Izaberite jezik:

Udruženje Ash američki ugalj (ACAA) godišnje istraživanje proizvodnje i upotrebe pepelu muva izveštava da je između 1966 i 2011, Gotovo 2.3 billion short tons of fly ash were produced by coal-fired utility boilers. Of this amount, otprilike 625 milion tona povoljno upotrebljavan, uglavnom za proizvodnju cementa i betona. Međutim, preostala 1.7+ milijarde tona nalaze se prvenstveno na deponijama ili ispunjen ponded impoundments.

Beneficiation Triboelectrostatic od Landfilled i Ponded pepeo leti

Napisao Luis Bejker,Abhishek Gupta, Stephen Gasiorowski, i Frenk Hrač

Udruženje Ash američki ugalj (ACAA) godišnje istraživanje proizvodnje i upotrebe pepelu muva izveštava da je između 1966 i 2011, Gotovo 2.3 billion short tons of fly ash were produced by coal-fired utility boilers.1 Of this amount, otprilike 625 milion tona povoljno upotrebljavan, uglavnom za proizvodnju cementa i betona. Međutim, preostala 1.7+ milijarde tona nalaze se prvenstveno na deponijama ili ispunjen ponded impoundments. While use rates for freshly generated fly ash have increased considerably over recent years, sa trenutnom stopom blizu 45%, otprilike 40 milion tona muva ash i dalje dostupni, godišnje. While use rates in Europe have been much higher than in the United States, znatne volumene pepela muva takođe smešteno je u deponije i impoundments u nekim evropskim zemljama

Nedavno, interesovanje za povraćaj ovog rashodovanog materijala je poraslo, delimično zbog potražnje za visokokvalitetnim mušičarskim pepelom za proizvodnju betona i cementa u periodu smanjene proizvodnje jer se proizvodnja energije na ugalj smanjila u Evropi i Severnoj Americi. Zabrinutost zbog dugoročnog uticaja takvih deponija na životnu sredinu takođe podstiče komunalne službe da pronađu aplikacije za blagotvornu upotrebu ovog uskladištenog pepela.

Dok neki od ovih uskladištenih mušičarenih pepela mogu biti pogodni za blagotvornu upotrebu kao što je prvobitno iskopano, velika većina će zahtevati određenu preradu da bi zadovoljila standarde kvaliteta za proizvodnju cementa ili betona. Because the material has been typically wetted to enable handling and compaction while avoiding airborne dust generation, drying and deagglomeration is a necessary requirement for use in concrete because concrete producers will want to continue the practice of batching fly ash as a dry, fini puder. Međutim, assuring the chemical composition of the ash meets specifications—most notably the carbon content, measured as loss on ignition (LOI)—is a greater challenge. As fly ash use has increased in the last 20+ godina, većina "in-spec" pepela je blagotvorno korišćena, i nekvalitetni pepeo odložen. Tako, LOI reduction will be a requirement for using the vast majority of fly ash recoverable from utility impoundments.

Dok su drugi istraživači koristili tehnike sagorevanja i procese flotacije za LOI smanjenje oporavljene deponije i jezerceta leteće pepela, ST opreme & Tehnologije (STET JE) has found that its unique triboelectrostatic belt separation system, dugo se koristi za beneficaciju sveže generisanog mušičarskog pepela, je takođe efikasan na oporavljenom pepelu nakon odgovarajućeg sušenja i deagglomeracije.

Istraživači STET-a testirali su ponašanje triboelektrostatičnog razdvajanja osušenog isušenog pepela sa nekoliko deponija pepela u Americi i Evropi. Ovaj oporavljeni pepeo se odvojio veoma slično sveže generisanom pepelu sa jednom iznenađujućom razlikom: the particle charging was reversed from that of fresh ash, with the carbon charging negative in relation to the mineral.2 Other researchers of electrostatic separation of fly ash carbon have also observed this phenomenon.3-5 The polarity of the STET triboelectrostatic separator can easily be adjusted to allow rejection of negatively charged carbon from dried landfilled fly ash sources. No special modifications to the separator design or controls are necessary to accommodate his phenomena

U znak za razdvajanje ugljen STET (Smokva. 1), materijal je hranio u tankom jaz između dva paralelna planar elektrode. Иestice su triboelectrically optužen od strane interparticle kontakt. Pozitivno nabijen ugljen i negativno nabijen mineralne (u sveže generisane pepeo koji ima ne raskvašenog i sušeni) privlači ih nasuprot elektrode. Иestice su onda zahvatio i kontinuirani pokretni pojas i preneo u suprotnim smerovima. Pojas se pomera na čestice graniče sa svake elektrode prema suprotnim stranama znak za razdvajanje. The high belt speed also enables very high throughputs up to 36 tona po satu na jednoj razdvajanje. Mali razmak, high-voltage field, counter—current flow, vigorous particle-particle agitation, and self-cleaning action of the belt on the electrodes are the critical features of the STET separator. Kontrolisanjem različitih parametara procesa, kao što je brzina pojas, Nahrani tačka, i nahrani stopa, proces STET proizvodi nisko LOI muva ash na ugljen sadržaj manje od 1.5 da 4.5% iz feed leti pepeo koji se kreću u LOI iz 4% da je gotovo 25%.

Za razdvajanje dizajn je relativno jednostavna i kompaktne. Stroj je dizajniran da se 40 tona po satu je približno 30 FT (9 m) duga, 5 FT (1.5 m) širok, i 9 FT (2.75 m) tall. Pojas i pridruženi oblice su samo delovi. Elektrode su stacionarni i čine je na odgovarajući način otpornih materijala. Pojas je napravljen od nonconductive plastike. Znak za razdvajanje potrošnju energije u pitanju 1 kilowatt-hour / t materijala obrađen sa najve obuzet 2 motora vozila pojasa.

Proces je potpuno suva., requires no additional materials other than the fly ash, and produces no waste water or air emissions. Spasene materijali koji se sastoje od muva ash u ugljenika smanjen na nivo pogodan za upotrebu kao pozzolanic admixture u beton, and a high-carbon fraction useful as fuel. Use of both product streams provides a 100% rešenje problema muva ash rashoda.

Četiri izvora pepela dobijena su sa deponija: Sample A from a power plant located in the United Kingdom and Samples B, C, i D iz SJEDINJENIH DRŽAVA. Svi ovi uzorci su se sastojali od pepela od sagorevanja bituminoznog uglja od strane velikih komunalnih kotla. Zbog mešanja materijala na deponijama, nema više informacija u vezi sa specifičnim izvorom uglja ili uslovima sagorevanja.

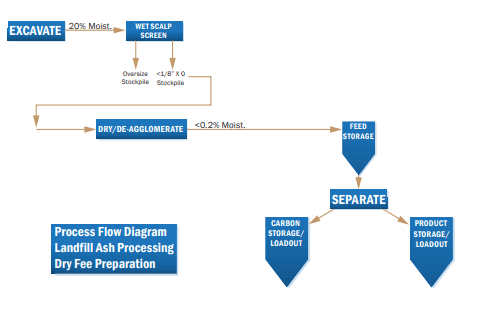

Uzorci koje je steT primio sadržali su između 15 i 27% Voda, as is typical for landfilled material. Uzorci su takođe sadržali različite količine velikih >1/8 u. (3 mm) Materijal. Priprema uzoraka za razdvajanje ugljenika, velike krhotine su uklonjene skriningom i uzorci su se potom osušili i deagglomerirali pre beneficacije ugljenika. Several methods for drying/deagglomeration have been evaluated at the pilot scale to optimize the overall process. STET has selected an industrially proven feed processing system that offers simultaneous drying and deagglomeration necessary for effective electrostatic separation. A general process flowchart is presented in Fig. 2.

The properties of the prepared samples were well within the range of pepeo leti obtained directly from normal utility boilers. Najvaћnija svojstva feedova i proizvoda za razdvajanje su rezimirana u tabeli 2, zajedno sa spasenim proizvodom.

STET separator processing dried, na deponiji mušičaren pepeo

Process flow diagram

Carbon reduction trials using the STET triboelectric belt separator resulted in very good recovery of low-LOI products from all four landfill fly ash sources. The reverse charging of the carbon as discussed previously did not degrade the separation in any way as compared to processing fresh ash.

The properties of the low-LOI fly ash recovered using the STET process for both freshly collected ash from the boiler and ash recovered from the landfill is summarized in Table 1. The results show that the product quality for ProAsh® produced from landfilled material is equivalent to product produced from fresh fly ash sources.

The properties of the ProAsh generated from the reclaimed landfill material were compared to that of ProAsh produced from fresh fly ash generated by the utility boilers from the same location. The processed reclaimed ash meets all the specifications of ASTM C618 and AASHTO M 250 standards. Tabela 2 summarizes the chemistry for samples from two of the sources showing the insignificant difference between the fresh and reclaimed material.

Razvoj snage 20% substitution of the low-LOI fly ash in a mortar containing 600 lb/yd3 cementitious material (see Table 3) showed the ProAsh product derived from landfilled ash yielded mortars with strength comparable to mortars produced using ProAsh from fresh fly ash produced at the same location. The end product of the beneficiated reclaimed ash would support high-end uses in the concrete industry consistent with the highly valuable position ProAsh enjoys in the markets it currently serves.

The availability of low-cost natural gas in the United States greatly enhances the economics of drying processes, uključujući i sušenje mokastog mušičarenja sa deponija. Tabela 4 summarizes the fuel costs for operations in the United States for 15% i 20% sadržaj vlage. Tipične neefikasnosti sušenja su uključene u izračunate vrednosti. Troškovi se zasnivaju na masi materijala nakon sušenja. Postepeni troškovi sušenja mušičarenja za STET triboelektrostatičnu obradu razdvajanja su relativno mali.

Čak i uz dodatak troškova sušenja hrane, the STET separation process offers a low-cost, industrially proven process for LOI reduction of landfilled fly ash. The STET process for reclaimed fly ash is one-third to one-half of the capital cost compared to combustion-based systems. The STET process for reclaimed fly ash also has significantly lower emissions to the environment compared to combustion or flotation-based systems. Because the only additional air emission source to the standard STET process installation is a natural gas-fired dryer, permitting it would be relatively simple.

| Feed sample to separator | LOI, % | ProAsh LOI, % | ProAsh fineness, % +325 Armaturna mreža |

ProAsh mass yield, % |

|---|---|---|---|---|

| Sveže A | 10.2 | 3.6 | 23 | 84 |

| Landfilled A | 11.1 | 3.6 | 20 | 80 |

| Sveže B | 5.3 | 2.0 | 13 | 86 |

| Deponija B | 7.1 | 2.0 | 15 | 65 |

| Sveže C | 4.7 | 2.6 | 16 | 82 |

| Deponija C | 5.7 | 2.5 | 23 | 72 |

| Landfilled D | 10.8 | 3.0 | 25 | 80 |

| Material source | SiO2 | Al2O3 | Fe2O3 | CaO | MgO | K2O | Na2O | SO3 |

|---|---|---|---|---|---|---|---|---|

| Sveže B | 51.60 | 24.70 | 9.9 | 2.22 | 0.85 | 2.19 | 0.28 | 0.09 |

| Deponija B | 50.40 | 25.00 | 9.3 | 3.04 | 0.85 | 2.41 | 0.21 | 0.11 |

| Sveže C | 47.7 | 23.4 | 10.8 | 5.6 | 1.0 | 1.9 | 1.1 | 0.03 |

| Deponija C | 48.5 | 26.5 | 11.5 | 1.8 | 0.86 | 2.39 | 1.18 | 0.02 |

| 7-day compressive strength, % kontrole svežeg pepela | 28-day compressive strength, % kontrole svežeg pepela | |

|---|---|---|

| Sveže B | 100 | 100 |

| Deponija B | 107 | 113 |

| Sveže C | 100 | 100 |

| Deponija C | 97 | 99 |

| Sadržaj vlage, % | Heat requirement KWhr/T wet basis | Drying cost/T dry basis (natural gas cost $3.45/mmBtu) |

| 15 | 165 | $ 2.28 |

| 20 | 217 | $ 3.19 |

In addition to the low-carbon product for use in concrete— brand-named ProAsh—the STET separation process also recovers otherwise wasted unburned carbon in the form of carbon-rich fly ash, brendirani EcoTherm™. EcoTherm has significant fuel value and can easily be returned to the electric power plant using the STET EcoTherm Return system to reduce the coal use at the plant. When EcoTherm is burned in the utility boiler, the energy from combustion is converted to high-pressure/high-temperature steam and then to electricity at the same efficiency as coal, obično 35%. The conversion of the recovered thermal energy to electricity in the STET EcoTherm Return system is two to three times higher than that of the competitive technology where the energy is recovered as low-grade heat in the form of hot water, which is circulated to the boiler feed water system. EcoTherm is also used as a source of alumina in cement kilns, displacing the more expensive bauxite, which is usually transported long distances. Using the high-carbon EcoTherm ash either at a power plant or a cement kiln maximizes the energy recovery from the delivered coal, smanjuje potrebu da svoj i transporta dodatni goriva do toaleta.

STET je Talen energija Brendon obale, SMEPA R.D. Jutro, NBP Belledune, RWEnpower Didkotu, EDF energije zapadni Burton, RWEnpower Aberthaw, and the Korea South-East Power fly ash plants all include EcoTherm Return systems.

STET’s separation process has been used commercially since 1995 za beneficaciju mušičarenja i generisao je preko 20 milion tona visokokvalitetne leti pepeo za proizvodnja betona. Controlled low-LOI ProAsh is currently produced with STET’s technology at 12 elektrane širom SAD, Kanada, Ujedinjeno Kraljevstvo, Poljska, i Republike Koreje. ProAshfly ash has been approved for use by more than 20 državne vlasti autoput, kao i mnoge druge agencije Specifikacija. ProAsh has also been certified under the Canadian Standards Association and EN 450:2005 standardi kvaliteta u Evropi. Eš obrada objekata pomoću tehnologije STET navedene u tabeli 5.

Nakon odgovarajućeg skalpinga krupnog materijala, Suљi, i deagglomeration, mušičarski pepeo pronađen na deponijama komunalnih postrojenja može se smanjiti u sadržaju ugljenika pomoću komercijalizovanog STET triboelektričnog znaka za razdvajanje pojasa. Kvalitet proizvoda od mušičare, ProAsh, using the STET system on reclaimed landfill material, is equivalent to ProAsh produced from fresh feed fly ash. The ProAsh product is very well-suited and proven in concrete production. The recovery and beneficiation of landfilled ash will provide a continuing supply of high-quality ash for concrete producers in spite of the reduced production of “fresh” ash as coal-fired utilities reduce generation. Pored toga, power plants that need to remove ash from landfills to meet changing environmental regulations will be able to use the process to alter a waste product liability into a valuable raw material for concrete producers. The STET separation process with feed preprocessing equipment for drying and deagglomerating landfilled fly ash is an attractive option for ash beneficiation with significantly lower cost and lower emissions compared to other combustion- and flotation-based systems. ❖

1. American Coal Ash Coal Combustion Products and Use Statistics, http://www.acaausa.org/Publications/Production-Use-Reports.

2. ST Internal Report, Aug. 1995.

3. Li, T. X.; Љafer, J. L.; Ban, H.; Neathery, J. K.; i Stencel, J. M., “Dry Beneficiation Processing of Combustion Fly Ash,” Proceedings of the DOE Conference on Unburned Carbon on Utility Fly Ash, Pitsburg, Tata, Maja 19-20, 1998.

4. Baltrus, J. P.; Diehl, J. R.; Uskoro, Y.; and Sands, W., “Triboelectrostatic Separation of Fly Ash and Charge Reversal,” Fuel, V. 81, 2002, PP. 757-762.

5. Cangialosi, F..; Notarnicola, M.; Liberti, L.; i Stencel, J., “The Role of Weathering on Fly Ash Charge Distribution during Triboelectrostatic Beneficiation,” Journal of Hazardous Materials, V. 164, 2009, PP. 683-688.

Luis Bejker je evropski menadžer tehničke podrške za ST opremu & Tehnologija (STET JE) sa sedištem u Ujedinjenom Kraljevstvu

Abhishek Gupta is a Process Engineer based at the STET pilot plant and lab facility in Needham, MAMA.

Stephen Gasiorowski is a Senior Research Scientist for ST Equipment & Tehnologija (STET JE) based in New Hampshire.

Frank Hrach is Vice President of Process Engineering based at the STET pilot plant and lab facility in Needham, MAMA.

| Utility and power station | Lokacija | Početak komercijalnih operacija | Detalji o objektu |

|---|---|---|---|

| Duke Energy—Roxboro Station | U Severnoj Karolini | Sept. 1997 | 2 separators |

| Talen Energy—Brandon Shores Station | Maryland | Apr. 1999 | 2 separators 35,000 ton storage dome Ecotherm Return 2008 |

| ScotAsh (Lafarge / Škotski zajednički poduhvat moći)—Longannet Station | Scotland, VELIKA BRITANIJA | Oct. 2002 | 1 Razdvajanje |

| Jacksonville Electric Authority— St. John je River parka, FL | Na Floridi | Maja 2003 | 2 separators Coal/petcoke blends Ammonia removal |

| South Mississippi Electric Power Authority R.D. Stanica Morou | Misisipi | Jan. 2005 | 1 separator Ecotherm return |

| New Brunswicka elektroenergetska kompanija Belledune stanica | New Brunswick, Kanada | Apr. 2005 | 1 separator Coal/petcoke blends Ecotherm return |

| RWE npower Didkotu stanica | Engleska, U | Aug. 2005 | 1 separator Ecotherm return |

| Stanica ostrva Talen Energy Brunner | Pennsylvania | Dec. 2006 | 2 separators 40,000 tona za skladištenje kupole |

| Tampa El. Co. Big benda stanice | Na Floridi | Apr. 2008 | 3 separators, Dvostruki prolaz 25,000 ton storage dome Ammonia removal |

| RWE npower Aberthaw stanica (Lafarge Cement UK) | Wales, VELIKA BRITANIJA | Sept. 2008 | 1 separator Ammonia removal Ecotherm return |

| EDF energije zapadni Burton stanice (Lafarge Cement UK, Cemexa) | Engleska, VELIKA BRITANIJA | Oct. 2008 | 1 separator Ecotherm return |

| ZGP (Lafarge Cement Poljske / Ciech Janikosoda JV) | Poljska | Mar. 2010 | 1 separato |

| Korea South-East Power Yeongheung Units 5&6 | Južna Koreja | Sept. 2014 | 1 separator Ecotherm return |

| PGNiG Termika-Siekierki | Poljska | Planirano 2016 | 1 separator Ecotherm return |

| To Be Announced | Poljska | Planirano 2016 | 1 separator Ecotherm return |