Select Puo:

inahaneloang

ST Helmets & Technology, LLC (STET) e qapa tribo-electrostatic lebanta karohano tsamaiso e khopo e lokisa hore e fana ka indasteri ea matsoai lokisa mokhoa oa ho beneficiate thepa e ntle le e thekenoloji ka ho feletseng omileng. Ho fapana le tse ling tse dithulaganyo electrostatic karohano hore ba ka tloaelo ho lekanyetsoa feela likaroloana moholo ho 75μm ka boholo, le triboelectric lebanta kgaoganyo e sebakeng se loketseng loketseng bakeng sa karohano ea e ntle haholo (<1μm) ho tekano mahoashe (300μm) likaroloana le throughput phahameng haholo. The triboelectric lebanta kgaoganyo thekenoloji 'nile la sebelisoa ho arohana e mengata e fapaneng ea thepa ho akarelletsa le mashala combustion e fofa molora, calcite / quartz, talc / magnesite, barite / quartz, le feldspar / quartz. diphetho karohano tse hlahisoang e hlalosang tribo-lefisa boitšoaro ba ho liminerale bauxite.

Selelekela

Ho haella ha metsi a hloekileng e ho ba ntlha e ka sehloohong e amang ea bokgono ea merero meepo lefatšeng ka bophara. Ho latela Hubert Fleming, pele e neng e mookameli oa lefatše lohle bakeng sa Hatch Metsi, "Ea merero tsohle meepo lefatšeng hore ba e ka ba se ile a khaotsa ho, kapa khoehlisa fetang selemo e fetileng, e bile, hoo e ka bang 100% ba maemong, ka lebaka la metsi, ka ho toba kapa ka tsela e sa tobang ".1 Dry mekhoa matsoai sebetsa fana ka tharollo ea bothata bona tlang.

mekhoa Dry kang karohano electrostatic tla felisa ho hlokahala hore metsi a hloekileng, le fana ka le monyetla oa ho fokotsa ditjeo. mekhoa ea motlakase karohano hore sebelisa ho ikopanya, kapa tribo-motlakase, tjhaja ke dintlha ka botlalo e thahasellisang ka lebaka la bokhoni ba bona ba arohane e le tse ngata tse metsoako e nang le conductive, kokabolaka, le likaroloana seka-conductive.

Tribo-motlakase tjhaja etsahala ha discrete, likaroloana dissimilar a thulana le ba bang, kapa ka holim'a boraro, sephetho le ka holim 'qoso phapang pakeng tsa mefuta e' meli phatsa. pontšo ea ho le boholo ba phapang qoso itšetlehile karolo e 'ngoe ka ho se tšoane ha elektrone amana (kapa mosebetsi mosebetsi) pakeng tsa mefuta e sa phatsa. Karohano ka ka nako eo ho fihlellwa sebelisa ya kwa sebelisoa tšimo motlakase.

mokhoa ona o 'nile sebelisoa industrially ka paatsepama mahala-ho oa mofuta separators. Ka separators mahala-ho oa, likaroloana pele fumana qoso, ebe oe ka matla a khoheli ka sesebediswa sa le hanyetsa li-electrode e sebetsang e matla ea tšimo ea motlakase ho hlokomoloha ka tsela ya likaroloana ka latela letšoao le boholo ba holim charge.2 bona Free-ho oa separators ka ba molemo bakeng sa ho likaroloana mahoashe, empa ha e atlehang ka ho tshwara likaroloana molemo ho feta ka 0.075 ho 0.1 mm.3,4 mong oa ka ho fetisisa tsepisa tsoelo-pele e ncha ka karohano omileng matsoai ke tribo-electrostatic lebanta kgaoganyo. theknoloji ena e atoloswa ho phatsa boholo mefuta e fapaneng ya ho molemo likaroloana ho feta tloaelehileng theknoloji e electrostatic karohano, ka mefuta e fapaneng moo feela flotation e atlehile nakong e fetileng.

Tribo-Electrostatic lebanta arohana

Ka tribo-electrostatic lebanta kgaoganyo (Figure 1 le Figure 2), lintho tse bonahalang feptjoang ka lekhalo tšesaane 0.9 - 1.5 cm, pakeng tsa tse peli tse li-electrode e tšoanang planar. likaroloana li triboelectrically qosoa ke interparticle o ikopanye. Ka mohlala, tabeng ea mashala combustion e fofa molora, motsoako oa likaroloana k'habone le likaroloana matsoai, carbon sebele qosoa le matsoai a hlonamisitsoe qosoa ba khahloa ke li-electrode bo fapaneng. likaroloana li ebe hoholoa ho fihlela ke e tsoelang pele ho fallela lebanta bulehileng-letlooeng le fetisoa ka litaelo bo fapaneng. Lebanta susumelletsa ho likaroloana haufi le e mong le e eleketrode nģ'a lipheletsong fapaneng kgaoganyo ho. Ea tšimo ea motlakase ho hlokahale feela susumelletsa likaroloana karoloana e nyenyane ea disentimitara ka ho fallela ka phatsa tswa letšehali-fallela letona fallisetseng le molapo. The stats jwale phallo ya likaroloana arola le tsoele pele triboelectric tjhaja ke thulana k'habone-diminerale fana bakeng sa karohano selotlolo sethaleng le ho fella ka ho hloka sekoli babatsehang le hlaphoheloe ka unit trust le 'ngoe-fetisetsana. The phahameng lebanta lebelo hape nolofalletsa throughputs phahameng haholo, ho fihlela ho 40 tonnes ka hora ka kgaoganyo e le 'ngoe. Ke ho laola entsprechen tse fapa-fapaneng thulaganyou e, tse kang lebelo lebanta, fepa ka ntlha, eleketrode lekhalo le sekhahla iphepe, sesebediswa hlahisa tlaase k'habone fofa molora ka dikahare k'habone ya 2 % ± 0.5% ho tloha fepa ka fofa molora ho tloha carbon ho tswa 4% ka holimo ho 30%.

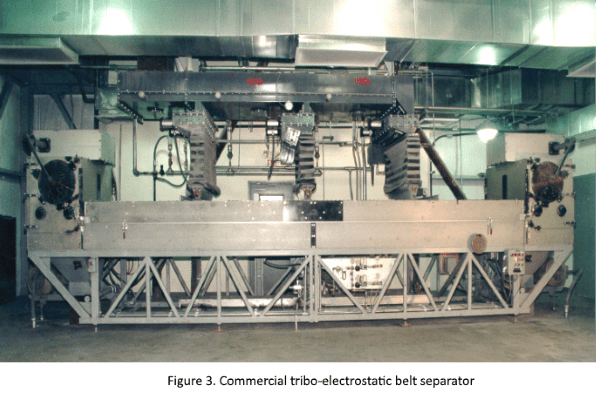

Moralo kgaoganyo ke batlang e bonolo. Lebanta le rollers se amahanngoang ke likarolo feela ho fallela. li-electrode ho ba ema le entsoe ka e lintho tse bonahalang ka nepo tsoarellang. lebanta e entsoe ka lintho tse bonahalang polasetiki. The kgaoganyo eleketrode bolelele ke hoo e ka bang 6 limithara tse (20 feat.) le bophara 1.25 limithara tse (4 feat.) bakeng sa e tletseng boholo diyuniti khoebo. The tshebediso ya matla e ka tlase ho 2 kilowatt-hora ka tonne boitsebiso sebetswa ka ho fetisisa ea matla a chesa ke Motors tse peli khanna lebanta.

tshebetso e ommeng ka ho feletseng, hloka ha thepa tse eketsehileng 'me a hlahisa metsi litšila kapa mesi e kotsi moeeng. Tabeng ea k'habone tloha fofa karohano molora, thepa hlaphoheloa bopilwe fofa molora fokotswa ka dikahare k'habone ho maemo a loketse bakeng sa tshebediso ya ka admixture pozzolanic ka konkreiti s, le phahameng k'habone karoloana e ka chesa ka motlakase fehla motlakase dimela. Tshebediso ya melapo sehlahisoa bobeli e fana ka 100% tharollo ho fofa mathata molora lahla. Bakeng sa karohano matsoai, sebetsa bauxite mohlala, le kgaoganyo fana ka thekenoloji ho fokotsa tšebeliso ea metsi, eketsa pokello bophelo le / kapa hlaphoheloa le reprocess tailings.

The tribo-electrostatic lebanta kgaoganyo ke batlang diseke ee. A mochini etselitsoeng ho sebetsa 40 tonnes ka hora ke hoo e ka bang 9.1 limithara tse (30 feat.) nako e telele, 1.7 limithara tse (5.5 feat.) bophara le 3.2 limithara tse (10.5 feat.) phahameng. Hlokahalang ho leka-lekana ea limela e na le tsamaiso ea ho fetisa boitsebiso bo bongata omileng ho le ho tloha kgaoganyo ho. The compactness ea tsamaiso e lumella tenyetsehe merero tlhomamiso.

The tribo-electrostatic lebanta karohano thekenoloji ke robust le industrially proven, le ile la pele e sebelisoa industrially ho e lokisa ya mashala combustion e fofa molora ka 1995. thekenoloji ke atleha ho arola likaroloana k'habone ho tswa ho go tuka ga molelo fella oa mashala, ho tswa ho le kang khalase le likaroloana aluminosilicate matsoai ka fofa molora. theknoloji e bile phetha karolo nolofalletsa recycle ea matsoai ho rua fofa molora ka Phetolo samente tlhahiso ka konkreiti. Ho tloha 1995, tse fetang 20,000,000 tonnes tsa fofa molora e se e sebetswa ke 19 tribo-electrostatic lebanta separators hlomamisa ka USA, Canada, UK, Poland, le Korea Boroa. Histori liindasteri tsa karohano fofa molora e ngotsweng tafole 1.

tafole 1. Industrial kopo ya tribo-electrostatic lebanta karohano ho fofa molora

| utility / seteishene matla | Location | Qala tshebetso khoebo | dintlha setsing |

|---|---|---|---|

| Duke Energy - Roxboro Station | North Carolina USA | 1997 | 2 Separators |

| lipuo Energy- Brandon Shores | Maryland USA | 1999 | 2 Separators |

| Scotland Power- Longannet Station | Scotland UK | 2002 | 1 kgaoganyo |

| Jacksonville Electric-St. Johns River Power Park | Florida USA | 2003 | 2 Separators |

| Motlakase oa South Mississippi -R.D. Morrow | Mississippi USA | 2005 | 1 kgaoganyo |

| New Brunswick Power-Belledune | New Brunswick Canada | 2005 | 1 kgaoganyo |

| OF npower-Didcot Station | Engelane UK | 2005 | 1 kgaoganyo |

| Seteishene sa Sehlekehleke sa Talen Energy-Brunner | Pennsylvania USA | 2006 | 2 Separators |

| Tampa Electric-Big Bend Station | Florida USA | 2008 | 3 Separators ho qhekella ka makhetlo a mabeli |

| OF npower Aberthaw-Station | Wales UK | 2008 | 1 kgaoganyo |

| EDF Energy-West Burton Station | Engelane UK | 2008 | 1 kgaoganyo |

| ZGP (Lafarge Cement / Ciech Janikosoda JV) | Poland | 2010 | 1 kgaoganyo |

| Korea Boroa-bochabela Power- Yeongheung | Korea Boroa | 2014 | 1 kgaoganyo |

| PGNiG Termika-Sierkirki | Poland | 2018 | 1 kgaoganyo |

| Khampani ea Taiheiyo Cement-Chichibu | Japane | 2018 | 1 kgaoganyo |

| Armstrong Fly Fly Ash- Samente ea Ntsu | Philippines | lokiselitsoe 2019 | 1 kgaoganyo |

| Korea Boroa-bochabela Power- Samcheonpo | Korea Boroa | lokiselitsoe 2019 | 1 kgaoganyo |

Tribo-Electrostatic arohana tsa Bauxite liminerale

ST Helmets & Technology (STET) o ile a etsa bencheng tekanyo e ommeng tribo-electrostatic karohano liteko ka disampole multiple oa liminerale bauxite. disampole a boletsoeng ka tlaase ho tafole 2.

tafole 2. Properties tsa disampole bauxite lekoa ke STET

| Tlhaloso | Sehlahisoa se lakatsehang & Lipakane | |

|---|---|---|

| sampole 1 | ROM Bauxite | Al2O3 ho hlaphoheloa Fokotsa SiO2, Fe2O3, TiO2 |

| sampole 2 | PLC (Partially Lateritised Khondalite) | Al2O3 ho hlaphoheloa Fokotsa SiO2, Fe2O3, TiO2 |

| sampole 3 | Seretse se Sefubelu | Fe2O3 ho hlaphoheloa Fokotsa SiO2, Al2O3, TiO2 |

| sampole 4 | ROM Bauxite Slimes | Al2O3 ho hlaphoheloa Fokotsa SiO2, Fe2O3, TiO2 |

Lik'hemik'hale bakeng sa bohle fepa ka le sehlahisoa arohane disampole ile lekanngoa ka X-Ray khanyang (XRF) sebedisa tsamaiso WD-XRF. Sephetho sa and analysis lik'hemik'hale tsa disampole ho fepa ka ba tse bontšitsoeng tlaase mona ka tafole 3.

tafole 3. Lik'hemik'hale thepa ea disampole bauxite lekoa ke STET

| Al2O3 wt.% | Fe2O3 wt.% | SiO2 wt.% | SiO2 wt.% | LOI wt.% | |

|---|---|---|---|---|---|

| sampole 1 | 43.7 | 25.9 | 3.9 | 2.3 | 23.6 |

| sampole 2 | 34.9 | 19.4 | 28.5 | 2.1 | 14.7 |

| sampole 3 | 19.0 | 52.1 | 6.7 | 4.9 | 11.1 |

| sampole 4 | 34.6 | 23.2 | 18.0 | 4.4 | 18.8 |

Phatsa boholo ile lekanngoa ka mong bang laser phatsa boholo go lekanya sebelisa omileng pneumatici hasana. Sephetho bakeng disampole ho fepa ka ba tse bontšitsoeng tlaase mona ka tafole 4.

tafole 4. Phatsa boholo ba disampole bauxite lekoa ke STET

| D10 micron | D50 micron | D90 micron | D90 micron |

|

|---|---|---|---|---|

| sampole 1 | 2 | 19 | 73 | 118 |

| sampole 2 | 2 | 45 | 575 | 898 |

| sampole 3 | 1 | 27 | 212 | 325 |

| sampole 4 | 1 | 7 | 59 | 93 |

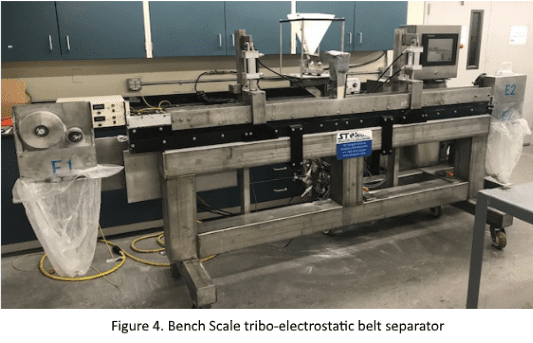

Disampole ile ka khethoa ke sebedisa STET benchtop kgaoganyo. The kgaoganyo benchtop e sebediswa bakeng sa ho screening 'bakeng sa bopaki bo tribo-electrostatic tjhaja le ho fumana hore na lintho tse bonahalang le ke nkgetheng molemo bakeng sa ho beneficiation electrostatic. Phapang e ka sehloohong pakeng tsa kgaoganyo benchtop le motsamaisi-tekanyo e le separators khoebo-tekanyo e ke hore bolelele ba kgaoganyo benchtop ke hoo e ka bang 0.4 linako tse bolelele ba diyuniti motsamaisi-tekanyo e le ea khoebo-tekanyo e. E le bokgoni kgaoganyo ke mosebetsi wa bolelele eleketrode, bencheng ka tekanyo e etsa liteko ka se sebelisoa e le ka nkang sebaka sa liteko motsamaisi tekanyo. Pilot tekanyo liteko ke ke ho hlokahala ho fumana hore na isa tekanyong ea karohano eo tshebetso STET ka fihlella, le ho fumana hore na STET thulaganyou e ka kopana le liphofu sehlahiswa tlas'a ditefello fanoeng iphepe. Ho ena le hoo, le kgaoganyo benchtop e sebediswa ea ho busa tsoa thepa nkgetheng tse hlola a bontša karohano leha e le efe bohlokoa ka boemo ba motsamaisi-tekanyo e. Results fumana ka bencheng ka tekanyo e tla bao e seng optimized, le karohano a hlokomela e ka tlase ho e neng e tla ho ketekoa ka khoebo boholo bo lekaneng STET kgaoganyo.

Testing ka kgaoganyo STET benchtop bontša mokhatlo oa bohlokoa oa Al2O3 le boholo ba disampole e lekiloeng. Ka tse tharo tsa disampole tse 'nè lekoa ke STET, mokhatlo oa mohlomong ba Al2O3 ile a hlokomela. Holim'a moo, likarolo tse ling tse khōlō tsa Fe2O3, SiO2 le TiO2 bontša mokhatlo oa bohlokoa maemong a mangata. ka Sample 1, sampole 3 le Sample 4, motsamao oa le tahlehelo ka thothetsang molelo (MOLAO) lateloa motsamao oa Al2O3. Motsamao oa thepa ea motheo e ka sehloohong e bontšitsoeng tlaase mona ka Figure 5.

The STET kgaoganyo ke 'meleng karohano thulaganyo le khetha arola mekhahlelo e matsoai e thehiloeng tribocharging, le lipono tse makatsang holim. Hore na liminerale tse bonolo hore tribocharging ke maemong a mang khona ho bolela esale pele ka tsela rerisana ya letoto triboelectric, empa tabeng ea rarahaneng tšepe matsoai, hangata e le ka ka go ikatisetsa lokela ho ikemisetsa empirically. A kakaretso ea thepa e tribocharging bakeng disampole e lekiloeng e bontšitsoeng tlaase mona ka tafole 5.

tafole 5. Kakaretso ea tribocharging boitšoaro ba bakeng sa likarolo tse khōlō. POS = qosoa positive,, Dimana = qosoa mpe.

| Al2O3 | Fe2O3 | SiO2 | TiO2 | MOLAO | |

|---|---|---|---|---|---|

| sampole 1 | POS | NEG | NEG | NEG | POS |

| sampole 2 | NEG | POS | NEG | N/A | N/A |

| sampole 3 | POS | NEG | N/A | NEG | POS |

| sampole 4 | POS | N/A | NEG | NEG | POS |

Dry sebetsa le kgaoganyo STET fana le menyetla ea ho hlahisa boleng bakeng bauxite le aluminium bahlahisi. The tshebediso ya le tlaase sehlopheng mobung bauxite 'na a lumella bakeng sa ditjeo tsa ka tlaase meepo ka ho fokotsa dikabo hlobolisa le ka fokotswa moloko oa tailings. Holim'a moo, pele ho tšebetso ea tšepe ea bauxite ka karohano e ommeng ea triboelectrostatic e ka baka moruo o ntlafalitsoeng oa ho hloekisa aluminium ka ho fana ka limaraka tse phahameng tsa bauxite molemong oa ho hloekisa, kapa ka ho fokotsa meqolo e tsa e khubelu seretse generated. Holim'a moo, aluminium dikahare phahame ka khubelu seretse 'na a lumella bakeng sa metamorphism. A kakaretso ea litšobotsi tse loketseng bakeng sa ho metallurgical sehlopheng bauxite e hlahiswa, hammoho le ka kakaretso ba melemo ya kgaoganyo STET, ka tlase ho tafole 6.

tafole 6. Kakaretso ea litšobotsi tse loketseng bakeng sa ho metallurgical sehlopheng bauxite.5

| Sebopeho se nepahetseng sa Kereiti | Tšusumetso haeba e sa lekana | E shebiloe ka karohano ea STET |

|---|---|---|

| "Silika e sebetsang" e tlase (>1.5% - <3.0%) (kaolinite) | E eketsa tšebeliso ea caustic, ntlha ea bohlokoa ea litšenyehelo tsa ts'ebetso. | Ho fokotseha ha silika ka kakaretso |

| Alumina e ntšitsoeng holimo | E eketsa chelete le litšenyehelo tsa ts'ebetso bakeng sa merafo, ho sebetsa le ho lahla seretse. | Keketseho ea alumina |

| Khabone ea tlhaho e tlase | E eketsa litšenyehelo tsa ts'ebetso ka ho fokotsa katleho ea limela. | |

| Boehmite e tlase (<3%) | E thibela ts'ebetso ea mocheso o tlase o ka eketsang chelete le litšenyehelo tsa ts'ebetso. | |

| Goethite e tlase (e mamellehang semeleng sa mocheso o phahameng kapa se nang le hematite e ngata) | E fokotsa ho hlakisa, e theola boleng ba sehlahisoa mme e eketsa tahlehelo ea alumina ka potoloho ea seretse. | Phokotso ea tšepe e felletseng |

| Mongobo o tlase (e ka baka lerōle la tšitiso haeba e le tlase haholo) | E eketsa litšenyehelo tsa capital (setsi se seholo sa mouoane), tshebediso ya mafura, litšenyehelo tsa ho romella. | |

| Likahare tsa tšepe (ideally >5%-<15%) | Tšepe e tlase e ka theola boleng ba sehlahisoa. Tšepe e phahameng e hlapolla alumina e ka har'a bauxite. | Phokotso ea tšepe e felletseng |

| Quartz e tlase | E eketsa litšenyehelo tsa tlhokomelo (ho roala liphaephe). E eketsa ts'ebeliso ea caustic limela tse nang le mocheso o phahameng. | Ho fokotseha ha silika ka kakaretso |

| Litšila tse tlase le likarolo tsa mohlala | E ka fokotsa katleho ea ts'ebetso (sebabole, chlorine, calcium) le boleng ba tšepe (gallium, zinki, vanadium, phosphorus). | |

| E bonolo ebile e bonolo | E eketsa litšenyehelo tsa merafo le ho sila. | |

| E qhalana hang-hang | E eketsa capital (lisebelisoa tse kholo tsa ho sila lijo) le litšenyehelo tsa ho sebetsa. | |

| Titania e tlase | E ka eketsa ts'ebeliso ea caustic limela tse nang le mocheso o phahameng. | Ho fokotseha ha titania |

| Li-carbonate tse tlase | E ka hloka ts'ebetso e khethehileng. |

Qetello

karohano Tribo-electrostatic ile a bontša ka mokhoa e atlehang bakeng sa generating e phahameng-sehlopheng bauxite manya bakeng sa ho sebelisoa ho hlahisoeng ea alumina. Testing ka kgaoganyo STET benchtop bontša mokhatlo oa bohlokoa oa Al2O3 le boholo ba disampole e lekiloeng. Ka tse tharo tsa disampole tse 'nè lekoa ke STET, mokhatlo oa mohlomong ba Al2O3 ile a hlokomela. Holim'a moo, likarolo tse ling tse khōlō tsa Fe2O3, SiO2 le TiO2 bontša karohano bohlokoa maemong a mangata. Dry sebetsa le kgaoganyo STET fana le menyetla ea ho hlahisa boleng bakeng bauxite le aluminium bahlahisi.

References

1. Bislama, P & Dion-Ortega, A (2013) Phahameng le Dry, CIM Magazine, volume. 8, ha ho na. 4, maq. 48-51.

2. Manouchehri, H, Hanumantha Roa, k, & Fors Mountain, k (2000), Tlhahlobo ea Mekhoa ea motlakase arohana, Karolo 1: likarolo tse ka sehloohong, liminerale & Processing Metallurgical, volume. 17, ha ho na. 1 maq 23-36.

3. Manouchehri, H, Hanumantha Roa, k, & Fors Mountain, k (2000), Tlhahlobo ea Mekhoa ea motlakase arohana, Karolo 2: e sebetsang nahanelwa, liminerale & Processing Metallurgical, volume. 17, ha ho na. 1 maq 139-166.

4. Ralston O. (1961) Electrostatic arohana ea dilo tse di komota tsoakane Granular, Elsevier Publishing Company, ha e sa hatisoa.

5. Kogel, Jessica Elzea; Trivedi, Oberoi C; Barker, James M; Krukowski, Stanley T.; Industrial le liminerale le Rocks: thepa ea, Markets, le Sebelisa bo7 Edition, (2006), Page 237.