Fè chwa lang:

Sen ekipman & Technology has developed a processing system based on triboelectrostatic belt separation that provides the mineral processing industry a means to beneficiate fine materials with an entirely dry technology…

Download PDF

Expanding Applications in Dry Triboelectric

Separation of Minerals

James D. Bittner, Kyle P. Flynn, e an. Hrach

Sen ekipman & Teknoloji, LLC, Needham Massachusetts 02494 NAN ETAZINI

Tel: +1‐781‐972‐2300, email: jbittner@titanamerica.com

ABSTRÈ

Sen ekipman & Teknoloji, LLC (STET) has developed a processing system based on triboelectrostatic belt separation that provides the mineral processing industry a means to beneficiate fine materials with an entirely dry technology. In contrast to other electrostatic separation processes that are typically limited to particles greater than 75μm in size, la séparation triboelectric senti bon aux pou separasyon trè byen (<1μm) modere (300μm) particles with very high throughput. The high efficiency multi‐stage separation through internal charging/recharging and recycle results in far superior separations that can be achieved with a conventional single‐stage free‐ fall triboelectrostatic separator. Kouwa triboelectric séparateur teknoloji ki te itilize pou mitan gwo pilye materyèl ki enkli mélange de miroitant aluminosilicates/kabòn, calcite/quartz, talc/magnésite, ak barite/quartz. An economic comparison of using the triboelectrostatic belt separation versus conventional flotation for barite / quartz separasyon illustre avantaj ki cheche otomatik pou inewo genyen.

Mots: inewo, separasyon chèch, barite, chaje triboelectrostatik, kouwa séparateur, mande pou vole

YON TI RALE

Mank de dwa ak dlo frè vin yon gwo faktè ki afekte faisabilité de min pwojè atravè lemond. Rapò a Hubert Fleming, ansyen direktè mondyal pou dlo kale, "Tout min site nan mond lan ki te swa te rete, ni te ralanti sou ane ki sot pase a, li te, nan prèske 100% nan ka yo, yon rezilta dlo, either directly or indirectly” Blin (2013). Chèch otomatik mineral metòd pou ofwi yon solisyon pou tout pwoblèm sa a imminente.

Metòd mouye separasyon tankou kimen flottaison egzije a plis réactifs chimik ki dwe fè traitées byen epi detwi nan yon fason responsab l'. Inevitabman se pa posib pou opere avèk 100% corbeille dlo, mande kontwòl pou pi piti ki pati nan pwosesis la, dlo, ke ki gen mak nonplis réactifs chimik.

Metòd chèch tankou électrostatique separasyon elimine bezwen pou dlo frè, epi yo ofri potansyèl pou yo ka diminye depans. Youn nan separateur yo ki pi pwomet nouvo nan separasyon mineral se se senti a triboelectrostatik. Teknoloji sa a te pwolonje ranje gwosè renn pou lèt matyè pase konvasyon separasyon électrostatique teknoloji, nan de konba kote flottaison sèlman te gen siksè nan tan lontan.

1

TRIBOELECTROSTATIC SENTI SEPARASYON

Triboelectrostatic senti separator itilize diferans chaj elektrik ant materyel ki te pwodwi pa kontak sifas oswa chaje triboelectric. Lè de materyèl yo nan kontak, materyel ki gen yon pi gwo afinite pou elektwon genyen elektwon e konsa chaj negatif, pandan yo ap materyel ak pi ba elektwon afinite chaje pozitif. Sa a kontak echanj chaj pwopozisyon yo obsève li pou tout materyèl, nan fè électrostatique nuisances sa se yon pwoblèm nan kèk endistri yo. Tirans microscope depandan sou chimik konpozisyon sifas renn ak ap rezilta nan salè konsiderab différentielle chaje materyèl nan yon melanj de disrè matyè ki diferan konpozisyon.

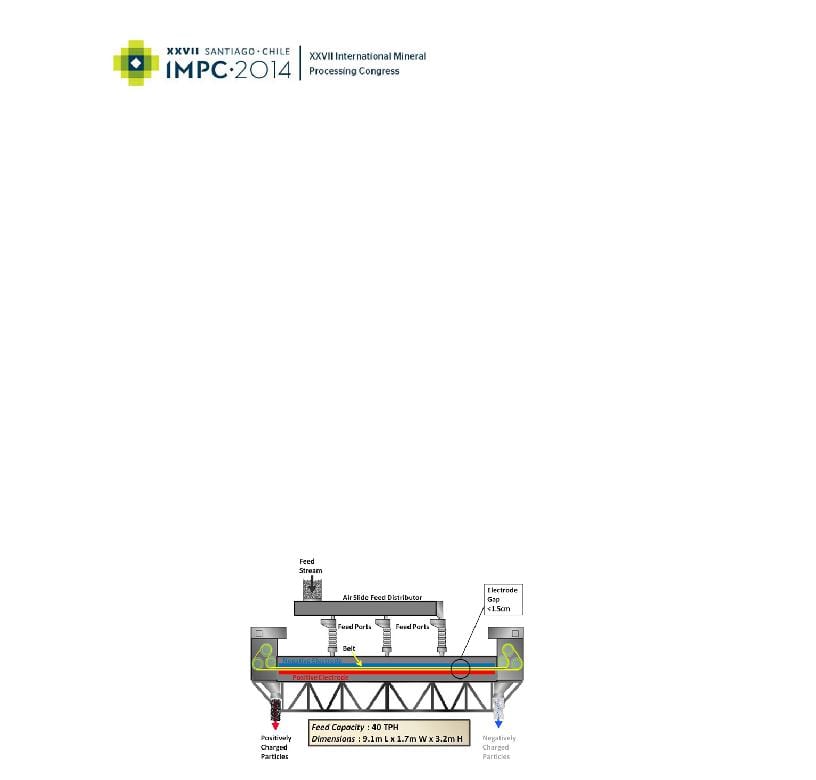

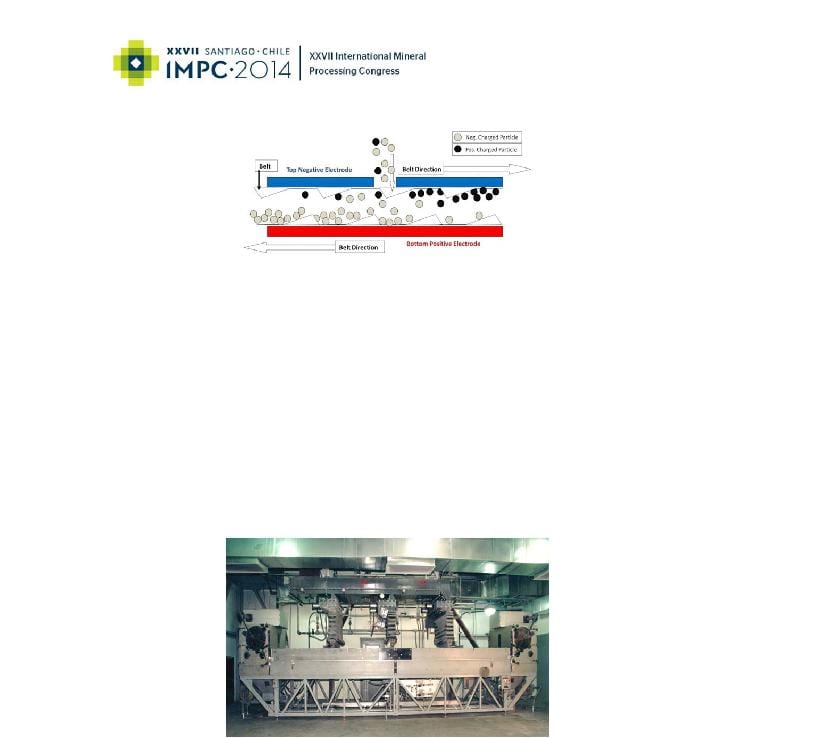

Nan triboelectrostatic séparateur senti (Figi 1 ak 2), materyèl nouri nan la mèg gap 0.9 - 1.5 cm (0.35 ‐0.6 in.) ant de paralèl) électrodes. Matyè yo triboelectrically yo akize interparticle kontak. Pa ekzanp, in the Case of chabon combustion vole saran, yon melanj de kabòn matyè ak matyè mineral, kabon ki pozitivman chaje ak mineral negativman chaje yo atire elektwod opoze a. The particles are then swept up by a continuous moving open‐mesh belt and conveyed in opposite directions. Kouwa a deplase matyè adjasan pou chak lektwòd anvè toupatou bò la séparation. The electric field need only move the particles a tiny fraction of a centimeter to move a particle from a left‐moving to a right‐moving stream. The counter current flow of the separating particles and continual triboelectric charging by carbon‐mineral collisions provides for a multistage separation and results in excellent purity and recovery in a single‐pass unit. Gwo vitès senti anwo nan syèl la tou permet débits trè wo, jiska 40 tòn pa è sou yon moun ki pa marye séparateur. Pa okipe kay yo plizyè karakteristik pwosesis, tankou senti vitès, bay manje pwen, elektwod ak pousantaj manje, aparey la pwodui ba kabon vole sann nan sa ki nan kabon 2 % ± 0.5% achte manje nan kabon 4% pou fini 30%.

Figi 1. Schematic nan senti triboelectric senti

Konsepsyon an se separateur se relativman senp. Kouwa ak asosye woulèt se sèl kalite manm. Électrodes èstasyone ak reyalize yon materyèl ki fè a se sa dirab. Se senti a te fe nan materyel plastik. Longe a separateur elektwod se apepre 6 met (20 .) e laje a 1.25 met (4 .) pou inite komesyal konple. Konsomasyon nan pouvwa se sou 1 kilowatt‐hour per tonne of material processed with most of the power consumed by two motors driving the belt.

2

Figi 2. Detay sou zon separasyon

Pwosè a chèch nèt, mande pou pa gen materyel adisyonel ak pwodui pa gen dlo deche oswa emisyon le. Nan ka a nan kabon soti nan vole sann separasyon, materyel yo refe konsiste de vole sann diminye nan kontni kabon nan nivo apwopriye pou itilize kom yon admixture pozzolanik nan konkre, ak yon fraksyon kabon segonde ki ka boule nan plant la génération elektrisite. Itilize nan toulede kouran pwodwi bay yon 100% solisyon vole sann dispozisyon pwoblem.

Senti senti triboelectrostatic se relativman kontra enfomel ant. Yon machin ki fèt pou travay 40 tòn pa lè se apeprè 9.1 met (30 -) lontan, 1.7 met (5.5 .) lajè ak 3.2 met (10.5 .) anwo nan syèl la. Mande balans plant lan menm se sistèm pou tansmèt chèch materyèl ki soti lakay la séparation. Caractère nan sistèm nan ki pèmèt pou fleksibilite nan konplo enstalasyon.

Figi 3. Separateur triboelectrostatik komesyal

Konpare pou lòt pratik électrostatique separasyon

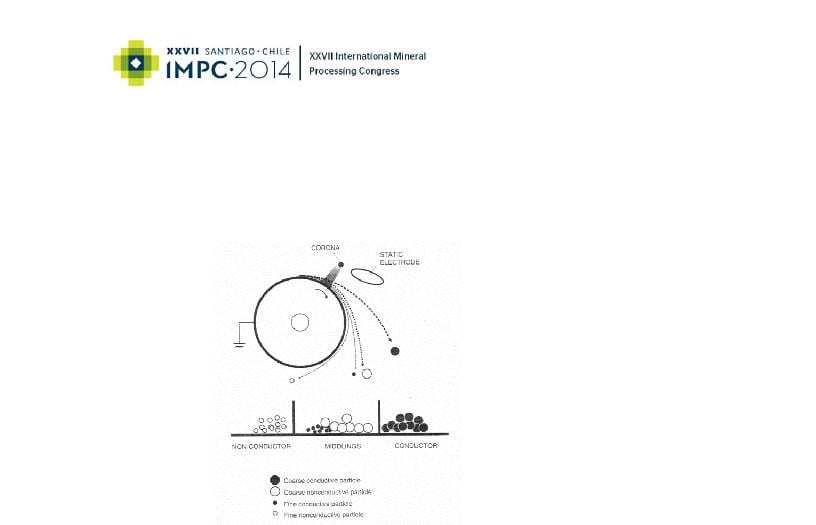

Triboelectrostatic senti teknoloji separasyon anpil elaji seri a nan materyel ki ka benefisye pa pwosesis elektwostatik. Pwosesis ki pi souvan itilize elektwostatik konte sou diferans ki genyen nan konduktivite elektrik nan materyel yo dwe separe. Nan pwosesis sa yo, materyel la dwe kontakte yon tanbou fonde oswa plak tipikman apre patikil yo materyel yo negativman chaje pa yon egzeyate korone. Materyel konduktif yo pral pedi chaj yo byen vit epi yo dwe jete soti nan tanbou la. The non‐conductive material continues to be attracted to the drum since the

3

charge will dissipate more slowly and will fall or be brushed from the drum after separation from the conducting material. Pwosesis sa yo limite nan kapasite akoz kontak ki nesese nan chak patikil nan tanbou oswa plak. Efikasite nan pwosesis sa yo chaje kontak yo tou limite a patikil sou 100 μm or greater in size due to both the need to contact the grounded plate and the required particle flow dynamics. Patikil nan gwose diferan ap gen tou dinamik koule diferan akoz efe ineral epi yo pral lakoz separasyon degrade. Dyagram sa a (Figi 4) ilistrasyon karakteristik fondamantal ki kalite separate.

Figi 4. Drum electrostatic separator “Elder (2003)”

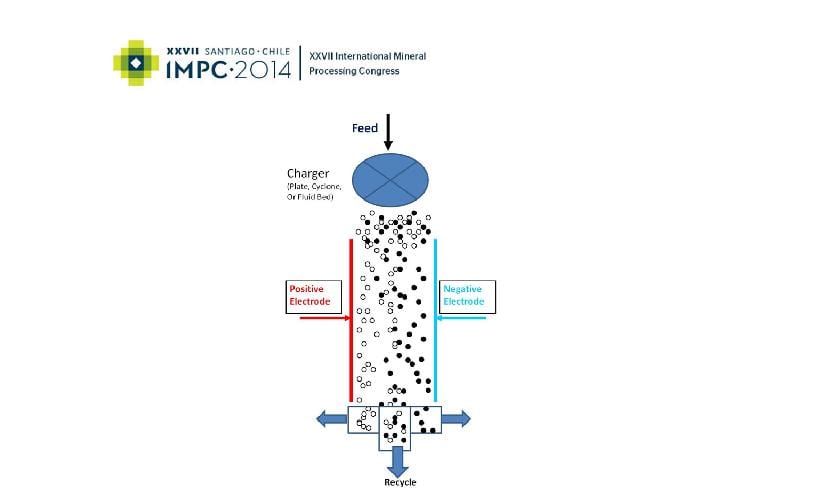

Separasyon Triboelectrostatic yo pa limite a separasyon nan konduktif / non‐conductive materials but depend on the well known phenomenon of charge transfer by frictional contact of materials with dissimilar surface chemistry. This phenomenon has been used in “free fall” separation processes for decades. Such a process is illustrated in Figure 5. Konpozan de yon melanj de matyè premye devlope diferan chaj kontak ni ak yon sifas an metal, oubyen pa renn renn pou kontakte nan yon kabann craquage alimentation aparèy. Menm jan matyè yo te tonbe nan jaden elektrik an nan zòn lektwòd, trajectoire renn chak détourner anvè lektwòd ki bò chaj. Apwè yon distans, ranmase kèt emplacements yo te anplwaye pou mitan larivyè. Atifnatal enstalasyon yo mande pou plizyè estaj séparateur ak corbeille yon fraksyon middling. Gen kèk ki bay sipò itilize yon sous estab gaz pou ede pou transmettre matyè nan zòn lektwòd a.

4

Figi 5. “Free fall” triboelectrostatic separator

Jan de séparation lib tonbe tou gen limit nan gwosè renn materyèl ki kapab trete. The flow within the electrode zone must be controlled to minimize turbulence to avoid “smearing” of the separation. Trajectoire a nan patikil amann yo pi efe pa turbulence depi fos yo trennen aerodynamic sou patikil amann yo pi gwo pase gravitational ak elektrostatik fos yo. Patikil yo tre amann pral gen tandans kolekte sou sifas yo elektwod epi yo dwe retire pa kek metod. Patikil ki pi piti pase 75 μm cannot be effectively separated.

Yon lot limitasyon se ke patikil la loading nan zon nan elektwod dwe ba yo anpeche efe chaj espas, ki limite pousantaj pwosesis la. Passing material through the electrode zone inherently results in a single‐stage separation, since there is no possibility for re‐charging of particles. Se poutet sa, multi‐stage systems are required for improving the degree of separation including re‐charging of the material by subsequent contact with a charging device. Volim ekipman an ki kapab lakoz ak konpleksite ogmante komsadwa.

Kontreman ak lot pwosesis yo separasyon elektwostatik ki disponib, se senti senti triboelectrostatik la depreferans adapte pou separasyon nan anpil amann (<1 μm) modere (300μm) materyel ki gen djob tre wo. Chaje nan patikil triboelectric se efikas pou yon paket domen materyel ak selman mande pou patikil - kontak patikil. A ti gap, teren elektrik segonde, kont kouran inondasyon, vigorous particle‐particle agitation and self‐cleaning action of the belt on the electrodes are the critical features of the separator. The high efficiency multi‐stage separation through charging / rezilta rechaje ak enten yo nan separasyon siperye byen lwen epi li efikas sou materyel amann ki pa ka separe nan tout pa teknik yo konvansyonel.

5

APLIKASYON POU SEPARASYON TRIBOELECTROSTATIC

Mande pou vole

Triboelectrostatic senti teknoloji separasyon te premye aplike endistriyelman nan pwosesis la nan konbinezon chabon vole sann nan 1995. Pou aplikasyon an sann dife, teknoloji a te efikas nan separe patikil kabon soti nan konbine a enkonple nan chabon, nan patikil mineral aliminyom glassyal nan sann lan vole. The technology has been instrumental in enabling recycle of the mineral‐rich flyash as a cement replacement in concrete production. Depi 1995, 19 separateur triboelectrostatik yo te opere nan USA a, Kanada, RETIRE, e Poland, otomatik sou 1,000,000 tòn vole mande pou chak ane. Teknoloji a se koulye a tou nan pwovens Lazi ak séparateur premye a ki enstale nan Kore di sid ane sa a. Lis endistriyèl istwa separasyon mande pou vole nan tab la 1.

|

Tab 1 |

Aplikasyon endistriyel nan triboelectrostatik separasyon separasyon pou vole sann |

|

||

|

Itilite / estasyon elektrik |

Kote yo ye |

Kòmanse |

Plant |

|

|

|

|

|

endistriyèl |

detay yo |

|

|

|

|

Operasyon |

|

|

Duke Eneji - Roxboro Estasyon |

North Carolina USA |

1997 |

2 Separateur yo |

|

|

Raven Power‐ Brandon Shores |

Maryland USA |

1999 |

2 Separateur yo |

|

|

Scottish Power‐ Longannet Station |

Scotland UK |

2002 |

1 Separateur |

|

|

Jacksonville Electric‐St. Jan an |

Florid USA |

2003 |

2 Separateur yo |

|

|

Rivye Pouvwa Park |

|

|

|

|

|

South Mississippi Electric Power ‐ |

Mississippi USA |

2005 |

1 Separateur |

|

|

R.D. Demen |

|

|

|

|

|

New Brunswick Power‐Belledune |

Nouvo Brunswick Kanada |

2005 |

1 Separateur |

|

|

RWE npower‐Didcot Station |

Anglete UK |

2005 |

1 Separateur |

|

|

PPL‐Brunner Island Station |

Penso |

2006 |

2 Separateur yo |

|

|

Tampa Electric‐Big Bend Station |

Florid USA |

2008 |

3 Separateur yo, |

|

|

|

|

|

|

doub pase |

|

RWE npower‐Aberthaw Station |

Wales UK |

2008 |

1 Separateur |

|

|

EDF Energy‐West Burton Station |

Anglete UK |

2008 |

1 Separateur |

|

|

ZGP (Lafarge Siman Poloy / |

Poloy |

2010 |

1 Separateur |

|

|

Ciech Janikosoda JV) |

|

|

|

|

|

Korea Southeast Power‐ Yong |

Kore di sid |

2014 |

1 Separateur |

|

|

Heung |

|

|

|

|

Aplikasyon pou mineral

Electrostatic separations have been extensively used for beneficiation for a large range of minerals “Manouchehri‐Part 1 (2000)”. While most application utilize differences in electrical conductivity of materials with the corona‐drum type separators, triboelectric charging behavior with free‐fall separators is also used at industrial scales “Manouchehri‐Part 2 (2000)”. Yon echantiyon nan aplikasyon pou pwosesis triboelectrostatic rapote nan literati a ki nan lis nan Table 2. Pandan ke sa a se pa yon lis fatigan nan aplikasyon pou, tab sa a montre seri a potansyel nan aplikasyon pou pwosesis elektwostatik nan mineral.

Tab 2. Rapote separasyon triboelectrostatik nan mineral

|

Mineral Separasyon |

Referans |

senti triboelectrostatik |

|

|

|

eksperyans separasyon |

|

|

|

|

|

Potasyom Ore - Halite |

4,5,6,7 |

Wi |

|

Talk – Mayi |

8,9,10 |

Wi |

|

Limestone – kwatz |

8,10 |

Wi |

|

Brucite – kwatz |

8 |

Wi |

|

Oksid fe - silik |

3,7,8,11 |

Wi |

|

Fosfate - kalsite – silik |

8,12,13 |

|

|

Mica ‐ Feldspar – quartz |

3,14 |

|

|

Wollastonite – kwatz |

14 |

Wi |

|

Boron mineral yo |

10,16 |

Wi |

|

Barik - Silicates |

9 |

Wi |

|

Zirkon – Rutile |

2,3,7,8,15 |

|

|

Zircon‐Kyanite |

|

Wi |

|

Magnesite‐Quartz |

|

Wi |

|

Ajan ak drapo lo |

4 |

|

|

Kabon – Aluminosilicates |

8 |

Wi |

|

Beryl – kwatz |

9 |

|

|

Fluorit – silik |

17 |

Wi |

|

Fluorite – Barite ‐ Calcite |

4,5,6,7 |

|

|

|

|

|

Anpil plant pilot ak tes jaden nan anpil separasyon materyel defi nan endistri mineral yo te fe le li sevi avek separateur la triboelectrostatik. Men kek egzanp rezilta separasyon yo montre nan Table 3.

7

Tab 3. Egzanp, separasyon mineral le li sevi avek senti triboelectrostatik separasyon

|

Minewo |

Kalsyòm Carbonate |

TALC |

|

|

|

|

|

|

|

Materyel separe |

Kako3 – Sio2 |

TALC / Manyez |

|

|

Pran swen konpozisyon |

90.5% Kako3 |

/ 9.5% Sio2 |

58% talc / 42% Manyez |

|

Pwodwi konpozisyon |

99.1% Kako3 |

/ 0.9% Sio2 |

95% talc / 5% Manyez |

|

Pwodwi sede mas |

82% |

46% |

|

|

rekiperasyon mineral |

89% Kako3 |

Rekiperasyon |

77% Talc Recovery |

|

|

|

|

|

Itilize nan senti senti senti triboelectrostatik te demontre efektivman benefisye anpil melanj mineral. Depi séparateur la ka travay materyel ki gen gwose patikil nan apwopo de 300 μm to less than 1 μm, ak separasyon triboelectrostatic la efikas pou tou de entansifye ak konduktif materyel, teknoloji a anpil pwolonje seri a nan materyel aplikab sou separateur konvansyonel elektwostatik. Since the triboelectrostatic process is entirely dry, sevi ak li elimine bezwen pou seche materyel ak likid fatra manyen soti nan pwosesis flotasyon.

PRI TRIBOELECTROSTATIC SENTI SEPARASYON

Konparezon ak Flot konvansyonel pou barik

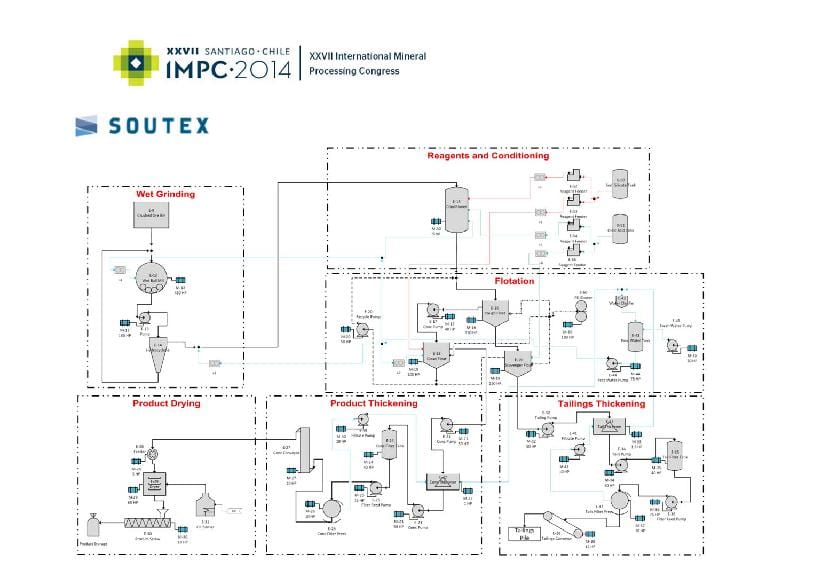

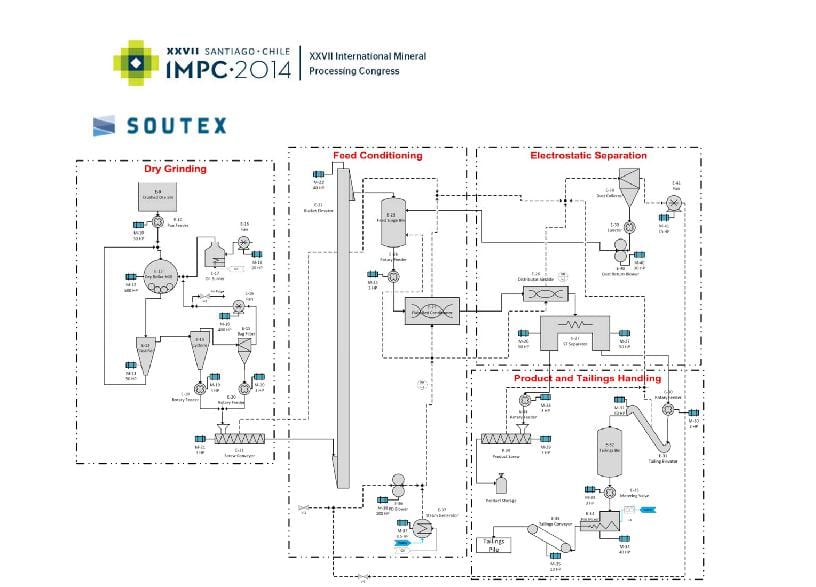

Yon etid pri konparatif te komisyone pa STET ak fet pa Soutex Inc. Soutex se yon konpayi jeni Quebec Kanada ki baze sou jeni ak eksperyans vaste nan tou de flotation mouye ak evalyasyon pwosesis separasyon elektwostatik ak konsepsyon. The study compared the capital and operating costs of triboelectrostatic belt separation process to conventional froth flotation for the beneficiation of a low‐grade barite ore. Tou de teknoloji ajou barik la pa retire nan solid dansite ki ba, pwensipalman kwats, pou pwodwi yon enstiti petwol Ameriken (API) drive klas ak SG pi gran pase 4.2 g/ ml. Flotation results were based on pilot plant studies conducted by the Indian National Mettalurgical Laboratory “NML (2004)”. Rezilta senti triboelectrostatik te baze sou etid plant pilot le li sevi avek manje menm jan an oswa. Etid ekonomik la konparatif enkli flowsheet devlopman, balans eneji ak eneji, major equipment sizing and quotation for both flotation and triboelectrostatic belt separation processes. Baz la pou toude fle se menm bagay la, pwosesis 200,000 t / y nan manje barik ak SG 3.78 pwodui 148,000 t / yo nan peryod barik klas barik ak SG 4.21 g/ ml. Pwosesis la flotasyon estime pa t 'gen ladan nenpot depans pou dlo pwosesis, oubyen tretman dlo.

Flowsheets yo te pwodwi pa Soutex pou pwosesis la flotasyon barik (Figi 6), ak pwosesis senti triboelectrostatik (Figi 7).

8

Figi 6 Barik flotation pwosesis flot

9

Figi 7 Barite triboelectrostatic senti separasyon pwosesis flowsheet

Sa yo flowsheets pa gen ladan yon sistem anvan tout koreksyon oswa kraze, ki komen pou toude teknoloji yo. Broyage nouriti pou ka flottaison an te akonpli w ap itilize yon mill boul mouye pâtes ak siklon Section. Nouri fanm ki ap pile pou triboelectrostatic senparasyon ka a akonpli le li sevi avek yon sek, mill vètikal eksplozif ak Section dinamik entegral.

Triboelectrostatic senti a separasyon fle se pi senp pase flotation. Triboelectostatic belt separation is achieved in a single stage without the addition of any chemical reagents, compared to three‐stage flotation with oleic acid used as a collector for barite and sodium silicate as a depressant for the silica gangue. Se yon flokulan tou te ajoute kom yon reyaktif pou epese nan ka a flotasyon barik. Pa gen ekipman deteryore ak siye obligatwa pou separasyon senti triboelectrostatik, konpare ak epese, pres filtre, ak sechwa rotary obligatwa pou pwosesis flotasyon an barik.

10

Kapital ak opere Depans

Yon kapital detaye ak opere estimasyon pri te fet pa Soutex pou tou de teknoloji le li sevi avek sitasyon ekipman ak metod la pri fakte. Depans yo opere yo te estime genyen ladan yo travay opere, Antretyen, Eneji (gaz elektrik ak gaz), e konsomasyon (pa egzanp, depans reyaktif chimik pou flotasyon). Depans yo opinyon yo te baze sou vale tipik pou yon plant ipotetik ki sitiye tou pre Battle Mountain, Nevada USA. Pri total de an komen pandan dis ane te kalkile nan kapital la ak pri opere pa sipoze yon 8% pousantaj rabe. Rezilta yo nan konparezon pri yo prezan kom pousantaj relatif nan Table 4

Tab 4. Pri Konparezon pou Pwosesis Barit

|

|

Benefisye lwes |

Benefisye sek |

|

Teknoloji |

flotasyon Froth |

Triboelectrostatic senti separasyon |

|

|

|

|

|

Achte gwo Ekipman |

100% |

94.5% |

|

Total KAPEX |

100% |

63.2% |

|

Anyel OPEX |

100% |

75.8% |

|

inite OPEX ($/ton konk.) |

100% |

75.8% |

|

Pri total de An komen |

100% |

70.0% |

|

|

|

|

Pri total a achte nan ekipman kapital pou pwosesis la senparasyon triboelectrostatik se yon ti kras mwens pase pou flotasyon. Sepandan lè total de sibtansyèl kapital espre pou genyen ladan yo enstalasyon ekipman, pwi balan ak elèktrik yo, ak pwosesis pou bati pwi yo, diferans gwo. The total capital cost for the triboelectrostatic belt separation process is 63.2% nan pwi pwosesis flottaison. Siyifikativman pi ba pri pou pwosesis la cheche rezilta yo de a simplier flowsheet. Depans yo opere pou pwosesis la senti separasyon triboelectrostatik se 75.5% nan pwosesis la flotasyon akoz sitou pi ba kondisyon anplwaye opere ak pi ba konsomasyon eneji.

Pri total de an komen nan pwosesis la senti separasyon triboelectrostatik siyifikativman mwens pase pou flotation. Etid la ote, Soutex Inc., konkli ke pwosesis la triboelectrostatik senti separasyon ofri avantaj evidan nan CAPEX, OPEX, e senplisite operasyonel.

11

KONKLIZYON

Triboelectrostatic senti senti a bay endistri a pwosesis mineral yon vle di yo benefisye materyel amann ak yon teknoloji sek antyeman. Pwosesis la anviwonman an zanmitay ka elimine pwosesis omwen ak obligatwa siye nan materyel final la. Pwosesis la mande ti kras, si genyen, pre‐treatment of the material other than grinding and operates at high capacity – up to 40 tonnes per hour by a compact machine. konsomasyon eneji ki ba, mwens pase 2 kWh/tonne of material processed. Depi selman emisyon potansyel pwosesis la se pousye te, otorize se relativman fasil.

Yon etid pri konpare pwosesis senti a separasyon triboelectrostatik nan flotasyon konvansyonel pou barik te konplete pa Soutex Inc. Etid la montre ke pri a kapital total pou pwosesis la triboelectrostatik sek sek se 63.2% de pwosesis flotasyon an. The total operating cost for tribo electrostatic belt separation is 75.8% ki opere pri pou flottaison. Otè etid la se sa sèk la, triboelectrostatic senti pwosesis separasyon ofri avantaj evidan nan CAPEX, OPEX, e senplisite operasyonel.

12

REFERANS

1.Blin, P I & Dion‐Ortega, YON (2013) E seche, Magazin CIM, vol. 8, Non. 4, pp. 48‐51.

2.Ansyen, J. & Yan, E (2003) eForce.‐ Newest generation of electrostatic separator for the minerals sands industry, Inewo lou konferans, Johannesburg, Enstiti min Sid Afriken yo ak metaliji.

3.Manouchehri, H, Hanumantha Roa,SOUFRI, & Foressberg, SOUFRI (2000), Revi tout metòd separasyon elèktrik, Pati 1: Aspè fondamantal yo, Inewo & Métallurgiques otomatik, vol 17, Non. 1 pp 23 - 36.

4.Manouchehri, H, Hanumantha Roa, SOUFRI, & Foressberg, SOUFRI (2000), Revi tout metòd separasyon elèktrik, Pati 2: Considérations pwatik, Inewo & Métallurgiques otomatik, vol 17, Non. 1 pp 139‐ 166.

5.Searls, J (1985) Potasse, Chapit nan fè Mineral ak pwoblèm yo: 1985 Edisyon, Biwo Biwo Mines, Washington DC.

6.Bet, R & Bichara, M, (1975) Separasyon elektwostatik nan potash oswa, Patant Ameriken # 3,885,673.

7.Brands, L, Beier, P I, & Stahl, mwen (2005) Separasyon elektwostatik, Wiley‐VCH verlag, GmbH & Plak bla.

8.Fraas, F (1962) Separasyon elektwostatik nan Materyel Granular, Biwo us de Mines, Aflen 603.

9.Fraas, F (1964), Pretreatman nan mineral pou separasyon elektwostatik, Patant us 3,137,648.

10.Lindley, SOUFRI & Ranjeon, Nou (1997) Fakte preparasyon manje ki afekte efikasite nan separasyon elektwostatik, Mayetik ak Elektrik Separasyon, vol 8 pp 161‐173.

11.Enkilet, mwen (1984) Separasyon Mineral Elektwostatik, Elektwostatik ak Aplikasyon elektwostatik Seri, Etid rechech Pou Lapres, Ltd, John Wiley & Pitit gason, Inc.

12.Fet, D (1966) Free‐Fall Electrostatic Separation of Phosphate and Calcite Particles, Mineral rechech laboratwa, Labs Nos. 1869, 1890, 1985, 3021, ak 3038, Liv 212, Rapo pwogre.

13.Pyes, J & Jiang, X (2003) Pneumatic Transport, Benefis triboelectrik pou endistri A florid, Florida Enstiti pou Rechech Fosfate, Piblikasyon Non. 02‐149‐201, Desanm.

14.Manouchehri, H, Hanumantha R, & Foressberg, SOUFRI (2002), Chaj triboelectrik, Pwopriyete elektwofik ak potansyel benefis elektrik nan Chimik Trete Feldspaar, Kwatz, e Wollastonite, Mayetik ak Elektrik Separasyon, vol 11, no 1‐2 pp 9‐32.

15.Venter, J, Vermaak, M, & Bruwer, J (2007) Enfliyans efe sifas sou separasyon elektwostatik nan zircon ak rutile, 6th Konferans Mineral Lou Entenasyonal la, Enstiti Nan Sid Afriken nan Mining ak Metallurgy.

16.Selik, M ak Yasar, E (1995) Efe tanperati ak enpurte sou separasyon elektwostatik nan Materyel Boron, Mineral Jeni, vol. 8, Non. 7, pp. 829‐833.

17.Fraas, F (1947) Notes on Drying for Electrostatic Separation of Particles, AIME teknik. Pub 2257, Novanm.

18.NML (2004) Benefisyasyon ba barik (rezilta plant pilot yo), Rapo final, Laboratwa metalik nasyonal, Jamshedpur peyi Zend, 831 007

13