru akụkọ ihe mere eme nke ada uyi nkewa na-depụtara na Isiokwu 1.

Isiokwu 1. Industrial ngwa nke tribo-electrostatic belt nkewa maka ada uyi

| Utility / ike ojii | Location | Malite nke azụmahịa arụmọrụ | Facility nkọwa |

|---|---|---|---|

| Duke Energy - Roxboro Station | North Carolina USA | 1997 | 2 Separators |

| Energy asụsụ- Brandon mben | Maryland USA | 1999 | 2 Separators |

| Scottish Power- Longannet Station | Scotland UK | 2002 | 1 separator |

| Jacksonville Electric-St. Johns River Power Park | Florida USA | 2003 | 2 Separators |

| South Mississippi Electric Power -R.D. Morrow | Mississippi USA | 2005 | 1 separator |

| New Brunswick Power-Belledune | New Brunswick Canada | 2005 | 1 separator |

| OF npower-Didcot Station | England UK | 2005 | 1 separator |

| Talen Energy Brunner Island Station | Pennsylvania USA | 2006 | 2 Separators |

| Tampa Electric-Big Bend Station | Florida USA | 2008 | 3 Separators two-pass scavenging |

| OF npower Aberthaw-Station | Wales UK | 2008 | 1 separator |

| EDF Energy-West Burton Station | England UK | 2008 | 1 separator |

| ZGP (Lafarge Cement / Ciech Janikosoda JV) | Poland | 2010 | 1 separator |

| Korea Southeast Power- Yeongheung | South Korea | 2014 | 1 separator |

| PGNiG Termika-Sierkirki | Poland | 2018 | 1 separator |

| Taiheiyo ciment Company-Chichibu | Japan | 2018 | 1 separator |

| Armstrong ada uyi- Eagle Cement | Philippines | ndokwa 2019 | 1 separator |

| Korea Southeast Power- Samcheonpo | South Korea | ndokwa 2019 | 1 separator |

Tribo-Electrostatic Nkewa nke Bauxite mineral

ST Equipment & Technology (STET) rụrụ bench ọnụ ọgụgụ akọrọ tribo-electrostatic nkewa ule na otutu samples of bauxite minerals. The samples e depụtara n'okpuru ebe na Isiokwu 2.

Isiokwu 2. Njirimara nke bauxite samples nwalere site STET

| Description | Desired Product & Goals | |

|---|---|---|

| sample 1 | ROM Bauxite | Al2O3 recovery Reduce SiO2, Fe2O3, TiO2 |

| sample 2 | PLK (Partially Lateritized Khondalite) | Al2O3 recovery Reduce SiO2, Fe2O3, TiO2 |

| sample 3 | Red Mud | Fe2O3 recovery Reduce SiO2, Al2O3, TiO2 |

| sample 4 | ROM Bauxite Slimes | Al2O3 recovery Reduce SiO2, Fe2O3, TiO2 |

Chemical mejupụtara niile na ndepụta ma iche ngwaahịa samples e ji amata X-Ray Fluorescence (XRF) eji a WD-XRF usoro. The results nke chemical analysis maka ndepụta samples na-egosi n'okpuru na Isiokwu 3.

Isiokwu 3. Chemical Njirimara nke bauxite samples nwalere site STET

| Al2O3 wt.% | Fe2O3 wt.% | SiO2 wt.% | SiO2 wt.% | LOI wt.% | |

|---|---|---|---|---|---|

| sample 1 | 43.7 | 25.9 | 3.9 | 2.3 | 23.6 |

| sample 2 | 34.9 | 19.4 | 28.5 | 2.1 | 14.7 |

| sample 3 | 19.0 | 52.1 | 6.7 | 4.9 | 11.1 |

| sample 4 | 34.6 | 23.2 | 18.0 | 4.4 | 18.8 |

Urughuru size e ji amata laser urughuru size n'ihe eji akọrọ pneumatic dispersion. The results maka ndepụta samples na-egosi n'okpuru na Isiokwu 4.

Isiokwu 4. Urughuru size of bauxite samples nwalere site STET

| D10 micron | D50 micron | D90 micron | D90 micron |

|

|---|---|---|---|---|

| sample 1 | 2 | 19 | 73 | 118 |

| sample 2 | 2 | 45 | 575 | 898 |

| sample 3 | 1 | 27 | 212 | 325 |

| sample 4 | 1 | 7 | 59 | 93 |

N'omume ndị e kewapụrụ na iji STET benchtop separator. The benchtop separator na-eji maka screening na-egosi nke tribo-electrostatic Nchaji na-ekpebi ma ọ bụrụ na a na ihe onwunwe bụ ezigbo nwa akwukwo maka electrostatic beneficiation. The isi ihe dị iche n'etiti benchtop separator na pilot-ọnụ ọgụgụ na azụmahịa-ọnụ ọgụgụ separators bụ na ogologo nke benchtop separator bụ mkpokọta 0.4 ugboro ogologo nke pilot-ọnụ ọgụgụ na azụmahịa-ọnụ ọgụgụ nkeji. Dị ka separator arụmọrụ bụ a ọrụ nke electrode ogologo, bench-ọnụ ọgụgụ ule apụghị-eji dị ka a dochie anya pilot-ọnụ ọgụgụ ule. Pilot-ọnụ ọgụgụ ule dị mkpa iji chọpụta na-ruo n'ókè nke na nkewa na STET usoro nwere ike nweta, na-ekpebi ma ọ bụrụ na STET usoro nwere ike izute ngwaahịa zaa n'okpuru nyere oriri udu. Kama, na benchtop separator a na-eji achị si nwa akwukwo ihe na-eleghi anya na-egosi na ọ bụla dị ịrịba nkewa na pilot-ọnụ ọgụgụ larịị. Results nwetara na bench-ọnụ ọgụgụ ga-ndị na-abụghị kachasị, na nkewa hụrụ bụ ihe na-erughị nke ga-hụrụ na a azụmahịa sized STET separator.

Testing na STET benchtop separator gosiri ịrịba ije nke Al2O3 na ọtụtụ ndị samples anwale. Na atọ nke anọ samples nwalere site STET, ọkpụrụkpụ ije nke Al2O3 chọpụtara. Na mgbakwunye, na ndị ọzọ na isi ihe nke Fe2O3, SiO2 na TiO2 gosiri dị ịrịba ama ije na ọtụtụ ikpe. na Sample 1, sample 3 na Sample 4, ije nke ọnwụ na mgbanye (iWU) soro ije nke Al2O3. The ije nke isi ọcha na-egosi n'okpuru na Ọgụgụ 5.

The STET separator bụ a anụ ahụ nkewa usoro na bibiri ekewapụ ịnweta n'ụzọ dabeere tribocharging, a elu onu. Ka ókè minerals pụrụ itinye aka tribocharging bụ na ụfọdụ na-enwe ike ike buru amụma site oge nke a triboelectric usoro, ma na ikpe nke mgbagwoju ịnweta ores, mgbe na omume aghaghị ikpebisi empirically. A nchịkọta nke tribocharging Njirimara maka samples anwale na-egosi n'okpuru na Isiokwu 5.

Isiokwu 5. Nchịkọta nke tribocharging omume maka isi ihe. Naa = ebubo mma, NEG = ebubo ọjọọ.

| Al2O3 | Fe2O3 | SiO2 | TiO2 | iWU | |

|---|---|---|---|---|---|

| sample 1 | POS | NEG | NEG | NEG | POS |

| sample 2 | NEG | POS | NEG | N/A | N/A |

| sample 3 | POS | NEG | N/A | NEG | POS |

| sample 4 | POS | N/A | NEG | NEG | POS |

Akọrọ nhazi na STET separator awade ohere n'ịwa uru maka bauxite na aluminum emepụta. Itinye n'ọrụ nke ala ọkwa bauxite ego nwere ike ikwe ka ala Ngwuputa-akwụ ụgwọ site na mbenata na-agba oke na site belata ọgbọ nke tailings. Na mgbakwunye, nhazi tupu bauxite mmanụ site na nkewa triboelectrostatic nkewa nwere ike bute akụ na ụba nke nchacha aluminom site na ịnye ọkwa bauxite dị elu na usoro nnụcha., ma ọ bụ site na mbenata mpịakọta nke red apịtị eme. Na mgbakwunye, elu aluminum ọdịnaya red apịtị nwere ike ikwe ka ihe reprocessing. A nchịkọta nke ezigbo e ji mara maka Metallurgical ọkwa bauxite na-dị, nakwa dị ka a nchịkọta nke abamuru nke STET separator, n'okpuru na Isiokwu 6.

Isiokwu 6. Nchịkọta nke ezigbo e ji mara maka Metallurgical ọkwa bauxite.5

| Ideal Grade Characteristic | Impact if Inadequate | Observed with STET Separation |

|---|---|---|

| Low “reactive silica” (>1.5% - <3.0%) (kaolinite) | Increases caustic usage, a critical operating cost factor. | Reduction in total silica |

| High extractable alumina | Increases capital and operating costs for mining, processing and mud disposal. | Increase in alumina |

| Low organic carbon | Increases operating costs by reducing plant efficiency. | |

| Low boehmite (<3%) | Precludes low-temperature processing that can increase capital and operating costs. | |

| Low goethite (tolerable in a high-temperature plant or with high hematite) | Slows clarification, lowers product quality and increases alumina loss via mud circuit. | Reduction in total iron |

| Low moisture (can create nuisance dust if too low) | Increases capital costs (larger evaporation facility), fuel consumption, shipping costs. | |

| Iron content (ideally >5%-<15%) | Low iron can lower product quality. High iron dilutes alumina content of bauxite. | Reduction in total iron |

| Low quartz | Increases maintenance costs (pipe wear). Increases caustic usage in high-temperature plants. | Reduction in total silica |

| Low impurities and trace elements | Can lower process efficiency (sulfur, chlorine, calcium) and metal quality (gallium, zinc, vanadium, phosphorus). | |

| Soft and friable | Increases mining and grinding costs. | |

| Dissolves readily | Increases capital (larger digestion equipment) and operating costs. | |

| Low titania | Can increase caustic usage in high-temperature plants. | Reduction in titania |

| Low carbonates | Can require special processing. |

mmechi

Tribo-electrostatic nkewa e gosipụtara dị ka dị irè usoro nke na-amụba a elu-ọkwa bauxite ore maka ojiji na alumina mmepụta. Testing na STET benchtop separator gosiri ịrịba ije nke Al2O3 na ọtụtụ ndị samples anwale. Na atọ nke anọ samples nwalere site STET, ọkpụrụkpụ ije nke Al2O3 chọpụtara. Na mgbakwunye, na ndị ọzọ na isi ihe nke Fe2O3, SiO2 na TiO2 gosiri ịrịba nkewa ọtụtụ mgbe. Akọrọ nhazi na STET separator awade ohere n'ịwa uru maka bauxite na aluminum emepụta.

References

1. Blin, P & Dion-Ortega, A (2013) High na akọrọ, CIM Magazine, vol. 8, dịghị. 4, p. 48-51.

2. Manouchehri, H, Hanumantha Roa, K, & Fors Mountain, K (2000), Review nke Ọdụdọ Nkewa Ụzọ, Part 1: isi akụkụ, mineral & Metallurgical nhazi, vol. 17, dịghị. 1 p 23-36.

3. Manouchehri, H, Hanumantha Roa, K, & Fors Mountain, K (2000), Review nke Ọdụdọ Nkewa Ụzọ, Part 2: Uru Ntụle, mineral & Metallurgical nhazi, vol. 17, dịghị. 1 p 139-166.

4. Ralston O. (1961) Electrostatic Nkewa nke Mixed granular solids, Elsevier Publishing Company, ebipụta.

5. Kogel, Jessica Elzea; Trivedi, Nikhil C; Barker, James M; Krukowski, Stanley T.; Industrial mineral na Rocks: onu ahia, ahịa, na-eji 7th Edition, (2006), Page 237.