Select Language:

Kyle Flynn, Abhishek Gupta, Frank Hrach

Mkota

Review mabuku zogwirizana limasonyeza kuti kafukufuku kwambiri wakhala anayesetsa ntchito electrostatically

njira kupatukana kuti ziume granular mbewu zochokera chakudya (i.e., organic) zipangizo. Zimenezi ali inapita patsogolo m'mbuyomu 10 - 20 zaka, with many researchers in Europe and the United States applying electrostatic kulekana techniques to a wide variety of beneficiation challenges. Kuyambira kafukufuku, zikuonekeratu kuti njira electrostatic timatha kupanga latsopano, mankhwala apamwamba mtengo chomera, kapena kupereka njira kunyowetsa njira processing. Ngakhale amapatukana yolimbikitsa ya zakudya zachimanga yambewu, pulse and oilseed materials have been demonstrated at the laboratory and in some cases, pilot scale, machitidwe electrostatic pofuna kusonyeza zotsatira izi sizingakhale abwino kapena yosafuna zida processing kuchita kutali choncho tsiku ndi malonda. umisiri ambiri electrostatic sali oyenera ndondomeko finely pansi, otsika kachulukidwe ufa monga zipangizo chomera. Komabe, ndi cha ku Switzerland Zida & Technology (STET) triboelectrostatic lamba olekanitsa ali anasonyeza imapanga pokonza particles zabwino 500 - 1 μm. The STET belt separator is a high-rate, m'mafakitale kutsimikiziridwa processing chipangizo kuti akhale abwino zopindulitsa zikuchitika posachedwapa processing organic zakuthupi. The STET lamba olekanitsa anayesedwa pa chitsanzo cha lonse ufa wa tirigu ndi anapezeka bwino kuchotsa chinangwa ku wowuma kachigawo. kuyezetsa tsogolo ndi olekanitsa STET izichitikira pa tirigu zitsanzo chinangwa, ufa chimanga

ndi nyemba monga soya ndi lupine.

Keywords: Fuko-Electrostatic, Electrostatic, kupatukana, Fractionation, tirigu, mapira, ufa, CHIKWANGWANI, mapuloteni, Oilseeds, nyemba

Chiyambi

njira Electrostatic kulekana akhala ntchito kale 50 Zaka pa beneficiation amalonda lonse

mafakitale mchere ndi yobwezeretsanso zipangizo zinyalala. Electrostatic beneficiation lowuma granular chakudya chomera ofotokoza (i.e, organic) zipangizo akhala ankafufuza zoposa 140 zaka, ndi setifiketi woyamba kupatukana electrostatic ufa wa tirigu middlings wodzazidwa mwamsanga 1880. [1] Electrostatic beneficiation limalola amapatukana zochokera kusiyana umagwirira pamwamba (ntchito ntchito) kapena katundu dielectric. Nthawi zina, Kulekanitsidwa izi sizikanakhala zotheka kugwiritsa ntchito kukula kapena osalimba amapatukana nokha. Electrostatic machitidwe kulekana ntchito mfundo zofanana. Onse machitidwe electrostatic kulekana muli dongosolo kuti electrically mlandu particles, ndi kunja kwaiye munda magetsi kwa kulekana chidzachitika, ndi njira pofotokoza particles kukhala kunja chipangizo kulekana. adzapereke magetsi angayambe ndi njira imodzi kapena angapo kuphatikizapo kupatsidwa ulemu conductive, tribo-nawuza (kukhudzana electrification) ndipo ion kapena kuŵala kwa m'mlengalenga nawuza. Electrostatic machitidwe kulekana ntchito imodzi mwa njira izi nawuza. [2]

Mkulu mavuto mpukutu electrostatic machitidwe kulekana akhala akugwiritsidwa ntchito m'mafakitale ambiri ndi ntchito kumene

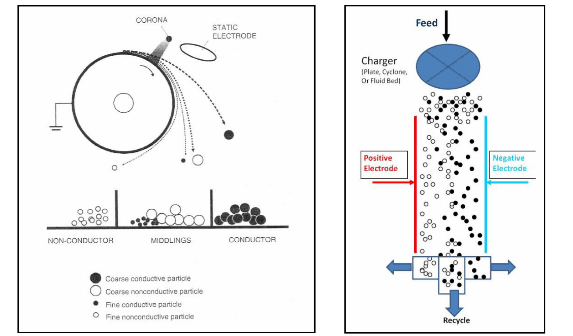

chigawo chimodzi ndi zambiri electrically conductive kuposa ena. Zitsanzo za ntchito mkulu mavuto mpukutu separators monga titaniyamu zimakhudza mchere kulekana, komanso ntchito yobwezeretsanso, Mwachitsanzo kusanja zitsulo kuchokera pulasitiki. Pali Kusiyana angapo ndipo geometries ntchito kachitidwe mkulu mavuto mpukutu, koma ambiri, iwo ntchito mfundo zofanana. particles chakudya ali ndi udindo zoipa ndi ionizing kuŵala kwa m'mlengalenga kumaliseche. particles chakudya anamwazikana n'kufika ng'oma onsewo, kumene ng'oma ndi electrically chinakhazikika. The particles electrically conductive kusiya akuwayang'anira pa kulankhula padziko ng'oma chinakhazikika. The kasinthasintha wa ng'oma amachititsa particles conductive kuti ukaponyedwe padziko ng'oma ndi waikamo choyamba mankhwala hopper. The particles si conductive kusunga akuwayang'anira magetsi ndipo anamukhomera padziko ng'oma ndi. m'kupita, mlandu magetsi particles sanali conductive kudzatha, kapena particles adzakhala akukankhira kwa ng'oma pambuyo ng'oma wakhala zimayenda kuti particles si conductive ndi waikamo mu sanali conductive tinthu hopper. Mu ena ofunsira, ndi middlings hopper aikidwa pakati pa conductive ndipo sanali conductive mankhwala hopper. Mphamvu ya mtundu wa chipangizo kulekana ambiri okha particles amene ali ndi coarse ndi / kapena mkulu enieni yokoka, chifukwa kufunika particles zonse zolankhulirana padziko ng'oma ndi. Kuphatikiza apo, tinthu otaya mphamvu n'kofunika ngati okhota patsogolo ndi kwenikweni Ndikuuzani particles kuchokera pamwamba pa ng'oma kwa hoppers mankhwala ziwalo. Chabwino particles ndi otsika kachulukidwe particles tikhoza kumangotsatira maganizo ndi mafunde mpweya ndipo motero sangakhale ndi kuti ukaponyedwe kwa ng'oma pamalo pazikhala. [2] [3] [4]

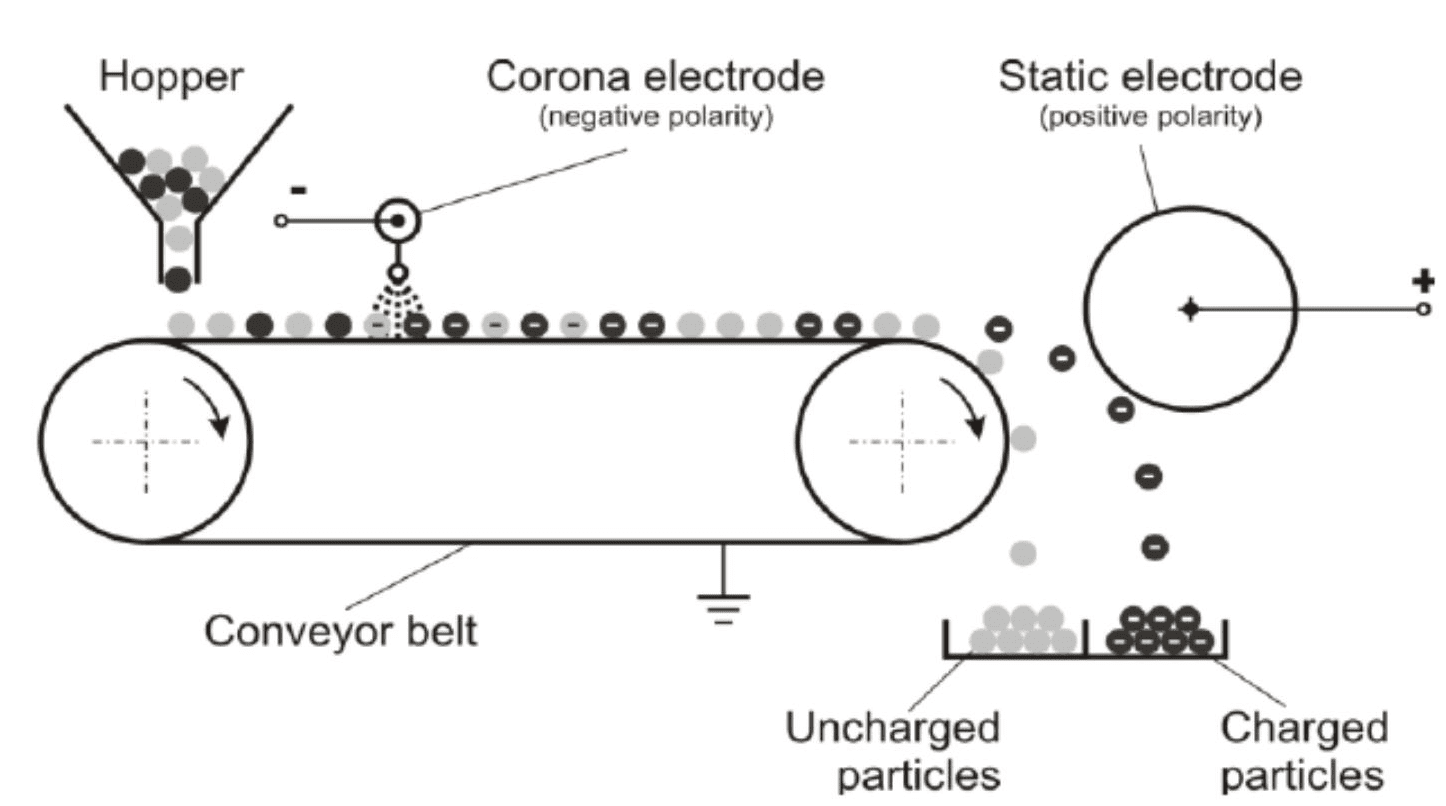

Mkulu mavuto lamba olekanitsa ndi zosinthika wa mkulu mavuto olekanitsa mpukutu tafotokozazi. particles chakudya anamwazikana wogawana kudutsa m'lifupi ndi electrically otsendereka conveyor lamba. Particles ali ndi udindo, Nthawi zambiri ndi kuŵala kwa m'mlengalenga zoipa, ngakhale njira zina za nawuza zitheka. Apanso particles conductive kupereka chiweruzo chawo magetsi kuti ochirimika conveyor lamba, pamene particles si conductive kusunga akuwayang'anira. The particles conductive kuguluka wa m'mphepete mwa lamba ndi yokoka, pamene adawalamulira particles si conductive ndi "kukwezedwa" kuchokera ku padziko lamba ndi mphamvu electrostatic. Kachiwiri kulekana kuti azigwira, aliyense tinthu ayenera kulankhula ndi pamwamba pa lamba kuti mpata particles conductive kupereka chiweruzo chawo ndi lamba. Choncho, okha wosanjikiza umodzi wa particles akhoza kungozifotokoza olekanitsa pa nthawi ina. Monga tinthu kukula chakudya amakhala ang'onoang'ono, mlingo processing chipangizo yafupika. [5] [6]

Kufanana mbale separators electrostatic ali ambiri pokhuzana kulekanitsa particles osati pamaziko a madutsidwe, koma kusiyana umagwirira pamwamba kuti amalola mlandu kutengerapo magetsi ndi kukhudzana frictional. Particles ali electrically mlandu ndi kukhudzana wolimba ndi particles ena, kapena ndi pamwamba lachitatu monga chitsulo kapena pulasitiki kufunika katundu tribo-nawuza. Zida zimene electronegative (ili pa mapeto zoipa mndandanda tribo za magesi) kuchotsa ma elekitironi padziko tribo-nawuza ndipo motero tikhale ukonde mlandu zoipa. pokhudzana, zipangizo amene ali kumapeto zabwino mndandanda tribo-magetsi amapereka ma elekitironi ndi mlandu ndithu. The particles mlandu ndiye anadzetsa minda magetsi kwaiye awiriwa maelekitirodi kufanana mbale mwa njira zosiyanasiyana mayendedwe (yokoka, pneumatic, kugwedera). Pamaso pa munda magetsi, particles mlandu kusuntha cha maelekitirodi oppositely mlandu ndipo anasonkhana pa hoppers mankhwala lolingana. kachiwiri, ndi middlings kachigawo munali chisakanizo cha particles Mwina amatengedwa, malingana kasinthidwe chipangizo kulekana. [4] [7]

chithunzi 1: Chithunzi cha mkulu mavuto olekanitsa mpukutu (anasiya) ndi kufanana mbale ufulu kugwa olekanitsa (chabwino).

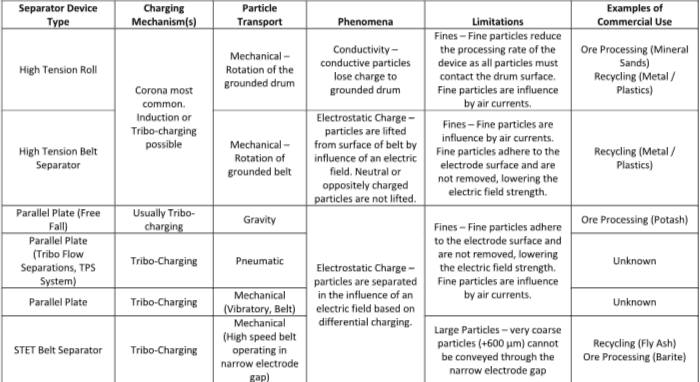

Table 1: Chidule cha amagwiritsidwa ntchito zipangizo electrostatic kulekana.

Mlanduwu 1 - Tirigu ndi Tirigu chinangwa Beneficiation.

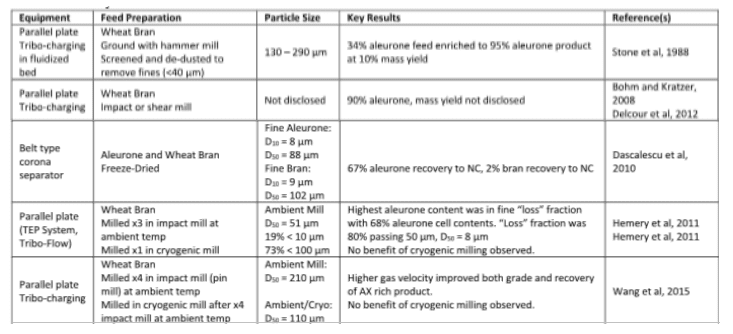

Tirigu chinangwa ndi chochokera kwa ochiritsira mphero tirigu, woimira 10-15% ya tirigu. Tirigu chinangwa tichipeza zigawo lakunja kuphatikizapo pericarp ndi, mutu, ndipo aleurone. Tirigu chinangwa ndi mabuku ambiri a micronutrients ndi, CHIKWANGWANI, ndipo phytochemicals ali mbewu, amene anasonyeza thanzi labwino kwa anthu. [8] chidwi kwambiri kulekanitsa ndi beneficiating tirigu chinangwa wakhala inanena. chidwi m'mbiri yakale kulekanitsa tirigu chinangwa anali luso ndi mtengo wa mankhwala ufa. Komabe, zambiri chidwi zaposachedwapa zalembedwa mu akuchira zigawo zikuluzikulu zofunika kuchokera ku chinangwa tirigu.

mu 1880, Thomas Osborne setifiketi woyamba malonda electrostatic olekanitsa kochotsa chinangwa ku middlings ufa. The olekanitsa inkakhala masikono TACHIMATA ndi mphira zovuta kapena zinthu ofanana amene anali wokhoza kuti electrically mlandu kudzera frictional tribo-ndi wakhalidwe ubweya. Ngakhale limafotokoza, amaganiza masikono akaweruka kuthi mlandu zoipa wachibale ubweya, mogwirizana ndi ambiri tribo-magetsi mndandanda. The masikono electrically mlandu ndiye anakopeka ndithu mlandu chinangwa CHIKWANGWANI particles, Ndikuuzani iwo padziko mayina mpaka zikumangidwa CHIKWANGWANI particles ali akukankhira padziko mayina. izi (kapadera) zabwino adzapereke kwa chimanga tirigu kumatsutsana ndi zotsatira ananenedwa ndi ena. Tribo-adzapereke particles chinangwa anali mothandizana fluidizing mpweya anayambitsa pansi pa chipangizo, amene anali ndi phindu zina kuchititsa zochepa wandiweyani chinangwa particles pamwamba, pafupi kuti akhazikitsa ndi. [1]

mu 1958 ndi zida kupatukana electrostatic wa chinangwa ndi endosperm ali middlings ufa anali anafotokoza mu setifiketi Kutengera ndi Branstad ntchito pa General Mills. chipangizo munali zikufanana olekanitsa mbale imene particles anali zoperekedwa pakati pa mbale awiri kugwedera. particles chinangwa, adawalamulira ndi kukhudzana frictional ndi particles endosperm, ndiye anali atakwezeka kwa elekitirodi pamwamba kupyolera perforations mu elekitirodi pamwamba. [9]

mu 1988 ndi zida ndi ndondomeko akuchira aleurone kwa malonda chinangwa tirigu anali anafotokoza mu setifiketi Kutengera. Malonda tirigu chinangwa ndi kuyambira aleurone zili 34% linatukuka ndi maganizo a 95% pa 10% zokolola misa (28% aleurone kuchira) ndi osakaniza nyundo mphero, sizing ndi kuyezetsa magazi, mpweya elutriation ndi electrostatic kulekana ntchito yomweyi mbale electrostatic olekanitsa. Tinthu mlandu pa chipangizo mpweya elutriator, amene ali ndi udindo wapawiri kuchotsa ndalama (<40 μm) by conveying, while simultaneously tribo-charging the aleurone particles positive (reporting to the negative electrode plate) and the pericarp/testa particles negative. The particle size of the bran mixture was carefully controlled by hammer milling and multi-level screening, to obtain a feed mostly sized in the 130 - 290 µm range. [10]

Recent work on recovering aleurone from wheat bran continues. mu 2008, Buhler AG patented an electrostatic separation device for separating aleurone particles from shell particles made of commuted bran. One embodiment of the device consists of a rotor operating in a narrowly sized treatment area, which allows for particle-to-particle and particle-to-wall contact and subsequent tribo-charging. The charged particles are then conveyed mechanically into a separation vessel containing parallel plate electrodes. Particles fall through the separation vessel by gravity, as the differentially charged particles move toward the oppositely charged electrodes under the influence of the electric field. [11] When combined with proper sizing of the feed bran and mechanical sorting methods, aleurone concentrations of up to 90% have been reported. [12] [8]

chithunzi 2: Chinaonekeranso ku Hemery neri Al, 2007 [8].

Tribo-nawuza ndi kuŵala kwa m'mlengalenga nawuza zatsopano pa chinangwa tirigu kunachitika ndi anthu ogwira ntchito pa Electrostatics wa omwazika Media Unit Research, University of Poitiers, France mu 2010. Ofufuzawa anayeza mlandu pamwamba ndi zimaonekera lingathe kuvunda nthawi chinangwa tirigu ndi 10% chinyontho ndi lyophilized (amaundana-zouma) chinangwa tirigu. A mayeso kulekana chitachitidwa pa chitsanzo cha 50% amaundana-zouma tirigu chinangwa ndi 50% amaundana-zouma aleurone chakudya pogwiritsa ntchito lamba mtundu kuŵala kwa m'mlengalenga electrostatic olekanitsa. (chithunzi 3) Kupatukana zotsatira za olekanitsa zasayansi lonse kuŵala kwa m'mlengalenga anasonyeza 67% wa aleurone anali anachira kuti sanali wochititsa hopper, pamene okha 2% wa chimanga tirigu lipoti ku si wochititsa hopper. Tribo-nawuza zatsopano anali kuchitidwa chinangwa tirigu ndi aleurone, koma kuyeza yeniyeni mlandu pamwamba [μC / g] kwaiye pa chilichonse kachigawo, monga kuyenera akuchira malonda ndi kulekana electrostatic. zipangizo onse chakudya mlandu ntchito Teflon monga nyemba kukhudzana. Onse chinangwa tirigu ndi aleurone amafotokozedwa ngati nawuza wachibale zabwino Teflon, chimene mwa icho chokha electronegative kwambiri. Ukulu wa mlandu anapezeka zimadalira mavuto opaleshoni ntchito pa tribo-naupereka, ankatanthauza kuti kugwedezekagwedezeka apamwamba kumabweretsa kulankhula ndi kokwanira kwambiri tribo-adzapereke. [13]

chithunzi 3: Chinaonekeranso ku Dascalescu neri Al, 2010 [13]

mu 2009, Akatswiri ayesedwa ndi electrostatic nawuza katundu wa aleurone olemera ndi pericarp zipangizo wolemera chakudya. [14] mu 2011 Akatswiri a anachita electrostatic kulekana kuyezetsa pa zitsanzo za finely kuuluka chinangwa tirigu ntchito woyendetsa lonse electrostatic mbale olekanitsa (TEP System, Tribo mumayenda amapatukana, Lexington, USA). The TEP System yagwiritsa ntchito ndi adzapereke mzere, kumene particles chakudya tikuuzidwa mu chipwirikiti wothinikizidwa mpweya mtsinje, ndipo pneumatically zoperekedwa kudzera adzapereke mzere m'chipinda kulekana. particles ndi tribo-mlandu ndi tinthu kuti tinthu kukhudzana, komanso tinthu kukhudzana ndi pamwamba pa mzere adzapereke. Zotsatira analandira ndi System TEP anasonyeza kuti electrostatic kulekana anali mogwira kukulitsa aleurone ndi beta-glucan zili chinangwa tirigu. N'zochititsa chidwi, kachigawo zakuthupi kuti anapezeka kuti ali apamwamba aleurone selo okhutira, pa 68%, anali wabwino kwambiri (D50 = 8 μm) nusu kuti anali pambuyo pa chubu nawuza. Si bwino chifukwa chake nkhaniyi anali preferentially anaikira mu zida adzapereke, Komabe, limasonyeza kuti luso la pokonza nkhani selo aleurone kungafune njira electrostatic kuti angathe processing zabwino kwambiri ufa. Komanso, ntchito anasonyeza kuti chakudya pokonzekera chinangwa tirigu anali yofunika. Zitsanzo anawakonzera cryogenic akupera mu nyundo mphero anapezeka kuti zochepa kwathunthu dissociated (omasulidwa) kuposa anthu pansi zimakhudza mtundu mphero pa yozungulira kutentha. [15] [16]

chithunzi 4: Chinaonekeranso ku Hemery neri Al, 2011 [16]

ntchito Recent anaphunzira ndende ya arabinoxylans tirigu chinangwa ndi njira electrostatic. Ofufuzawa ntchito ndi zasayansi lonse electrostatic olekanitsa wopangidwa mwa chubu ndi kulekanitsidwa nawuza chipinda munali kufanana awiri mbale maelekitirodi. Milled tirigu chinangwa anali anadzetsa chubu nawuza ndipo anakauza pneumatically m'chipinda kulekana ntchito wothinikizidwa asafe. The kugwedezekagwedezeka ndiponso gasi mkulu mathamangidwe mu chubu nawuza anapereka tinthu kukhudzana zofunika tribo-adzapereke. The particles adawalamulira (mankhwala olekanitsa ndi) anasonkhana kuchokera pamwamba pa maelekitirodi yoganizira. Chifukwa lathu ndi ofukula za maelekitirodi a kwambiri kuchuluka kwa zinthu sanali anasonkhana. Izi middlings kachigawo akhoza zobwezerezedwanso kwa processing mu electrostatics ochiritsira, Komabe, mokhudzana ndi kuyesera, zakuthupi si anasonkhana pa maelekitirodi ankaona otaika. Akatswiri lipoti kuwonjezeka mu kalasi mankhwala (arabinoxylan zili mu mankhwala) ndi kulekanitsidwa Mwachangu ngati mathamangidwe kupereka kuchuluka. [17]

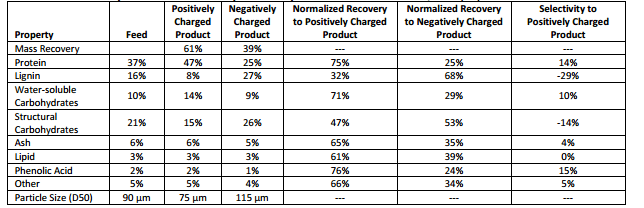

zoyesayesa zamakono kuti beneficiate tirigu chinangwa ntchito njira electrostatic zakambidwa mwachidule pansi Table 2.

Table 2: Chidule cha njira electrostatic ayesedwa kwa beneficiate tirigu chinangwa.

Mlanduwu 2 - Mapuloteni Kusangalala kwa Lupine ufa

Akatswiri pa Njira Chakudya Engineering Gulu mu Wageningen, The Netherlands, ayesedwa lingathe patsogolo mapuloteni ntchito nyemba. Mtola ndi lupine ufa ankachitiramo wakudya zosiyanasiyana njira mapuloteni patsogolo kuphatikizapo gulu mpweya pamodzi kulekana electrostatic. Popanda kuchitapo kanthu mtola ndi lupine mbewu anayamba milled pafupifupi 200 μm. Chakudya zipangizo gulu ndi electrostatic kulekana anali kenako milled ntchito zimakhudza mtundu mphero ndi classifier mkati (Hosokawa-Alpine ZPS50). Apakatikati tinthu kukula (d50) inanena pafupifupi 25 μm chifukwa ufa mtola, ndipo pafupifupi 200 μm chifukwa ufa lupine, isanafike gulu mpweya. Pomaliza, ndi kagawo aliyense nyemba, mtola ndi lupine ufa, Kenako mpweya wachinsinsi (Hosokawa-Alpine ATP50). Chakudya kwa olekanitsa electrostatic inkakhala flours onse Popanda kuchitapo kanthu, komanso njira ndi mankhwala abwino kuchokera kwa gulu mpweya. [18]

The electrostatic kupatukana chipangizo ntchito pa zatsopano anali zikufanana mbale mtundu, ndi adzapereke ikuchitika kudzera adzapereke triboelectric mu 125 mamilimita kutalika adzapereke chubu, ndi particles zoperekedwa pneumatically ndi asafe wothinikizidwa. chipangizo ndi ofanana mu kasinthidwe kwa chipangizo ntchito ndi Wang neri Al (2015). [17] Electrostatic zatsopano kulekana inkachitikira pa ufa pansi mtola ufa lupine, komanso njira ndi chabwino tuzigawo twa ufa mtola ufa lupine kuwapeza gulu mpweya. The ufa mtola anasonyeza chabe kayendedwe ka mapuloteni pa kuyezetsa electrostatic. Komabe, ufa lupine anasonyeza gulu lapadera la mapuloteni mu zitsanzo zonse zitatu anayesedwa (milled ufa - 35% mapuloteni, milled wachinsinsi ndalama - 45% mapuloteni, milled wachinsinsi coarse - 29% mapuloteni). Mapuloteni kulemera mankhwala pafupifupi 60% anali anachira pa elekitirodi kuulukira aliyense wa atatu zitsanzo lupine anayesedwa. [18]

Mlanduwu 3 - CHIKWANGWANI Kuchotsedwa Chimanga

Akatswiri pa Dipatimenti ya ulimi ndi Tizilombo Engineering, Mississippi State University anachita kuyezetsa electrostatic pansi ufa chimanga, ndi cholinga cha kuchotsa CHIKWANGWANI. The electrostatic kupatukana chipangizo inkakhala ndi pazimalamba zozungulira ndi elekitirodi zoipa anayikidwa pa mapeto a conveyor ndi. The particles ndithu adawalamulira, CHIKWANGWANI particles, pamenepa, anali atakwezeka pa pazimalamba zozungulira ndipo zosankhidwa mu hopper yachiwiri. The sanali CHIKWANGWANI particles anagwapo wa conveyor lamba ndi mphamvu yakukoka ndi adayikidwa ku woyamba mankhwala hopper. Olemba chiyani kufotokoza mmene adzapereke magetsi ikuchitika. The chakudya chuma olekanitsa uyu anali ndi coarse, ndi makulidwe tinthu ya chakudya kuyambira 12 thumba (1,532 μm) kuti 24 thumba (704 μm). Sikuti kuti undersize (<704 μm) material was processed during this study. Each test condition was completed using 1 kg of feed material which was uniformly dispersed across the belt. [6]

chithunzi 5: Chinaonekeranso ku Pandya neri Al, 2013 [6]

The ofufuza Mississippi State anamaliza electrostatic kulekana kuyezetsa pa ufa unscreened chimanga, ndi ndisanabadwe chimanga ufa tuzigawo twa ndi CHIKWANGWANI kulemera tuzigawo twa pambuyo pa gulu mpweya. kuyezetsa Electrostatic sanali anamaliza pa otsika-CHIKWANGWANI mitsinje pambuyo pa gulu mpweya. Analysis wa zotsatira za kulekana electrostatic amaperekedwa pansipa:

Table 3: Zotsatira olekanitsa CHIKWANGWANI chinaonekeranso ku Pandya neri Al, 2013 [6]

Mlanduwu 4 - Mapuloteni Yozunzirako ku Oilseeds

Oilseeds monga rapeseed (canola), mpendadzuwa, zitsamba, mpiru, soybean-chimanga nyongolosi, ndipo flaxseed ambiri ali ndi kuchuluka zochuluka onse mapuloteni ndi CHIKWANGWANI. Processing umisiri kuchotsa usasungunuke, chotero kuwonjezera mapuloteni okhutira, wa oilseeds adzakhala zofunika kwambiri monga kufunika padziko lonse ukuwonjezeka mapuloteni. [19] ntchito posachedwapa ofufuza pa French Institute National kuti ulimi Research anafufuza ultrafine mphero pamodzi processing electrostatic wa mpendadzuwa mbewu chakudya, kuikira mapuloteni. The chakudya mpendadzuwa zitsanzo chakudya anali kuuluka mu zimakhudza mphero zikugwira ntchito pa yozungulira kutentha kwa kukula tinthu (D50) wa 69.5 μm. The olekanitsa electrostatic ntchito kukayezetsa anali kufanana mbale chipangizo kumene chachikulu adzapereke limagwirira anali tribo-adzapereke. The tribo-adzapereke zinachitikadi kumtunda kwa maelekitirodi mu mzere tribo-nawuza, ndi particles zoperekedwa kudzera mu mzere adzapereke, ndi maelekitirodi ndi, kudzera zoyendera pneumatic. Mapuloteni anapezeka kuti azilipiritsa zabwino (malipoti kwa elekitirodi zoipa) ndi CHIKWANGWANI kulemera kachigawo anapezeka kuti azilipiritsa moyipa. Mapuloteni selectivity anapezeka mkulu. Chakudya mapuloteni anali 30.8%, ndi mapuloteni kulemera mankhwala choyezera 48.9% ndi mapuloteni zatha (CHIKWANGWANI kulemera) mankhwala kuyeza okha 5.1% mapuloteni. Mapuloteni kuchira anali 93% kwa mankhwala abwino. mapadi, hemicelluloses, ndipo lignin Anayesa ndipo anapeza kuti akapezeke ku mankhwala zoipa adawalamulira, zosiyana kuti mapuloteni. [20]

Table 4: Zotsatira za mpendadzuwa mbewu chakudya kulekana chinaonekeranso ku Barakat neri Al, 2015 [20]

mu 2016, kuphunzira zina inatha ntchito finely kuuluka rapeseed mafuta mbewu chakudya, kapena mikate rapeseed mafuta (ROC), monga chakudya ndi electrostatic ndondomeko kulekana. Kachiwiri ultrafine mphero pa yozungulira kutentha chitachitidwa ntchito chipangizo mpeni mphero (Retsch SM 100). Nkhani milled, ndi apakatikati tinthu kukula (D50) pafupifupi 90 μm, anali kukonzedwa ntchito woyendetsa lonse kufanana mbale olekanitsa (TEP System, Tribo mumayenda amapatukana). The TEP System yagwiritsa ntchito triboelectric adzapereke ndi kupereka pneumatic wa particles kupyolera kuthamanga adzapereke mzere m'mikhalidwe yovuta. A osakwatira chiphaso kulekana mayeso ndi System TEP zinachititsa ndende kwambiri mapuloteni, ndi chakudya mapuloteni a 37%, ndi zabwino mlandu mankhwala mapuloteni mlingo wa 47% ndi zoipa mlandu mankhwala mapuloteni mlingo wa 25%. Zina magawo kulekana ankachiritsa, potsirizira pake kutulutsa mapuloteni kulemera mankhwala ndi 51% mapuloteni pambuyo 3 masiteji kulekana motsatizana. [21]

Table 5: Zotsatira za rapeseed mafuta mbewu chakudya kulekana chinaonekeranso ku Basset neri Al, 2016 [21]

zokambirana

Review mabuku zogwirizana limasonyeza kuti kafukufuku kwambiri wakhala anayesetsa kukhala njira electrostatic olekanitsa kwa zipangizo organic. Zimenezi wapitiriza kapena ngakhale inapita m'mbuyomu 10 - 20 zaka, ndi ofufuza ambiri ku Ulaya ndi ku United States kutsatira njira electrostatic kulekana osiyanasiyana mavuto beneficiation. Kuyambira kafukufuku, mutha kuona kuti njira electrostatic timatha kupanga latsopano, mankhwala apamwamba mtengo chomera, kapena kupereka njira kunyowetsa njira processing.

Ngakhale kulimbikitsa Kulekanitsidwa kwa mbewu monga chimanga, nyemba, ndi zipangizo oilseed akhala anasonyeza pa zasayansi ndi ena lonse milandu woyendetsa, the electrostatic systems used to demonstrate these results may ultimately not serve as the most suitable or cost-effective processing equipment to perform such separations on a commercial basis. Existing commercial electrostatic systems are most commonly used in separations of minerals, metals or plastics. Minerals and metals are both relatively dense materials with high specific gravity, as compared to plant materials. Even with the high specific gravity of minerals and metals, zothandiza tinthu kukula zofooka kwa ng'oma mpukutu ndi kufanana mbale electrostatic separators zimakhalanso coarse, ndi particles ochepa pansipa 100 μm Mwachitsanzo. Mapulasitiki ndi a kachulukidwe poyerekeza mchere ndi zitsulo koma nthawi zambiri ndi kukonzedwa pa zamitundu coarse tinthu, flakes monga pulasitiki Mwachitsanzo. The introduction of fine particles creates operational difficulties for both high-tension roll and parallel plate separators. chabwino, otsika kachulukidwe particles ali tcheru kwambiri mafunde mpweya, makamaka poyerekezera mchere ndi zitsulo. kusiyana Small mu mafunde mpweya mkati chipangizo kulekana zimakhudzira njira kuyenda ndi tinthu zabwino, kuwagwiritsa magulu ena kuposa anthu chifukwa cha munda electrostatic.

Kachitidwe kwambiri kufanana mbale olekanitsa, finely nthaka ndi otsika kachulukidwe particles amene electrostatically mlandu ndi anasonkhana pa maelekitirodi wa separators kufanana mbale. Ngati awa abwino particles electrically Ufumuyo si kuchotsedwa pa maziko zonse, the electric field strength and efficiency of the device degrade. The work of the researchers at The Food Process Engineering Group Wageningen UR (Wang et al, 2015) took advantage of this phenomenon to collect samples off the surface of the electrodes of the parallel plate separator to analyze the products of the separation. Parallel plate separator systems, particularly those that rely upon gravity to convey particles through the electric field, have attempted to address this problem in several ways. Stone et al (1988) described a process in which fine particles were removed upstream of the electrostatic separator by air elutriation. [10] Others have reported maintaining a laminar stream of air flowing across the electrodes to prevent fine particles from being influenced by air currents. [22Komabe, maintaining laminar airflow becomes challenging as the separation device becomes larger, effectively limiting the processing capacity of such devices. Ultimately the particle size in which components are physically separate from other (present as discrete particles), will be the largest driver in determining the particle size at which processing must occur.

As mentioned previously, conventional electrostatic separation devices are limited in processing capacity, especially with low-density and finely ground powders such as plant materials. For high-tension drum and belt separation devices, the effectiveness is limited to particles that are relatively coarse and/or have high specific gravity, chifukwa kufunika particles zonse zolankhulirana padziko ng'oma ndi. As particles become smaller the processing rate is reduced. Parallel plate separators are further limited by the particle density that can be processed in the electrode zone. Particle loading must be relatively low to prevent space charge effects.

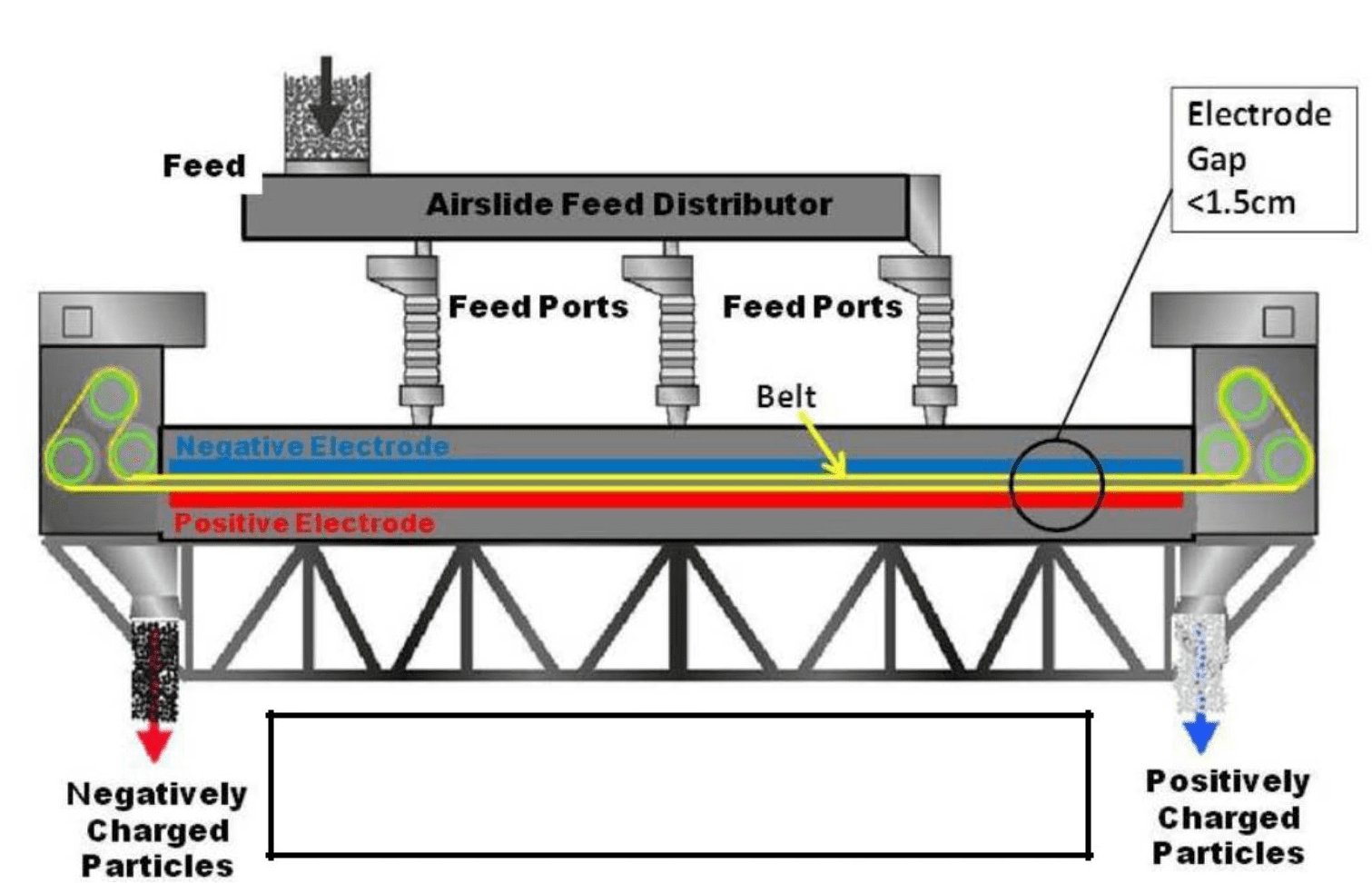

cha ku Switzerland Zida & Technology Belt Separator

The cha ku Switzerland Zida & Technology (STET) triboelectrostatic lamba olekanitsa ali anasonyeza imapanga pokonza particles zabwino 500 - 1 μm. Olekanitsa STET ndi mbale yofananira electrostatic separator, Komabe, mbale za elekitirodi zimalunjika mopingasa kusiyana ndi vertically monga momwe zimakhalira muzolekanitsa mbale zambiri zofanana.. (Onani Chithunzi 6) Komanso, ndi STET olekanitsa amakwaniritsa ndi tinthu tribo-nawuza ndipo Ndikuuzani imodzi ndi mkulu-liwiro lotseguka mauna conveyor lamba. Mbali imeneyi zimathandiza kuti onse mkulu kwambiri ndalama yeniyeni processing chakudya, komanso imapanga kuti pokonza ufa bwino kwambiri kuposa zipangizo ochiritsira electrostatic. Mtundu wa chipangizo kulekana wakhala ntchito malonda kuyambira 1995 kulekanitsa unburned mpweya ku ntchentche mchere phulusa (lililonse D50 pafupifupi 20 μm) zomera malasha amapanga mphamvu. Izi electrostatic kulekana chipangizo wakhalanso bwino pa beneficiating zinthu zina inorganic, kuphatikizapo mchere monga calcium carbonate, talc, barite, and others.

The fundamental details of the STET separator are illustrated in Figure 7. The particles ndi mlandu ndi zotsatira triboelectric kudzera tinthu-to-tinthu kugunda mkati mwa kusiyana pakati maelekitirodi.. Magetsi ogwiritsidwa ntchito pakati pa maelekitirodi ali pakati pa ± 4 ndi ± 10 kV poyerekeza ndi pansi, kupereka okwana voteji kusiyana kwa 8 - 20 kV kudutsa mpata wopapatiza kwambiri wa elekitirodi mwamwambo 1.5 cm (0.6 mainchesi). Zakudya particles anayambitsa kwa olekanitsa STET pa imodzi mwa malo atatu (Dyetsani Madoko) via a distributor air slide system with knife gate valves. The olekanitsa STET umabala mankhwala awiri okha, tinthu tating'ono ting'onoting'ono tomwe timasonkhanitsidwa pa electrode yabwino, ndi mpweya wabwino tinthu mtsinje anasonkhanitsidwa pa elekitirodi zoipa mlandu. The products are conveyed to the respective hoppers at each end of the STET separator by the separator belt and conveyed out of the separator by gravity. The STET olekanitsa sangabereke ndi middlings kapena akonzanso mtsinje, ngakhale masanjidwe angapo chikudutsa kusintha mankhwala chiyero ndi / kapena kuchira zitheka.

chithunzi 6: STET Triboelectric m'Galimoto olekanitsa

Particles ali zoperekedwa kudzera kusiyana elekitirodi (zone kulekana) ndi kuzungulira mosalekeza, lotseguka mauna lamba. Lamba ukugwira ntchito pa liwilo, variable ku 4 kuti 20 Ms (13 - 65 Ft / s). Masamu lamba amagwirabe kusesa particles bwino kuzichotsa maelekitirodi ndi, preventing the accumulation of fine particles that degrade the performance and voltage field of traditional free-fall parallel plate type separation devices. Kuphatikiza apo, lamba limapanga chotchinga chachikulu, mkulu chipwirikiti zone pakati maelekitirodi awiri, kulimbikitsa tribo-adzapereke. Kuyenda kwamakono kwa lamba wolekanitsa kumalola kulipira kosalekeza ndi kulipiritsanso kapena tinthu ting'onoting'ono mkati mwa olekanitsa., kuchotsa kufunika kwa dongosolo chisanadze kulipiritsa kumtunda kwa olekanitsa STET.

chithunzi 7: Fundamentals of operation of STET Belt Separator

The STET olekanitsa ndi mkulu mlingo chakudya, malonda kutsimikiziridwa processing dongosolo. The pazipita processing mphamvu ya olekanitsa STET makamaka ntchito ya mlingo volumetric chakudya kuti akhoza kuperekedwa kudzera electrode kusiyana ndi STET olekanitsa lamba.. Zosintha zina, monga liwiro la lamba, mtunda pakati pa maelekitirodi ndi kachulukidwe aerated wa ufa zotsatira pazipita chakudya mlingo, kawirikawiri mpaka pang'ono. For relatively high-density materials, Mwachitsanzo, kuuluka phulusa, pazipita processing mlingo a 42 inchi (106 cm) Elekitirodi m'lifupi malonda kulekana unit ndi pafupifupi 40 - 45 Matani pa ola la chakudya. Pakuti zochepa wandiweyani chakudya zipangizo, mlingo waukulu wa chakudya ndi wotsika.

Table 6: Approximate maximum feed rate for various materials processed with STET 42 inch electrostatic separator.

Dust explosions are a major hazard in grain and other organic powder processing operations. The STET separator is suitable for processing combustible organic powders with only minor modifications. There are no heated surfaces in the STET separator. The only moving parts are the separator belt and drive rollers. The roller bearings are located outside of the powder stream on the external shell of the unit. Therefore they are not a risk for overheating/sparking in the material stream. Komanso, the STET separator bearings are available with factory fitted temperature measurement capability to detect bearing failure well before dangerously high temperatures are reached. The separator belt and drive system pose no higher risk than other conventional rotating machinery. The STET separator high voltage components are also located outside of the material stream and contained in dust-tight enclosures. The maximum energy of a spark across the separator gap is limited by the design of the high voltage components. An additional level of safety can be introduced via nitrogen purging.

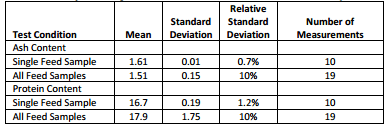

Whole Wheat Flour Processing by STET Separator

Whole wheat flour is derived from grinding the entire grain of wheat (bran, germ, and endosperm). Commercially available, off-the-shelf, whole wheat flour was purchased for use as test material to evaluate the capability of the STET separator to remove the fibrous bran and germ from the starchy endosperm fraction of wheat flour. The whole wheat flour sample was analyzed by STET prior to beginning the testing. Ash content was tested by ICC Standard 104 / 1 (900° C). Repeated ash measurements of the same sample, an unseparated feed sample, measured 10 times, were found to have an ash content of 1.61%, a standard deviation of 0.01 and a relative standard deviation of 0.7%. Tinthu kukula kusanthula anamaliza laser mapindidwe akuwala ntchito Malvern Mastersizer 3000 ndi zida youma kupezeka. kusanthula mapuloteni kunachitidwa ntchito njira DUMAS, ndi pulaimale mofulumira N upambana asafe / mapuloteni chowunikira. A kutembenuka chinthu cha N × 6.25 anamugwiritsa. The katundu osiyanasiyana lonse ufa wa tirigu nyemba zakambidwa mwachidule m'munsimu. (Onani Table 7)

Table 7: Analysis athunthu ufa wa tirigu chakudya ndi STET

Ash zili ndi mapuloteni okhutira anapezeka kuti repeatable kwambiri pamene anayesedwa chitsanzo yemweyo, but significant variability was identified between the multiple bags of whole wheat flour used as the feed sample. (Onani Table 8) This feed sample variability resulted in some scatter in the test data.

Table 8: Analysis of separation test results of whole wheat flour by STET

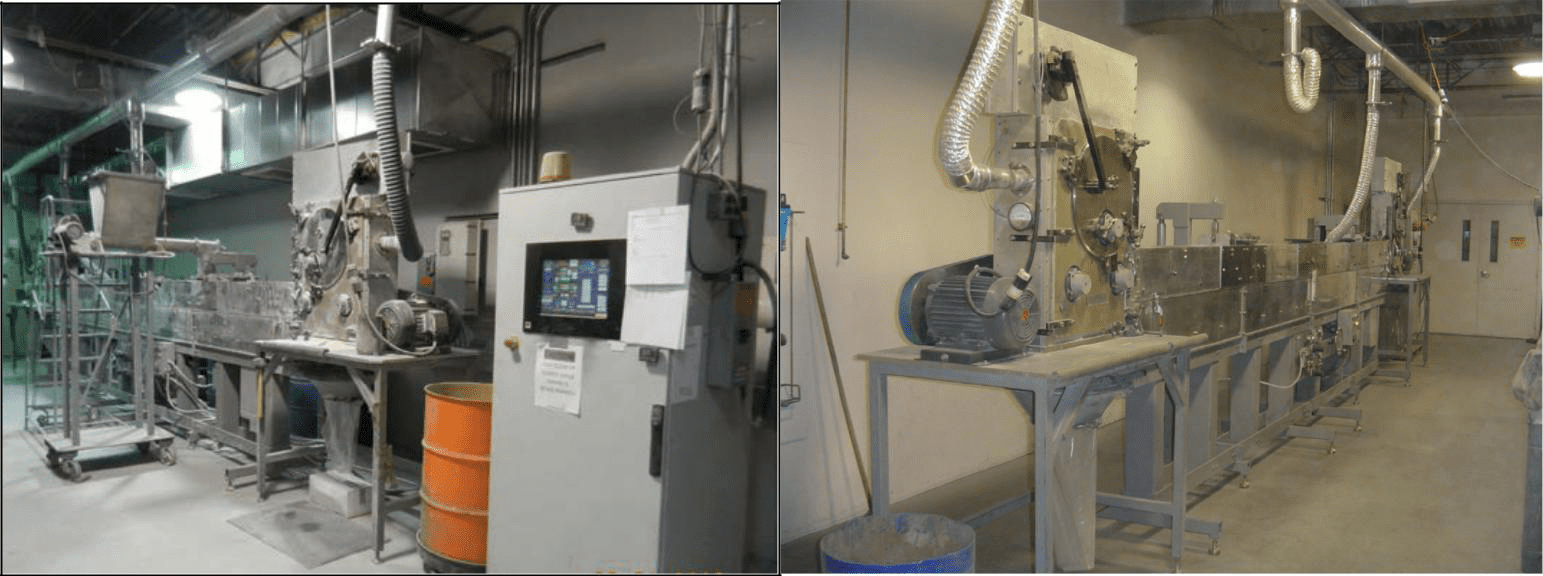

Electrostatic separation testing of the whole wheat flour sample was performed at the ST Equipment & Technology (STET) pilot plant facility in Needham, Massachusetts. The STET woyendetsa chomera lili awiri separators woyendetsa lonse STET pamodzi ndi zida ancillary ntchito kufufuza kulekana kwa zipangizo zopangira phungu. Woyendetsa-ang'ono STET separators ndi kutalika ngati malonda STET olekanitsa, pa 30 mapazi (9.1 meters) yaitali, Komabe, woyendetsa chomera olekanitsa elekitirodi m'lifupi ndi yekhayo 6 mainchesi (150 mamilimita), kapena mmodzi chiwiri m'lifupi yaikulu malonda STET olekanitsa pa 42 mainchesi (1070 mamilimita) elekitirodi m'lifupi. The chakudya mphamvu ya olekanitsa STET mwachindunji njila kwa m'lifupi maelekitirodi ndi, Choncho, the feed rate of the pilot plant separator is one-seventh the feed rate of the 42-inch wide commercial separator unit. The maximum feed rate with whole wheat flour was 2.3 Tons per hour at pilot scale, which corresponds to 16 Tons per hour for the 42-inch wide commercial separator. In comparison to the scale at which the majority of the electrostatic separation studies have been conducted to date, the STET separator testing was carried out at a considerably higher feed rate. Testing was performed in 10 kg (20 pound) batch tests, due to the practical considerations of supplying 2.3 Tons per hour of feed continuously. For each batch test condition, the products of the separation process were weighed to calculate the mass recovery. Subsamples from each test were collected and analyzed for ash content and protein content.

chithunzi 8: STET Pilot Plant Separator.

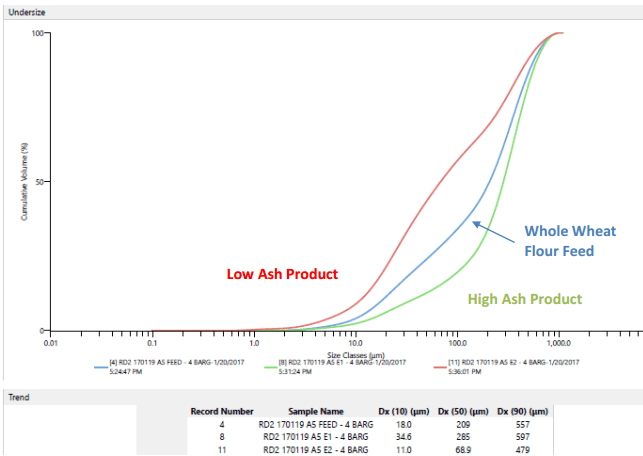

Particle size measurement of the whole wheat flour feed and two product samples is shown below in Figure 9.

chithunzi 9: Particle size measurement of whole wheat flour feed, and the two separated product samples.

A picture of the recovered separation products is included below. (Onani Chithunzi 10) A noticeable color shift was observed during the separation, which the high ash content product fraction considerably darker than the feed whole wheat flour sample.

chithunzi 10: Typical products recovered from the STET separation process.

Ash content for all products from the separation process was measured. (Onani Chithunzi 11)

chithunzi 11: Ash content versus the mass recovery of low ash product for whole wheat flour separation tests by STET

Testing of the STET electrostatic separator with whole wheat flour demonstrated significant movement of the high ash (bran) fraction of the wheat kernel to the positive electrode. The reduced ash product was subsequently collected on the negative electrode. Testing was performed on a single pass scheme, Komabe, it is possible to perform further upgrading of either of the separation products by performing another separation stage. kuyezetsa tsogolo ndi olekanitsa STET izichitikira pa tirigu zitsanzo chinangwa, as well as corn flour and legumes such as Lupin.

Mawuwo

Review mabuku zogwirizana limasonyeza kuti kafukufuku kwambiri wakhala anayesetsa kukhala njira electrostatic olekanitsa kwa zipangizo organic. Zimenezi wapitiriza kapena ngakhale inapita m'mbuyomu 10 - 20 zaka, ndi ofufuza ambiri ku Ulaya ndi ku United States kutsatira njira electrostatic kulekana osiyanasiyana mavuto beneficiation. Kuyambira kafukufuku, zikuonekeratu kuti njira electrostatic timatha kupanga latsopano, mankhwala apamwamba mtengo chomera, kapena kupereka njira kunyowetsa njira processing. Although encouraging separations of wheat, corn and lupin-based plant materials have been demonstrated at the laboratory and in some cases pilot scale, the electrostatic systems used to demonstrate these results may not be the most suitable or cost-effective processing equipment to perform such separations on a commercial basis. umisiri ambiri electrostatic sali oyenera ndondomeko finely pansi, otsika kachulukidwe ufa monga zipangizo chomera. Komabe, ndi cha ku Switzerland Zida & Technology (STET) triboelectrostatic lamba olekanitsa ali anasonyeza imapanga pokonza particles zabwino 500 - 1 µm at high rates. The STET lamba olekanitsa ndi ndalama yapamwamba, industrially proven processing device that may be suitable to commercialize the recent developments in plant material processing. The STET lamba olekanitsa anayesedwa pa chitsanzo cha lonse ufa wa tirigu ndi anapezeka bwino kuchotsa chinangwa ku wowuma kachigawo. kuyezetsa tsogolo ndi olekanitsa STET izichitikira pa tirigu zitsanzo chinangwa, as well as corn flour and pulses such as soy and lupin.

Zothandizira

[1] T. B. Osborne, “Middlings-Purifier”. United States of America Patent 224,719, 17 February 1880.

[2] H. Manouchehri, K. Hanumantha Rao and K. Forsberg, “Review of electrical separation methods – Part 1: mbali wofunikila,” mchere & Processing zitsulo, Vol. 17, palibe. 1, mas. 23-36, 2000.

[3] J. Elder and E. Yan, “eForce – m'badwo zatsopano za olekanitsa electrostatic kwa makampani mchere mchenga,” in Heavy Minerals Conference, Johannesburg, 2003.

[4] R. H. Perry and D. W. Green, Perry’s Chemical Engineers’ Handbook Seventh Edition, New York: McGraw-Hill, 1997.

[5] S. Messal, R. Corondan, ine. Chetan, R. Ouiddir, K. Medles and L. Dascalescu, “Electrostatic separator for micronized mixtures of metals and plastics originating from waste electric and electronic equipment,” Journal of Physics, Vol. 646, mas. 1-4, 2015.

[6] T. S. Pandya, R. Srinivasan and C. P. Thompson, “Fiber Separation for Ground Corn Flour Using an Electrostatic Method,”Cereal Chemistry, Vol. 90, palibe. 6, mas. 535-539, 2013.

[7] L. zopangidwa, P. M. Beier, ndipo ine. Stahl, Electrostatic Kupatukana, Weinheim: Wiley VCH Verlag GmbH & Co. KGaA, 2005.

[8] ndipo. Hemery, X. Rouau, V. Lullien-Pellerin, C. Barron and J. Abecassis, “Dry process to develop wheat fractions and products with enhanced nutritional quality,” Journal of Cereal Science, palibe. 46, mas. 327-347, 2007.

[9] W. A. Brastad and E. C. Gear, “Method and Apparatus for Electrostatic Separation”. United States of America Patent 2,848,108, 19 August 1958.

[10] B. A. Stone and J. Minifie, “Recovery of Aleurone Cells from Wheat Bran”. United States of America Patent 4,746,073,24 mulole 1988.

[11] A. Bohm and A. zikande, “Method for Isolating Aleurone Particles”. United States of America Patent 7,431,228, 7 October 2008.

[12] J. A. Delcour, X. Rouau, C. M. Courtin, K. Poutanen and R. Ranieri, “Technologies for enhanced exploitation of the health-promoting potential of cereals,” Trends in Food Science & Technology, mas. 1-9, 2012.

[13] L. Dascalescu, C. Dragan, M. Bilici, R. Beleca, ndipo. Hemery and X. Rouau, “Electrostatic Basis for Separation of Wheat Bran Tissues,” IEEE Transactions on Industry Applications, Vol. 46, palibe. 2, mas. 659-665, 2010.

[14] ndipo. Hemery, X. Rouau, C. Dragan, R. Bilici and L. Dascalescu, “Electrostatic properties of wheat bran and its constitutive layers: Influence of particle size, composition, and moisture content,” Journal of Food Engineering, palibe. 93, mas. 114-124, 2009.

[15] ndipo. Hemery, M. Chaurand, The. Holopainen, A.-M. Lampi, P. Lehtinen, V. Piironen, A. Sadoudi and X. Rouau, “Potential of dry fractionation of wheat bran for the development of food ingredients, part I: Influence of ultra-fine grinding,” Journal of Cereal Science, palibe. 53, mas. 1-8, 2011.

[16] ndipo. Hemery, The. Holopainen, A.-M. Lampi, P. Lehtinen, T. Nurmi, V. Piironen, M. Edlemann and X. Rouau, “Potential of dry fractionation of wheat bran for the development of food ingredients, part II: Electrostatic separation of particles,” Journal of Cereal Science, palibe. 53, mas. 9-18, 2011.

[17] J. Wang, E. Smits, R. M. Boom, ndi M. A. Schutyser, “Arabinoxylans concentrates from wheat bran by electrostatic separation,” Journal of Food Engineering, palibe. 155, mas. 29-36, 2015.

[18] P. J. Pelgrom, J. Wang, R. M. Boom, ndi M. A. Schutyser, “Pre- and post-treatment enhance the protein enrichment from milling and air classification of legumes,” Journal of Food Engineering, palibe. 155, mas. 53-61, 2015.

[19] D. Chereau, P. Videcoq, C. Ruffieux, L. Pichon, J.-C. Motte, S. Belaid, J. Ventureira and M. Lopez, “Combination of existing and alternative technologies to promote oilseeds and pulses proteins in food applications,” Oilseeds & fats Crops and Lipids, Vol. 23, palibe. 4, mas. 1-11, 2016.

[20] A. Barakat, F. Jerome and X. Rouau, “A Dry Platform for Separation of Proteins from Biomass-Containing

Polysaccharides, Lignin, and Polyphenols,” ChemSusChem, Vol. 8, mas. 1161-1166, 2015.

[21] C. Basset, S. Kedidi and A. Barakat, “Chemical- ndi zosungunulira-Free Mechanophysical Fractionation a zotsalira zazomera anachititsa ndi Tribo-Electrostatic adzapereke: Separation Proteins and Lignin,” ACS Sustainable Chemistry & Engineering, Vol. 4, mas. 4166-4173, 2016.

[22] J. M. Stencel, J. L. Schaefer, H. Ban, ndipo J. K. Neathery, “Apparatus and Method for Triboelectrostatic Separation”.United States of America Patent 5,938,041, 17 August 1999.