Fè chwa lang:

Triboelectrostatic separation has been used for the commercial beneficiation of coal combustion fly ash to produce a low carbon product for use as a cement replacement in concrete for nearly twenty years…. STET’s patented electrostatic separator has been used to produce over 15 Million tonnes of low carbon product…Recent environmental legislation…coupled with a requirement …to empty historical landfill sites, has created the need to develop a process to beneficiate historically landfilled ash…

Download PDFTriboelectrostatic Beneficiation of

Land Filled Fly Ash

L. Baker, YON. Gupta, e S. Gasiorowski

Sen ekipman & Teknoloji LLC, 101 Hampton avni, Needham MA 02494 NAN ETAZINI

CONFERENCE: 2015 World of Coal Ash – (www.worldofcoalash.org)

MOTS: Triboelectrostatic, Beneficiation, Mande pou vole, Landfilled, Dried, Separasyon, Carbon

ABSTRÈ

Triboelectrostatic separation has been used for the commercial beneficiation of coal combustion fly ash to produce a low carbon product for use as a cement replacement in concrete for nearly twenty years. With 18 separators in 12 coal-fired power plants across the world, Sen ekipman & Teknoloji LLC a (STET) technologie séparateur électrostatique ki te itilize pou pwodwi sou 15 Milyon tòn pwodwi ti kabòn.

Dat, beneficiation komèsyal ki mande pou vole te jwe espesyalman sou tè sèk "kouri a station‿. Dènye lejislasyon anviwònman an ki te kreye, nan sèten mache yo, yon nesesite pou yo founi mande pou beneficiated nan tan ki mande pou desann pitit an pitit. Sa a, makonnen ak yon kondisyon nan kèk kote yo mande pou vid istorik fatra lokal, te kreye bezwen pou devlope yon pwosesis pou mande pou beneficiate istorikman palan te kon décharge.

Ki vini anvan etid yo te montre ke lavant ki ekspoze a mande pou vole pou midite, ak ki fèt aprè siye pakonsekan triboelectrostatic a chaje ki asèptab, ak chaje nan bò polarité pou eksperyans ak kouri a estasyon matyè kabòn epi minewo. Etid yo te jwe pa otè yo pou detèmine efè ekspoze labou sou separasyon ki pi efikas selon plizyè sann ki gen te récupéré de décharges secs. Lan vè chaj te konn swiv siye, Men an tou efikasite separasyon te atteint egal a eksperyans ak nouvo kouri a estasyon.

Efè secs saran nouriti fanmi imidite sou triboelectrostatic separasyon efikasite te konsilte, e sansiblite li te genyen anpil diminye konpare li a sa eksperyans ak kouri nan estasyon saran, an tou diminye travay pwi yo.

YON TI RALE

Asosyasyon Ash chabon Ameriken (ACAA) ankèt anyèl pwodiksyon ak itilize chabon vole ash te rapòte ke ant 1966 ak 2011, sou 2.3 milya tòn talè a vole te pwodwi pa te tire chabon itilite chodyè pou chofaj.1 Sa total apeprè 625 milyon tòn te beneficially itilize, sitou pou pwodiksyon siman ak beton. Sepandan, ki te rete a 1.7+ milya tòn premyèman te twouve nan décharges oubyen lasi / ponded

impoundments. Pandan tout tan pousantaj itilizasyon yo pou prije généré mande pou vole te anpil anpil nan ane resan, ak yon pousantaj aktyèl tou pwe 45%, apeprè 40 milyon tòn a vole kontinye pou jete mò nan chak ane. Pandan tout tan pousantaj itilizasyon yo an Ewòp te genyen pi wo ke nan Etazini, konsiderab volumes a vole te tou te sere nan décharges ak impoundments nan kèk peyi Ewopeyen yo.

Depi kèk tan, enterè nan apwè dekouvèt sa a disposé materyèl yo kontinye ogmante, ò/demi akòz a demand lan pou bon kalite vole ash pou beton ak siman pwodiksyon pandan yon peryòd diminye pwodiksyon tankou chabon te tire pouvwa pitit an pitit te diminye an Ewòp ak Amerik di Nò. Kesyon sou yon tan ki long anviwònman enpak décharges konsa tou ap pouse peman pou sèvis piblik pou jwenn benefik itilize aplikasyon pou sa a mande pou lontan.

PEYI BON KALITE MANDE POU TE RANPLI EPI MANDE BENEFICIATION

Pandan tout tan sa, gen kèk depo mande pou vole ka fè fèt nan Kiba pou itilize avantaje ke okòmansman an te defouye pyès, the vast majority will require some processing to meet quality standards for cement or concrete production. Since the material has been typically wetted to enable handling and compaction while avoiding airborne dust generation, drying will probably be a minimal requirement for use in concrete since concrete producers will want to continue the practice of batching fly ash as a dry powder. Sepandan, assuring the chemical composition of the ash meets specifications, most notably the carbon content measured as loss-on-ignition (LOI), se yon pi gwo defi. Mande pou vole tankou itilizasyon yo kontinye ogmante nan dènye 20+ ane, ki pi "saran nan-spec‿ ki te beneficially itilize, ak tout bon kalite debwi mò. Konsa, LOI sou zafè pou diminye yo va yon kondisyon pou utilisant vas majorite a vole recouvrable soti itilite impoundments.

LOI SOU ZAFÈ POU DIMINYE PA TRIBOELECTRIC SEPARASYON

Pandan plizyè travayè yo te itilize teknik combustion ak pratik flottaison pou LOI sou zafè pou diminye a rejwenn décharge ak ponded vole, Sen ekipman & Teknoloji (STET) te jwenn ke sistèm otomatik estanda, lontan te itilize pou beneficiation de prije généré mande pou vole, menm efèktif sou mande pou rejwenn apre fèt nan Kiba siye yo ak deagglomeration nan anba tout depans fonksyònman.

Pandan ranp pou leve pou aplikasyon komèsyal sistèm otomatik rele STET la pou mande pou vole, STET chèchè teste separasyon a secs décharge. Sa a mande récupérés pou separe trè menm pou mande pou prije te pwodwi ak yon diferans etone: a renn chaje te Food sòti de sa a nouvo ak kabòn a chaje ak ineral a negatif.2 Lòt chèchè de separasyon électrostatique kabòn mande pou vole tou te obsève phénomènes sa a.3,4,5

TEKNOLOJI KOURIKOULÒM-MANDE POU VOLE CARBON SEPARASYON

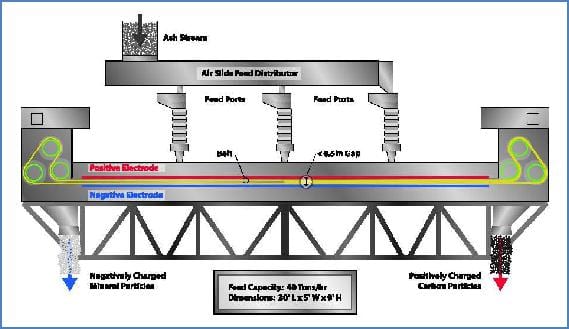

Nan rele STET séparateur kabòn (Figi 1), materyèl nouri nan ti gap ant de paralèl) électrodes. Matyè yo triboelectrically yo akize interparticle kontak. Kabòn pozitivman accusé a ak a accusé négative ineral (nan prije généré mande sa yo ki pa te humide e secs) a pou opoze électrodes. Matyè yo lè sa a te baleye pa yon senti dwa kontinyèl, transmis nan direksyon yo bò. Kouwa a deplase matyè adjasan pou chak lektwòd anvè toupatou bò la séparation. Gwo vitès senti anwo nan syèl la tou permet débits trè wo, jiska 36 tòn pa è sou yon moun ki pa marye séparateur. A ti gap, anwo nan syèl la vòltaj jaden, kont kouran inondasyon, wòdpòte renn-renn ajitasyon ak pwòp tèt nettoyage aksyon senti sou électrodes yo vizaj kritik a rele STET séparateur. Pa okipe kay yo plizyè karakteristik pwosesis, tankou senti vitès, bay manje pwen, ak manje bèt yo ki te konn, pwosesis la te rele STET pwodwi ba LOI vole ash kabòn sa ki nan liv la nan mwens ke 1.5 pou 4.5% nan manje vole sann ki sòti nan LOI de 4% pou fini 25%.

Pye fig. 1 STET Séparateur

Plan séparateur relativman senp ak kontra. Yon machin ki fèt pou travay 36 tòn pa lè se apeprè 9 m (30 .) lontan, 1.5 m (5 .) lajè, ak 2.75 m (9 .) anwo nan syèl la. Kouwa ak asosye woulèt se sèl kalite manm. Électrodes èstasyone ak reyalize yon materyèl ki fè a se sa dirab. Kouwa a ap fè moun ki pa- plastik conducteur. Pouvwa konsomasyon la séparation se osijè de 1 Kilowatè tòn pa materyèl ki te trete ak pi fò nan pouvwa consommée pa de motè mete senti a.

Pwosè a chèch nèt, requires no additional materials other than the fly ash and produces no waste water or air emissions. The recovered materials consist of fly ash reduced in carbon content to levels suitable for use as a pozzolanic admixture in

concrete, and a high carbon fraction useful as fuel. Itilize nan toulede kouran pwodwi bay yon 100% solisyon vole sann dispozisyon pwoblem.

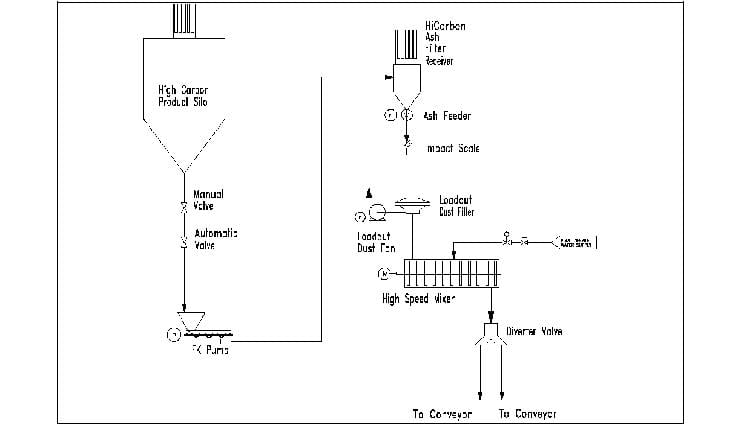

RECOVERED FUEL VALUE OF HIGH-CARBON FLY ASH

In addition to the low carbon product for use in concrete, brand named ProAsh®, the STET separation process also recovers otherwise wasted unburned carbon in the form of carbon-rich fly ash, branded EcoTherm™. EcoTherm™ has significant fuel value and can easily be returned to the electric power plant using the STET EcoTherm™ Return system to reduce the coal use at the plant. When EcoTherm™ is burned in the utility boiler, the energy from combustion is converted to high pressure / high temperature steam and then to electricity at the same efficiency as coal, typically 35%. The conversion of the recovered thermal energy to electricity in ST Equipment & Technology LLC EcoTherm™ Return system is two to three times higher than that of the competitive technology where the energy is recovered as low-grade heat in the form of hot water which is circulated to the boiler feed water system. EcoTherm™ is also used as a source of alumina in cement kilns, displacing the more expensive bauxite which is usually transported long distances. Utilizing the high carbon EcoTherm™ ash either at a power plant or a cement kiln, maximizes the energy recovery from the delivered coal, reducing the need to mine and transport additional fuel to the facilities.

STET’s Raven Power Brandon Shores, SMEPA R.D. Demen, NBP Belledune, RWEnpower Didcot, EDF Energy West Burton, and RWEnpower Aberthaw fly ash plants, all include EcoTherm™ Return systems. The essential components of the system are presented in Figure 2.

Pye fig. 2 EcoTherm™ Return system

STET ASH PROCESING FACILITIES

Controlled low LOI fly ash is produced with STET’s technology at twelve power stations throughout the U.S., Kanada, the U.K., Poloy, and Republic of Korea. ProAsh® fly ash has been approved for use by over twenty state highway authorities, as well as many other specification agencies. ProAsh® has also been certified under Canadian Standards Association and EN 450:2005 quality standards in Europe. Ash processing facilities using STET technology are listed in Table 1.

Tab 1. STET Commercial Operations

|

Itilite / Power Station |

Kote yo ye |

Start of Commercial operations |

Facility Details |

|

Progress Energy – Roxboro Station |

North Carolina USA |

Sept. 1997 |

2 Separateur yo |

|

Kase puisans – Brandon Shores Station |

Maryland USA |

Avril 1999 |

2 Separateur yo 35,000 ton storage dome. Ecotherm™ Return 2008 |

|

ScotAsh (Lafarge / Scottish Power Joint Venture) – estasyon longannet |

Scotland UK |

Okt. 2002 |

1 Separateur |

|

Jacksonville Electric Authority – St. John’s River Power Park,fl |

Florid USA |

Me 2003 |

2 Separators Coal/Petcoke blends Ammonia Removal |

|

South Mississippi Electric Power Authority R.D. Morrow Station |

Mississippi USA |

Jan. 2005 |

1 Separator Ecotherm™ Return |

|

New Brunswick Power Company Belledune Station |

New Brunswick, Kanada |

Avril 2005 |

1 Separator Coal/Petcoke Blends Ecotherm™ Return |

|

RWE npower Didcot Station |

Anglete UK |

Out 2005 |

1 Separator Ecotherm™ Return |

|

PPL Brunner Island Station |

Penso |

Desanm 2006 |

2 Separateur yo 40,000 Ton storage dome |

|

Tampa Electric Co. Big Bend Station |

Florid USA |

Avril 2008 |

3 Separateur yo, doub pase 25,000 Ton storage dome Ammonia Removal |

|

RWE npower Aberthaw Station (Lafarge Cement UK) |

Wales UK |

Septanm 2008 |

1 Separator Ammonia Removal Ecotherm™ Return |

|

EDF Energy West Burton Station (Lafarge Cement UK, Cemex) |

Anglete UK |

Oktòb 2008 |

1 Separator Ecotherm™ Return |

|

ZGP (Lafarge Siman Poloy / Ciech Janikosoda JV) |

Poloy |

Mas 2010 |

1 Separateur |

|

Korea South-East Power Yeongheung Units 5&6 |

Kore di sid |

Septanm 2014 |

1 Separator Ecotherm™ Return |

COAL ASH RECOVERED FROM LAND FILLS

Two sources of ash were obtained from landfills: sample A from a power plant located in

the United Kingdom and sample B: from the United States. Both these samples consisted of ash from the combustion of bituminous coal by large utility boilers. Due to the intermingling of material in the landfills, no further information is available concerning specific coal source or combustion conditions.

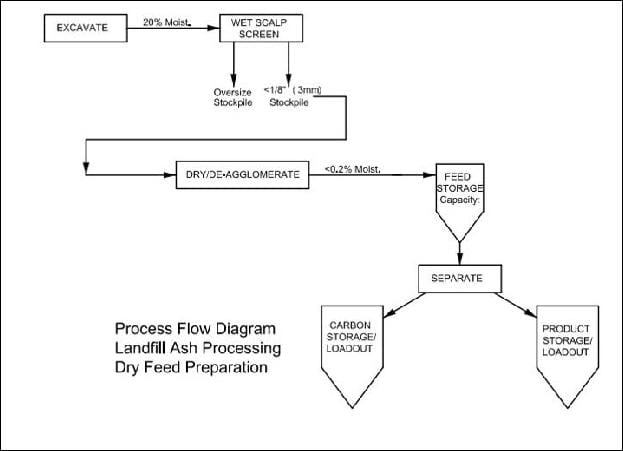

The samples as received by STET contained between 15% ak 20% water as is typical for landfilled material. The samples also contained varying amounts of large >1/8 Pous (~3 mm) material. To prepare the samples for carbon separation, the large debris was removed by screening and the samples then dried and deagglomerated prior to carbon beneficiation. Various methods for drying/deagglomeration are being evaluated in order to optimize the overall process. A general process flow sheet is presented in Figure 3.

Figi 3: Process flow sheet

The properties of the prepared samples were well within the range of fly ash obtained directly from normal utility boilers. The most relevant properties for both the separator feeds and products are summarized in Table 2 along with recovered product.

CARBON SEPARATION

Carbon reduction trials using the STET triboelectric belt separator resulted in very good recovery of low LOI product. The interesting phenomena observed was the reversal of charging of the carbon discussed above. While this behavior has been observed previously by STET and other researchers, the mechanism that changes the relative work functions and thus contact charging behavior of the material is not understood. One suggested mechanism is the redistribution of soluble ions on the mineral and

carbon particles, possibly further influenced by the pH of the aqueous solution on the ash4. Whatever the fundamental mechanism is, it does not appear to degrade the practical application of triboelectric separation to reduce the carbon content of the ash.

The properties of the low LOI fly ash recovered using the STET process for both freshly collected ash from the boiler and ash recovered from the landfill is summarized in Table

2.The results show that the STET process efficiency for the recovered landfill ash is within the range expected for ash freshly collected from the utility boiler.

Tab 2: Properties of feed and recovered low-LOI ash.

|

Feed Sample to Separator |

LOI |

ProAsh LOI® |

ProAsh Fineness, %® +45 μm |

ProAsh® Mass Yield |

EcoTherm® High Carbon Product |

|

Fresh A |

10.2 % |

3.6 % |

23 % |

84 % |

39 % |

|

Landfill A |

9.8 % |

3.3 % |

20 % |

75 % |

28 % |

|

Fresh B |

5.3 % |

2.8 % |

17 % |

91 % |

28 % |

|

Landfill B |

6.9 % |

4.5 % |

24 % |

86 % |

26 % |

PROCESS ECONOMICS

In addition to the normal costs of the STET process, the cost of drying the recovered, high moisture content ash will increase the overall operating costs of the process. Tab 3 summarizes the fuel costs for both operations in the USA and UK for 15% ak 20% moisture contents. Typical inefficiencies of drying are included in the calculated values. Costs are based on the mass of material after drying.

Tab 3: Drying costs on basis of dried mass.

| Moisture content | Heat Requirement KWhr/t | Drying cost / T dry basis UK | Drying cost / T dry basis US |

|---|---|---|---|

| Gas cost 0.027 £/kWhr | Gas cost $4.75 / mmBtu | ||

| 15 % | 165 | £ 5.24 | £ 1.94 |

| £ 8.48 | £ 3.14 | ||

| £ 6.73 | £ 2.49 | ||

| 20 % | 217 | £ 7.23 | £ 2.71 |

| £ 11.85 | £ 4.39 | ||

| £ 9.40 | £ 3.48 |

ASH CHEMISTRY AND PERFORMANCE IN CONCRETE

The properties of the low carbon ash generated from the dried landfill material were compared to that of freshly obtained ash to check the suitability for use in concrete production. A

following table summarizes the chemistry for samples from source B. Testing on source A material has not been completed.

Tab 4: Ash Chemistry of low LOI ash.

|

Source B material |

Sio2 |

Al2O3 |

Fe2O3 |

Kao |

MgO |

K2O |

Na2O |

SO3 |

|

Fresh Production |

51.60 |

24.70 |

9.9 |

2.22 |

0.85 |

2.19 |

0.28 |

0.09 |

|

Landfilled |

50.40 |

25.00 |

9.3 |

3.04 |

0.85 |

2.41 |

0.21 |

0.11 |

Strength development of a 20% substitution of the low LOI fly ash in a mortar containing 600 flannen / yd3 showed the material derived from landfilled ash performed somewhat better than material from fresh production. Wè tab la 5 Anba.

Tab 5: Compressive strength of mortar cubes.

|

|

7 day Compressive Strength PSI |

28 day Compressive Strength PSI |

|

Fresh |

3948 |

5185 |

|

Landfilled |

4254 |

5855 |

CONCLUSIONS

After suitable scalping of large material, drying, and deagglomeration, fly ash recovered from utility plant landfills can be reduced in carbon content using the commercialized STET triboelectric belt separator. The efficiency of the STET system is essentially equivalent for ashes obtained freshly from boiler operations and dried landfilled material. The separator product is suitable for use in concrete production without further beneficiation with nearly identical performance properties. The recovery and beneficiation of landfilled ash will provide a continuing supply of high quality ash for concrete producers in spite of the reduced production of “fresh‿ ash as coal-fired utilities reduce generation. Additionally, power plants that need to remove ash from landfills to meet changing environmental regulations will be able to utilize the process to alter a waste product liability into a valuable raw material for concrete producers.

REFERANS

[1]American Coal Ash Coal Combustion products and Use Statistics: https://www.acaa-usa.org/Publications/Production-Use-Reports/

[2]ST internal report, Out 1995.

[3]Bay manti,T.X,. Schaefer, J.L., Ban, H. H., Neathery, J.K., and Stencel, J.M. Dry Beneficiation Processing of Combustion Fly Ash, Proceedings of the DOE Conference on Unburned Carbon on Utility Fly Ash, Me 19 20, Pittsburgh, PA, 1998.

[4]Baltrus, J.P., Diehl, J.R., Soong, Yo., Sands, W. Triboelectrostatic separation of fly ash and charge reversal, Fuel 81, (2002) pp.757-762.

[5]Cangialosi, F., Notarnicola, madanm, Liberti, L, Pyes, J. The role of weathering on fly ash charge distribution during triboelectrostatic beneficiation, Journal of Hazardous Materials, 164 (2009) pp.683-688.

Word to PDF Converter Converted By BCLTechnologies