Họrọ asụsụ:

Kyle Flynn, Abhishek Gupta, Frank Hrach

Abstract

Nyochaa akwụkwọ ederede dị mkpa na-egosi na emeela nchọpụta dị mkpa iji tinye n'ọrụ ọkụ

ụzọ esi kewapụta nri sitere na ihe ọkụkụ (i.e., organic) ihe. Na mmepe ya ngwa ngwa na ihe ndị gara aga 10 - 20 afọ, with many researchers in Europe and the United States applying electrostatic nkewa techniques to a wide variety of beneficiation challenges. Site na nke a research, oputara ihe na electrostatic ụzọ nwere ike n'ịwa ọhụrụ, elu-uru osisi ngwaahịa, ma ọ bụ na-enye onye ọzọ na mmiri nhazi ụzọ. Ọ bụ ezie na na-agba ume iche iche nke cereal ọka, pulse and oilseed materials have been demonstrated at the laboratory and in some cases, pilot scale, sistemu eletriki ejirila gosipụta nsonaazụ ndị a nwere ike ọ gaghị adabara ma ọ bụ akụrụngwa nhazi ọnụ ahịa dị oke ọnụ iji wee ikewapụta ụdị azụmaahịa a.. Ọtụtụ teknụzụ elektrik adịghị mma maka nhazi nke ọma, ntụ dị ala dị ala dịka ihe ọkụkụ. Otú ọ dị, na ST Equipment & Technology (STET) Ihe mgbochi nke eriri triboelectrostatic gosipụtara ike hazie ụmụ irighiri ihe si 500 - 1 μm. The STET belt separator is a high-rate, Ngwaọrụ egosiputara na ngwa oru nwere ike idi nma izuputa ihe nmeghari ohuru na nhazi ihe osisi. A nwalere eriri igwe STET na ntanetị ntụ ọka ọka niile wee hụ na ọ nwere ihe ịga nke ọma iwepu ụdị ahụ na steepụ starch.. A ga-eme onye ga-eme nyocha STET dị iche iche na usoro akara ọka, ntụ ọka

na nsị dị ka soy na lupine.

Keywords: Tribe-Electrostatic, Elektrọnik, nkewa, Nkewa, Ọka, Ọka, Ntụ ọka, Eriri, Nri protin, Mkpụrụ mmanụ, Pulses

Okwu Mmalite

Ejirila ụzọ usoro electrotiiki mee ihe n'oge gara aga 50 afọ na uru nke usoro azụmaahịa nke

ihe ndi ozo n’eghe eji eme ihe na imeghari ihe ndi ozo. Elele elekere ihe ọkụkụ sitere na nri ahịhịa dị na ala akọrọ (i.e, organic) Ihe nyochachaala 140 afọ, na patent izizi maka electrostatic nkewa nke ọka ntụ ọka ọka juru etolite n’oge 1880. [1] Ntinye Electrostatic na-enye ohere maka nkewa dabere na ọdịiche dị iche iche nke onwu (ọrụ ọrụ) ma ọ bụ Njirimara dielectric. N'ụfọdụ, ikewapụ ndị a agaghị ekwe omume site na iji nha ma ọ bụ nbipụta nke naanị. Usoro nkewa nke electromatic na-arụ ọrụ na otu ụkpụrụ ahụ. Usoro usoro nkewa nke electromatic niile nwere otu usoro iji chajụọ ihe, ebe a na-ewepụta ọkụ eletrik maka nkewa iji banye na, na ụzọ esi etinye irighiri akụrụngwa n'ime na mpụga ngwaọrụ nkewa. Nchaji eletriki nwere ike ime site na otu ma obu otutu uzo nke gunyere induction, tribo-odori (kọntaktị elebanye anya) na ion ma obu chaja igbaji. Usoro nkewa nke electromatic na-eji opekata mpe otu n'ime ọrụ ndị a. [2]

Ejirila usoro nke ikewapụta elektrọnik dị n'ọtụtụ ọrụ na ngwa ebe otu

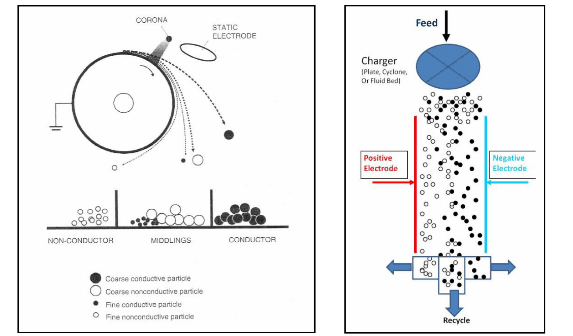

akụrụngwa bụ ihe eletrik karịa ndị ọzọ. Ihe omuma nke ngwa nke oghawara ogba aghara di iche iche na - etinye titanium nke na - eke ndi nwere ihe nkpa, yana ngwa imegharị ihe, dịka ọmụmaatụ metal na-ekepụta metal site na rọba. E nwere ọtụtụ ọdịiche na geometries eji maka sistemụ mpịakọta dị elu, ma n'ozuzu, ha na-arụ ọrụ na yiri ụkpụrụ. Ndepụta ahụ na-ebubo na-ezighị ezi site ionizing corona orùrù. Ndepụta ahụ na-chụgara jidesie a n'usoro n'usoro drum, ebe drum na-electrically ebe. The electrically conductive ahụ mbà ha ụgwọ n'elu ịkpọtụrụ elu nke ebe drum. Adiana nke drum akpata conductive ahụ a tụbara si n'elu drum na-edebe ke akpa ngwaahịa hopper. The na-abụghị conductive ahụ idowe ha eletriki ụgwọ ma na-pinned ka elu nke drum. N'ikpeazụ, eletriki ụgwọ na-abụghị conductive ahụ ga dissipate, ma ọ bụ ndị ahụ ga-leghaara si drum mgbe drum ka na-agba gburugburu nke mere na ndị na-abụghị conductive ahụ na-edebe ke-abụghị conductive urughuru hopper. Na ụfọdụ ngwa, a middlings hopper etinye n'etiti conductive na-abụghị conductive ngwaahịa hopper. Ofdị nke ụdị nke nkewa a bụ sọsọ oke maka urukurubụba nke nwere obere ike na / ma ọ bụ nwee ike ndọda, n'ihi mkpa ọ bụla iji metụ elu nke drum ahụ. Na mgbakwunye, urughuru na-agbanye ike dị mkpa ka ihe na-adọ adọ adọ wee dị na-ahụ maka ibuga ụmụ irighiri mmiri ahụ gaa na mmiri dị iche iche.. Akpukpo ikuku na urukurubụba dị ala na-emetụta ikuku dị mfe ma si otú ahụ yie ka ị ga-atụpụ ya site na drum na mpaghara amụma. [2] [3] [4]

Nnukwu esemokwu dị iche iche dị iche iche bụ ụdị dịgasị iche iche nke mpịakọta esemokwu dị elu akọwapụtara n'elu. A na-ekesasị ụdị nri were were were gafee obosara nke eriri ebu ala. A na-akwụ ụgwọ maka ihe, na-abụkarị site na corona na-adịghị mma, n'agbanyeghị na usoro ndị ọzọ nke odori ike. Ọzọ, conductive ahụ nye ha eletriki ụgwọ ruo ebe ebu belt, mgbe ndị na-abụghị conductive ahụ idowe ha ụgwọ. The conductive ahụ dapụ nke ihu belt site ike ndọda, mgbe ebubo ndị na-abụghị conductive ahụ bụ "weliri" anya nke elu nke belt site electrostatic agha. Ọzọ maka nkewa na-adị irè, onye ọ bụla urughuru ga kpọtụrụ elu nke belt ka ohere maka conductive ahụ na-enye ha ụgwọ ájị. Ya mere, naanị otu oyi akwa nke ahụ pụrụ igosipụta na separator otu mgbe. Dị ka urughuru size nke na ndepụta na-aghọ nta, nhazi ọnụego nke ngwaọrụ na-ebelata. [5] [6]

Parallel efere electrostatic separators na-a dabeere na n'elu kewara ahụ abụghị ihe na-adabere conductivity, ma na iche iche na n'elu onwu na-enye ohere maka eletriki ụgwọ nyefe site frictional kọntaktị. Ahụ na-electrically boro ebubo site ike na kọntaktị na ndị ọzọ ahụ, ma ọ bụ na a atọ n'elu dị ka a metal ma ọ bụ plastic ga-chọrọ tribo-odori Njirimara. Materials na-electronegative (dị na-adịghị mma na njedebe nke tribo-electric usoro) wepu electrons si tribo-odori elu ma si otú nweta a net ọjọọ ụgwọ. na kọntaktị, ihe na-na mma njedebe nke tribo-electric usoro inye electrons na-elekọta ghaghị. The ebubo ahụ na-mgbe ahụ ẹkenam n'ime ihe ọkụ ubi eme n'etiti abụọ yiri efere electrodes site iche iche na njem n'aka (ndọda, pneumatic, vibration). Na ọnụnọ nke electric ubi, na ebubo ahụ gaa oppositely ebubo electrodes na-anakọtara na kwekọrọ ekwekọ ngwaahịa hoppers. ọzọ, a middlings nta nwere a ngwakọta nke ahụ nwere ike ma ọ ike ikpokọta, dabere na nhazi nke nkewa ngwaọrụ. [4] [7]

Ọgụgụ 1: Osise nke a elu erughị ala mpịakọta separator (ekpe) na a yiri efere free ọdịda separator (nri).

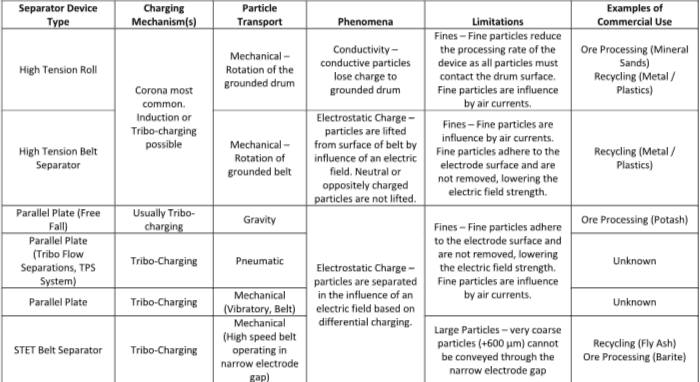

Isiokwu 1: Nchịkọta nke ọtụtụ ndị na-eji electrostatic nkewa ngwaọrụ.

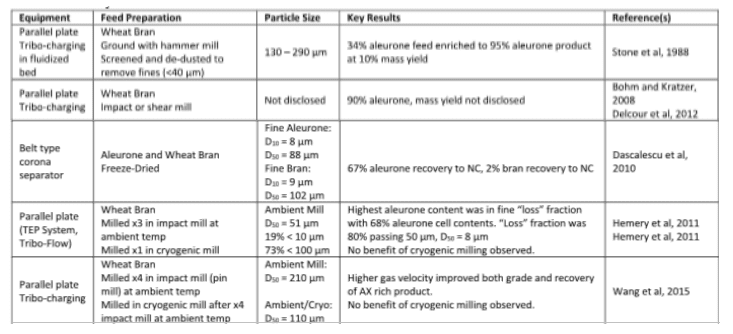

Ileba 1 - Wheat na Wheat bran Beneficiation.

Wheat bran bụ a site-ngwaahịa nke ot wheat-egwe ọka, na-anọchite anya 10-15% nke wheat na ọka. Wheat bran mejupụtara nke elu n'ígwé gụnyere pericarp, isi, na aleurone. Wheat bran nwere ọtụtụ ndị micronutrients, eriri, na phytochemicals dị na ọka, nke gosiri ike uru ụmụ mmadụ. [8] Enweela mmasị dị ukwuu maka ikewa na ịba uru na ọka wit. Mmasị akụkọ ihe mere eme nkewapụ n'iche ọka bụ iji mee ka mma na uru nke ngwa ọka ahụ dị mma. Otú ọ dị, Achọpụtawo mmasị ọzọ na-adịbeghị anya na iweghachi ihe bara uru sitere na ọka wit.

na 1880, Thomas Osborne gbadoro onye mbụ na-ere ahịa electrostatic maka iwepu bran na ntụ ọka. Nkewa nwere nke mpịakọta nke roba siri ike ma ọ bụ ihe ọ bụla kwekọrọ na ya nke nwere ike ịbụ onye e boro ebubo eletriki site na iji ajị anụ. Ọ bụ ezie na akọwaghị ya, a na-ewere ya na mpịakọta rọba nwetara ụgwọ na-adịghị mma gbasara ajị anụ, na-agbanwe agbanwe na ọtụtụ usoro tribo-electric. Na-acha odo odo na-acha ọkụ mgbe ahụ dọtara ụmụ irighiri akụrụngwa nke nwere ngwa ahịa, na-ebugharị ha n’elu mpịakọta ahụ ruo mgbe a ga-awụ ya n’elu eriri ahụ. Nke a (chere) Nchapu nke ọka wheat na-emegide ihe ndị ọzọ gosipụtara. Ejiri nnyemaaka nke obere ihe ndị ahụ site na ikuku ikuku ewepụtara na ala ngwaọrụ ahụ, nke nwere abamuru nke ọzọ nke ime ka obere ahụ dị ala na-adị ala, ikpere nso na mpịakọta ahụ. [1]

na 1958 Egosiputara ngwa oru maka electrostatic nkewa nke bran na endosperm nke di n’ime ntụ ọka n’otu n’ime ya ka a gosiputara n’otu ihe omuma nke Branstad na aru oru General Mills. The ngwaọrụ gụnyere a yiri efere separator na nke ahụ na-ekekpepde n'etiti abụọ efere site vibration. bran ahụ, boro ebubo site frictional kọntaktị na endosperm ahụ, mgbe ahụ weliri n'elu electrode site perforations na n'elu electrode. [9]

na 1988 ihe ngwa na usoro maka agbake aleurone si azụmahịa wheat bran e mara na a patent ịgba akwụkwọ. Commercial wheat bran na a na-amalite aleurone ọdịnaya nke 34% e mma ka a uche nke 95% na 10% uka mkpụrụ (28% aleurone mgbake) site a Nchikota hama-egwe ọka, sizing site echetakwa, ikuku elutriation na electrostatic nkewa eji a yiri efere electrostatic separator. Ahụ e boro ebubo na ikuku elutriator ngwaọrụ, nke nwere a sọrọ ọrụ nke wepụ Iwu (<40 μm) site n'ibu, ebe ị na-egwu bogba asịrị ndị ahụ dị mma (na - akukota na platerode electrode na-adịghị mma) na ụmụ irighiri mmiri pericarp / testa adịghị mma. Ejiri nlezianya na igwe na-enyocha ogo nke ngwakọta ika ahụ nke ọma, iji nweta udiri nri kariri nke ha 130 - 290 rangem nso. [10]

Ọrụ na-adịbeghị anya na-agbake aleurone na ọka wit na-aga n'ihu. na 2008, Buhler AG tụkwasara ngwaọrụ nkewa nke electromatic iche maka irighiri akwara si na shei mere nke commised bran. Otu ihe eji eme ya bu igwe rotor nke na-aru oru n’ebe ogugu di warawara, nke na-enye ohere ka o nwee ike ime ka irighiri ihe na nrube ya na mgbidi gaa n'ihu. A na-enyezi ihe ahụ eji ebu ma dozie ya n'ime arịa nkewa nke nwere electrodes plate dị na ya. Ọkpụkpụ na-adaba na arịa nkewa site na ike ndọda, dị ka ụmụ irighiri ihe dị iche iche na - agagharị na electrodes ndị ebubo na - akwụ ụgwọ n'okpuru ike nke mpaghara eletriki. [11] Mgbe jikọtara ya na mma sizing nke ndepụta bran na n'ibu usoro usoro, anabatacha ndọrọndrị ruo 90% akọla. [12] [8]

Ọgụgụ 2: Bipụtaghachiri si Hemery et al, 2007 [8].

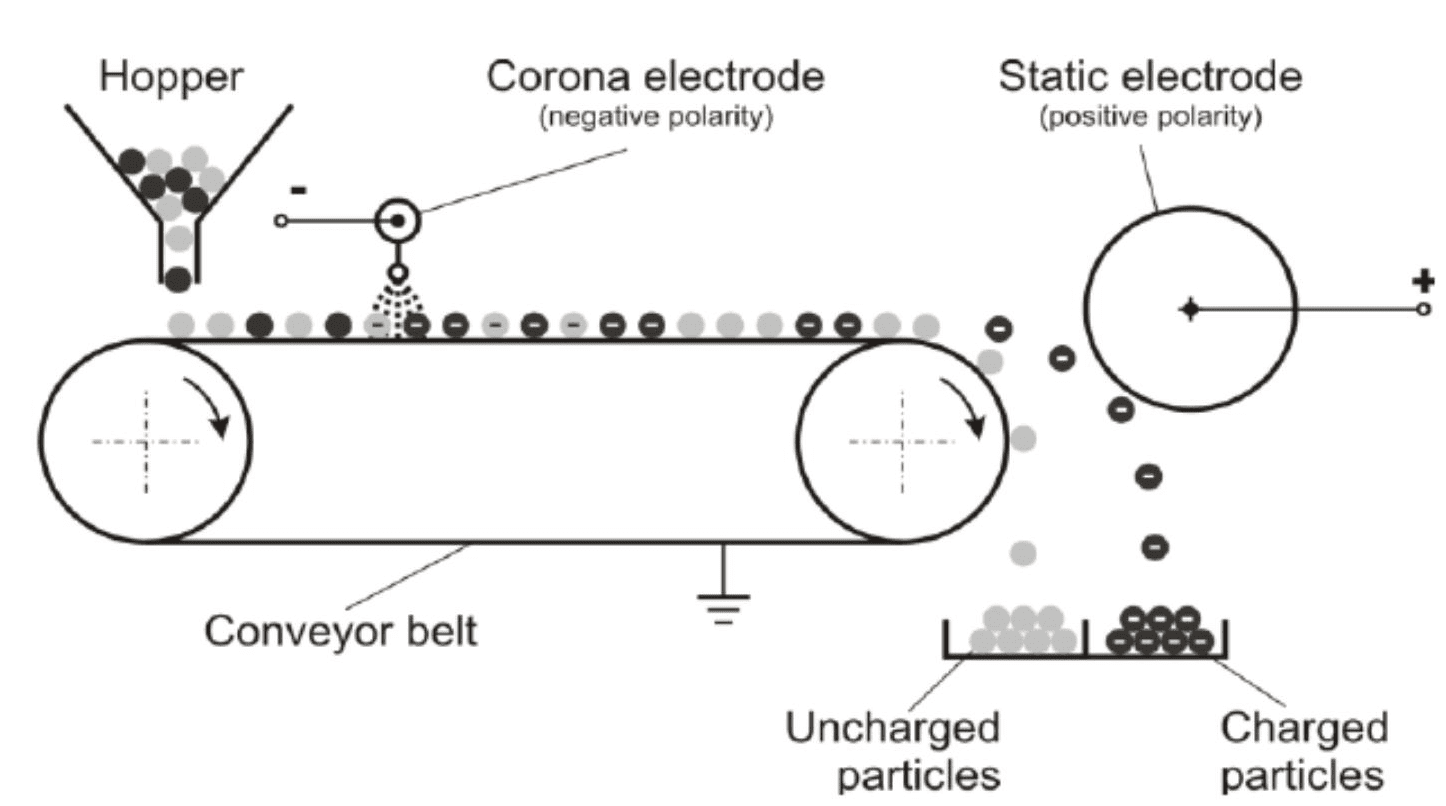

Tribo-odori na corona odori nwere na wheat bran e rụrụ site na ọrụ na Electrostatics nke chụgara Media Research Unit, University of Poitiers, France na 2010. The na-eme nnyocha tụọ elu ụgwọ na elu nwere ire ere oge on wheat bran na 10% mmiri ma lyophilized (ifriizi-Fikiere) wheat bran. A nkewa ule e rụrụ na a sample nke 50% ifriizi-Fikiere wheat bran na 50% ifriizi-Fikiere aleurone oriri iji a belt ụdị corona electrostatic separator. (Ọgụgụ 3) Nkewa results maka laabu ọnụ ọgụgụ corona separator gosiri 67% nke aleurone e natara na-abụghị eduzi hopper, mgbe naanị 2% nke wheat bran kọọrọ ndị na-abụghị ndị na-eduzi ya hopper. Tribo-odori nwere na-eduziri wheat bran na aleurone, ma naanị tụọ kpọmkwem n'elu ụgwọ [μC / g] eme na nke ọ bụla nta, ka megide na-agbake ngwaahịa ihe electrostatic nkewa. Ma na ndepụta ihe ndị e boro ebubo iji Teflon ka kọntaktị n'elu. Ma wheat bran na aleurone na-kọrọ dị ka odori mma ikwu na Teflon, nke ya onwe ya bụ nnọọ electronegative. The ịdị ukwuu nke ihe-ndebe e hụrụ na-adabere na ọrụ nrụgide ji na tribo-chaja, atụ aro na elu ịgbā eduga ọzọ kọntaktị na ndị ọzọ zuru ezu tribo-Nchaji. [13]

Ọgụgụ 3: Bipụtaghachiri si Dascalescu et al, 2010 [13]

na 2009, na-eme nnyocha inyocha ndị electrostatic odori Njirimara nke aleurone ọgaranya na pericarp ọgaranya oriri ihe. [14] na 2011 na-eme nnyocha rụrụ electrostatic nkewa ule na samples of finely ground wheat bran eji a pilot ọnụ ọgụgụ electrostatic efere separator (TEP System, Tribo Flow nkewa, Lexington, USA). The TEP System utilizes a Nchaji akara, ebe oriri ahụ na-ẹkenam n'ime a jupụtara n'ọgba aghara abịakọrọ ikuku stream, na pneumatically ekekpepde site Nchaji akara na nkewa ulo. The ahụ na-tribo-boro ebubo site na urughuru na urughuru kọntaktị, nakwa dị ka urughuru na kọntaktị na elu nke Nchaji akara. Results nwetara na TEP System gosiri na electrostatic nkewa dị irè na upgrading aleurone na beta-glucan ọdịnaya nke wheat bran. na-akpali mmasị, mpekere nke ihe achọpụtara nwere ọdịnaya sel kachasị mma, na 68%, dị mma nke ukwuu (D50 = 8 μm) akụkụ nke gbakere na ọkpọkọ nkwụghachi. Anabataghi ihe kpatara eji etinye ihe omimi a na ngwa nchaji, Otú ọ dị, o gosiputara na ikike hazie ihe gbasara mkpụrụ ndụ akwara nwere ike ịchọ usoro iji mepụta ike dị mma. Ọzọkwa, Ọrụ a gosipụtara na nhazi nri maka ọka wit bụ ihe dị mkpa. N'omume na-akwadebe site cryogenic egweri na a hama na nkume igwe nri a chọpụtara na ha na-na-erughị kpamkpam dissociated (tọhapụrụ atọhapụ) karịa ndị ala mmetụta ụdị nkume igwe na ihere okpomọkụ. [15] [16]

Ọgụgụ 4: Bipụtaghachiri si Hemery et al, 2011 [16]

Adịbeghị anya na-arụ ọrụ na-amụ ịta nke arabinoxylans si wheat bran site electrostatic ụzọ. The na-eme nnyocha tinye n'ọrụ a laabu ọnụ ọgụgụ electrostatic separator esịnede a odori tube na nkewa ulo nwere abụọ yiri efere electrodes. Milled wheat bran ẹkenam n'ime odori tube na ekekpepde pneumatically n'ime nkewa ulo iji abịakọrọ nitrogen. The ịgbā na elu gas ike ọsọ na odori tube nyere urughuru kọntaktị mkpa maka tribo-Nchaji. The ebubo ahụ (ngwaahịa nke nkewa) na-anakọtara site na elu nke electrodes maka analysis. N'ihi na vetikal nghazi nke electrodes a ịrịba ego nke ihe onwunwe e bụghị anakọtara. Enwere ike iji mpempe akwụkwọ a na-emezigharị emezigharị maka nhazi ọzọ na electrostatics, Otú ọ dị, maka nzube nke nnwale a, A na - ahụta ihe anakọghị na electrodes. Ndị nyocha ahụ kọpụtara mmụba na ọkwa ngwaahịa abụọ a (arabinoxylan ọdịnaya ngwaahịa a) na nhazigharị nkewa ka ọkụkụ na-abawanye. [17]

Mgbalị ndị a na-eme n'oge na-adịbeghị anya iji rite uru ọka wit na-eji usoro electrostatic chịkọtara n'okpuru Table 2.

Isiokwu 2: Nchịkọta nke usoro ụzọ electromatik iji rite uru na ọka wit.

Ileba 2 - Protein Recovery si Lupine ntụ ọka

Eme nchọpụta na Food Usoro Engineering Group na Wageningen, Mba netherland, inyocha ike protein inwetara iji legumes. Agwa na lupine ntụ ọka e ji dị ka azụ maka a dịgasị iche iche nke protein inwetara usoro tinyere ikuku nhazi ọkwa jikọtara na electrostatic nkewa. Untreated agwa na lupine osisi na-akpa milled ihe dị ka 200 μm. Ndepụta ihe maka nhazi ọkwa na electrostatic nkewa na-ekemende milled iji mmetụta ụdị nkume igwe na esịtidem classifier (Hosokawa-Alpine ZPS50). Midia urughuru size (d50) kọrọ dị ka ihe dị 25 μm maka agwa ntụ ọka, na ihe dị ka 200 μm maka lupine ntụ ọka, tupu ikuku nhazi ọkwa. N'ikpeazụ, a subset nke ọ bụla sample, agwa na lupine ntụ ọka, mgbe ahụ ikuku na nkewa (Hosokawa-Alpine ATP50). Ndepụta na electrostatic separator gụnyere ma untreated flours, nakwa dị ka N'ezie na ịrụ ezi ngwaahịa si ikuku nhazi ọkwa. [18]

The electrostatic nkewa ngwaọrụ eji mee ihe n'oge nwere bụ a yiri efere ụdị, na Nchaji rụrụ via triboelectric Nchaji na a 125 mm ogologo Nchaji tube, na ahụ ekekpepde pneumatically site abịakọrọ nitrogen. The ngwaọrụ bụ yiri na nhazi na ngwaọrụ eji Wang et al (2015). [17] Electrostatic nkewa nwere e duziri na ala agwa ntụ ọka na lupine ntụ ọka, yana usoro ya na ezi nke pea flour na ntụ ọka lupine enwetara site na nhazi ikuku. Ntụ ọka ahụekere gosipụtara naanị obere mmegharị nke protein n’oge a na-ele elele. Otú ọ dị, ntụ ọka lupine gosipụtara mmegharị protein dị ukwuu na sample atọ a nwalere (ntụ ọka milled - 35% protein, milled fines - 45% protein, milled keadighi oke - 29% protein). Ngwa ahịa bara ụba nke protin 60% Eweputara na ala electrode nke ọ bụla n’ime lupine sample atọ anwalere. [18]

Ileba 3 - Wepụ eriri sitere na ọka

Eme nchọpụta na Department of Agricultural na Biological Engineering, Mississippi State University rụrụ electrostatic ule na ala ọka ntụ ọka, na ebumnobi nke wepụ eriri. The electrostatic nkewa ngwaọrụ gụnyere a ebu belt na a na-adịghị mma electrode enịm na njedebe nke na-ebu. The ghaghị ebubo ahụ, eriri ahụ, n'okwu a, e bupụrụ ebu belt na ota n'ime a abụọ hopper. Akụkụ ndị na-abụghị eriri wee daa na eriri ebupụ site na ike ndọda ma debe ha na hopper ngwaahịa mbụ. Ndị dere anaghị akọwapụta otu esi etinye chaja eletriki. Nri akụrụngwa nke onye na-ekewapụsị a bụ ihe dị ọcha, na urughuru nha nke ndepụta sitere na 12 ntupu (1,532 μm) ka 24 ntupu (704 μm). Ọ pụtaghị na ihe erughi eru (<704 μm) A haziri ihe omume n’oge ọmụmụ a. Emechara ọnọdụ ule ọ bụla site na iji ya 1 n'arọ nke ihe oriri nke na-agbasasịkwa n'ofe eriri. [6]

Ọgụgụ 5: Mepụtara site na Pandya et al, 2013 [6]

Ndị nchọpụta Mississippi State mezuru ule nkewa nke electromatic na ọka ọka na-enweghị akwụkwọ, na ekpuchi ọka ntụ ọka fractions na eriri-ọgaranya fractions napụtara n'aka ikuku nhazi ọkwa. Electrostatic ule e dechara na ala-na-eriri iyi napụtara n'aka ikuku nhazi ọkwa. Analysis nke pụta nke electrostatic nkewa na-nyere n'okpuru:

Isiokwu 3: Results nke eriri nkewa aruputaghari si Pandya et al, 2013 [6]

Ileba 4 - Protein Ịta si Oilseeds

Oilseeds dị ka rapeseed (canola), sunflower, sesame, mustard, soybean-ọka izizi, na flaxseed n'ozuzu nwere a ọkpụrụkpụ ego nke ma protein na eriri. Nhazi teknụzụ iji wepu eriri ahụ, ma si otú a mee ka ihe ndị nwere protein na-aba ụba, nke mmanụ ga - adịwanye mkpa ka ihe ụwa chọrọ maka protin na-abawanye. [19] Ọrụ ndị na-eme nchọpụta na Nationallọ Ọrụ Mba Na-ahụ Maka Ọrụ Ugbo na France nyochachara mkpụ ọka ultrafine yana nhazi nri mkpụrụ osisi sunflower., itinye protein n’ọrụ. Nri nri anịla na-eri nri bụ nke dị n'okirikiri mmetụta a na-arụ na-arụ ọrụ na ọnọdụ amamịghe wee nwee nha (D50) nke 69.5 μm. The electrostatic separator eji maka ule bụ a yiri efere ngwaọrụ ebe bụ isi Nchaji usoro bụ tribo-Nchaji. The tribo-Nchaji e rụrụ upstream nke electrodes na a tribo-odori akara, na ahụ ekekpepde site Nchaji akara, na na electrodes, via pneumatic iga. Protein e hụrụ na-ana nti (kọọrọ ọjọọ electrode) na eriri-ọgaranya nta e hụrụ na-ana na-ezighị ezi. Protein selectivity e hụrụ na-elu. Ndepụta protein bụ 30.8%, ya na ịba ụba protein 48.9% na protein na-agbari (bara ọgaranya) naanị ịlele ngwaahịa 5.1% protein. Mgbake protin bụ 93% ruo ezigbo ngwaahịa. Cellulose, hemicelluloses, na lignin tụọ wee hụ ka ọ kọọrọ ngwaahịa a na-anaghị akwụ ụgwọ, na nke protein. [20]

Isiokwu 4: Nsonaazụ nke mkpụrụ osisi sunflower sitere na Barakat et al, 2015 [20]

na 2016, emejuputara omumu ihe omumu site na iji nri nkpuru mmanu nri, ma ọ bụ achicha mmanụ (ROC), dika ntinye aka na nhazi nkewa nke electromatic. Ọzọ ultrafine-egwe ọka na ihere okpomọkụ e rụrụ iji a mma na nkume igwe nri ngwaọrụ (Retsch SM 100). The milled ihe, na a etiti urughuru size (D50) nke na mkpokọta 90 μm, e esichara iji a pilot ọnụ ọgụgụ yiri efere separator (TEP System, Tribo Flow nkewa). The TEP System utilizes triboelectric Nchaji site pneumatic erute nke ahụ site na a elu nsogbu Nchaji akara n'okpuru jupụtara n'ọgba aghara ọnọdụ. A otu ngafe nkewa ule na TEP System rụpụtara na ịrịba ịta nke protein, na a oriri protein nke 37%, oke ike protin nke ngwaahịa 47% na ọkwa protin ngwaahịa nke na-adịghị mma 25%. Emere nkebi nkewa ọzọ, emesịa mepụta ngwaahịa nwere protein bara ụba 51% protein mgbe 3 nkewa nkewa nkewa. [21]

Isiokwu 5: Nsonaazụ nke nri mkpụrụ osisi rapeseed sitere na Basset et al, 2016 [21]

Nkwurịta

Nyochaa akwụkwọ ndị dị mkpa na-egosi na emeela nchọpụta dị mkpa iji zụlite usoro nkewa nke electromatic maka ihe ndị sitere na Organic. Nke a development anọgidewo ma ọ bụ ọbụna accelerated na n'oge gara aga 10 - 20 afọ, na ọtụtụ na-eme nnyocha na Europe na United States n'itinye electrostatic nkewa usoro a dịgasị iche iche nke beneficiation nsogbu. Site na nke a research, o doro anya na electrostatic ụzọ nwere ike n'ịwa ọhụrụ, elu uru osisi ngwaahịa, ma ọ bụ na-enye onye ọzọ na mmiri nhazi ụzọ.

Ọ bụ ezie na na-agba ume iche iche nke ọka, pulses, na oilseed ihe e gosiri na laabu na ụfọdụ pilot ọnụ ọgụgụ, na electrostatic usoro eji na-egosi na ndị a na-arụpụta nwere ike n'ikpeazụ bụghị eje ozi dị ka ndị kasị mma ma ọ bụ na-eri-irè nhazi akụrụngwa na-arụ dị otú ahụ nkewa na a azụmahịa ndabere. A na-ejikarị usoro sistemumazụ azụmaahịa dị adị na nkewa nke mineral, ọla ma ọ bụ plastik. Ma mineral ma ọla bụ ihe ndị dịtụ mkpirisi na nnukwu ikike ha, dika aturu osisi. N'agbanyeghị nnukwu ike nke mineral na ọla, Ikike oke urukurubụba na -eme ihe ngosipụta maka ihe egwu mmiri na oghere efere electrostatic nkewa bụ obere ihe, ya na ugba ole na ole n’okpuru 100 form maka ihe atụ. Plastik nwere ntakịrị nha karịa ma mineral na ọla mana a na-edozi ya na nha urughuru, dị ka plastik flakes dịka ọmụmaatụ. The introduction of fine particles creates operational difficulties for both high-tension roll and parallel plate separators. Ọma, Mkpụrụ irighiri ihe pere mpe nwere mmetụta miri emi na oke ikuku, ọkachasị ma e jiri ya tụnyere mineral na ọla. Obere ọdịiche dị na ikuku ikuku dị n’ime ngwaọrụ nkewa na-emetụta ụzọ njem nke aghịrịrị ahụ, na-edo ha agha ndị ọzọ karịa ndị mere site electrostatic ubi.

N'ihi na ọtụtụ yiri efere separator usoro, finely n'ala na ala-na-njupụta ahụ na-electrostatically ebubo na-anakọtara na electrodes nke yiri efere separators. Ọ bụrụ na ndị a mma electrically mmasị ahụ na-adịghị wepụrụ na a mgbe nile na-ndabere, na electric ubi ike na arụmọrụ nke ngwaọrụ degrade. The ọrụ nke na-eme nnyocha na The Food Usoro Engineering Group Wageningen Ua (Wang et al, 2015) wee uru nke a onu na-anakọta samples n'elu nke electrodes nke yiri efere separator inyocha ihe na ngwaahịa nke nkewa. Parallel efere separator usoro, karịsịa ndị na-adabere n'ebe ndọda ime ahụ site electric ubi, nwere nwara iji lebara nsogbu a na ọtụtụ ụzọ. Stone et al (1988) kọwara a usoro nke ezi ahụ e wepụrụ upstream nke electrostatic separator site n'ikuku elutriation. [10] Ndị ọzọ akọ akụkọ na-enwe mmiri laminar nke ikuku na-agafe na electrodes iji gbochie ụmụ irighiri ikuku nke ikuku na-emetụta.. [22Otú ọ dị, ịnọgide na-enwe ikuku laminar na-abụ ihe ịma aka ka ngwaọrụ nkewa na-ebuwanye ibu, na-egbochi ikike nhazi nke ngwaọrụ ndị a ọfụma. Na ngwụcha nke urughuru nke akụkụ ya dị iche na nke ọzọ (dị ka ụrọ pụrụ iche), ga - abụ onye kacha akwọ ụgbọ mmiri na - achọpụta oke urughuru nke nhazi ọrụ ga - eme.

Dị ka e kwuru na mbụ, ot electrostatic nkewa na ngwaọrụ na-ejedebeghị na nhazi ike, especially with low-density and finely ground powders such as plant materials. For high-tension drum and belt separation devices, ịdị irè na-ejedebeghị na irighiri ihe ndị dị ntakịrị na / ma ọ bụ nwere nnukwu ike ndọda, n'ihi mkpa ọ bụla iji metụ elu nke drum ahụ. Dị ka ahụ na-nta nhazi ọnụego na-ebelata. Parallel efere separators na-n'ihu ejedebeghị site na urughuru njupụta na ike ga-esichara na electrode mpaghara. Urughuru loading ga-dịtụ ala igbochi ohere ụgwọ mmetụta.

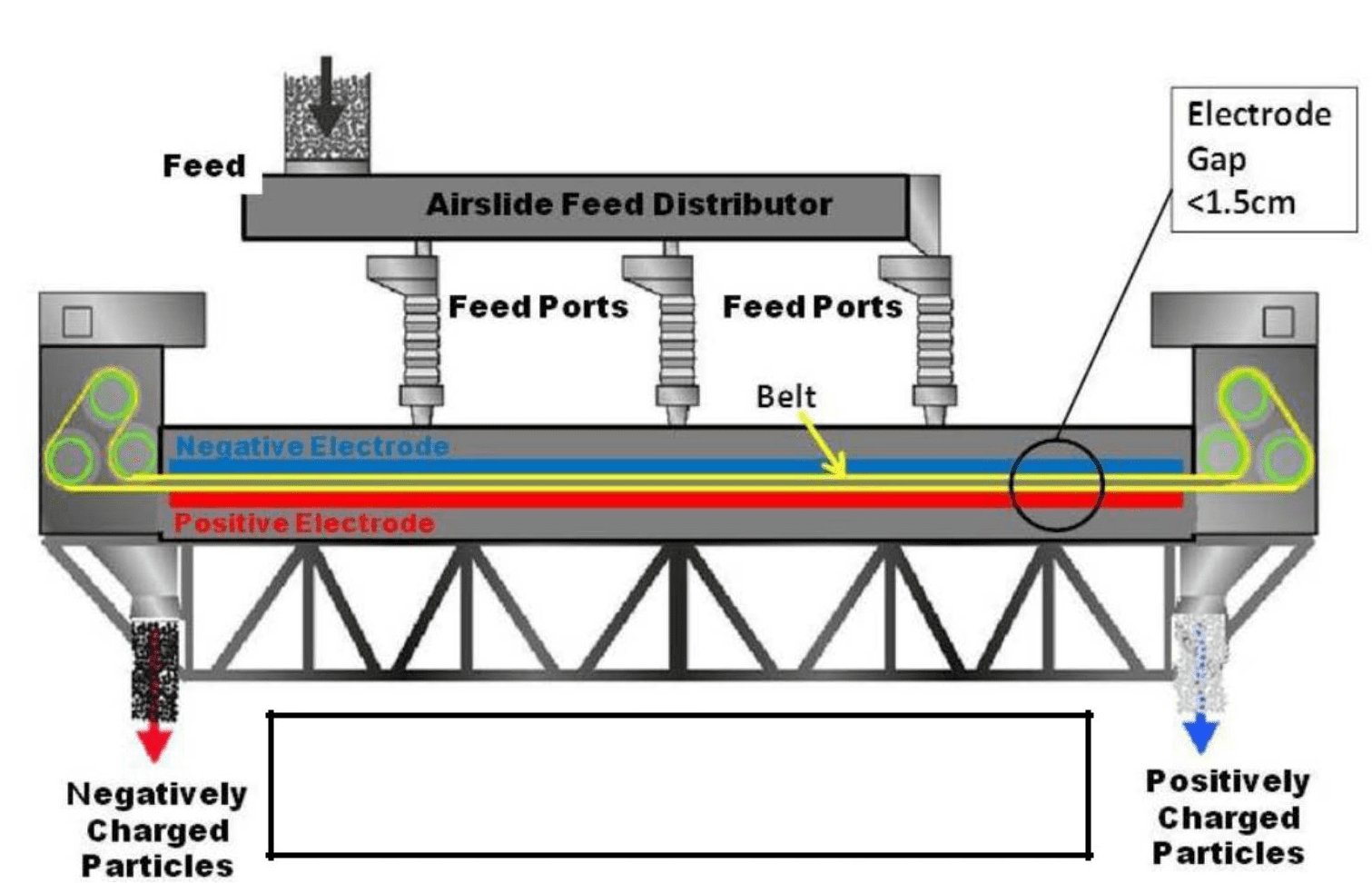

ST Equipment & Technology-echebe Mmadụ separator

The ST Equipment & Technology (STET) triboelectrostatic belt separator nwere gosiri ike hazie iwu ahụ si 500 - 1 μm. The STET separator bụ ihe yiri efere electrostatic separator, Otú ọ dị, na electrode efere na-agba mbọ ịgbasapụ ka megide ekwesị dị ka ọ na ọtụtụ ihe yiri efere separators. (Lee Ọgụgụ 6) Ọzọkwa, na STET separator emezu urughuru tribo-odori na-erute n'out oge site a elu-ọsọ na-emeghe ntupu ebu belt. Nke a na atụmatụ-enye ohere maka ma a nnọọ elu kpọmkwem nhazi ọnụego nke oriri, nakwa dị ka ike hazie ntụ ọtụtụ mma ka ot electrostatic ngwaọrụ. Nke a na ụdị nke nkewa ngwaọrụ anọwo na azụmahịa ọrụ kemgbe 1995 kewara unburned carbon si ada uyi minerals (ahụkarị D50 odika 20 μm) na coal-chụọ n'ọrụ ike osisi. Nke a electrostatic nkewa ngwaọrụ nwekwara ihe ịga nke ọma na beneficiating ọzọ inorganic ihe, gụnyere mineral ndị dị otú ahụ dị ka calcium carbonate, talc, barite, na ndị ọzọ.

The isi nkọwa nke STET separator na-e gosiri na ọgụgụ 7. A na-anakpo ururu ihe ahụ site na triboelectric mmetụta site na nchikota urughuru na-urughuru ihe dị n'etiti oghere dị n'etiti electrodes. Volta etinyere n’etiti electrodes dị n’agbata ± 4 na ± 10 kV, na-enye ngụkọta voltaji nke 8 - 20 kV gafere oghere electrode dị warara nke ọnụ 1.5 cm (0.6 sentimita). A na-ewebata ngwa nri na STET kewapụtara n'otu n'ime ebe atọ (Ọdụ mmiri n'ọdụ ụgbọ mmiri) site na sistemụ ikuku na - ekesa ikuku nwere valvụ ọnụ ụzọ mma. Ndị na - ekewa STET na - emepụta naanị ngwaahịa abụọ, a na-ezighị ezi na ebubo urughuru stream anakọtara na ghaghị ebubo electrode, na a ghaghị ebubo urughuru stream anakọtara na-ezighị ezi na ebubo electrode. The ngwaahịa na-ekekpepde ka nwoke hoppers na onye ọ bụla na njedebe nke STET separator site separator belt na ekekpepde nke separator site ike ndọda. The STET separator adịghị amị a middlings ma ọ bụ egweri stream, ọ bụ ezie na multiple ngafe configurations ka mma ngwaahịa ọcha na / ma ọ bụ mgbake kwere omume.

Ọgụgụ 6: STET Triboelectric echebe separator

Ahụ na-ekekpepde site electrode ọdịiche (nkewa mpaghara) site a na-aga n'ihu loop, emeghe ntupu belt. The belt na-arụ ọrụ na elu na-agba, agbanwe site 4 ka 20 m / s (13 - 65 ft / s). The jiometrị nke belt-eje ozi iji ekpochapụ ezi ahụ n'elu nke electrodes, na-egbochi ìgwè nke ezi ahụ na ịkparị arụmọrụ na voltaji ubi nke ọdịnala free-ọdịda yiri efere ụdị nkewa ngwaọrụ. Na mgbakwunye, ájị site a elu n'oké, elu ịgbā mpaghara n'etiti abụọ electrodes, akwalite tribo-Nchaji. The counter-ugbu a njem nke separator belt-enye ohere maka na-aga n'ihu Nchaji na re-Nchaji ma ọ bụ ahụ n'ime separator, iwepụ mkpa nke a tupu odori usoro upstream nke STET separator.

Ọgụgụ 7: Fundamentals nke ọrụ STET echebe separator

The STET separator bụ a elu ndepụta ọnụego, commercially pụtara nhazi usoro. The kacha nhazi ike nke STET separator bụ ukwuu n'ime a ọrụ nke volumetric ndepụta ọnụego na ike ga-ekekpepde site electrode ọdịiche site STET separator belt. Ndị ọzọ na-agbanwe, dika ososo nke eriri, Anya dị n'etiti electrodes na njupụta nke ntụ ntụ na-emetụta ọnụego nri kachasị, n'otu aka. Maka ihe dị elu, ọmụmaatụ, ofufe ash, ọnụego nhazi kachasị nke a 42 inch (106 cm) electrode obosara azụmahịa nkewa bụ Olee ihe enyemaka 40 - 45 Tọn kwa awa nke fiidi. N'ihi na erughi ndepụta ihe, ọnụego nri kacha dị ala.

Isiokwu 6: Odi nri kachasi ọnụ maka ihe dị iche iche ejiri na STET 42 inch electrostatic iche.

Ájá ntiwapụ bụ isi odachi na ọka na ndị ọzọ organic powder nhazi arụmọrụ. The STET separator adabara maka nhazi combustible organic ntụ na naanị obere mgbanwe. E nweghị ndị na kpụ ọkụ n'ọnụ na-ebupụta na STET separator. The naanị akpụ akpụ akụkụ bụ separator belt na mbanye rollers. The ala biarin na-emi odude n'èzí nke powder iyi na mpụga shei nke unit. Ya mere ha na-adịghị ize ndụ maka ekpo oke ọkụ / sparking na ihe iyi. Ọzọkwa, na STET separator biarin dị na ụlọ ọrụ mmepụta ihe ruo eruo okpomọkụ n'ihe ike ịchọpụta na-agba ọdịda ọma tupu egwu okpomọkụ na-ahụ ruru. The separator belt na mbanye usoro inwe ọ bụla dị elu n'ihe ize ndụ karịa ndị ọzọ na ot n'usoro ígwè. The STET separator elu voltaji mmiri na-na-emi odude n'èzí nke ihe iyi na ẹdude na ájá-uko enclosures. Ike nke ihe na-acha uhie uhie gafere oghere dị iche site na imewe nke ihe ndị dị na ya. Enwere ike ịme ọkwa nke nchekwa ọzọ site na ịkọcha nitrogen.

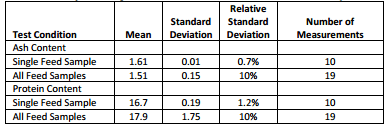

Nhazi ọka niile dị na Steet site na STET Separator

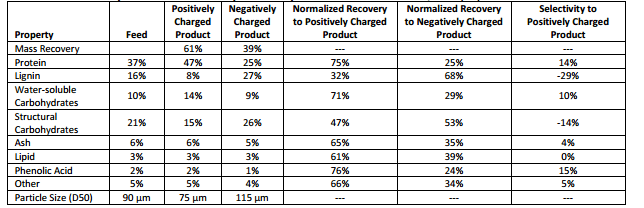

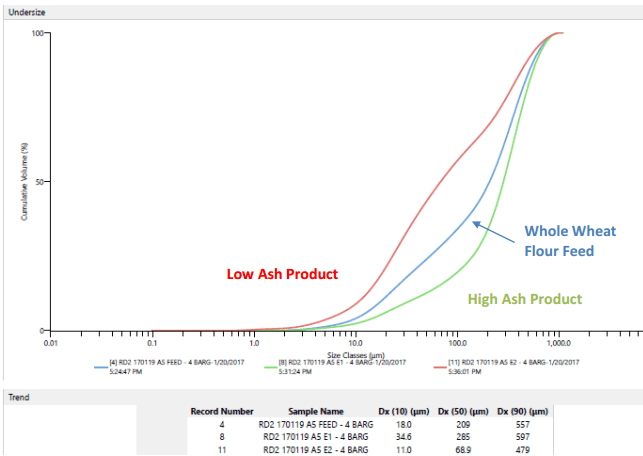

A na-enweta ntụ ọka niile ọka wit na-ata site na-ata ọka wit niile (bran, izizi, na ogwugwu). Azụmaahịa dị, adịghị adị, dum ntụ ọka wit e zụrụ maka iji dị ka ule ihe onwunwe iji chọpụta ihe ndị ike nke STET separator wepụ fibrous bran na izizi si starchy endosperm nta nke ntụ ọka wit. The dum wheat ntụ ọka sample e nyochara na-egosi site na STET tupu a malite ule. Ash content nwalere ICC Standard 104 / 1 (900° C). Ugboro ugboro ash nha nke otu sample, ihe unseparated oriri sample, tụrụ 10 ugboro, chọpụtara nwere ihe ash ọdịnaya nke 1.61%, a ọkọlọtọ ndiiche nke 0.01 na a ikwu ọkọlọtọ ndiiche nke 0.7%. Ejiri nyocha nke otu akụkụ ahụ site na iji mgbasa ozi laser jiri Malvern Mastersizer 3000 ya na ngwaọrụ mkpokọ akọrọ. Protein analysis E duziri iji Dumas usoro, na ụmụntakịrị ngwa N gafere nitrogen / protein analyzer. A akakabarede akpata nke N x 6.25 e ji. The dị iche iche Njirimara nke dum wheat ntụ ọka sample na-chịkọtara n'okpuru. (Lee Isiokwu 7)

Isiokwu 7: Analysis nke dum wheat ntụ ọka iri nri site STET

Ash ọdịnaya na protein ọdịnaya a chọpụtara na-adị nnọọ repeatable mgbe nwalere n'ime otu sample, ma ịrịba mgbanwe e kwuru n'etiti multiple akpa nke dum wheat ntụ ọka eji dị ka ndepụta sample. (Lee Isiokwu 8) A na ndepụta sample mgbanwe rụpụtara ụfọdụ ikposa na ule data.

Isiokwu 8: Analysis nke nkewa ule results nke dum wheat ntụ ọka site STET

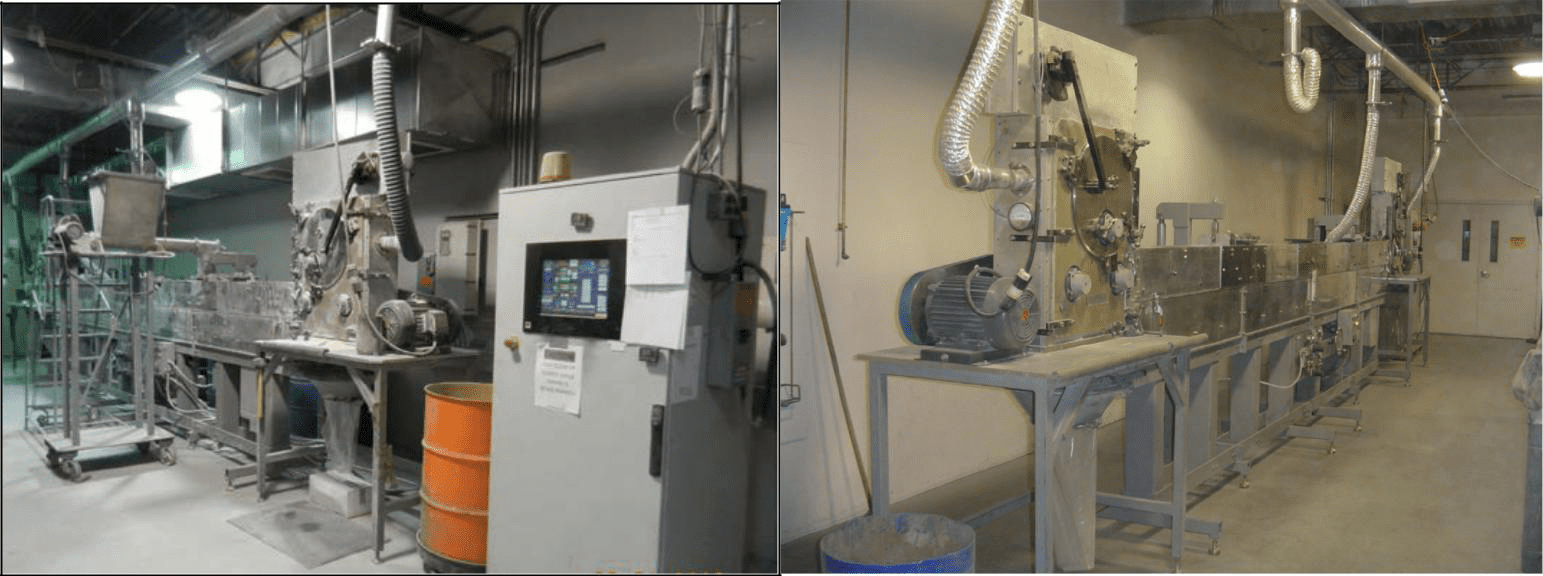

Electrostatic nkewa ule nke dum wheat ntụ ọka sample e rụrụ na ST Equipment & Technology (STET) pilot osisi eweta na Needham, Massachusetts. The STET pilot osisi dere abụọ pilot ọnụ ọgụgụ STET separators tinyere ancillary ngwá eji ichoputa nkewa nke ihe si nwa akwukwo na isi mmalite. The pilot-ọnụ ọgụgụ STET separators bụ otu ogologo dị ka a azụmahịa STET separator, na 30 ụkwụ (9.1 mita) ogologo, Otú ọ dị, na pilot osisi separator electrode obosara bụ naanị 6 sentimita (150 mm), ma ọ bụ onye na-na-asa na obosara nke kasị azụmahịa STET separator na 42 sentimita (1070 mm) electrode obosara. Ndepụta ikike nke STET separator bụ ihe ra nrata nye obosara nke electrodes, Ya mere, ndepụta ọnụego nke pilot osisi separator bụ otu-na-asa na ndepụta ọnụego nke 42-anụ ọhịa dịgasị azụmahịa separator unit. Ọnụego nri kacha mma na ntụ ọka niile 2.3 Tọn kwa awa na ọkwa pilot, nke kwekọrọ na 16 Tọn kwa awa maka 42-inch akwa azụmahịa separator. N'iburu uzo etu omumu imirikiti ihe omumu ihe onwa di ugbua, Emere nnwale nke STET na nha nke ukwu. Emere nnwale na 10 kg (20 paụnd) nnwale, n'ihi echiche bara uru ọkọnọ 2.3 Tọn kwa awa nke nri na-aga n'ihu. Maka ọnọdụ nnwale ọ bụla, A tụtara ngwaahịa nke usoro nkewa iji gbakee mgbake ahụ. A na-anakọta mpempe akwụkwọ site na nyocha nke ọ bụla maka ọdịnaya ash na ọdịnaya protein.

Ọgụgụ 8: Ọtọ SepETtor PiET PiET.

Nkpakọba nke otu achịcha ọka wit na atụ ngwaahịa abụọ ka egosiri n’okpuru nke a 9.

Ọgụgụ 9: Nkata nke ntụ ọka ọka ji aka mee, yana ihe nlere ahia abuo.

A na foto nke natara nkewa ngwaahịa a gụnyere n'okpuru. (Lee Ọgụgụ 10) A kwesiri ngosi agba mgbanwe chọpụtara n'oge nkewa, nke elu ash ọdịnaya ngwaahịa nta ukwu darker karịa ndepụta dum wheat ntụ ọka sample.

Ọgụgụ 10: Ahụkarị ngwaahịa si gbakee site STET nkewa usoro.

Ash ọdịnaya niile na ngwaahịa si nkewa usoro e tụrụ. (Lee Ọgụgụ 11)

Ọgụgụ 11: Ash content vesos uka mgbake nke ala ash ngwaahịa maka dum wheat ntụ ọka nkewa ule site STET

Ule nke STET electrostatic separator na dum na ntụ ọka wit gosiri ịrịba ije nke elu ash (bran) nta nke ndị wheat kernel ha mma electrode. The belata ash ngwaahịa ekemende anakọtara na-adịghị mma electrode. Testing e rụrụ na a otu ngafe atụmatụ, Otú ọ dị, ọ bụ ike ịrụ n'ihu upgrading nke ma nke nkewa ngwaahịa site n'ịrụ ọzọ nkewa ogbo. A ga-eme onye ga-eme nyocha STET dị iche iche na usoro akara ọka, nakwa dị ka ọka ntụ ọka na legumes dị ka Lupine.

Mkpebi

Nyochaa akwụkwọ ndị dị mkpa na-egosi na emeela nchọpụta dị mkpa iji zụlite usoro nkewa nke electromatic maka ihe ndị sitere na Organic. Nke a development anọgidewo ma ọ bụ ọbụna accelerated na n'oge gara aga 10 - 20 afọ, na ọtụtụ na-eme nnyocha na Europe na United States n'itinye electrostatic nkewa usoro a dịgasị iche iche nke beneficiation nsogbu. Site na nke a research, oputara ihe na electrostatic ụzọ nwere ike n'ịwa ọhụrụ, elu uru osisi ngwaahịa, ma ọ bụ na-enye onye ọzọ na mmiri nhazi ụzọ. Ọ bụ ezie na na-agba ume iche iche nke wheat, ọka na lupine dabeere osisi ihe e gosiri na laabu na ụfọdụ pilot ọnụ ọgụgụ, na electrostatic usoro eji na-egosi na ndị a na-arụpụta nwere ike ọ gaghị abụ ihe kasị mma ma ọ bụ na-eri-irè nhazi akụrụngwa na-arụ dị otú ahụ nkewa na a azụmahịa ndabere. Ọtụtụ teknụzụ elektrik adịghị mma maka nhazi nke ọma, ntụ dị ala dị ala dịka ihe ọkụkụ. Otú ọ dị, na ST Equipment & Technology (STET) Ihe mgbochi nke eriri triboelectrostatic gosipụtara ike hazie ụmụ irighiri ihe si 500 - 1 μm na elu udu. Ndị na - ekewa akwa eriri STET bụ ọnụego dị elu, industrially pụtara nhazi ngwaọrụ ahụ nwere ike ịbụ kwesịrị ekwesị commercialize na-adịbeghị anya na nmepe nke osisi ihe onwunwe nhazi. A nwalere eriri igwe STET na ntanetị ntụ ọka ọka niile wee hụ na ọ nwere ihe ịga nke ọma iwepu ụdị ahụ na steepụ starch.. A ga-eme onye ga-eme nyocha STET dị iche iche na usoro akara ọka, nakwa dị ka ọka ntụ ọka na pulses dị ka soy na lupine.

References

[1] T. B. Osborne, “Middlings-Purifier”. United States of America Patent 224,719, 17 February 1880.

[2] H. Manouchehri, K. Hanumantha Rao na K. Forsberg, “Nyochaa nke ụzọ nkewa eletriki – Part 1: isi akụkụ,” mineral & Metallurgical nhazi, vol. 17, dịghị. 1, p. 23-36, 2000.

[3] J. Okenye na E. Yan, “eforce – Kacha ọhụrụ ọgbọ nke electrostatic separator maka minerals ájá ụlọ ọrụ,” na Arọ mineral Conference, Johannesburg, 2003.

[4] R. H. Perry na D. W. Green, Perry si Chemical Engineers’ Handbook Seventh Edition, New York: McGraw-Hill, 1997.

[5] S. Messal, R. Corondan, m. Chetan, R. Ouiddir, K. Medles na L. dascalescu, “Electrostatic separator maka micronized mixtures nke ọla na plastik si n'efu electric na kọmputa akụrụngwa,” Journal of Physics, vol. 646, p. 1-4, 2015.

[6] T. S. Pandya, R. Srinivasan na C. P. Thompson, “Eriri Nkewa maka Ground Ọka ntụ ọka Iji ihe Electrostatic Method,”Mkpụrụ akụkụ Chemistry, vol. 90, dịghị. 6, p. 535-539, 2013.

[7] L. ụdị, P. M. Beier, na m. Stahl, Electrostatic Nkewa, Weinheim: Wiley VCH Verlag GmbH & Co. KGaA, 2005.

[8] na. Hemery, X. Rouau, V. Lullien-Pellerin, C. Barron na J. Abecassis, “Akọrọ usoro ịzụlite wheat fractions na ngwaahịa na enwekwukwa ekwukwa n'akwụkwọ quality,” Journal of Mkpụrụ akụkụ Science, dịghị. 46, p. 327-347, 2007.

[9] W. A. Brastad na E. C. Gear, “Method na ngwa maka Electrostatic Nkewa”. United States of America Patent 2,848,108, 19 August 1958.

[10] B. A. Nkume na J. Minifie, “Mgbake nke Aleurone Sel si Wheat bran”. United States of America Patent 4,746,073,24 Ka 1988.

[11] A. Bohm na A. ọkọ, “Method maka akpa iche Aleurone ahụ”. United States of America Patent 7,431,228, 7 October 2008.

[12] J. A. Delcour, X. Rouau, C. M. Courtin, K. Poutanen na R. Ranieri, “Technologies maka enwekwukwa nrigbu ahụ ike-akwalite nwere nke ọka,” Trends na Food Science & Technology, p. 1-9, 2012.

[13] L. dascalescu, C. Dragan, M. Bilici, R. ịma mma, na. Hemery na X. Rouau, “Electrostatic eji Nwee Nkewa nke Wheat bran nsụkọrọ,” IEEE Azụmahịa na Mmeputa Ngwa, vol. 46, dịghị. 2, p. 659-665, 2010.

[14] na. Hemery, X. Rouau, C. Dragan, R. Bilici na L. dascalescu, “Electrostatic Njirimara nke wheat bran na ya constitutive n'ígwé: Mmetụta nke urughuru size, mejupụtara, na mmiri ọdịnaya,” Journal of Food Engineering, dịghị. 93, p. 114-124, 2009.

[15] na. Hemery, M. Curnd, The. Holopainen, A.-M. oriọna, P. Lehtinen, V. piironen, A. Sadoudi na X. Rouau, “Nwere nke akọrọ fractionation nke wheat bran maka mmepe nke nri Efrata, akụkụ m: Mmetụta ultra-ezi egweri,” Journal of Mkpụrụ akụkụ Science, dịghị. 53, p. 1-8, 2011.

[16] na. Hemery, The. Holopainen, A.-M. oriọna, P. Lehtinen, T. ahihia, V. piironen, M. Edlemann na X. Rouau, “Nwere nke akọrọ fractionation nke wheat bran maka mmepe nke nri Efrata, akụkụ II: Electrostatic nkewa nke ahụ,” Journal of Mkpụrụ akụkụ Science, dịghị. 53, p. 9-18, 2011.

[17] J. Wang, E. Smits, R. M. ọganihu, na M. A. Schutyser, “Arabinoxylans ụtụtụ site wheat bran site electrostatic nkewa,” Journal of Food Engineering, dịghị. 155, p. 29-36, 2015.

[18] P. J. Pelgrom, J. Wang, R. M. ọganihu, na M. A. Schutyser, “Nga- na post-omume welie protein inwetara si egwe ọka ma na ikuku nhazi ọkwa nke legumes,” Journal of Food Engineering, dịghị. 155, p. 53-61, 2015.

[19] D. Chereau, P. Videcoq, C. Ruffieux, L. Pichon, J.-C. Motte, S. Belaid, J. Ventureira na M. Lopez, “Nchikota ẹdude na ọzọ teknụzụ iji kwalite oilseeds na pulses edozi nri ngwa,” Mkpụrụ mmanụ & abụba Crops na Lipids, vol. 23, dịghị. 4, p. 1-11, 2016.

[20] A. Barakat, F. Jerome na X. Rouau, “A kpọrọ nkụ Platform maka Nkewa nke na-edozi site biomass-nwere

polysaccharides, Lignin, na polyphenols,” ChemSusChem, vol. 8, p. 1161-1166, 2015.

[21] C. Basset, S. Kedidi na A. Barakat, “Chemical- na mgbaze-Free Mechanophysical Fractionation nke biomass rata site Tribo-Electrostatic Nchaji: Nkewa na-edozi na Lignin,” ACS Sustainable Chemistry & Engineering, vol. 4, p. 4166-4173, 2016.

[22] J. M. Stencel, J. L. Schaefer, H. Ban, na J. K. Neathery, “Ngwa na Method maka Triboelectrostatic Nkewa”.United States of America Patent 5,938,041, 17 August 1999.