Họrọ asụsụ:

ST Equipment & Technology LLC si (STET) Triboelectrostatic belt separator (Ọgụgụ 1) nwere gosiri ike hazie iwu ahụ si 1995 kewara Unburned carbon si ada uyi minerals na coal-chụọ n'ọrụ ike osisi na North America, Europe and Asia to produce a concrete grade Pozzolan for use as a cement substitute. 1 Site pilot osisi ule, in-osisi ngosipụta oru na / ma ọ bụ azụmahịa arụmọrụ, STET’s separator has demonstrated Beneficiation of many minerals including potash, barite, calcite, na talc.2

Ebe ọ bụ na ihe bụ isi mmasị na nke a technology kemgbe ike hazie ahụ erughị 0.1 mm, Ókè nke ot free-ọdịda na drum mpịakọta separators, the upper particle size limit of STET’s current design has not been a focus of the development of the technology in the past. Otú ọ dị, efforts are under way to increase it by design changes. STET ugbu manufactures abụọ nha na elu ọnụ akọ of 40 na 23 metric tonne kwa hour.

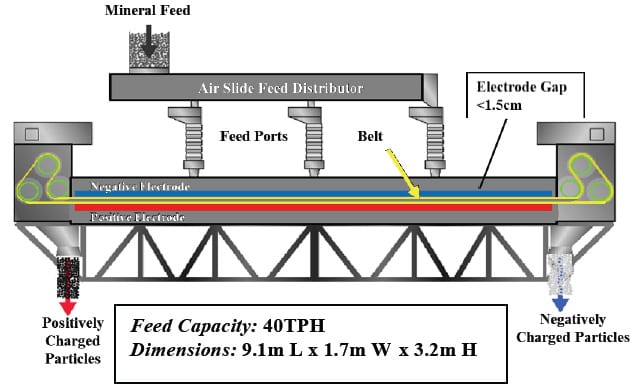

Ọgụgụ 1: ST Equipment & Technology nke Triboelectric echebe separator

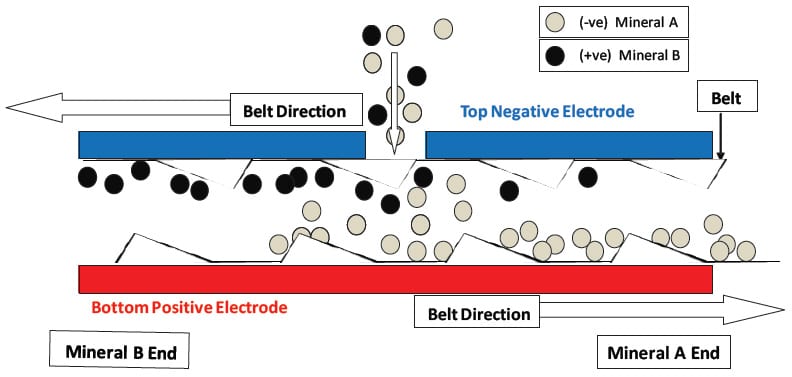

Ụkpụrụ nke ime ihe nke STET separator na-gosiri na osise 2 & 3. The ahụ na-boro ebubo site na triboelectric mmetụta site urughuru-to-urughuru collisions na ikuku slide oriri nkesa na n'ime oghere dị n'etiti electrodes. The etinyere voltaji na electrodes bụ n'etiti ± 4 na ± 10kV ikwu n'ala, na-enye ngụkọta voltaji nke 8 ka 20 kV. The belt, nke ka nke a na-abụghị ndị na-eduzi plastic, bụ a nnukwu ntupu na banyere 60% emeghe ebe. The ahụ nwere ike mfe gabiga oghere na belt.

Ọgụgụ 2: Schematic nke STET separator

ndepụta ikike: 40TPH Dimensions: 9.1m L x 1.7m W x 3.2m H

The flow patterns and particle-to-particle contact within the electrode gap that is established by the moving belt are key to the effectiveness of the separator. N'elu ntinye n'ime ọdịiche n'etiti electrodes na-ezighị ezi na ebubo ahụ na-dọọrọ mmasị electric ubi agha na ala nke oma electrodes. The ghaghị ebubo ahụ na-dọtara na-ezighị ezi na ebubo n'elu electrode. The ọsọ nke na-aga n'ihu loop belt bụ agbanwe site 4 ka 20 m / s. The geometry of the belt cross-direction strands serves to sweep the particles of the electrodes moving them towards the proper end of the separator and back into the high shear zone between the oppositely moving sections of the belt. N'ihi na urughuru nọmba njupụta dị elu n'ime ọdịiche n'etiti electrodes (approximately one-third the volume is occupied by particles) na na eruba na-ike mkpatụ, e nwere ọtụtụ collisions n'etiti ahụ na ezigbo Nchaji etịbe nọgidere ofụri nkewa mpaghara. The counter-current flow induced by the oppositely moving belt sections and the continual re-charging and re-separation creates a countercurrent multistage separation within a single apparatus. This continuous charging and recharging of particles within the separator eliminate the need for any “charger” system prior to introducing material to the separator, thus removing a serious limitation on the capacity of electrostatic separation. Mmepụta nke a separator bụ Mmiri iyi abụọ, a concentrate, na a fọduru, enweghị a middlings stream. The arụmọrụ nke a separator e gosiri na-Ẹkot dị atọ nkebi nke free-ọdịda nkewa na middlings egweri.

Ọgụgụ 3: Electrode Nsogbu nke STET echebe separator

The STET separator has many process variables that enable optimization of the trade-off between product purity and recovery that is inherent in any Beneficiation process. The coarse adjustment is the feed port through which the feed is introduced to the separation chamber. The port furthest from the discharge hopper of the desired product gives the best grade but at the expense of a lower recovery. A mma ukpụhọde bụ ọsọ nke belt. The electrode gap, nke bụ mgbanwe n'etiti 9 na 18 mm, na etinyere voltaji (± 4 ± 10 kV) are also important variables. The polarity nke electrodes nwere ike gbanwere nke aka nkewa nke ụfọdụ ihe. Pretreatment of feed material by precise control of trace moisture content (ka tụrụ site oriri ikwu iru mmiri) is important to achieve optimum separation results. The addition of trace amounts of charge-modifying chemical agents can also aid in optimizing the process.

Dị ka e kwuru n'elu, the initial commercial application of the belt separator has been a separation of coal char from the glassy Aluminosilicate mineral from fly ash from coal-fired power plants. This technology is unique among electrostatic separators in its ability to separate fly ash, nke a nwere a pụtara urughuru size erughị 0.02 mm. The STET separator has also been proven to effectively separate magnesite from talc, halite from kieserite and sylvite, silicates si Bart, and silicates from calcite.3 The mean particle size of all of these feed materials has been in the range of 0.02 na 0.1mm. Ihe Nlereanya nke nkewa maka ọtụtụ ihe na-gụnyere ke Isiokwu 1.

Isiokwu 1 - Ihe Nlereanya nkewa

| nkewa | ndepụta | Product | mgbake |

|---|---|---|---|

| calcium Carbonate - Silicates | 9.5% Acid Insols | <1% A.I. | 89% CaCO3 |

| talc - Magnesite | 58% talc | 95% talc | 77% talc |

| 88% talc | 82% talc | ||

| Kierserite + KCl - NaCl | 11.5% K2O | 27.1% K2O | 90% K2O |

| 12.2% kieserite | 31.8% kieserite | 94% kieserite | |

| 64.3% NaCl | 14.3% NaCl | 92% NaCl reject | |

| Fly Ash Mineral - carbon | 6.3% carbon | 1.8% carbon | 88% ịnweta |

| 11.2% carbon | 2.1% carbon | 84% ịnweta | |

| 19.3% carbon | 2.9% carbon | 78% ịnweta |

na ozizi, ebe urughuru Nchaji dabeere triboelectric mmetụta, abụọ ọ bụla, minerals na-atọhapụ onye ọ bụla ọzọ (eduzi- eduzi ma ọ bụ nonconductor-eduzi) nwere ike iche iche site na usoro a. Ndị ọzọ nwere ngwa na-agụnye magnesite-quartz, feldspar-quartz, ịnweta ájá, ọzọ potash ịnweta nkewa, na

Phosphate-calcite-silica nkewa.

1 Bittner, J.D., Gasiorowski, S.A., Bush, T.W.,, Hrach, F.J., Separation technologies’ automated fly ash beneficiation process selected for new Korean power plant, Ikpe nke 2013 World of Coal Ash conference, April 22-25, 2013. 2 Bittner, J.D., Hrach, F.J., Gasiorowski, S.A., Canellopoulus, L.A., Guicherd, H. Triboelectric belt separator for Beneficiation of fine minerals, SYMPHOS 2013 – 2nd International Symposium on Innovation and Technology for the Phosphate Industry. gaba Engineering, Vol. 83 eyi 122-129, 2014. 3 Bittner, J.D., Flynn, K.P., Hrach, F.J., Ịmụba ngwa ke akọrọ Triboelectric nkewa nke minerals, Ikpe nke XXVII International Ịnweta nhazi Congress - IMPC 2014, Santiago, Chile, Oct 20 - 24, 2014.