Pilih Bahasa:

ABSTRAK

ST Equipment & Teknologi, LLC (STET) has developed a tribo-electrostatic belt separation processing system that provides the mineral processing industry a means to beneficiate fine materials with an entirely dry technology. In contrast to other electrostatic separation processes that are typically limited to particles greater than 75µm in size, Pemisah tali pinggang triboelektrik sangat sesuai untuk pemisahan yang sangat halus (<1µm) kepada sederhana coarse (300µm) zarah dengan daya pemprosesan yang sangat tinggi. The triboelectric belt separator technology has been used to separate a wide range of materials including coal combustion fly ash, calcite/kuarza, ENCHANTEUR di samping bedak/magnesite, barite/quartz, and feldspar/quartz. Separation results are presented describing the tribo-charging behavior for bauxite minerals.

Pengenalan

Kekurangan akses kepada air tawar menjadi faktor utama yang mempengaruhi kebolehlaksanaan projek perlombongan di seluruh dunia. Menurut Hubert Fleming, bekas pengarah global untuk Hatch Water, "Daripada semua projek perlombongan di dunia yang telah dihentikan atau diperlahankan sejak setahun lalu, ia telah, dalam hampir 100% kes-kes, akibat air, either directly or indirectly”.1 Dry mineral processing methods offer a solution to this looming problem.

Kaedah kering seperti pemisahan elektrostatik akan menghapuskan keperluan air tawar, dan menawarkan potensi untuk mengurangkan kos. Electric separation methods that utilize contact, or tribo-electric, charging are particularity interesting because of their potential to separate a wide variety of mixtures containing conductive, insulating, and semi-conductive particles.

Tribo-electric charging occurs when discrete, dissimilar particles collide with one another, or with a third surface, resulting in a surface charge difference between the two particle types. The sign and magnitude of the charge difference depends partly on the difference in electron affinity (or work function) between the particle types. Separation can then be achieved using an externally applied electric field.

The technique has been utilized industrially in vertical free-fall type separators. In free-fall separators, the particles first acquire charge, then fall by gravity through a device with opposing electrodes that apply a strong electric field to deflect the trajectory of the particles according to sign and magnitude of their surface charge.2 Free-fall separators can be effective for coarse particles, but are not effective at handling particles finer than about 0.075 untuk 0.1 mm.3,4 One of the most promising new developments in dry mineral separations is the tribo-electrostatic belt separator. Teknologi ini telah memperluaskan julat saiz zarah kepada zarah yang lebih halus daripada teknologi pemisahan elektrostatik konvensional, ke dalam julat di mana hanya pengapungan telah berjaya pada masa lalu.

Tribo-Electrostatic Belt Separation

In the tribo-electrostatic belt separator (Rajah 1 and Figure 2), bahan diberi makan ke dalam jurang nipis 0.9 – 1.5 cm between two parallel planar electrodes. Zarah-zarah dicaj secara triboelektik oleh kenalan interparticle. Sebagai contoh, dalam kes abu lasak pembakaran arang batu, campuran zarah karbon dan zarah mineral, mineral yang dikenakan secara positif dan mineral yang dikenakan negatif tertarik kepada elektrod-elektrod yang bertentangan. Zarah-zarah kemudian disapu oleh tali pinggang terbuka yang berterusan dan disampaikan ke arah yang bertentangan. Tali pinggang menggerakkan zarah bersebelahan setiap elektrod ke arah hujung bertentangan pemisah. Medan elektrik hanya perlu menggerakkan zarah pecahan kecil sentimeter untuk menggerakkan zarah dari kiri bergerak ke aliran yang bergerak kanan. The counter current flow of the separating particles and continual triboelectric charging by carbon-mineral collisions provides for a multi-stage separation and results in excellent purity and recovery in a single-pass unit. Kelajuan tali pinggang yang tinggi juga membolehkan kendandahan yang sangat tinggi, selewat-lewatnya 40 tan sejam pada pemisah tunggal. Dengan mengawal pelbagai parameter proses, seperti kelajuan tali pinggang, titik suapan, jurang elektrod dan kadar suapan, peranti menghasilkan abu terbang rendah karbon pada kandungan karbon 2 % ± 0.5% daripada makanan terbang abu yang terdiri daripada karbon dari 4% kepada lebih 30%.

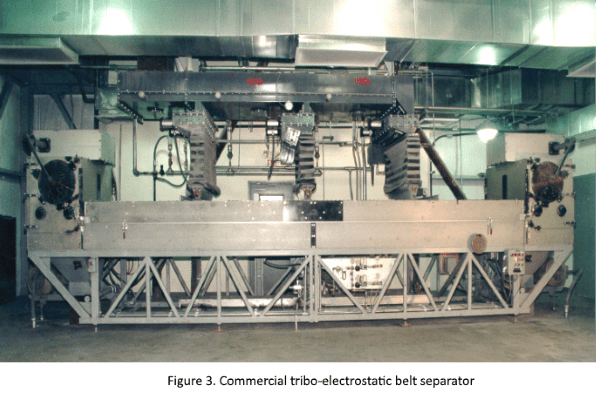

Reka bentuk pemisah agak mudah. Tali pinggang dan penggelek yang berkaitan adalah satu-satunya bahagian yang bergerak. Elektrod-elektrod adalah alat tulis dan terdiri daripada bahan tahan lama yang sesuai. Tali pinggang diperbuat daripada bahan plastik. Pemisah elektrod panjang adalah kira-kira 6 meter (20 Ka.) dan lebar 1.25 meter (4 Ka.) bagi unit-unit komersil saiz penuh. The power consumption is less than 2 kilowatt-hour per tonne of material processed with most of the power consumed by two motors driving the belt.

Proses ini sama sekali Kering, memerlukan bahan-bahan tambahan yang tiada dan menghasilkan tiada sisa pelepasan air atau udara. Dalam kes karbon dari pemisahan Abu Terbang, bahan-bahan yang pulih terdiri daripada abu terbang dikurangkan dalam kandungan karbon ke tahap yang sesuai untuk digunakan sebagai campuran pozzolanic dalam konkrit, dan pecahan karbon yang tinggi yang boleh dibakar di loji penjanaan elektrik. Penggunaan kedua-dua aliran produk menyediakan 100% penyelesaian kepada masalah penjualan Abu Terbang. For mineral separations, processing bauxite for example, the separator provides a technology to reduce water usage, extend reserve life and/or recover and reprocess tailings.

The tribo-electrostatic belt separator is relatively compact. Mesin yang direka untuk memproses 40 tan sejam adalah lebih kurang 9.1 meter (30 Ka.) panjang, 1.7 meter (5.5 Ka.) luas dan 3.2 meter (10.5 Ka.) Tinggi. Keseimbangan loji yang diperlukan terdiri daripada sistem untuk menyampaikan bahan kering ke dan dari pemisah. Kekopatan sistem membolehkan fleksibiliti dalam reka bentuk pemasangan.

The tribo-electrostatic belt separation technology is robust and industrially proven, and was first applied industrially to the processing of coal combustion fly ash in 1995. The technology is effective in separating carbon particles from the incomplete combustion of coal, daripada zarah mineral aluminosilicate sayu pada Abu Terbang. Teknologi ini memainkan peranan penting dalam membolehkan kitar semula abu terbang kaya mineral sebagai pengganti simen dalam pengeluaran konkrit. Sejak 1995, over 20,000,000 tonnes of fly ash has been processed by the 19 tribo-electrostatic belt separators installed in the USA, Kanada, Uk, Poland, and South Korea. The industrial history of fly ash separation is listed in Jadual 1.

Jadual 1. Industrial application of tribo-electrostatic belt separation for fly ash

| Utiliti / stesen janakuasa | Lokasi | Start of commercial operations | Facility details |

|---|---|---|---|

| Duke tenaga – Stesen Roxboro | North Carolina Amerika Syarikat | 1997 | 2 Pemisah |

| Talen tenaga- Brandon Shores | Maryland Amerika Syarikat | 1999 | 2 Pemisah |

| Kuasa Scotland- Stesen Longannet | Scotland UK | 2002 | 1 Pemisah |

| Jacksonville Electric-St. Johns River Power Park | Florida Amerika Syarikat | 2003 | 2 Pemisah |

| South Mississippi Electric Power -R.D. Morrow | Mississippi Amerika Syarikat | 2005 | 1 Pemisah |

| Brunswick Baru Power-Belledune | Baru Brunswick Kanada | 2005 | 1 Pemisah |

| Stesen RWE npower-Didcot | England UK | 2005 | 1 Pemisah |

| Talen Energy-Brunner Island Station | Pennsylvania Amerika Syarikat | 2006 | 2 Pemisah |

| Stesen Selekoh Elektrik-Besaran Tampa | Florida Amerika Syarikat | 2008 | 3 Pemisah two-pass scavenging |

| Stesen RWE npower-Aberthaw | Wales UK | 2008 | 1 Pemisah |

| Stesen Burton EDF Energy-West Burton | England UK | 2008 | 1 Pemisah |

| ZGP (Lafarge Cement /Ciech Janikosoda JV) | Poland | 2010 | 1 Pemisah |

| Kuasa Korea Tenggara- Yeongheung | Korea Selatan | 2014 | 1 Pemisah |

| PGNiG Termika-Sierkirki | Poland | 2018 | 1 Pemisah |

| Taiheiyo Cement Company-Chichibu | Japan | 2018 | 1 Pemisah |

| Armstrong Fly Ash- Eagle Cement | Philippines | Scheduled 2019 | 1 Pemisah |

| Kuasa Korea Tenggara- Samcheonpo | Korea Selatan | Scheduled 2019 | 1 Pemisah |

Tribo-Electrostatic Separation of Bauxite Minerals

Peralatan ST & Teknologi (STET) performed bench scale dry tribo-electrostatic separation testing on multiple samples of bauxite minerals. The samples are listed below in Jadual 2.

Jadual 2. Properties of bauxite samples tested by STET

| Description | Desired Product & Goals | |

|---|---|---|

| Sample 1 | ROM Bauxite | Al2O3 recovery Reduce SiO2, Fe2O3, TiO2 |

| Sample 2 | PLK (Partially Lateritized Khondalite) | Al2O3 recovery Reduce SiO2, Fe2O3, TiO2 |

| Sample 3 | Red Mud | Fe2O3 recovery Reduce SiO2, Al2O3, TiO2 |

| Sample 4 | ROM Bauxite Slimes | Al2O3 recovery Reduce SiO2, Fe2O3, TiO2 |

Chemical composition for all feed and separated product samples was measured by X-Ray Fluorescence (XRF) using a WD-XRF system. The results of the chemical analysis for the feed samples are shown below in Jadual 3.

Jadual 3. Chemical properties of bauxite samples tested by STET

| Al2O3 wt.% | Fe2O3 wt.% | SiO2 wt.% | SiO2 wt.% | LOI wt.% | |

|---|---|---|---|---|---|

| Sample 1 | 43.7 | 25.9 | 3.9 | 2.3 | 23.6 |

| Sample 2 | 34.9 | 19.4 | 28.5 | 2.1 | 14.7 |

| Sample 3 | 19.0 | 52.1 | 6.7 | 4.9 | 11.1 |

| Sample 4 | 34.6 | 23.2 | 18.0 | 4.4 | 18.8 |

Particle size was measured by laser particle size measurement using dry pneumatic dispersion. The results for the feed samples are shown below in Jadual 4.

Jadual 4. Particle size of bauxite samples tested by STET

| D10 micron | D50 micron | D90 micron | D90 micron |

|

|---|---|---|---|---|

| Sample 1 | 2 | 19 | 73 | 118 |

| Sample 2 | 2 | 45 | 575 | 898 |

| Sample 3 | 1 | 27 | 212 | 325 |

| Sample 4 | 1 | 7 | 59 | 93 |

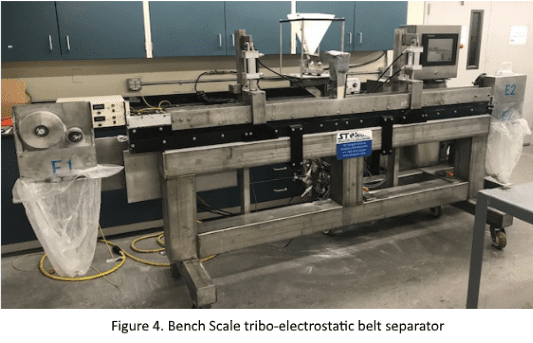

Samples were separated using the STET benchtop separator. The benchtop separator is used for screening for evidence of tribo-electrostatic charging and to determine if a material is a good candidate for electrostatic beneficiation. The primary difference between the benchtop separator and pilot-scale and commercial-scale separators is that the length of the benchtop separator is approximately 0.4 times the length of pilot-scale and commercial-scale units. As the separator efficiency is a function of the electrode length, bench-scale testing cannot be used as a substitute for pilot-scale testing. Pilot-scale testing is necessary to determine the extent of the separation that the STET process can achieve, and to determine if STET process can meet the product targets under given feed rates. Sebaliknya, the benchtop separator is used to rule out candidate materials that are unlikely to demonstrate any significant separation at the pilot-scale level. Results obtained on the bench-scale will be non-optimized, and the separation observed is less than which would be observed on a commercial sized STET separator.

Testing with the STET benchtop separator demonstrated significant movement of Al2O3 with the majority of the samples tested. In three of the four samples tested by STET, substantial movement of Al2O3 was observed. sebagai tambahan, the other major elements of Fe2O3, SiO2 and TiO2 demonstrated significant movement in most cases. In Sample 1, Sample 3 and Sample 4, the movement of loss on ignition (LOI) followed movement of Al2O3. The movement of the major elements is shown below in Rajah 5.

The STET separator is a physical separation process and selectively separates mineral phases based on tribocharging, a surface phenomenon. The degree to which minerals are susceptible to tribocharging is in some cases able to be predicted via consultation of a triboelectric series, but in the case of complex mineral ores, often in practice must be determined empirically. A summary of the tribocharging properties for the samples tested is shown below in Jadual 5.

Jadual 5. Summary of tribocharging behaviour for major elements. POS = charged positive, NEG = charged negative.

| Al2O3 | Fe2O3 | SiO2 | TiO2 | LOI | |

|---|---|---|---|---|---|

| Sample 1 | POS | NEG | NEG | NEG | POS |

| Sample 2 | NEG | POS | NEG | N/A | N/A |

| Sample 3 | POS | NEG | N/A | NEG | POS |

| Sample 4 | POS | N/A | NEG | NEG | POS |

Dry processing with the STET separator offers opportunities to generate value for bauxite and aluminium producers. The utilization of lower grade bauxite deposits may allow for lower mining costs by reducing stripping ratios and by reduced generation of tailings. sebagai tambahan, the pre-processing of bauxite ores by dry triboelectrostatic separation may result in improved economics of aluminium refining by supplying higher grades of bauxite to the refining process, or by reducing volumes of red mud generated. sebagai tambahan, higher aluminium content in red mud may allow for reprocessing. A summary of ideal characteristics for metallurgical grade bauxite is presented, as well as a summary of the benefit of the STET separator, below in Jadual 6.

Jadual 6. Summary of ideal characteristics for metallurgical grade bauxite.5

| Ideal Grade Characteristic | Impact if Inadequate | Observed with STET Separation |

|---|---|---|

| Low “reactive silica” (>1.5% - <3.0%) (kaolinite) | Increases caustic usage, a critical operating cost factor. | Reduction in total silica |

| High extractable alumina | Increases capital and operating costs for mining, processing and mud disposal. | Increase in alumina |

| Low organic carbon | Increases operating costs by reducing plant efficiency. | |

| Low boehmite (<3%) | Precludes low-temperature processing that can increase capital and operating costs. | |

| Low goethite (tolerable in a high-temperature plant or with high hematite) | Slows clarification, lowers product quality and increases alumina loss via mud circuit. | Reduction in total iron |

| Low moisture (can create nuisance dust if too low) | Increases capital costs (larger evaporation facility), fuel consumption, shipping costs. | |

| Iron content (ideally >5%-<15%) | Low iron can lower product quality. High iron dilutes alumina content of bauxite. | Reduction in total iron |

| Low quartz | Increases maintenance costs (pipe wear). Increases caustic usage in high-temperature plants. | Reduction in total silica |

| Low impurities and trace elements | Can lower process efficiency (sulfur, chlorine, calcium) and metal quality (gallium, zinc, vanadium, phosphorus). | |

| Soft and friable | Increases mining and grinding costs. | |

| Dissolves readily | Increases capital (larger digestion equipment) and operating costs. | |

| Low titania | Can increase caustic usage in high-temperature plants. | Reduction in titania |

| Low carbonates | Can require special processing. |

Kesimpulan

Tribo-electrostatic separation was demonstrated as an effective method for generating a high-grade bauxite ore for use in alumina production. Testing with the STET benchtop separator demonstrated significant movement of Al2O3 with the majority of the samples tested. In three of the four samples tested by STET, substantial movement of Al2O3 was observed. sebagai tambahan, the other major elements of Fe2O3, SiO2 and TiO2 demonstrated significant separation in most cases. Dry processing with the STET separator offers opportunities to generate value for bauxite and aluminium producers.

Rujukan

1. Buta, P & Dion-Ortega, A (2013) Tinggi dan Kering, Majalah IKM, Vol. 8, tidak. 4, PP. 48-51.

2. Manouchehri, H, Hanumantha Roa, K, & Forssberg, K (2000), Kajian Semula Kaedah Pemisahan Elektrik, Sebahagian 1: Aspek-aspek asas, Mineral & Pemprosesan logam, Vol. 17, tidak. 1 pp 23–36.

3. Manouchehri, H, Hanumantha Roa, K, & Forssberg, K (2000), Kajian Semula Kaedah Pemisahan Elektrik, Sebahagian 2: Pertimbangan Praktikal, Mineral & Pemprosesan logam, Vol. 17, tidak. 1 pp 139–166.

4. Ralston O. (1961) Electrostatic Separation of Mixed Granular Solids, Elsevier Publishing Company, out of print.

5. Kogel, Jessica Elzea; Trivedi, Nikhil C; Barker, James M; Krukowski, Stanley T.; Industrial Minerals and Rocks: Commodities, Markets, and Uses 7th Edition, (2006), Page 237.