ST 設備 & Technology LLC has developed a process that removes ammonia from fly ash. 進程恢復 100% 處理的粉煤灰和由此產生的灰燼符合混凝土使用的所有規格. STET 的氨去除工藝可以單獨使用,也可以與公司的碳分離技術結合使用. 碳分離過程不受粉煤灰上是否存在氨的影響. 這種模組化方法為處理其他無法使用的粉煤灰提供了最低的解決方案。

下載 PDF尼德姆技術中心

從粉灰中去除氨

J. 特納, S. 美元進行收買, 和 f. 赫拉赫

分離技術, Llc 101 漢普頓大道, 李約瑟, 麻塞諸塞州, 美國

摘要

供混凝土用作氣灰的粉煤灰供應可能受到空氣品質法規對公用設施廠運營影響的嚴重影響. 特別, 強制減少氮氧化物, 顆粒, 和 SO3 containing aerosol emission levels are expected to require the installation of control systems which may use ammonia as a reagent. Depending on the level of ammonia present in the flue gas at the unit precipitators, the collected fly ash may be heavily contaminated with ammonia primarily as ammonium sulfate salts.

ST 設備 & 技術有限責任公司 (STET) has developed a process that removes ammonia from fly ash. 進程恢復 100% 處理過的粉煤灰和產生的灰燼符合用於混凝土的所有規格. ST’s ammonia removal process can be used alone or in combination with the company’s carbon separation technology. 碳分離過程不受粉煤灰上是否存在氨的影響. 這種模組化方法為處理原本無法使用的粉煤灰提供了成本最低的解決方案.

The ST ammonia removal system is operating at two locations in the USA and one in Europe. The ammonia levels of the untreated fly ash have varied between 200 和 3000 mg NH3 / kg ash (part per million by mass, or ppm). The ST process has successfully reduced the ash ammonia level to less than 50 mg NH3 / kg ash. 超過。 500,000 tons of fly ash has been sold to ready mix concrete producers from ST’s ammonia removal process.

Ammonia Contaminated Fly Ash

供混凝土用作氣灰的粉煤灰供應可能受到空氣品質法規對公用設施廠運營影響的嚴重影響.1 特別, 強制減少氮氧化物 , 顆粒, 和 SO3 containing aerosol emission levels are expected to require the installation of control systems which may use ammonia as a reagent. Depending on the level of ammonia present in the flue gas at the electrostatic precipitators, the collected fly ash may be heavily contaminated with ammonia primarily as ammonium sulfate salts 1,2. For NOx control, the flue gas ammonia level will be set by the amount of ammonia “slip‿, 即. unreacted ammonia present after the SCR or SNCR unit. 減少顆粒物或溶質3 氣溶膠排放, ammonia is injected into the flue gas prior to the precipitators and will be deposited on the fly ash. The degree to which this occurs is dependent on the SO3 內容, fly ash sulfur content, alkalinity of the fly ash, the ammonia concentration, and ash loading in the flue gas.

The use of 飛灰 in concrete requires that the fly ash have specific physical and chemical properties3. The pozzolanic properties of the ash are activated in the concrete by the generation of highly alkaline free lime from hydration of the cement. When fly ash contains ammonia, this ammonia is liberated as a gas by the action of the highly alkaline solution of the concrete. The alkalinity shifts the equilibrium of ammonium ion in solution to molecular ammonia according to the following equation:

NH4+(aq) + 哦–(aq) ↔ NH3(aq) + H2O

The dissolved molecular ammonia is easily released from solution as free ammonia gas.

ST 設備 & 技術有限責任公司 101 Hampton Avenue Needham, 馬 02494 電話: 781-972-2700

尼德姆技術中心

Ammonia is a strong smelling compound that carries the connotation of barnyards, manure and urine. A strong odor of ammonia is unacceptable to the concrete producer, the contractor working with the concrete, and the ultimate concrete user.4

The finished properties of the concrete are not adversely affected when using ammonia contaminated fly ash, but the odor is unacceptable, particularly if the concrete is used in underground or enclosed spaces.5,6,7 Depending on the specifics of the location, including the amount of fresh air circulation, ammonia odor was found not to be objectionable when using fly ashes containing 100 自 200 mg NH3 / 公斤 (part per million by mass, or ppm). In order to assure that no problems are encountered, the ammonia content of fly ash should be no greater than 100 ppm2,8.

然而, the addition of ammonia at the power generation plant can result in fly ash ammonia contents of 200 自 2500 ppm, rendering the fly ash unacceptable for use in concrete.8 因此, 通過控制發電廠的空氣排放來減少空氣品質問題,從而增加固體廢物處理問題,並增加CO2 通過增加混凝土生產中使用的水泥量來減少溫室氣體排放. 從粉煤灰中去除氨,使其可用於混凝土,避免固體廢物處理,有利於公用事業, 混凝土生產商, 使用者, 和最終擁有者通過降低材料成本和提高產品質量, 通過減少水泥生產產生的溫室氣體的排放來保護環境.

在粉煤灰中發現的氨和銨鹽的數量與煙氣中存在的氨量有關. 對於使用東部瀝青煤的典型粉碎煤單元,其加熱值高達 12,000 BTU/磅 (6667 千卡/千克), 煙氣與煤品質之比約為 8 自 9.5. 當煤的灰含量是 10%, 和 80% 煤中的灰燼被回收為粉煤灰 (20% 到底部灰燼), 煙氣 / 灰分比約為 100. 如果煙氣中所有的氨物種都沉積或吸附在粉煤灰上, 灰燼中的氨濃度約為 50 品質上比煙氣大一倍, 例如. 氨 “滑” 的 2 ppm 的體積將導致含有灰燼 100 鎂 / 公斤 (ppm 乘以 wt。) 氨. 實際測量顯示這種關係是正確的.9 根據煤的灰含量和粉煤灰與底灰的比例以及其他因素,粉煤灰的氨濃度因操作單位而異.

向靜電沉澱器注入氨 (Esp) to improve efficiency and reduce plume opacity can result in very high levels of ammonia in fly ash. Levels up to 2500 ppm ammonia in ash have been found for such systems. SNCR operations typically operate with ammonia slip concentrations of 5 自 20 ppm, with ash contaminated to a level of 200 自 1000 ppm ammonia. SCR systems generally are designed to operate at maximum ammonia slip levels of 2 或 5 ppm, depending on the specifics of the installation.10 Generally, the greater the NH3/NOx ratio, the greater the NOx reduction which will be obtained, with a higher ammonia slip resulting. 然而, ammonia slip greater than 2 ppm may result in ash-ammonia contents of greater than 100 ppm, producing an unmarketable ash.11 Many power plants in Japan and Germany operating SCR units designed for a 2 ppm maximum slip have seen little impact on the marketability of fly ash.1,5 然而, some SCR’s around the world have been designed for 5 ppm ammonia slip. Operation of these units at this high slip level will most likely result in greater than 100 ppm of ammonia on the fly ash.

Controlling ammonia slip to low levels also reduces plugging and corrosion of downstream equipment due to deposition of ammonium sulfates.1,10 Avoiding air preheater plugging due to this phenomenon is expected to be even more important to unit operators when burning high sulfur, US coals. 因此, management of ammonia slip to minimize unit outage time will be a greater concern than controlling the ammonia level of fly ash. The result

ST 設備 & 技術有限責任公司 101 Hampton Avenue Needham, 馬 02494 電話: 781-972-2700

尼德姆技術中心

may be that no significant problem develops for the utilization of ash at some utility sites, depending on the specific design and operation of the emission control systems.

The STET Process

STET has developed a process that removes ammonia from fly ash.12 進程恢復 100% 處理過的粉煤灰和產生的灰燼符合用於混凝土的所有規格. STET 的氨去除工藝可以單獨使用,也可以與公司的碳分離技術結合使用. The carbon separation process is not affected by the presence of ammonia. 這種模組化方法為處理原本無法使用的粉煤灰提供了成本最低的解決方案.

從粉煤灰中去除作為氣體的氨, the STET process utilizes the same fundamental chemical reaction that results in ammonia release in concrete. 從粉煤灰中釋放氨需要銨離子

–分子氨平衡因鹼的存在而向有利於氨的方向轉變. 天然高鹼度的粉煤灰不需要額外的鹼. 用於鹼性灰分較少, 任何強鹼都會服務. 最便宜的鹼源是石灰 (草). 銨鹽與石灰釋放氨的反應受到化學平衡的強烈青睞. 一旦化合物溶解,化學反應迅速發生.

The overall reaction can be generalized as:

(NH4)2SO4(s) + 草(s) → 2NH3(G) + CaSO4(s) + H2O(G)

然而, the vapor pressures of the solids are quite low and the reaction cannot occur in the gas or solid phase. Ammonium sulfate is highly soluble in water and dissociates to ammonium ions and sulfate ions.

(NH4)2SO4(aq) → 2NH4+(aq) + SO42-(aq)

Lime is highly unstable on exposure to water, favoring a highly exothermic reaction commonly known as “slaking”, producing calcium hydroxide or hydrated lime.

草s +H2O → Ca(哦)2(s)

The hydrated lime is only sparingly soluble in water, producing calcium and hydroxide ions.

Ca(哦)2(s) ↔ Ca2+(aq) + 2 哦–(aq)

Calcium sulfate is also sparingly soluble, so as calcium ions are made available by dissolving the hydrated lime, they are primarily consumed by precipitation of calcium sulfate.

Ca2+(aq) + SO42-(aq) → CaSO4(s)

最後, an equilibrium exists between ammonium ions and ammonia dissolved in water.

NH4+(aq) + 哦–(aq) ↔ NH3(aq) + H2O

ST 設備 & 技術有限責任公司 101 Hampton Avenue Needham, 馬 02494 電話: 781-972-2700

尼德姆技術中心

The degree to which ammonium ions are converted to molecular ammonia is dependent on the pH of the aqueous system, higher pH’s favoring the formation of molecular ammonia. This equilibrium is well known.13

A key feature of the STET process is the use of a minimum quantity of water (1 自 4%, 通常 2%) and minimal quantities of alkali (< 2%). Large amounts of water are detrimental to the process, slowing the rate of ammonia release. The pH of the resulting ash / lime / water mixture should be greater than pH 10.0. Very small quantities of alkali are added to assure this pH, depending on the natural pH of the ash. Typically, 少於 1% Ca(哦)2 is required, even with fly ash with naturally acidic pH. Calcium based alkalis are used which result in minimal alteration of the fly ash chemistry. The process is performed at ambient temperature.

Since the cost of the alkali and cost of drying the product are major operating expenses and sizing the mixing and drying equipment are the major components of capital cost, carefully measuring the reagent requirements for a specific ash is necessary to optimize the economics of the process.

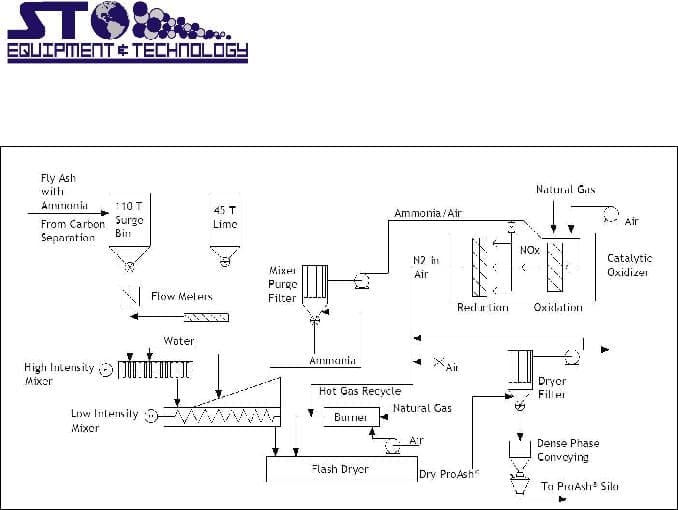

The process flow diagram for the continuous operation of the STET process is presented in Figure 1. 灰, water and alkali in controlled proportions are metered to a mixer. 確保添加的水和鹼的快速混合和均勻分散, 使用高強度混合器. The residence time in this type of mixer is very low, on the order of one second. Ammonia is immediately released but complete evolution requires mixing times of 3 自 4 分鐘,允許從大部分灰燼中大量運輸氣體,以便從大部分灰燼中大量運輸氣體.

獲得這種混合時間,並確保從大部分灰燼中很好地輸送氨, 低強度設備(如 pug mill)用作輔助混合器. 由於灰的含水量很低, 材料流經這個混合器作為高度攪拌的乾粉. 在高速和低速混合器中收集的氨氣要麼被回收到發電機組煙氣中,要麼在兩個中轉化為氮氣- 階段催化裝置.

ST 設備 & 技術有限責任公司 101 Hampton Avenue Needham, 馬 02494 電話: 781-972-2700

尼德姆技術中心

圖 1: STET 氨去除工藝流程圖

脫氨灰通過閃光乾燥器輸送材料以去除多餘的水來乾燥. 由於添加的水量最少, 與灰中可溶性硫酸鹽發生反應時,在形成水合鈣硫酸鈣時消耗的水, 低強度混合階段水流失, 只有少量的水需要由乾燥器去除. 這最大限度地減少了乾燥階段的能源需求. 最終灰燼溫度約為 150oF 足以產生完全自由流動, 產品粉煤灰與水分含量遠低於ASTM C 618 規格 3 wt. %.3

STET 的氨去除工藝首次全面應用, 2003 在位於傑克遜維爾電局街的ST灰燼處理設施. 傑克遜維爾的約翰斯河電力公園, 佛羅里達州. 這種商業規模運營可處理 40 每小時數噸污染灰燼, 將氨含量降低到小於 30 ppm. 傳入的粉煤灰中的氨含量從 ±200 到 900 ppm. 這個過程非常可靠, 導致 90+% 在所有試驗設置下去除氨, 產生火山灰遠低於我們的最大目標 50 ppm ammonia. 最終水分含量是 <0.3%. 代表結果列在表中 2. 超過。 250,000 傑克遜維爾工廠成功處理了數噸受氨污染的灰燼.

ST 設備 & 技術有限責任公司 101 Hampton Avenue Needham, 馬 02494 電話: 781-972-2700

尼德姆技術中心

表 2: 典型商業規模氨系統結果

|

進給率, |

初始氨, |

最終氨, |

石灰率, |

水率, |

|

噸/小時 |

ppm |

ppm |

% 飼料 |

% 飼料 |

|

21 |

910 |

25 |

1.35 |

1.9 |

|

25 |

190 |

9 |

0.88 |

2.6 |

|

40 |

350 |

12 |

0.70 |

2.05 |

|

18 |

242 |

20 |

0.82 |

1.52 |

坦帕大彎站的飛灰, 佛羅里達州被氨污染,因為向發電廠的ESP系統注入氨來控制SO的排放3 SCR 氮氧化物控制系統產生的氣溶膠. 在其他發電廠, SNCR 氮氧化物控制和使用氨增強 ESP 系統中的顆粒收集也會發生氨污染. 在大彎處, 氨注入範圍的單位的粉煤灰氨水準,從 750 自 3360 ppm ammonia. 因此, 用於混凝土生產的粉煤灰必須通過ST氨去除工藝處理.

安裝在大彎處的 STET 氨去除工藝的設計 (圖 2) 是第二個全規模安裝,包括許多改進. 改進物料搬運設備,以便以更高的速率運行. 乾燥系統從以前的設計縮小,包括熱氣體的回收,以減少系統的整體能源需求. 最後, the ammonia released in the process is fed to a two-stage catalytic unit where the collected ammonia gas is converted into nitrogen. The heat generated by this reaction is recovered and used to supplement the energy requirement of the fly ash flash drying system. The use of the two-stage catalytic system results in minimal NOx emissions. 進程恢復 100% 處理過的粉煤灰和產生的灰燼符合用於混凝土的所有規格.

這種商業規模的操作可以處理多達 52 每小時數噸污染灰燼, 將氨含量降低到小於 75 毫克/公斤. 這個過程非常可靠, 導致 97+% ammonia removal, 產生火山灰遠低於我們的最大目標 100 mg/kg ammonia. 最終水分含量是 <0.5%.

An STET ammonia removal process has been in operation at the RWE npower Aberthaw station ash processing facilities in the UK since 2008. Aberthaw adds ammonia to improve ESP collection efficiency with ammonia levels on the ash typical 200 ppm and the process is designed for 500 ppm maximum.

ST 設備 & 技術有限責任公司 101 Hampton Avenue Needham, 馬 02494 電話: 781-972-2700

尼德姆技術中心

圖 2: Ammonia removal system at Big Bend Station, Tampa Florida

The Product Ash

The low ammonia fly ash product meets all chemical and physical requirements of the ASTM C 618 standard and resulting concrete properties are identical to ash not subjected to the ammonia removal process. Table I compares typical properties of ash from one generating station along with properties of the plant ash reduced in ammonia content from 250 鎂 / kg to 20 鎂 / kg by the continuous ST process. Note that the range of calcium oxide content observed for the ash from this source is 1.4 自 12%. The addition of up to 1% Ca(哦)2 (0.75% as CaO) will result in only minor changes in the ash chemistry, broadening the variability insignificantly.

Concrete testing performed on the deammoniated ash showed it to be an excellent pozzolanic material. 使用這種灰的壓縮強度開發與來自此來源的未氨化灰一樣好或更好. 長期混凝土耐久性性能也非常出色, 包括改進的耐腐蝕性, 硫酸鹽阻力, 氯化物滲透性, 和石灰收縮.

ST 設備 & 技術有限責任公司 101 Hampton Avenue Needham, 馬 02494 電話: 781-972-2700

尼德姆技術中心

表一: 粉灰物理和化學特性.

|

|

ASTM C 618 規範 |

植物 # 1 灰燼屬性, 典型 |

植物 # 1 氨去除後的灰分 |

|

|

化學成分 |

|

|

|

|

|

二氧化矽 |

– |

55 – 61 % |

59.8 % |

|

|

氧化鋁 |

– |

15 – 25 % |

23.8 % |

|

|

氧化鐵 |

– |

5 – 10.9% |

7.35 |

|

|

總 (西奧2 + 鋁2O3 + 鐵2O3) |

70.0 最小值. |

78 – 91 % |

90.9 % |

|

|

三氧化硫 |

5.0 麥克斯 |

0.13 – 1.4% |

0.87% |

|

|

氧化鈣 |

– |

1.4 – 12 % |

1.79 % |

|

|

水分 |

3.0 麥克斯. |

0.0 – 0.3 % |

0.21% |

|

|

燒失量 |

6.0 麥克斯. |

0.7 – 2.6 % |

0.91% |

|

|

氧化鈉 |

– |

0.1 – 0.7 |

0.14% |

|

|

氧化鉀 |

– |

0.5 – 2.2% |

0.56% |

|

|

可用堿 (作為 Na2O) |

1.5 % 麥克斯 |

0.5 – 0.8% |

0.51% |

|

|

物理測試結果 |

|

|

|

|

|

細, 保留在 #325 篩 |

34% 麥克斯. |

8 – 16% |

14% |

|

|

強度活動指數 |

|

|

|

|

|

比率與控制@ 7 天 |

– |

81 – 95 % |

94.8% |

|

|

比率與控制@ 28 天 |

75% 最小值. |

94 – 102% |

99.5% |

|

|

水需求, % 控制 |

105% 麥克斯. |

93 – 97% |

94.2% |

|

|

穩健, 高壓滅菌器擴展 |

0.8% 麥克斯. |

-0.035 – 0.010 |

-0.033 |

|

|

幹收縮, 增加@ 28 一天 |

0.03% 麥克斯. |

-0.01 – 0.010 |

-0.009 |

|

|

密度 |

– |

2.35 – 2.45 |

2.36 |

|

總結

The degree to which good quality fly ash will be compromised as the result of NOx or particulate emission systems in the future will depend upon technology choices made by utilities to reduce NOx, particulate matter emissions and plume opacity. 然而, STET’s ammonia removal process can be utilized to remove the ammonia from contaminated ash, producing a high value material for use in concrete production. Recovered ammonia can be recycled to the generating unit for reutilization. 這種除氨工藝可以作為獨立系統安裝,也可以與STET成功的粉煤灰除碳系統結合使用。.

1Stewart, B.R., Unintended Effects of EPA’s Recent Ozone Transport Rule, 程式, 1999 選擇性催化和非催化還原在NOx控制中的應用會議, 5 月 1999, pp.9-10.

2Sloss, L.L., Hjalmarsson, A-K, Soud, H.N., Campbell, L.M., Stone, D.K., Shareef, G.S., Emmel, T., Maibodi, M., Livengood, C.D., Markussen, J. Nitrogen Oxides Control Technology Fact Book, Noyes Data Corporation, pp. 94-95, 1992

3“Standard Specification for Coal Fly Ash and Raw or Calcined Natural Pozzolan for Use as a Mineral Admixture in Concrete”, ASTM C 618, American Society for Testing and Materials, Philadelphia, Pa.

4Majors, R.K., 山, R。, McMurry, R。, Thomas, S., A Study of the Impact of Ammonia Injection on Marketable Fly Ash including Quality Control Procedures, 程式, 1999 Conference on Selective Catalytic and Non-Catalytic Reduction for NOx control, 5 月 1999, pp.11-13.

5Van der Brugghen, F.W., Gast, C.H., Van den Berg, J.W., Kuiper, W.H., Visser, R., Problems encountered During the Use of Ammonium contaminated Fly Ash. 程式: EPRI / EPA 1995 Joint Symposium on Station Combustion NOx Control, 5 月 16-19, 1995. Book 4, Session 8A, pp. 1-16.

6Van den Berg, J.W., Cornelissen, H.A.W. ,Effect of low NOx Technologies on Fly Ash Quality, 程式: 13th 煤燃燒產品使用與管理國際研討會, 1999, pp. 29-1 – 29-11.

7科赫, H-J., 普倫澤爾, H。, 混凝土熨平板鑄造中氣味發展的試驗 – 使用 NH3-受污染的飛灰, 混凝土預製裝置與技術, 音量 11, 1989 pp. 72-75.

8費舍爾, 西元前。, 布萊克斯托克, T. 使用氨剝離工藝進行飛灰化, 12th 煤燃燒副產品管理與利用國際研討會, 1997 pp. 65-1 – 65-8.

ST 設備 & 技術有限責任公司 101 Hampton Avenue Needham, 馬 02494 電話: 781-972-2700

尼德姆技術中心

9拉裡莫爾, 我。, 道奇恩, D。, 夢 露, 我。, 氨效應對灰的表徵及去除方法評價, 程式: 13th 煤燃燒產品使用與管理國際研討會, 1999, pp. 16-1 – 16-15.

10氮氧化物排放控制: 選擇性催化還原 (Scr), 潔淨煤技術, 專題報告編號 9. 美國. 能源部和南方公司服務部, 公司. 7 月, 1997.

11奧康納, D。, 拉裡莫爾, L, 道奇恩, D。, 夢 露, 我。, 氨基氮氧化物還原對粉灰的影響: 灰燼上的氨吸附, 程式, EPRI-DOE-EPA 綜合公用事業空氣污染控制研討會: MEGA 研討會, 8 月, 1999, 紙 # 16.

12美元進行收買, S.A., 和赫拉奇, F.J., Method for Removing Ammonia from Ammonia Contaminated Fly Ash, United States Patent Number 6,077,494, 6 月 20, 2000.

13Thurston, R.V., Russo, 鋼筋混凝土。, Emerson, K。, Aqueous Ammonia Equilibrium – 未電離氨百分比製表, United States Environmental Protection, EPA-600/3-79-091, 8 月, 1979.

ST 設備 & 技術有限責任公司 101 Hampton Avenue Needham, 馬 02494 電話: 781-972-2700