Select Puo:

ST Helmets & Technology has developed a processing system based on triboelectrostatic belt separation that provides the mineral processing industry a means to beneficiate fine materials with an entirely dry technology…

Download PDF

Atolosa Dikopo ka Dry Triboelectric

Karohano oa liminerale

James D. Bittner, Kyle P. Flynn, le Frank J. Hrach

ST Helmets & Technology LLC, Needham Massachusetts 02494 usa

Tel: +1-781-972-2300, imeile: jbittner@titanamerica.com

inahaneloang

ST Helmets & Technology, LLC (STET) e tsoetseng pele tsamaiso ea sebetsa e thehiloeng triboelectrostatic lebanta karohano hore e fana ka indasteri ea matsoai lokisa mokhoa oa ho beneficiate thepa e ntle le e thekenoloji ka ho feletseng omileng. Ho fapana le tse ling tse dithulaganyo electrostatic karohano hore ba ka tloaelo ho lekanyetsoa feela likaroloana moholo ho 75μm ka boholo, le triboelectric lebanta kgaoganyo e sebakeng se loketseng loketseng bakeng sa karohano ea e ntle haholo (<1μm) ho tekano mahoashe (300μm) likaroloana le throughput phahameng haholo. The phahameng bokgoni selotlolo sethaleng karohano ka tjhaja hare / recharging le recycle ho fella ka karohano phahametseng hōle hore ka finyelloang le tloaelehileng le 'ngoe-sethaleng free- oela triboelectrostatic kgaoganyo. The triboelectric lebanta kgaoganyo thekenoloji 'nile la sebelisoa ho arohana e mengata e fapaneng ea thepa ho akarelletsa le metsoako ea aluminosilicates le kang khalase / k'habone, calcite / quartz, talc / magnesite, le barite / quartz. E bapisoa moruo sebedisa triboelectrostatic lebanta karohano e bapisiwa le tloaelehileng flotation bakeng barite / quartz karohano e bontša melemo ea ho e lokisa omileng bakeng liminerale.

Keywords: liminerale, karohano omileng, barite, triboelectrostatic tjhaja, lebanta kgaoganyo, fofa molora

SELELEKELA

Ho haella ha metsi a hloekileng e ho ba ntlha e ka sehloohong e amang ea bokgono ea merero meepo lefatšeng ka bophara. Ho latela Hubert Fleming, pele e neng e mookameli oa lefatše lohle bakeng sa Hatch Metsi, "Ea merero tsohle meepo lefatšeng hore ba e ka ba se ile a khaotsa ho, kapa khoehlisa fetang selemo e fetileng, e bile, hoo e ka bang 100% ba maemong, ka lebaka la metsi, ka ho toba kapa ka tsela e sa tobang "Bislama (2013). Dry mekhoa matsoai sebetsa fana ka tharollo ea bothata bona tlang.

karohano mekhoa metsi kang froth flotation hloka go tlaleletsa ka reagents lik'hemik'hale e lokelang ho sebetsoa ka tsela e sireletsehileng le ho lahloa ka mokhoa o tikoloho le boikarabelo ba. Hona joang kapa joang ho ke ke ha khoneha hore li sebetse le 100% recycle metsi, hlokang lahla bonyane oa karolo e itseng ea metsi a thulaganyou e, ka etsahala hore ebe e nang le mesaletsa e ngata ea reagents lik'hemik'hale.

mekhoa Dry kang karohano electrostatic tla felisa ho hlokahala hore metsi a hloekileng, le fana ka le monyetla oa ho fokotsa ditjeo. E mong oa ka ho fetisisa tsepisa tsoelo-pele e ncha ka karohano omileng matsoai ke triboelectrostatic lebanta kgaoganyo. theknoloji ena e atoloswa ho phatsa boholo mefuta e fapaneng ya ho molemo likaroloana ho feta tloaelehileng theknoloji e electrostatic karohano, ka mefuta e fapaneng moo feela flotation e atlehile nakong e fetileng.

1

TRIBOELECTROSTATIC pásek arohane

The triboelectrostatic lebanta kgaoganyo utilizes se tšoane motlakase qoso pakeng tsa thepa e hlahisitsoeng ke ho ikopanya le holim 'kapa triboelectric tjhaja. Ha thepa e 'meli ke kopana, lintho tse bonahalang le e amana e phahameng bakeng sa dieleketerone maruo dieleketerone 'me kahoo o file mpe, ha lintho tse bonahalang le ka tlaase le elektrone e amana file positive,. Sena phapanyetsano ho ikopanya ho tefo e hohle lemohiloeng bakeng sa thepa eohle ea, ka linako tse ling a etsa hore nuisances electrostatic tse le bothata ka bang liindasteri. Elektrone amana ke itšetlehile ka lik'hemik'hale tsa phatsa holim 'me li tla fella ka hore mohlomong differential tjhaja ea thepa e ka motsoako oa likaroloana discrete ya sebopeho fapaneng.

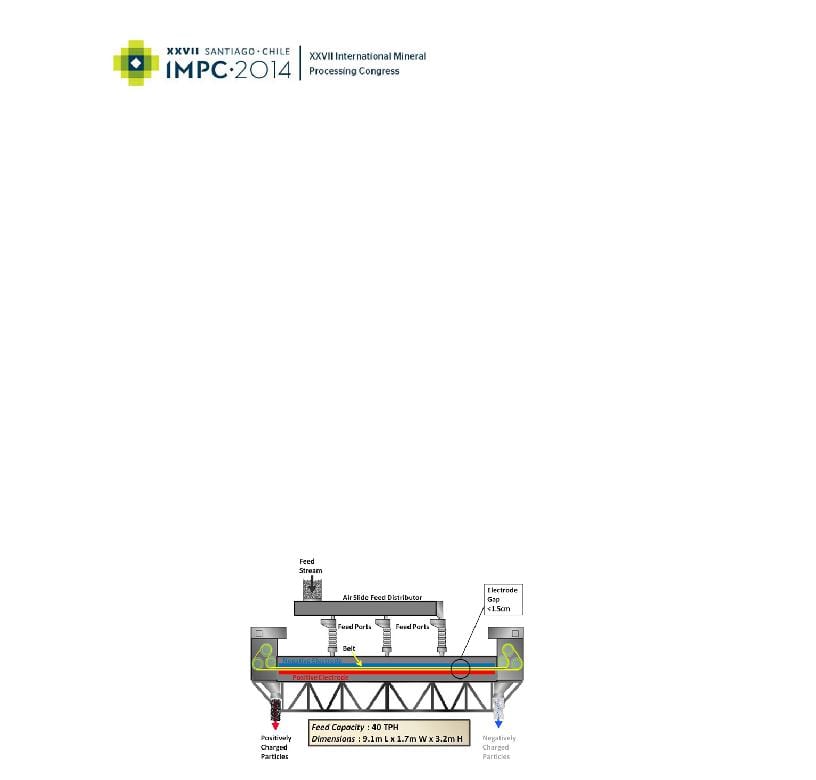

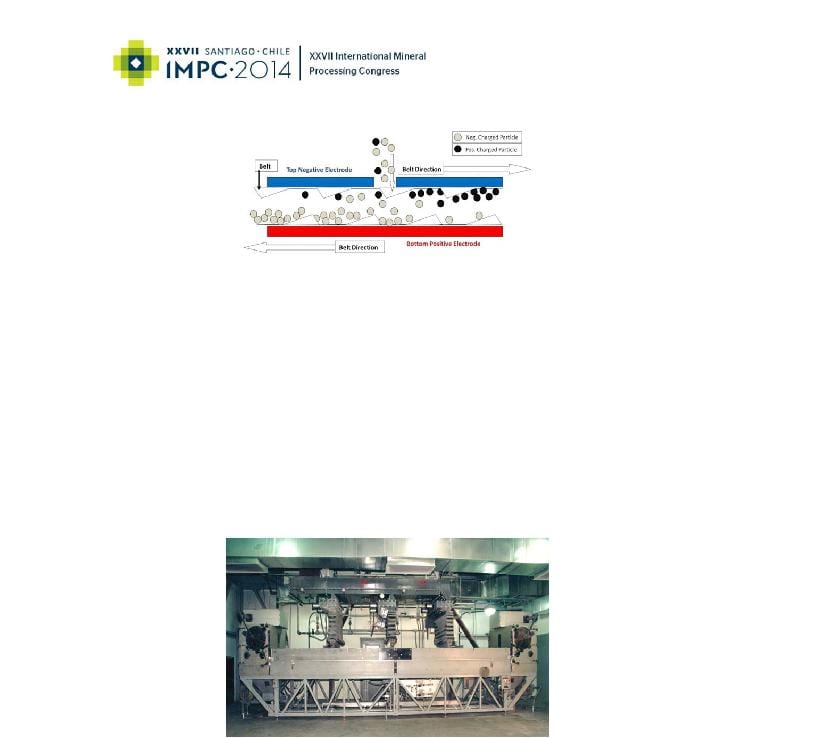

Ka triboelectrostatic lebanta kgaoganyo (Figures 1 le 2), lintho tse bonahalang feptjoang ka lekhalo tšesaane 0.9 - 1.5 cm (0.35 -0,6 ka.) pakeng tsa tse peli tse li-electrode e tšoanang planar. likaroloana li triboelectrically qosoa ke interparticle o ikopanye. Ka mohlala, tabeng ea mashala combustion e fofa molora, motsoako oa likaroloana k'habone le likaroloana matsoai, carbon sebele qosoa le matsoai a hlonamisitsoe qosoa ba khahloa ke li-electrode bo fapaneng. likaroloana li ebe hoholoa ho fihlela ke e tsoelang pele ho fallela lebanta bulehileng-letlooeng le fetisoa ka litaelo bo fapaneng. Lebanta susumelletsa ho likaroloana haufi le e mong le e eleketrode nģ'a lipheletsong fapaneng kgaoganyo ho. Ea tšimo ea motlakase ho hlokahale feela susumelletsa likaroloana karoloana e nyenyane ea disentimitara ka ho fallela ka phatsa tswa letšehali-fallela letona fallisetseng le molapo. The stats jwale phallo ya likaroloana arola le tsoele pele triboelectric tjhaja ke thulana k'habone-diminerale fana bakeng sa karohano multistage le ho fella ka ho hloka sekoli babatsehang le hlaphoheloe ka unit trust le 'ngoe-fetisetsana. The phahameng lebanta lebelo hape nolofalletsa throughputs phahameng haholo, ho fihlela ho 40 tonnes ka hora ka kgaoganyo e le 'ngoe. Ke ho laola entsprechen tse fapa-fapaneng thulaganyou e, tse kang lebelo lebanta, fepa ka ntlha, eleketrode lekhalo le sekhahla iphepe, sesebediswa hlahisa tlaase k'habone fofa molora ka dikahare k'habone ya 2 % ± 0.5% ho tloha fepa ka fofa molora ho tloha carbon ho tswa 4% ka holimo ho 30%.

Figure 1. Tlhohlomiso tsa triboelectric lebanta kgaoganyo

Moralo kgaoganyo ke batlang e bonolo. Lebanta le rollers se amahanngoang ke likarolo feela ho fallela. li-electrode ho ba ema le entsoe ka e lintho tse bonahalang ka nepo tsoarellang. lebanta e entsoe ka lintho tse bonahalang polasetiki. The kgaoganyo eleketrode bolelele ke hoo e ka bang 6 limithara tse (20 feat.) le bophara 1.25 limithara tse (4 feat.) bakeng sa e tletseng boholo diyuniti khoebo. The tshebediso ya matla e ka 1 kilowatt-hora ka tonne boitsebiso sebetswa ka ho fetisisa ea matla a chesa ke Motors tse peli khanna lebanta.

2

Figure 2. Dintlha tsa libaka karohano

tshebetso e ommeng ka ho feletseng, hloka ha thepa tse eketsehileng 'me a hlahisa metsi litšila kapa mesi e kotsi moeeng. Tabeng ea k'habone tloha fofa karohano molora, thepa hlaphoheloa bopilwe fofa molora fokotswa ka dikahare k'habone ho maemo a loketse bakeng sa tshebediso ya ka admixture pozzolanic ka konkreiti s, le phahameng k'habone karoloana e ka chesa ka motlakase fehla motlakase dimela. Tshebediso ya melapo sehlahisoa bobeli e fana ka 100% tharollo ho fofa mathata molora lahla.

The triboelectrostatic lebanta kgaoganyo ke batlang diseke ee. A mochini etselitsoeng ho sebetsa 40 tonnes ka hora ke hoo e ka bang 9.1 limithara tse (30 feat) nako e telele, 1.7 limithara tse (5.5 feat.) bophara le 3.2 limithara tse (10.5 feat.) phahameng. Hlokahalang ho leka-lekana ea limela e na le tsamaiso ea ho fetisa boitsebiso bo bongata omileng ho le ho tloha kgaoganyo ho. The compactness ea tsamaiso e lumella tenyetsehe merero tlhomamiso.

Figure 3. Commercial triboelectrostatic lebanta kgaoganyo

Papiso ho dithulaganyo tse ling electrostatic karohano

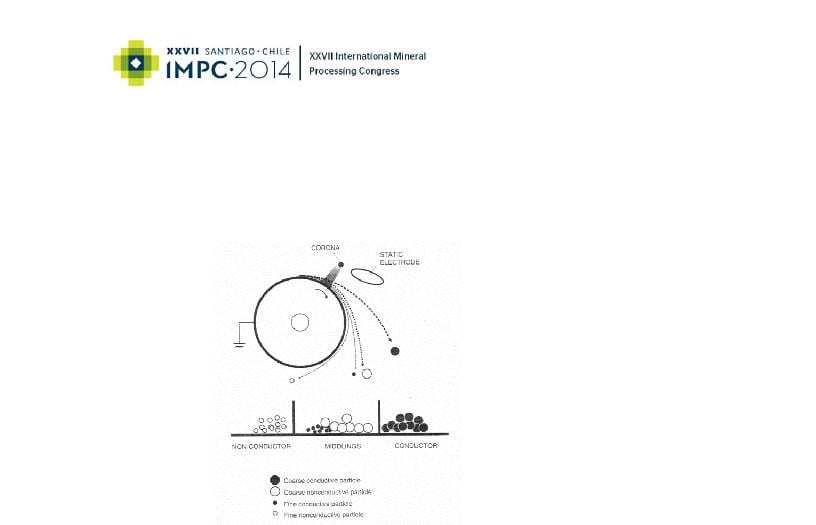

The triboelectrostatic thekenoloji lebanta karohano haholo atolosa e fapaneng ya thepa e ka beneficiated ke dithulaganyo electrostatic. Ka ho fetisisa e atisa ho sebelisoa e hlophisitsweng, electrostatic itšetleha ka ho se tšoane ka conductivity ea motlakase ea thepa le ho arohane. Ka dithulaganyo tsena, lintho tse bonahalang tse o lokela ho ikopanya le e moqomo motheo o tiileng kapa poleiti ka tloaelo ho ka mor'a hore likaroloana tse bonahalang di hlonamisitsoe qosoa ka ionizing Corona tjhajoloha. thepa Conductive tla lahleheloa ke qoso bona ka potlako le ka ho lahleloa tloha moqomo le. lintho tse bonahalang tse bao e seng conductive tsoela pele ho khahloa ke moqomo le ho tloha

3

qoso tla dissipate butle ho feta 'me a tla oela kapa ho brushed tloha moqomo le ka mor'a ho arohana le boitsebiso khanna. dithulaganyo tsena li felle feela ka ho ba le mothamo ka lebaka la ho ikopanya tlhokigang mong le o mong phatsa ho moqomo kapa poleiti. The e sebetsa ka ho ikopanya le lefisa dithulaganyo ba boetse ba felle feela likaroloana tse ka bang 100 μm kapa haholoanyane boholo ka lebaka la le hore ho hlokahala bobeli sa ho ikopanya le lekapa le motheo o tiileng le ho hlokahalang dipharologanyo phallo phatsa. Likaroloana tsa boholo bo fapaneng o tla le bona ba na dipharologanyo fapaneng phallo e loketseng ho litla inertial le tla fella ka karohano e thefulehile habohloko. Setshwantshothalo latelang (Figure 4) e bontša likarolo tsa motheo tsa mofuta ona wa kgaoganyo.

Figure 4. Drum electrostatic kgaoganyo "Elder (2003)"

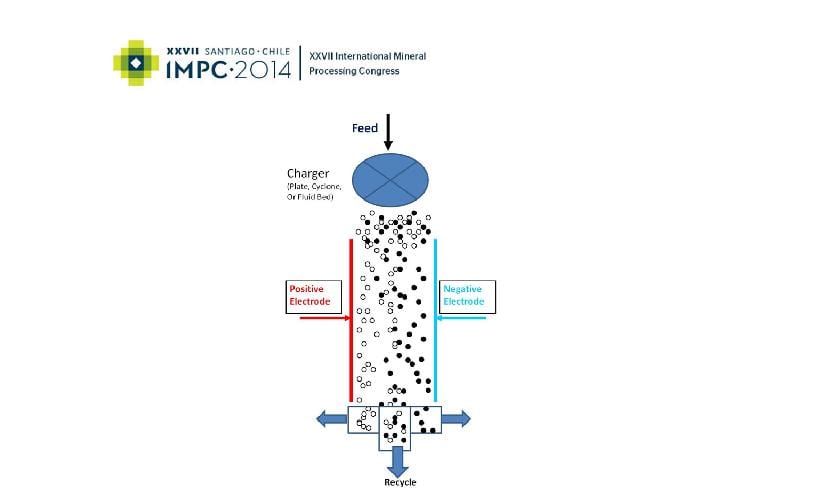

karohano Triboelectrostatic ha e felle karohano ya conductive / thepa bao e seng conductive empa li itšetlehile ka lipono tse makatsang tsa tsebahala ho tefo phetiso ke ho ikopanya frictional ea thepa le k'hemistri dissimilar holim. ketsahalo ena e 'nile ea sebelisoa ka "bolokolohi ho oa" dithulaganyo karohano ka lilemo tse mashome. tšebetso e joalo e bontšoa ka ho Figure 5. Dikarolo tsa motsoako oa likaroloana pele ho ntshetsa pele liqoso fapaneng ke ho ikopanya le e ka ba ka holim'a tšepe, kapa ke phatsa ho phatsa ikopanye le ka fluidized sesebediswa bethe fepa. E le likaroloana e oela tšimong ea motlakase ka libaka eleketrode, tsela e mong le e phatsa e khutlisetsa sepakapakeng ho ella eleketrode ho tefo bo fapaneng. Mora sebakeng se itseng, pokello tsa seretse tse hiriloe ho arole ba melapo. ditlhomo tloaelehileng hloka mekhahlelo multiple kgaoganyo le recycle ea karoloana middling. Ba bang ba le disebediswa tse sebelisa nōka e tsitsitseng ea khase ho thusa fetisetsana ya likaroloana ka ka libaka eleketrode.

4

Figure 5. "Free ho oa" triboelectrostatic kgaoganyo

mofuta ona wa ea bolokolohi ho oa kgaoganyo boetse o na le mefokolo ka phatsa boholo ba lintho tse bonahalang tse hore a ka ho sebetswa. Ho phalla hare ho libaka eleketrode tlameha ho laoloa ho fokotsa loebehlanang ho qoba "smearing" ho arohana le. The tsela ea likaroloana bo botle ba ho feta ba tlisa ho ke loebehlanang tloha aerodynamic e hula mabotho a ka likaroloana motle ke seholo ho feta sa makhotla a khoheli le electrostatic. The likaroloana e ntle haholo e tla boela le tšekamelo ea ho bokella ka bokaholimo eleketrode le lokela ho tlosoa ka mokhoa bang. Likaroloana ka tlase ho 75 μm ke ke ka tsela e atlehang arohane.

moedi 'ngoe ke hore phatsa play loading hara libaka eleketrode tlameha ho ba tlaase ho thibela liphello sebaka qoso, eo fokotsa sekhahla sebetsa. Ho fetisetsa boitsebiso bo bongata ka libaka eleketrode tlhaho fella ka karohano le 'ngoe-sethaleng, kaha ho na le ho na le monyetla bakeng sa botjha tjhaja ya likaroloana. Ka lebaka leo,, tsamaiso ea selotlolo sethaleng lia hlokahala bakeng sa ho ntlafatsa tekanyo ea karohano ho akarelletsa botjha tjhaja ya lintho tse bonahalang tse ke ho ikopanya le morago ga moo e le sesebelisoa lefisa. La sephetho le thepa bophahamo ba modumo le e rarahaneng ea eketseha loketseng.

Ka lehlakoreng le leng ho ba bang fumaneha dithulaganyo electrostatic karohano, le triboelectrostatic lebanta kgaoganyo e sebakeng se loketseng loketseng bakeng sa karohano ea e ntle haholo (<1 μm) ho tekano mahoashe (300μm) thepa le throughputs phahameng haholo. The triboelectric phatsa tjhaja ke e atlehang bakeng sa mefuta e fapaneng ya mefuta e ea thepa e le feela hloka phatsa - phatsa o ikopanye. Lekhalo nyane, phahameng tšimo motlakase, loantša phallo jwale, matla phatsa-phatsa pherekano le ho intša ho hloekisa bohato ba lebanta le ka li-electrode ho ba likarolo tse mahlonoko tseo tsa kgaoganyo ho. The phahameng bokgoni selotlolo sethaleng karohano ka lefisa / recharging le diphetho hare recycle ka karohano phahametseng hōle ebile e ka thepa e metle o ke keng oa aroloa ho hang ke mekhoa tloaelehileng.

5

Dikopo OF TRIBOELECTROSTATIC pásek arohane

fofa Ash

The triboelectrostatic thekenoloji lebanta karohano ile la pele e sebelisoa industrially ho e lokisa ya mashala combustion e fofa molora ka 1995. Bakeng sa fofa molora kopo, theknoloji e bile a atleha ho arola likaroloana k'habone ho tswa ho go tuka ga molelo fella oa mashala, ho tswa ho le kang khalase le likaroloana aluminosilicate matsoai ka fofa molora. theknoloji e bile phetha karolo nolofalletsa recycle tsa flyash matsoai e ngata ka Phetolo samente tlhahiso ka konkreiti. Ho tloha 1995, 19 triboelectrostatic lebanta separators di sebetsa ka USA, Canada, UK, le Poland, sebetsana fetang 1,000,000 tonnes tsa fofa molora selemo le selemo. thekenoloji ke hona joale e boetse e ka Asia le kgaoganyo pele hlomamisa ka Korea Boroa selemong sena. Histori liindasteri tsa karohano fofa molora e ngotsweng Lethathamo 1.

|

tafole 1 |

Industrial Kopo ya Triboelectrostatic lebanta karohano ho fofa molora |

|

||

|

utility / seteishene matla |

Location |

Qala |

setsing |

|

|

|

|

|

liindasteri |

lintlha |

|

|

|

|

tshebetso |

|

|

Duke Energy - Roxboro Station |

North Carolina USA |

1997 |

2 Separators |

|

|

Lekhoaba Power- Brandon Shores |

Maryland USA |

1999 |

2 Separators |

|

|

Scotland Power- Longannet Station |

Scotland UK |

2002 |

1 kgaoganyo |

|

|

Jacksonville Electric-St. Johanne |

Florida USA |

2003 |

2 Separators |

|

|

Noka Power Park |

|

|

|

|

|

South Mississippi Electric Power - |

Mississippi USA |

2005 |

1 kgaoganyo |

|

|

R.D. Morrow |

|

|

|

|

|

New Brunswick Power-Belledune |

New Brunswick Canada |

2005 |

1 kgaoganyo |

|

|

RWE npower-Didcot Station |

Engelane UK |

2005 |

1 kgaoganyo |

|

|

PPL-Brunner Island Station |

Pennsylvania USA |

2006 |

2 Separators |

|

|

Tampa Electric-Big Bend Station |

Florida USA |

2008 |

3 Separators, |

|

|

|

|

|

|

habeli fetisetsana |

|

OF npower Aberthaw-Station |

Wales UK |

2008 |

1 kgaoganyo |

|

|

EDF Energy-West Burton Station |

Engelane UK |

2008 |

1 kgaoganyo |

|

|

ZGP (Lafarge samente Poland / |

Poland |

2010 |

1 kgaoganyo |

|

|

Ciech Janikosoda JV) |

|

|

|

|

|

Korea Boroa-bochabela Power- Yong |

Korea Boroa |

2014 |

1 kgaoganyo |

|

|

Heung |

|

|

|

|

Dikopo matsoai

karohano Electrostatic di haholo sebediswa bakeng sa beneficiation bakeng sa mefuta e fapaneng e khōlō ea liminerale "Manouchehri-Karolo ea 1 (2000)". Ha a ntse a ho fetisisa kopo sebelisa ho se tšoane ka conductivity ea motlakase ea thepa le Corona-moqomo mofuta separators, triboelectric lefisa boitšoaro ba le separators mahala-ho oa le boetse le sebelisoa ka sekala indasteri "Manouchehri-Karolo ea 2 (2000)". A sampole ea dikopo tsa ho e lokisa triboelectrostatic tlalehile ka lingoliloeng e ngotsweng Lethathamo 2. Le hoja sena hase lethathamo fago ya dikopo, tafole ena e bontša fapaneng ba dikopo tsa ho e lokisa electrostatic oa liminerale.

tafole 2. Se tlalehiloe triboelectrostatic karohano oa liminerale

|

matsoai arohana |

Reference |

Triboelectrostatic lebanta |

|

|

|

Experience karohano |

|

|

|

|

|

Potassium Tšepe - Halite |

4,5,6,7 |

YES |

|

Talc - Magnesite |

8,9,10 |

YES |

|

Lejoe la mokoetla - quartz |

8,10 |

YES |

|

Brucite - quartz |

8 |

YES |

|

Tšepe oxide e - silica |

3,7,8,11 |

YES |

|

Phosphate - calcite - silica |

8,12,13 |

|

|

Mica - Feldspar - quartz |

3,14 |

|

|

Wollastonite - quartz |

14 |

YES |

|

Boron liminerale |

10,16 |

YES |

|

Barites - Silicates |

9 |

YES |

|

Zircon - Rutile |

2,3,7,8,15 |

|

|

Zircon-Kyanite |

|

YES |

|

Magnesite-Quartz |

|

YES |

|

Silevera le khauta slags |

4 |

|

|

K'habone - Aluminosilicates |

8 |

YES |

|

Beryl - quartz |

9 |

|

|

Fluorite - silica |

17 |

YES |

|

Fluorite - Barite - Calcite |

4,5,6,7 |

|

|

|

|

|

A pharaletseng a mofofisi ea amehileng ka ba lema 'me tšimo liteko tsa thata karohano tse ngata tse bonahalang ho indasteri liminerale di khanna sebedisa triboelectrostatic lebanta kgaoganyo. Mehlala ea sephetho karohano li bontšitsoe Lethathamo 3.

7

tafole 3. mehlala, karohano matsoai sebelisa triboelectrostatic lebanta karohano

|

matsoai |

k'halsiamo carbonate |

Talc |

|

|

|

|

|

|

|

thepa arohane |

CaCO3 - Sio2 |

Talc / Magnesite |

|

|

Feed sebopeho |

90.5% CaCO3 |

/ 9.5% Sio2 |

58% talc / 42% Magnesite |

|

Product sebopeho |

99.1% CaCO3 |

/ 0.9% Sio2 |

95% talc / 5% Magnesite |

|

'Misa ka lihlahisoa sehlahisoa |

82% |

46% |

|

|

matsoai a hlaphoheloe |

89% CaCO3 |

hlaphoheloa |

77% Talc Recovery |

|

|

|

|

|

Tshebediso ya triboelectrostatic lebanta kgaoganyo e se e bontšitse hore tsela e atlehang beneficiate metsoako ngata matsoai. Ho tloha kgaoganyo ka sebetsa thepa le boholo bo phatsa ho tloha ka 300 μm ho ka tlase ho 1 μm, le karohano triboelectrostatic ke e atlehang bakeng sa bobeli li sireletsang serameng le thepa conductive, theknoloji e haholo ho fetela le ho mefuta e fapaneng ya lintho tse bonahalang ho hlokehang fetang tloaelehileng separators electrostatic. Ho tloha ka tshebetso triboelectrostatic e ommeng ka ho feletseng, tshebediso ya ho felisa ho hlokahala hore omisa lintho tse bonahalang le ho tshwara mokelikeli litšila ho tswa dithulaganyo flotation.

HO TEFO OF TRIBOELECTROSTATIC pásek arohane

Papiso ho tloaelehileng Flotation bakeng Barite

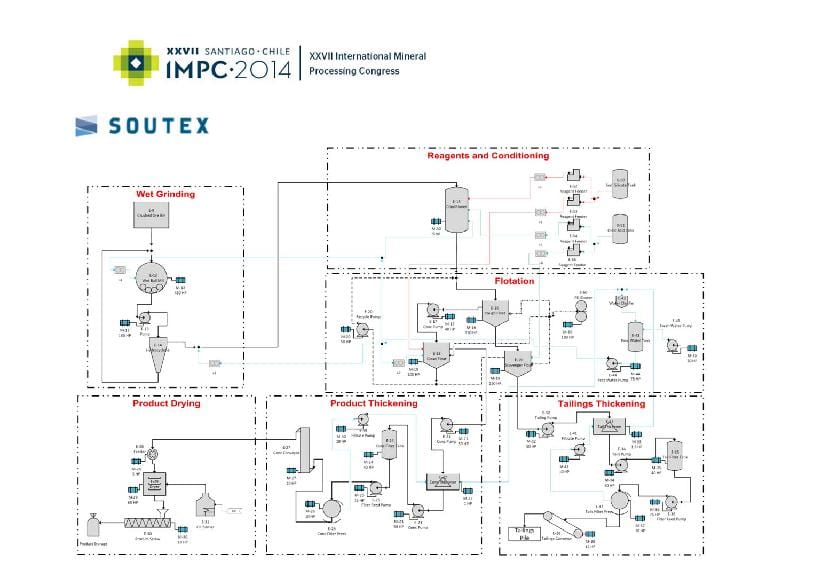

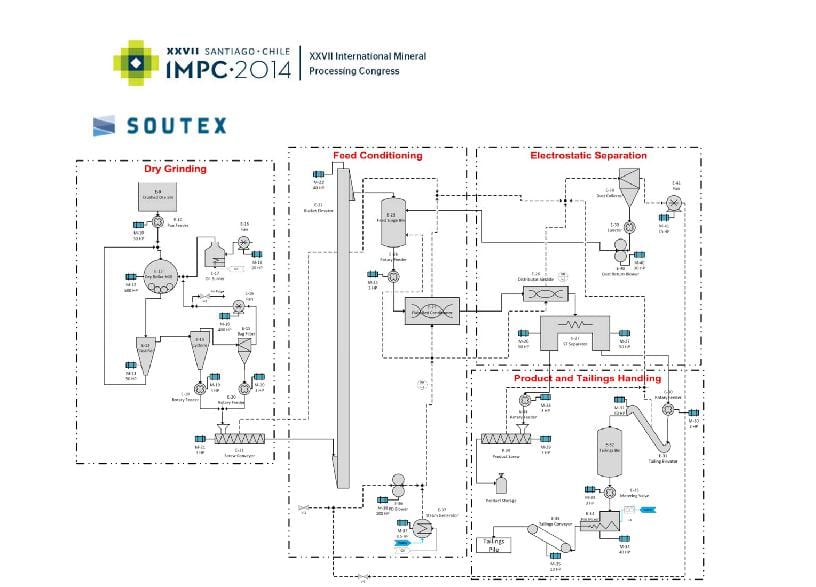

A ho ithuta theko bapisang a ne a laeloa ke STET le entsoeng ke Soutex Inc. Soutex ke Quebec Canada thehiloeng boenjiniere le khampani le boiphihlelo e pharaletseng ka bobeli metsi flotation le electrostatic karohano thulaganyou e sekasekale le moralo. ho ithuta ho bapisoa le motse-moholo 'me a sebelisa mehaho ditshenyehelo tsa triboelectrostatic thulaganyou e lebanta karohano ho tloaelehileng froth flotation bakeng sa beneficiation a tlaase sehlopheng barite manya. theknoloji e bobeli ntlafatsa ho barite ke tlosa tlaase segokanyipalo-butle, haholo-holo quartz, ho hlahisa American Petroleum Institute (API) cheka sehlopheng barite le SG moholo ho feta 4.2 g, / ml tse. diphetho Flotation ne e thehiloeng lithuto tsa motsamaisi dimela khanna ke Indian National Mettalurgical laboratori "NML (2004)". diphetho karohano Triboelectrostatic lebanta li ne li thehiloe ho lithuto tsa motsamaisi dimela sebelisa tšoanang fepa ka tšepe. Thuto ea bapisang a moruo kenyelleditswe ntshetsopeleng flowsheet, lintho tse bonahalang le matla sekaleng, thepa kgolo moleposelekanyi le khotheishene ya bobeli flotation le triboelectrostatic dithulaganyo lebanta karohano. Motheo oa flowsheets bobeli ke e tšoanang, sebetsa 200,000 sa t / featswan ya fepa ka barite le SG 3.78 ho hlahisa 148,000 sa t / featswan tsa cheka sehlopheng barite sehlahisoa le SG 4.21 g, / ml tse. The flotation thulaganyou e hakanya hore ba ne ba sa kenyeletsa ditjeo efe kapa efe ya thulaganyou e metsi, kapa kalafo metsi.

Flowsheets ne generated ka Soutex bakeng sa barite thulaganyou e flotation (Figure 6), le triboelectrostatic lebanta thulaganyou e karohano (Figure 7).

8

Figure 6 Barite flotation thulaganyou e flowsheet

9

Figure 7 Barite triboelectrostatic lebanta karohano thulaganyou e flowsheet

Litletlebo tsa flowsheets se kenyeletsa tsamaiso tala manya sithabetsa, e leng ke ho tloaelehile hore ho theknoloji e bobeli. Feed sila bakeng sa ha e flotation e finyeletseng ho sebedisa metsi makhasi ao bolo leloala le leholiotsoana classifier. Feed sila bakeng sa triboelectrostatic hlahletsoe nyeoe lebanta karohano e finyelloa sebelisa omileng, paatsepama rolara leloala le ea bohlokoa e matla classifier.

The triboelectrostatic lebanta karohano flowsheet ke bonolo ho feta flotation. Triboelectostatic lebanta karohano e fihlellwa ka sethaleng e le 'ngoe ntle le go tlaleletsa ka reagents lik'hemik'hale efe kapa efe, bapisoa le tse tharo-sethaleng flotation le asiti oleic sebelisoa e le 'mokelli oa bakeng sa barite le sodium metaborate ka depressant bakeng sa gangue silica. flocculant A o boetse o phaella ka ho re e le reagent bakeng sa thickening tabeng barite flotation. Ha ho dewatering le omisa thepa e hlokahalang bakeng sa triboelectrostatic lebanta karohano, bapisoa thickeners, filtara mechine, le oa rotary dryers hlokehang bakeng sa ho barite thulaganyou e flotation.

10

Motse-moholo 'me a sebetsa Ditjeo

A qaqileng motse-moholo 'me theko bueloang Khakanyo ile etsoa ke Soutex tsa theknoloji e bobeli sebedisa thepa qotsitsoe le factored theko mokhoa. Ditjeo sebetsa li ne li hakanyetsoa ho kenyeletsa mosebetsi o boima ho sebetsa, tokiso, eneji, le (motlakase le mafura), le consumables (e.g, lik'hemik'hale ditjeo reagent bakeng flotation). litšenyehelo input ne e thehiloeng melao ea boitšoaro e tloaelehileng bakeng sa semela inahaneloang haufi Battle Mountain, Nevada USA. Litšenyehelo kakaretso ea beng ba fetang lilemo tse leshome e ile balwa tswa litšenyehelo matlotlo le ho sebelisa mehaho ke ho nka e 8% theolelo sekhahla. Diphetho tsa theko bapisoa ba teng le ka diphesente a lekanyelitsoeng ka Lethathamo 4

tafole 4. Theko bapisoa bakeng Barite Processing

|

|

metsi Beneficiation |

Beneficiation Dry |

|

Technology |

Froth flotation |

Triboelectrostatic lebanta karohano |

|

|

|

|

|

Rekoa Major Helmets |

100% |

94.5% |

|

Kakaretso CAPEX |

100% |

63.2% |

|

OPEX selemo le selemo |

100% |

75.8% |

|

sebopego se se tshwaraganyang OPEX ($/conc hao.) |

100% |

75.8% |

|

Kakaretso Litšenyehelo tsa beng |

100% |

70.0% |

|

|

|

|

Kakaretso theko theko ea thepa ea motse-moholo bakeng sa triboelectrostatic lebanta thulaganyou e karohano e hanyenyane ka tlase ho bakeng sa flotation. Leha ho le joalo ha ditshenyehelo palo yohle motse-moholo e balwa ho kenyeletsa thepa ea tlhomamiso, piping le motlakase ditjeo, le ditjeho thulaganyou e na le mohaho, phapang e kholo. Kakaretso ea motse-moholo theko bakeng sa triboelectrostatic lebanta thulaganyou e karohano ke 63.2% ya theko ea ho flotation. Litšenyehelo haholo ka tlaase bakeng sa tshebetso e ommeng tlisoang ke ho ba simplier flowsheet. Ditjeo sebetsa bakeng sa triboelectrostatic lebanta thulaganyou e karohano ke 75.5% ea ho flotation ka lebaka la ho ditlhoko haholo-holo tlaase badirimmogong ba ho sebelisa mehaho le tshebediso ya eneji, ka tlaase.

Litšenyehelo kakaretso ea beng ba triboelectrostatic lebanta thulaganyou e karohano ke haholo ka tlaase ho moo ho feta bakeng sa flotation. Mongoli ithuta, Soutex Inc., etsa qeto ea hore ho triboelectrostatic lebanta karohano thulaganyou e fana ka menyetla e totobetseng ka CAPEX, OPEX, le tsela e bonolo a tshebetso.

11

QETELLO

The triboelectrostatic lebanta kgaoganyo fana ka indasteri matsoai sebetsa le ho bolela ho beneficiate thepa e ntle le e thekenoloji ka ho feletseng omileng. Tsela botsoalle tikoloho ka felisa sebetsa metsi le hlokahalang omisa ea lintho tse bonahalang tse ho qetela. tshebetso hloka hanyane, haeba leha e le efe, pele ho kalafo ya tse ling tse bonahalang ho feta ho sila le ho sebetsa ka bokgoni ba phahameng - ho fihlela ho 40 tonnes ka hora ke mochine o diseke ee. tshebediso ya Energy e tlaase, ka tlase ho 2 kWh / tonne boitsebiso sebetswa. Ho tloha feela 'nang mohlapo oa tshebetso ke leru la lerole, lumelle ke batlang e le bonolo.

A ho ithuta theko bapisa triboelectrostatic lebanta karohano tsamaiso ho tloaelehileng froth flotation bakeng barite e ile ea phethoa ka Soutex Inc. ho ithuta ho bontša hore kakaretso ea motse-moholo theko bakeng sa ho omileng triboelectrostatic thulaganyou e lebanta karohano ke 63.2% ea ho flotation. Kakaretso ea ho sebelisa mehaho theko bakeng sa tribo electrostatic lebanta karohano ke 75.8% ea theko ho sebetsa bakeng sa flotation. Mongoli ea ho ithuta e phetha ka ho re hore omileng, triboelectrostatic lebanta karohano thulaganyou e fana ka menyetla e totobetseng ka CAPEX, OPEX, le tsela e bonolo a tshebetso.

12

References

1.Bislama, P & Dion-Ortega, A (2013) Phahameng le Dry, CIM Magazine, volume. 8, ha ho na. 4, maq. 48-51.

2.Elder, J. & Yan, E (2003) eForce.- isa molokong o mong Newest tsa kgaoganyo electrostatic tsa indasteri ea liminerale lehlabathe, Boima liminerale Conference, Johannesburg, Institute of morafo le Metallurgy South African.

3.Manouchehri, H, Hanumantha Roa,k, & Foressberg, k (2000), Tlhahlobo ea Mekhoa ea motlakase arohana, Karolo 1: likarolo tse ka sehloohong, liminerale & Processing Metallurgical, volume 17, ha ho na. 1 maq 23 - 36.

4.Manouchehri, H, Hanumantha Roa, k, & Foressberg, k (2000), Tlhahlobo ea Mekhoa ea motlakase arohana, Karolo 2: e sebetsang nahanelwa, liminerale & Processing Metallurgical, volume 17, ha ho na. 1 maq 139- 166.

5.Searls, J (1985) Potash, Khaolo ea ka Facts matsoai le Mathata: 1985 khatiso, United States Bureau ea Mines, Washington DC.

6.Berthon, R & Bhicr, M, (1975) Electrostatic arohana tsa Potash tšepe, United States Patent # 3,885,673.

7.Brands, L, Beier, P, & Stahl, ke (2005) Electrostatic arohana, Wiley-VCH verlag, GmbH & Co.

8.polelo, F (1962) Electrostatic karohano ya Granular Materials, US Bureau ea Mines, Bulletin 603.

9.polelo, F (1964), Pretreatment oa liminerale karohano electrostatic, US Patent 3,137,648.

10.Lindley, k & Rowson, n (1997) lintlha Feed ho lokisetsa tse amang ka bokgoni ba ho karohano electrostatic, Matla a khoheli le ho motlakase arohana, volume 8 maq 161-173.

11.Inculet, ke (1984) Electrostatic matsoai arohana, Electrostatics le Electrostatic Dikopo Series, Ho etsa lipatlisiso Studies Tobetsa, Ltd, John Wiley & bara ba, Inc.

12.Feasby, D (1966) Free-Fall Electrostatic arohana ea phosphate le Calcite likaroloana, Liminerale Research laboratori, Labs dinmr. 1869, 1890, 1985, 3021, le 3038, buka 212, Tlaleha tsoela pele.

13.Stencel, J & Jiang, X (2003) pneumatici Transport, Triboelectric Beneficiation bakeng sa Florida phosphate Industry, Florida Institute of Research phosphate, sengoliloeng se No. 02-149-201, December.

14.Manouchehri, H, Hanumantha R, & Foressberg, k (2002), Triboelectric Charge, thepa Electrophysical le motlakase Beneficiation Bokhoni ba lik'hemik'hale Tšoara Feldspar, Quartz, le Wollastonite, Matla a khoheli le ho motlakase arohana, volume 11, ha ho na 1-2 maq 9-32.

15.a ntse a emetse, J, boithabiso, M, & Bruwer, J (2007) Tšusumetso ea litla holim'a ka karohano electrostatic ea zircon le rutile, The 6th International boima liminerale Conference, Mokhatlo oa morafo le Metallurgy Southern African.

16.Celik, M le Yasar, E (1995) Liphello tsa Mocheso le litšila ka Electrostatic arohana tsa Boron Materials, liminerale Engineering, volume. 8, ha ho na. 7, maq. 829-833.

17.polelo, F (1947) Lintlha ka omisa bakeng Electrostatic arohana ya likaroloana, LERATO Tec. pub 2257, November.

18.NML (2004) Beneficiation ea sehlopheng barite tlaase (diphetho motsamaisi dimela), Tlaleha ho qetela, National Metallurgical laboratori, Jamshedpur India, 831 007

13