Pilih Basa:

Kyle Flynn, Abhishek Gupta, Frank Hrach

abstrak

Tinjauan literatur anu relevan nunjukkeun yén panalungtikan signifikan parantos dilaksanakeun pikeun nerapkeun éléktrostatik

téhnik separation pikeun garing granular dahareun basis tutuwuhan (i.e., organik) bahan. Kamekaran ieu parantos gancang dina waktos kapengker 10 - 20 taun, with many researchers in Europe and the United States applying pamisahan éléktrostatik techniques to a wide variety of beneficiation challenges. Ti ieu panalungtikan nya, nya eta bukti yen metoda éléktrostatik boga potensi pikeun ngahasilkeun anyar, produk tutuwuhan leuwih luhur-nilai, atanapi nawiskeun alternatif pikeun baseuh padika ngolah. Sanajan separations encouraging of buckwheat sisikian, pulse and oilseed materials have been demonstrated at the laboratory and in some cases, pilot scale, sistem éléktrostatik dipaké pikeun demonstrate hasilna ieu bisa jadi alat-alat ngolah cocok atanapi cost-éféktif pikeun nedunan separations misalna dina dasar komérsial. Seueur téknologi éléktrostatik henteu cocog pikeun prosés ditumbuk halus, powders low-dénsitas kayaning bahan tutuwuhan. Sanajan, nu Equipment ST & teknologi (STET) SEPARATOR sabuk triboelectrostatic gaduh kamampuan nunjukkeun pikeun ngolah partikel anu saé 500 - 1 μm. The STET belt separator is a high-rate, Alat pangolahan anu kabuktian sacara industri anu tiasa cocog pikeun komersilkeun kamajuan panganyarna dina pamrosésan bahan organik. The SEPARATOR STET sabuk diuji dina sampel sakabeh tipung gandum jeung ieu kapanggih janten suksés di nyoplokkeun bran ti fraksi aci. nguji ka hareup jeung SEPARATOR STET bakal dilakukeun dina sampel bran gandum, tipung jagong

jeung pulsa kayaning filem jeung lupine.

Konci: Suku-éléktrostatik, éléktrostatik, papisahan, Fractionation, Gandum, paparean, tipung, serat, protéin, Oilseeds, pulsa

perkenalan

métode separation éléktrostatik geus garapan pikeun kaliwat 50 taun dina beneficiation komérsial-skala

mineral industri jeung daur ulang bahan runtah. Beneficiation éléktrostatik dahareun basis tutuwuhan granular garing (i.e, organik) bahan geus ditalungtik pikeun leuwih 140 taun, jeung patén munggaran pikeun separation éléktrostatik middlings tipung gandum dieusian salaku awal salaku 1880. [1] Beneficiation éléktrostatik ngamungkinkeun pikeun separations dumasar kana béda dina kimia permukaan (fungsi gawé) atawa sipat diéléktrik. Dina sababaraha kasus, separations ieu moal mungkin ngagunakeun ukuran atawa dénsitas separations nyalira. Sistem pamisahan éléktrostatik beroperasi dina prinsip anu sami. Sadaya sistem separation éléktrostatik ngandung sistem pikeun muatan listrik partikel, hiji médan listrik dihasilkeun externally pikeun separation lumangsung di, sarta metoda conveying partikel asup jeung kaluar alat separation. Ngecas listrik bisa lumangsung ku hiji atawa sababaraha métode kaasup induksi conductive, tribo-ngecas (éléktrifikasi kontak) sareng ngecas ion atanapi korona. Sistem pamisahan éléktrostatik ngagunakeun sahenteuna salah sahiji mékanisme ngecas ieu. [2]

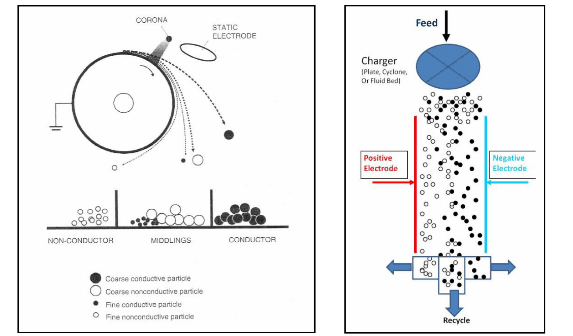

tegangan tinggi roll sistem separation éléktrostatik geus dipaké dina loba industri jeung aplikasi mana salah

komponénna téh beuki conductive listrik ti batur. Conto aplikasi pikeun tegangan tinggi roll separators kaasup separation mineral bearing titanium, kitu ogé aplikasi ngadaur mulang, contona asihan logam tina plastik. Aya sababaraha variasi na geometries dipaké pikeun sistim roll tegangan tinggi, tapi sacara umum, aranjeunna beroperasi dina prinsip sarupa. Partikel feed dieusi négatif ku sékrési korona pangionan. Partikel eupan disebarkeun kana kendang anu puteran, dimana kendang ieu grounded listrik. Partikel-partikel konduktif éléktrik nyerahkeun muatanna nalika ngahubungi permukaan drum anu dibumikeun. Rotasi kendang nyababkeun partikel konduktif dialungkeun tina permukaan kendang sareng disimpen dina hopper produk munggaran.. Partikel non-konduktif nahan muatan listrikna sareng disematkeun kana permukaan kendang. antukna, muatan listrik dina partikel non-conductive bakal dissipate, atawa partikel bakal brushed ti kendang sanggeus kendang geus diputer sahingga partikel non-conductive anu disimpen dina non-conductive Hopper partikel. Dina sababaraha aplikasi, a Hopper middlings ieu disimpen antara Hopper produk conductive sarta non-conductive. Éféktivitas tipe ieu alat separation umumna dugi ka partikel nu rélatif kasar jeung / atawa boga graviti husus tinggi, alatan kabutuhan sakabéh partikel ngahubungan beungeut kendang. Salaku tambahan, dinamika aliran partikel penting salaku moméntum sudut mangrupakeun pamustunganana jawab conveying partikel tina beungeut kendang jeung hoppers produk séwang-. partikel rupa jeung partikel low-dénsitas gampang dipangaruhan ku arus hawa sahingga kurang kamungkinan bisa dialungkeun ti kendang di wewengkon diprediksi. [2] [3] [4]

The SEPARATOR tegangan tinggi sabuk mangrupakeun varian ti SEPARATOR roll tegangan tinggi ditétélakeun di luhur. partikel Feed anu dispersed merata peuntas rubak hiji sabuk conveyor grounded listrik. Partikel nu boga muatan, biasana ku Corona négatip, najan mékanisme sejenna ngecas anu mungkin. Deui partikel conductive masihan muatan listrik maranéhanana nepi ka sabuk conveyor grounded, bari partikel non-conductive ngaropéa muatan maranéhna. Partikel conductive layu atawa gugur di ujung sabuk ku graviti, bari partikel non-conductive nu boga muatan nu "diangkat" kaluar tina beungeut sabuk nu ku pasukan éléktrostatik. Deui pikeun pisah teh janten éféktif, unggal partikel kudu ngahubungan beungeut tina sabuk ka ngawenangkeun keur partikel conductive nyerah muatan maranéhna pikeun sabuk nu. kituna, ngan hiji lapisan tunggal partikel bisa conveyed ku SEPARATOR di hiji waktos. Salaku ukuran partikel tina feed jadi leutik, laju ngolah alat nu diréduksi. [5] [6]

plat paralel separators éléktrostatik umumna dumasar kana misahkeun partikel teu dina dasar konduktivitas, Tapi dina béda dina kimia permukaan anu ngamungkinkeun pikeun mindahkeun muatan listrik ku kontak frictional. Partikel nu boga muatan listrik ku kontak vigorous kalawan partikel séjén, atawa kalayan permukaan katilu saperti logam atawa plastik baris nu dipikahoyong sipat tribo-ngecas. Bahan anu electronegative (lokasina dina tungtung négatip tina séri tribo-listrik) dipiceun éléktron ti beungeut tribo-ngecas sahingga acquire muatan négatip net. dina kontak, bahan anu dina tungtung positif serial tribo-listrik nyumbang éléktron na muatan positif. partikel nu boga muatan nu lajeng diwanohkeun ka médan listrik dihasilkeun antara dua éléktroda plat paralel ku rupa hartosna angkutan (grapitasi, pneumatic, Geter). Dina ayana médan listrik, partikel muatan pindah ka arah éléktroda muatan sabalikna sarta dikumpulkeun dina hoppers produk pakait.. Deui, fraksi middlings ngandung campuran partikel bisa atawa teu bisa dikumpulkeun, gumantung kana konfigurasi tina alat separation. [4] [7]

angka 1: Diagram separator roll tegangan tinggi (ditinggalkeun) sarta separator ragrag bébas plat paralel (leres).

meja 1: Ringkesan alat separation éléktrostatik ilahar dipaké.

Kasus 1 – Gandum jeung Gandum Bran Beneficiation.

Dedak gandum mangrupikeun produk sampingan tina panggilingan gandum konvensional, ngawakilan 10-15% tina sisikian gandum. Dedak gandum diwangun ku lapisan luar kaasup pericarp, tésa, jeung aleuron. Gandum bran ngandung lolobana micronutrients, serat, jeung phytochemicals dikandung dina gandum, anu parantos nunjukkeun mangpaat kaséhatan pikeun manusa. [8] Kapentingan anu penting pikeun misahkeun sareng mangpaatkeun dedak gandum parantos dilaporkeun. Minat sajarah pikeun misahkeun dedak gandum nyaéta pikeun ningkatkeun kualitas sareng nilai produk tipung. Sanajan, minat leuwih panganyarna geus dilaporkeun dina recovering komponén berharga tina bran gandum.

Di 1880, Thomas Osborne dipaténkeun séparator éléktrostatik komérsial munggaran pikeun ngaleungitkeun bran tina middlings tipung.. Separator diwangun ku gulungan coated kalawan karét teuas atawa bahan sarimbag nu éta sanggup keur muatan listrik via frictional tribo-ngecas kalawan wol.. Sanajan teu digambarkeun, eta dianggap gulungan karét kaala muatan négatip relatif ka wol, konsisten jeung paling runtuyan tribo-listrik. Gulungan nu muatanana listrik tuluy narik partikel serat bran nu muatanana positip, conveying aranjeunna dina beungeut roll dugi partikel serat pinned anu brushed tina beungeut roll. ieu (dianggap) ngecas positif dedak gandum aya dina konflik jeung hasil dilaporkeun ku batur. Tribo-ngecas partikel bran ieu ditulungan ku fluidizing hawa diwanohkeun dina handap alat, nu miboga mangpaat tambahan ngabalukarkeun partikel bran kirang padet kana beungeut cai, ngadeukeutan ka gulungan. [1]

Di 1958 alat pikeun misahkeun éléktrostatik dedak sareng endosperm anu dikandung dina tepung tengahan diungkabkeun dina patén patén ku Branstad damel di General Mills.. Alatna diwangun ku pemisah pelat paralel dimana partikel dikirimkeun antara dua pelat ku geter.. Partikel dedak, dieusi ku kontak gesekan jeung partikel endosperm, lajeng diangkat ka éléktroda luhur ngaliwatan perforations dina éléktroda luhur. [9]

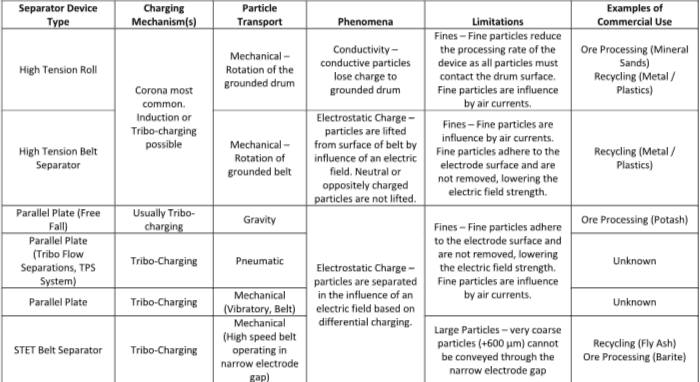

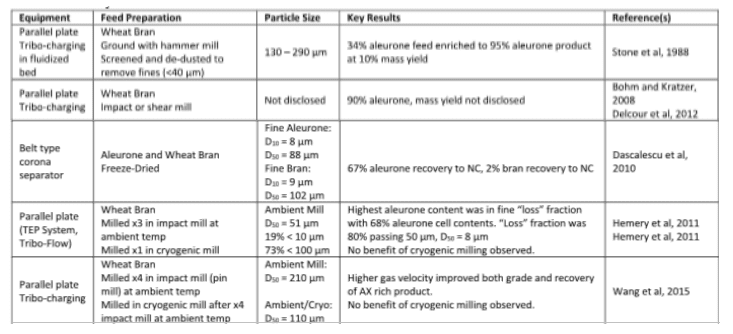

Di 1988 alat sareng prosés pikeun pulih aleuron tina dedak gandum komérsial diungkabkeun dina patén patén.. dedak gandum komérsial kalawan kandungan aleuron dimimitian tina 34% ieu enriched mun konsentrasi tina 95% di 10% ngahasilkeun massa (28% recovery aleuron) ku kombinasi palu panggilingan, ukuran ku screening, élutriation hawa sarta separation éléktrostatik ngagunakeun separator éléktrostatik plat paralel. Partikel dieusi dina alat elutriator hawa, nu boga peran ganda miceun denda (<40 μm) ku nepikeun, bari sakaligus tribo-ngecas partikel aleuron positif (ngalaporkeun ka plat éléktroda négatip) jeung partikel pericarp/testa négatip. Ukuran partikel tina campuran bran ieu sacara saksama dikawasa ku panggilingan palu jeung screening multi-level, pikeun ménta feed lolobana ukuran dina 130 - 290 rentang µm. [10]

Karya panganyarna dina recovering aleuron tina dedak gandum terus. Di 2008, Buhler AG dipaténkeun alat pamisah éléktrostatik pikeun misahkeun partikel aleuron tina partikel cangkang dijieunna tina dedak commuted.. Hiji perwujudan tina alat diwangun ku rotor a operasi di wewengkon perlakuan sempit, nu ngamungkinkeun pikeun partikel-to-partikel jeung partikel-to-témbok kontak jeung tribo-ngecas saterusna. Partikel-partikel anu muatanana teras dialihkeun sacara mékanis kana wadah pamisah anu ngandung éléktroda pelat paralel. Partikel ragrag ngaliwatan bejana separation ku gravitasi, salaku partikel muatan diferensial pindah ka arah éléktroda muatan sabalikna dina pangaruh médan listrik.. [11] Lamun digabungkeun jeung ukuran ditangtoskeun tina bran feed jeung métode asihan mékanis, konsentrasi aleuron nepi ka 90% geus dilaporkeun. [12] [8]

angka 2: Dihasilkeun ti Hemery et al, 2007 [8].

Percobaan ngecas tribo sareng ngecas korona dina dedak gandum dilaksanakeun ku pagawé di Unit Panaliti Média Éléktrostatik Dispersed., Universitas Poitiers, Perancis di 2010. Para panalungtik diukur muatan permukaan jeung beungeut poténsi waktu buruk on gandum bran kalawan 10% Uap jeung lyophilized (beku-garing) dedak gandum. Hiji tés separation dipigawé dina sampel tina 50% bran gandum freeze-garing jeung 50% eupan aleuron beku-garing ngagunakeun separator éléktrostatik tipe sabuk korona. (angka 3) Hasil pamisahan pikeun pamisah korona skala laboratorium dituduhkeun 67% tina aleuron ieu pulih ka Hopper non-konduktor, bari wungkul 2% tina dedak gandum dilaporkeun ka Hopper non-konduktor. Percobaan ngecas tribo ogé dilaksanakeun kalayan dedak gandum sareng aleuron, tapi ukur keur ngukur muatan permukaan husus [µC/g] dihasilkeun dina unggal fraksi, sabalikna recovering produk tina separation éléktrostatik. Kadua bahan pakan dieusi nganggo Teflon salaku permukaan kontak. Duanana dedak gandum sareng aleuron dilaporkeun ngecas positip relatif ka Teflon, nu sorangan pisan éléktronégatif. Gedéna muatan ieu kapanggih gumantung kana tekanan operasi dipaké dina tribo-carjer, suggesting that higher turbulence leads to more contacts and more complete tribo-charging. [13]

angka 3: Reproduced from Dascalescu et al, 2010 [13]

Di 2009, researchers evaluated the electrostatic charging properties of aleurone rich and pericarp rich feed materials. [14] Di 2011 the researchers performed electrostatic separation testing on samples of finely ground wheat bran using a pilot scale electrostatic plate separator (TEP System, Tribo Flow Separations, Lexington, AS). The TEP System utilizes a charging line, where feed particles are introduced into a turbulent compressed air stream, and pneumatically conveyed through the charging line to the separation chamber. The particles are tribo-charged by the particle to particle contact, as well as particle contact with the surface of the charging line. Results obtained with the TEP System demonstrated that electrostatic separation was effective in upgrading aleurone and beta-glucan content of wheat bran. Interestingly, the fraction of material that was found to contain the highest aleurone cell content, di 68%, was the very fine (D50 = 8 μm) fraction that was recovered from the charging tube. It is not clear why this material was preferentially concentrated in the charging apparatus, kumaha oge, eta teu nunjukkeun yén kamampuh ngolah aleurone eusi sél bisa merlukeun téknik éléktrostatik anu sanggup processing powders pohara rupa. Saterusna, Karya ieu ngabuktikeun yén préparasi feed keur bran gandum éta hiji tinimbangan penting. Sampel disiapkeun ku cryogenic grinding dina ngagiling palu nu kapanggih bisa kirang lengkep dissociated (liberated) ti maranéhanana taneuh dina ngagiling tipe dampak dina suhu ambient. [15] [16]

angka 4: Dihasilkeun ti Hemery et al, 2011 [16]

Recent work studied the concentration of arabinoxylans from wheat bran by electrostatic methods. The researchers utilized a laboratory scale electrostatic separator consisting of a charging tube and separation chamber containing two parallel plate electrodes. Milled wheat bran was introduced into the charging tube and conveyed pneumatically into the separation chamber using compressed nitrogen. The turbulence and high gas velocity in the charging tube provided the particle contact needed for tribo-charging. The charged particles (products of the separation) were collected from the surface of the electrodes for analysis. Due to the vertical orientation of the electrodes a significant amount of material was not collected. This middlings fraction may be recycled for further processing in conventional electrostatics, kumaha oge, for the purposes of this experiment, material not collected on the electrodes was considered lost. The researchers reported an increase in both product grade (arabinoxylan content in the product) jeung efisiensi separation salaku laju conveying ngaronjat. [17]

usaha panganyarna pikeun beneficiate bran gandum ngagunakeun métode éléktrostatik anu diringkeskeun handap di Table 2.

meja 2: Kasimpulan métode éléktrostatik dievaluasi mun beneficiate bran gandum.

Kasus 2 - Protéin Pamulihan ti Lupine Tepung

Peneliti di Prosés Food Téknik Grup di Wageningen, Walanda, dievaluasi potensi pengayaan protéin maké legumes. Kacang polong sarta lupine tipung anu dipaké salaku eupan pikeun rupa-rupa téhnik pengayaan protéin kaasup klasifikasi hawa digabungkeun jeung separation éléktrostatik. Untreated kacang polong sarta lupine siki anu munggaran giling nepi kira 200 μm. bahan Feed pikeun klasifikasi jeung separation éléktrostatik anu salajengna giling ngagunakeun hiji ngagiling tipe dampak kalawan classifier internal (Hosokawa-alpine ZPS50). Ukuran partikel median (d50) ieu dilaporkeun salaku ngadeukeutan 25 μm keur tipung kacang polong, tur kurang 200 μm keur tipung lupine, prior to air classification. tungtungna, a subset of each sample, pea and lupin flour, was then air classified (Hosokawa-Alpine ATP50). The feed to the electrostatic separator consisted of both untreated flours, as well as the course and fine product from air classification. [18]

The electrostatic separation device used during the experiments was a parallel plate type, with charging carried out via triboelectric charging in a 125 mm length charging tube, with particles conveyed pneumatically by compressed nitrogen. The device is similar in configuration to the device used by Wang et al (2015). [17] Electrostatic separation experiments were conducted on ground pea flour and lupin flour, as well as the course and fine fractions of pea flour and lupine flour obtained from air classification. The pea flour demonstrated only minor movement of protein during electrostatic testing. Sanajan, the lupin flour demonstrated significant movement of protein in all three samples tested (milled flour – 35% protéin, milled classified fines – 45% protéin, milled classified coarse – 29% protéin). Protein-rich products of approximately 60% were recovered on the grounded electrode for each of the three lupin samples tested. [18]

Kasus 3 – Fiber Removal from Corn

Researchers at the Department of Agricultural and Biological Engineering, Mississippi State University performed electrostatic testing on ground corn flour, with an objective of removing fiber. The electrostatic separation device consisted of a conveyor belt with a negative electrode placed at the end of the conveyor. The positively charged particles, fiber particles, dina hal ieu, anu diangkat off sabuk conveyor sarta dumasar kana Hopper kadua. Partikel non-serat murag kaluar tina sabuk conveyor ku graviti kukituna disimpen kana Hopper produk munggaran. Nu nulis teu ngajelaskeun kumaha ngecas listrik dilumangsungkeun. Bahan feed mun SEPARATOR ieu rélatif kasar, kalayan ukuran partikel tina feed mimitian ti 12 bolong (1,532 μm) ka 24 bolong (704 μm). Teu némbongan yén undersize (<704 μm) material was processed during this study. Each test condition was completed using 1 kg of feed material which was uniformly dispersed across the belt. [6]

angka 5: Dihasilkeun tina Pandya dkk, 2013 [6]

The Mississippi State researchers completed electrostatic separation testing on the unscreened corn flour, the screened corn flour fractions and the fiber-rich fractions recovered from air classification. Electrostatic testing was not completed on the low-fiber streams recovered from air classification. Analysis of the results of the electrostatic separation is provided below:

meja 3: Results of fiber separation reproduced from Pandya et al, 2013 [6]

Kasus 4 – Protein Concentration from Oilseeds

Oilseeds such as rapeseed (canola), sunflower, sesame, mustard, soybean-corn germ, and flaxseed generally contain a substantial amount of both protein and fiber. Processing technologies to remove the fiber, and thus increase the protein content, of oilseeds will become increasingly important as global demand for protein increases. [19] Recent work by researchers at the French National Institute for Agricultural Research examined ultrafine milling combined with electrostatic processing of sunflower seed meal, to concentrate protein. The feed sunflower hidangan sampel nya éta taneuh dina ngagiling dampak operasi di hawa ambient ka ukuran partikel (D50) ti 69.5 μm. SEPARATOR The éléktrostatik dipaké pikeun nguji ieu mangrupa alat plat paralel mana mékanisme ngecas primér éta tribo-ngecas. The tribo-ngecas ieu dilumangsungkeun hulu tina éléktroda dina garis tribo-ngecas, kalawan partikel conveyed ngaliwatan garis ngecas, jeung ka éléktroda, via angkutan pneumatic. Protéin ieu kapanggih waragad positif (ngalaporkeun ka éléktroda négatip) and the fiber-rich fraction was found to charge negatively. Protein selectivity was found to be high. Feed protein was 30.8%, with the protein-rich product measuring 48.9% and the protein depleted (fiber-rich) product measuring only 5.1% protéin. Protein recovery was 93% to the positive product. Cellulose, hemicelluloses, and lignin were measured and found to report to the negatively charged product, opposite that of protein. [20]

meja 4: Results of sunflower seed meal separation reproduced from Barakat et al, 2015 [20]

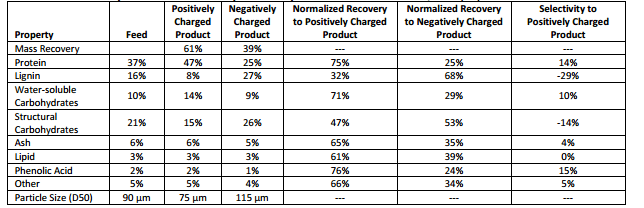

Di 2016, hiji ulikan tambahan ieu réngsé maké finely taneuh rapeseed cikal minyak hidangan, atanapi muih minyak rapeseed (RC), salaku feed ka prosés separation éléktrostatik. Deui panggilingan ultrafine dina suhu ambient ieu dipigawé maké alat keur ngagiling péso (Retsch SM 100). bahan nu giling, ku ukuran partikel median (D50) kira 90 μm, ieu olahan maké SEPARATOR plat paralel skala pilot (TEP System, Tribo Flow Separations). The TEP System utilizes triboelectric ngecas ku conveying pneumatic partikel ngaliwatan garis ngecas tekanan tinggi dina kaayaan ngagalura. Hiji tés separation lolos tunggal jeung System TEP nyababkeun konsentrasi signifikan protéin, ku protéin feed tina 37%, tingkat protéin produk boga muatan positif tina 47% sarta tingkat protéin produk nu muatanana négatif tina 25%. hambalan separation tambahan anu dipigawé, pamustunganana ngahasilkeun hiji produk-euyeub protéin kalawan 51% protéin sanggeus 3 hambalan separation saterusna. [21]

meja 5: Hasil si cikal minyak separation hidangan rapeseed dihasilkeun tina Basset dkk, 2016 [21]

diskusi

Review of literatur relevan nunjukkeun yén ieu panalungtikan signifikan geus undertaken ngamekarkeun téhnik separation éléktrostatik pikeun bahan organik. ngembangkeun ieu dituluykeun atawa malah gancangan nu geus kaliwat 10 - 20 taun, kalawan loba peneliti di Éropa sarta Amérika Serikat nerapkeun téknik separation éléktrostatik ka rupa-rupa tantangan beneficiation. Ti ieu panalungtikan nya, éta semu anu métode éléktrostatik boga potensi pikeun ngahasilkeun anyar, produk pepelakan nilai luhur, atanapi nawiskeun alternatif pikeun baseuh padika ngolah.

Sanajan encouraging separations of séréal buckwheat, pulsa, jeung bahan oilseed geus nunjukkeun di laboratorium jeung sababaraha skala kasus pilot, sistem éléktrostatik dipaké pikeun demonstrate hasilna ieu bisa pamustunganana henteu ngawula ka salaku parabot processing paling merenah atanapi cost-éféktif pikeun nedunan separations misalna dina dasar komérsial. Aya sistim éléktrostatik komérsial anu loba dipaké separations mineral, logam atawa plastik. Mineral jeung logam téh duanana bahan rélatif padet ku graviti husus tinggi, sakumaha dibandingkeun bahan tutuwuhan. Malah jeung gravitasi husus tinggi mineral sarta logam, keterbatasan ukuran partikel éféktif pikeun roll kendang sarta sajajar plat separators éléktrostatik relatif kasar, kalawan sababaraha partikel handap 100 μm contona. Plastik anu ti dénsitas handap ti duanana mineral jeung logam tapi anu sering diprosés di ukuran partikel kasar, flakes sakumaha palastik contona. The introduction of fine particles creates operational difficulties for both high-tension roll and parallel plate separators. dengda, partikel low-dénsitas pisan peka arus hawa, utamana dina ngabandingkeun kana mineral jeung logam. Bedana leutik di arus hawa jero alat separation dampak jalur lalampahan partikel rupa, subjecting eta pasukan lian ti eta disababkeun ku widang éléktrostatik.

Kanggo sabagéan ageung sistem SEPARATOR plat paralel, finely taneuh jeung low-dénsitas partikel nu electrostatically muatan dikumpulkeun dina éléktroda nu separators plat paralel. Lamun partikel ieu rupa iket listrik teu dihapus dina dasar konstan, the electric field strength and efficiency of the device degrade. The work of the researchers at The Food Process Engineering Group Wageningen UR (Wang et al, 2015) took advantage of this phenomenon to collect samples off the surface of the electrodes of the parallel plate separator to analyze the products of the separation. Parallel plate separator systems, particularly those that rely upon gravity to convey particles through the electric field, have attempted to address this problem in several ways. Stone et al (1988) described a process in which fine particles were removed upstream of the electrostatic separator by air elutriation. [10] Others have reported maintaining a laminar stream of air flowing across the electrodes to prevent fine particles from being influenced by air currents. [22Sanajan, maintaining laminar airflow becomes challenging as the separation device becomes larger, effectively limiting the processing capacity of such devices. Ultimately the particle size in which components are physically separate from other (present as discrete particles), will be the largest driver in determining the particle size at which processing must occur.

As mentioned previously, conventional electrostatic separation devices are limited in processing capacity, especially with low-density and finely ground powders such as plant materials. For high-tension drum and belt separation devices, the effectiveness is limited to particles that are relatively coarse and/or have high specific gravity, alatan kabutuhan sakabéh partikel ngahubungan beungeut kendang. As particles become smaller the processing rate is reduced. Parallel plate separators are further limited by the particle density that can be processed in the electrode zone. Particle loading must be relatively low to prevent space charge effects.

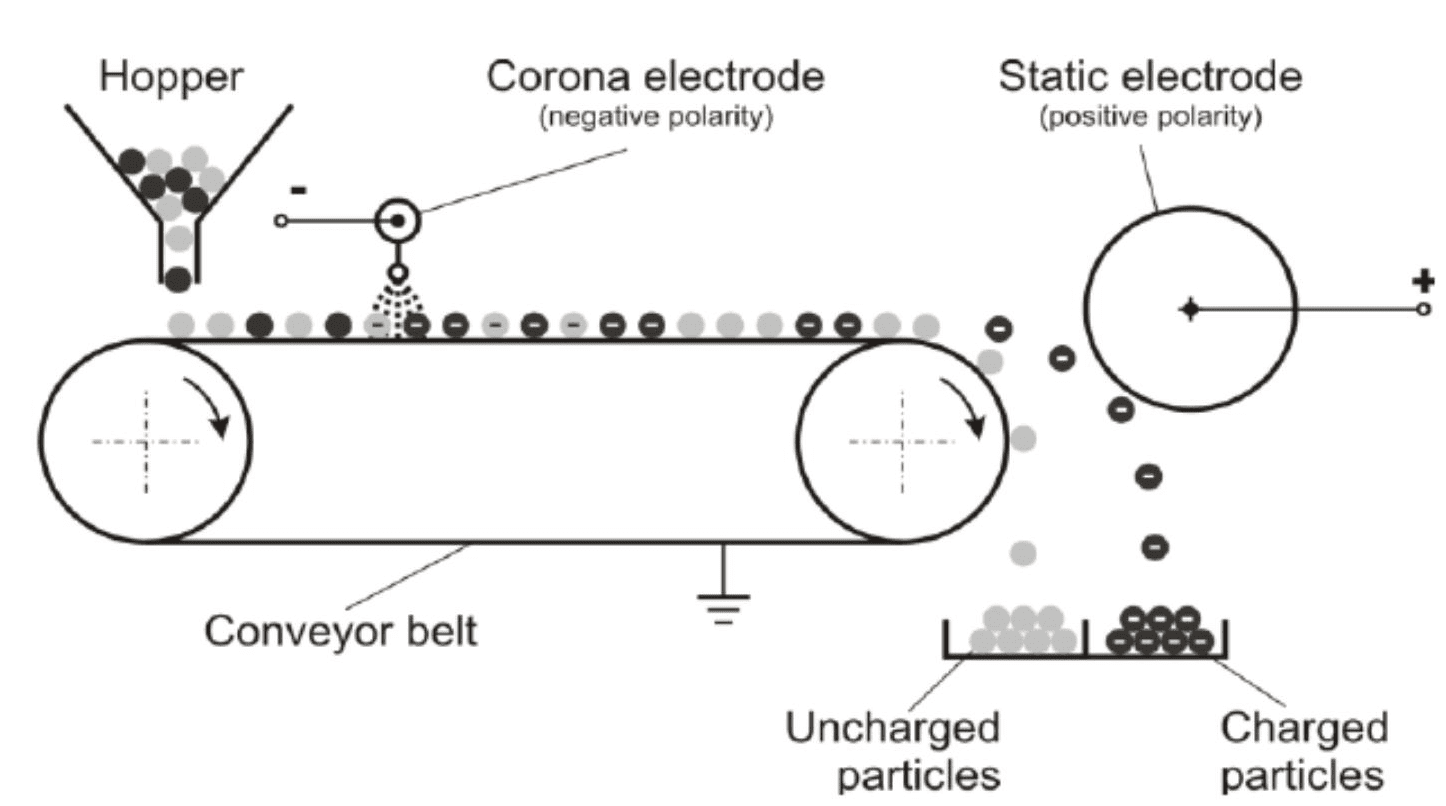

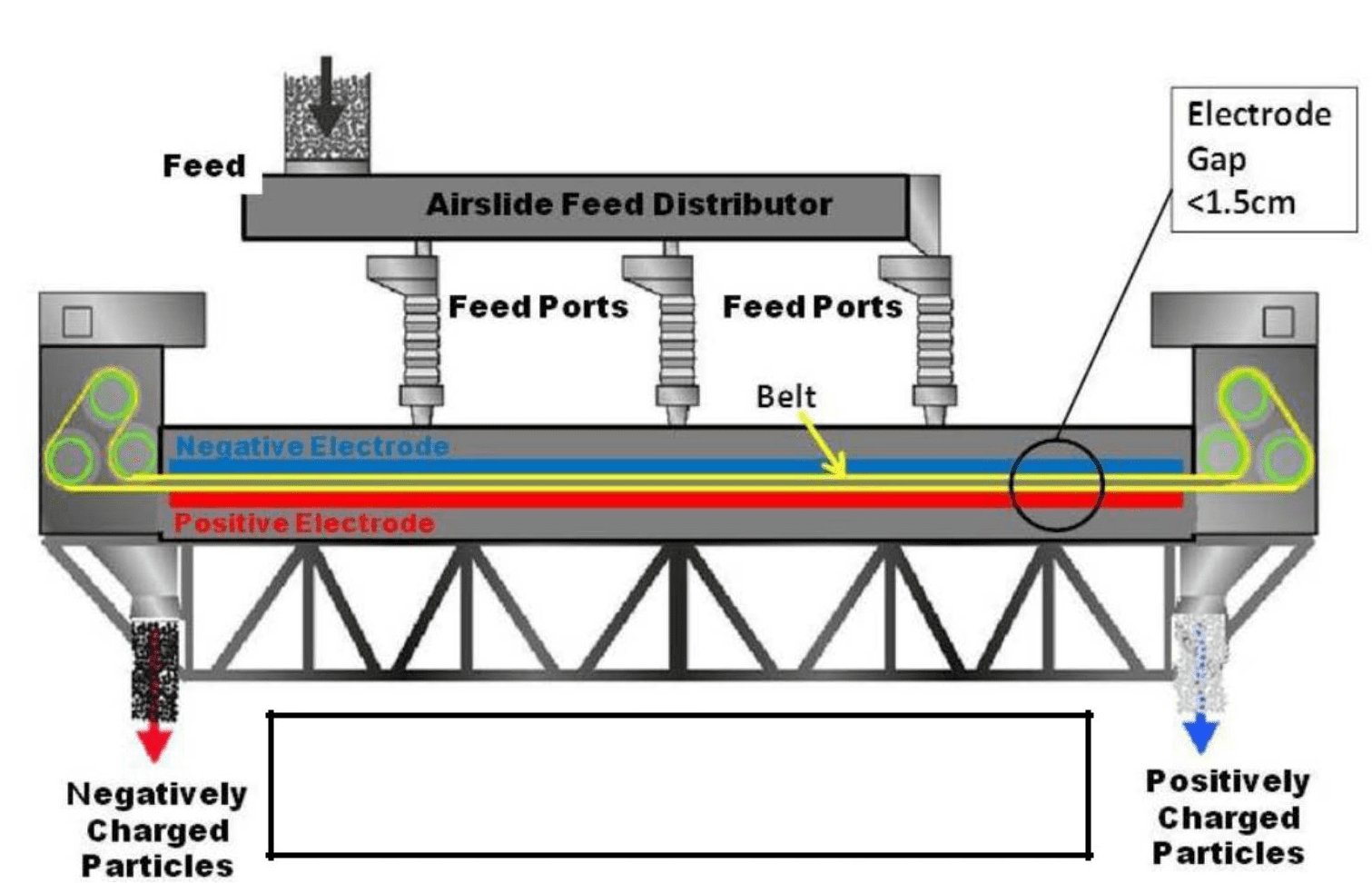

ST Equipment & Technology Belt Separator

The ST Equipment & teknologi (STET) SEPARATOR sabuk triboelectrostatic gaduh kamampuhan nunjukkeun ngolah partikel rupa ti 500 - 1 μm. SEPARATOR STET mangrupikeun separator éléktrostatik pelat paralel, kumaha oge, pelat éléktroda berorientasi horisontal sabalikna vertikal sakumaha dina kasus paling separators plat paralel.. (Tempo Gambar 6) Saterusna, nu SEPARATOR STET accomplishes partikel tribo-ngecas na conveying sakaligus ku-speed tinggi bolong kabuka conveyor sabuk. fitur ieu ngamungkinkeun pikeun duanana laju processing husus pisan luhur feed, kitu ogé kamampuhan pikeun ngolah powders teuing finer ti alat éléktrostatik konvensional. jenis ieu alat separation geus di operasi komérsial saprak 1995 misahkeun karbon unburned tina mineral lebu laleur (has D50 ngadeukeutan 20 μm) di pembangkit listrik batubara-dipecat. Alat separation éléktrostatik ieu ogé geus suksés di beneficiating bahan anorganik lianna, kaasup mineral kayaning kalsium karbonat, talc, barite, and others.

The fundamental details of the STET separator are illustrated in Figure 7. Partikel dieusi ku pangaruh triboelectric ngaliwatan tabrakan partikel-ka-partikel dina celah antara éléktroda.. Tegangan anu diterapkeun antara éléktroda antara ± 4 sareng ± 10 kV relatif ka taneuh, mere hiji bédana tegangan jumlahna aya 8 - 20 kV peuntas celah éléktroda sempit pisan tina nominal 1.5 cm (0.6 inci). Partikel feed diwanohkeun kana separator STET di salah sahiji tina tilu lokasi (Palabuhan eupan) via a distributor air slide system with knife gate valves. Pamisah STET ngan ukur ngahasilkeun dua produk, aliran partikel boga muatan négatip dikumpulkeun dina éléktroda muatan positif, sarta aliran partikel muatan positif dikumpulkeun dina éléktroda muatan négatip. The products are conveyed to the respective hoppers at each end of the STET separator by the separator belt and conveyed out of the separator by gravity. The SEPARATOR STET teu ngahasilkeun middlings atanapi aliran Daur mulang, najan sababaraha konfigurasi lolos pikeun ngaronjatkeun purity produk jeung / atawa recovery nu mungkin.

angka 6: STET Triboelectric Beubeur SEPARATOR

Partikel nu conveyed ngaliwatan celah éléktroda (zone separation) ku loop kontinyu, buka bolong sabuk. sabuk nu ngoperasikeun di speed tinggi, variabel tina 4 ka 20 Ibu (13 - 65 ft / s). Géométri tina beubeur fungsi nyapu partikel rupa kaluar beungeut éléktroda, preventing the accumulation of fine particles that degrade the performance and voltage field of traditional free-fall parallel plate type separation devices. Salaku tambahan, sabuk ngahasilkeun sheer tinggi, zona turbulensi tinggi antara dua éléktroda, promosi tribo-ngecas. Perjalanan kontra-ayeuna tina sabuk pamisah ngamungkinkeun pikeun ngecas kontinyu sareng ngecas ulang atanapi partikel dina separator., ngaleungitkeun kabutuhan sistem pra-ngecas hulu separator STET.

angka 7: Fundamentals of operation of STET Belt Separator

The SEPARATOR STET mangrupakeun laju feed tinggi, Sistim processing kabuktian komersil. Kapasitas processing maksimum nu SEPARATOR STET téh lolobana fungsi laju feed volumetric nu bisa conveyed ngaliwatan celah éléktroda ku sabuk SEPARATOR STET. variabel séjén, kayaning laju sabuk nu, jarak antara éléktroda jeung dénsitas aerated bubuk efek laju feed maksimum, ilaharna ka extent Lesser. Pikeun rélatif bahan tinggi-dénsitas, salaku conto, ngapung lebu, laju processing maksimum hiji 42 inci (106 cm) lebar éléktroda Unit separation komérsial nyaéta kasarna 40 - 45 Ton per jam eupan. Pikeun bahan feed kirang padet, laju feed maksimum leuwih handap.

meja 6: Laju feed maksimum perkiraan pikeun sagala rupa bahan olahan kalawan STET 42 inci SEPARATOR éléktrostatik.

ngabeledugna lebu anu mangrupa bahya utama dina gandum JEUNG KOPERASI processing bubuk organik lianna. The SEPARATOR STET téh cocog pikeun ngolah powders organik combustible kalawan ukur modifikasi minor. Aya henteu surfaces dipanaskeun dina SEPARATOR STET. Sésa ngan pindah anu SEPARATOR sabuk jeung drive rollers. The arah roller anu lokasina di luar tina aliran bubuk dina cangkang éksternal tina unit. Kituna aranjeunna lain resiko keur overheating / sparking di stream bahan. Saterusna, nu arah SEPARATOR STET nu sadia sareng pabrik dipasangan kamampuhan ukur hawa pikeun ngadeteksi bearing gagalna ogé saméméh hawa pibahyaeun tinggi anu ngahontal. The SEPARATOR sabuk sarta sistem drive pasang aksi henteu résiko luhur batan mesin puteran konvensional séjén. The STET separator high voltage components are also located outside of the material stream and contained in dust-tight enclosures. The maximum energy of a spark across the separator gap is limited by the design of the high voltage components. An additional level of safety can be introduced via nitrogen purging.

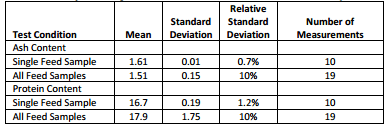

Whole Wheat Flour Processing by STET Separator

Whole wheat flour is derived from grinding the entire grain of wheat (bran, germ, and endosperm). Commercially available, off-the-shelf, whole wheat flour was purchased for use as test material to evaluate the capability of the STET separator to remove the fibrous bran and germ from the starchy endosperm fraction of wheat flour. The whole wheat flour sample was analyzed by STET prior to beginning the testing. Ash content was tested by ICC Standard 104 / 1 (900° C). Repeated ash measurements of the same sample, an unseparated feed sample, measured 10 times, were found to have an ash content of 1.61%, a standard deviation of 0.01 and a relative standard deviation of 0.7%. Analisis ukuran partikel ieu réngsé ku difraksi laser maké Malvern Mastersizer 3000 ku aparat dispersi garing. Analisis protéin ieu dipigawé maké metodeu Dumas, kalawan N gancang SD ngaleuwihan nitrogén / protéin analyzer. Hiji faktor konversi N x 6.25 ieu dipake. Rupa-rupa sipat sakabeh sampel tipung gandum diringkeskeun handap. (Tempo Table 7)

meja 7: Analisis sakabeh feed tipung gandum ku STET

Eusi lebu na kandungan protéin nu kapanggih janten pisan repeatable nalika diuji dina sampel nu sami, tapi variability signifikan ieu dicirikeun antara sababaraha tas ti sakabeh tipung gandum dipaké salaku sampel feed. (Tempo Table 8) variability sampel feed Hal ieu nyababkeun sababaraha paburencay di data tés.

meja 8: Analisis Hasil uji separation tina sakabeh tipung gandum ku STET

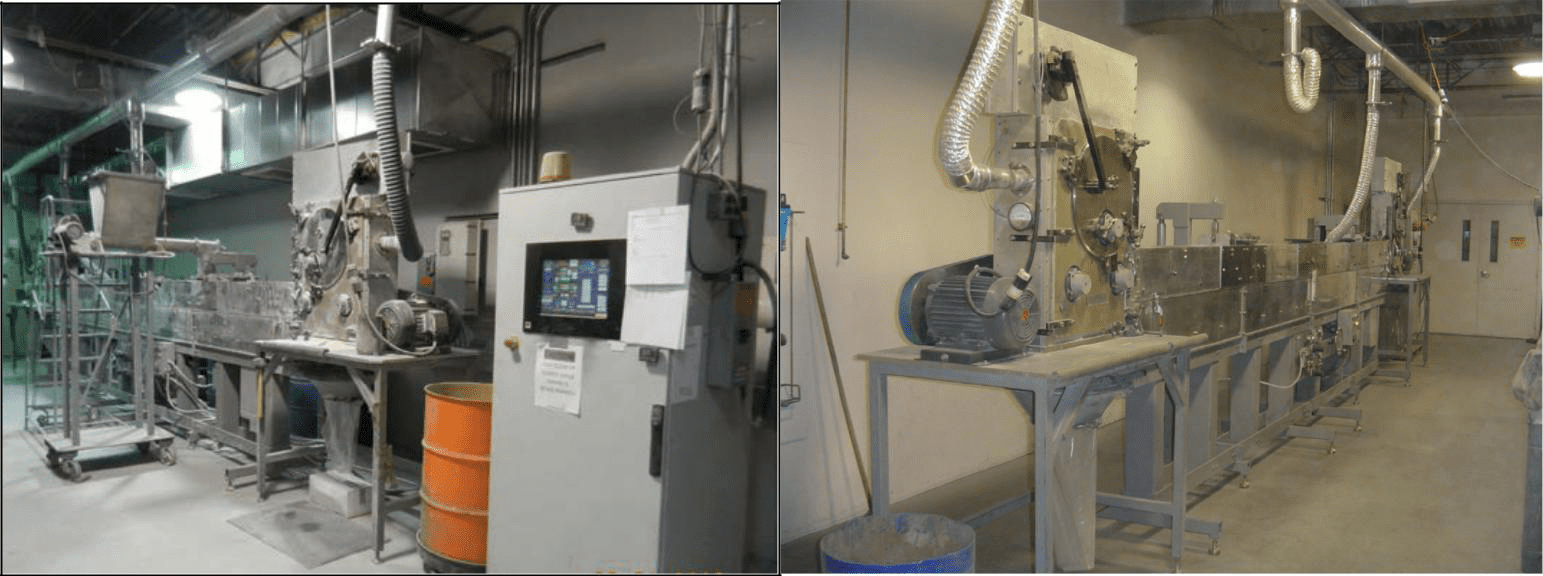

nguji separation éléktrostatik tina sakabeh sampel tipung gandum ieu dipigawé dina Equipment ST & teknologi (STET) fasilitas tutuwuhan pilot di Needham, Massachusetts. Tutuwuhan STET pilot ngandung dua separators skala pilot STET sapanjang kalawan parabot ancillary dipaké pikeun nalungtik separation bahan tina sumber calon. The separators pilot skala STET anu panjangna sarua salaku SEPARATOR STET komérsial, di 30 suku (9.1 méter) panjang, kumaha oge, tutuwuhan pilot SEPARATOR éléktroda lebar ngan 6 inci (150 mm), atawa salah-katujuh lebar tina SEPARATOR STET dagang panggedéna di 42 inci (1070 mm) lebar éléktroda. Kapasitas feed tina SEPARATOR STET téh langsung sabanding jeung lebar tina éléktroda, kituna, the feed rate of the pilot plant separator is one-seventh the feed rate of the 42-inch wide commercial separator unit. The maximum feed rate with whole wheat flour was 2.3 Tons per hour at pilot scale, which corresponds to 16 Tons per hour for the 42-inch wide commercial separator. Dibandingkeun sareng skala dimana seuseueurna studi pamisahan éléktrostatik parantos dilakukeun dugi ka ayeuna, nguji STET separator dilaksanakeun dina laju feed considerably luhur. Uji coba dilaksanakeun dina 10 kg (20 pon) tés bets, alatan pertimbangan praktis supplying 2.3 Ton per jam eupan terus. Pikeun unggal kaayaan test angkatan, produk tina proses separation anu ditimbang keur ngitung recovery Massa. Subsamples ti unggal test anu dikumpulkeun sarta dianalisis pikeun eusi lebu na kandungan protéin.

angka 8: STET Pilot Plant SEPARATOR.

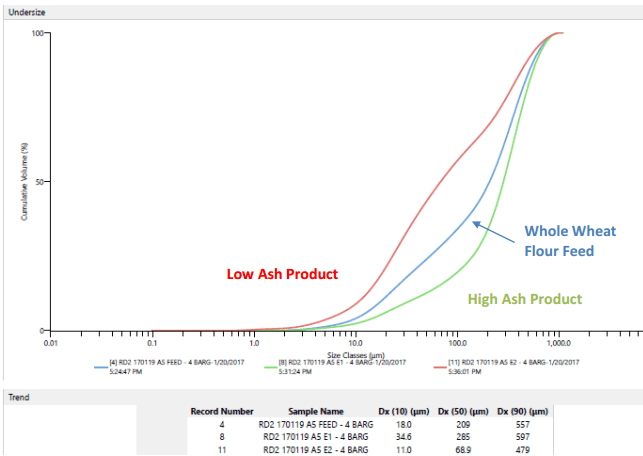

Ukuran partikel ukur tina sakabeh tipung gandum feed jeung dua sampel produk dipidangkeun di handap dina Gambar 9.

angka 9: Ukuran partikel ukur sakabeh gandum tipung feed, jeung dua dipisahkeun sampel produk.

Gambar tina produk separation pulih kaasup handap. (Tempo Gambar 10) A shift warna noticeable ieu katalungtik salila separation, nu fraksi produk eusi lebu luhur considerably darker ti feed sakabeh sampel tipung gandum.

angka 10: Produk has pulih tina prosés pamisahan STET.

Eusi abu pikeun sakabéh produk tina prosés separation ieu diukur. (Tempo Gambar 11)

angka 11: Eusi lebu versus recovery massa produk lebu low pikeun sakabéh tés separation tipung gandum ku STET

Nguji separator éléktrostatik STET sareng tipung gandum nunjukkeun gerakan anu signifikan tina lebu anu luhur (bran) fraksi kernel gandum ka éléktroda positif. Produk lebu anu diréduksi salajengna dikumpulkeun dina éléktroda négatip. Tés dilaksanakeun dina skéma pass tunggal, kumaha oge, kasebut nyaéta dimungkinkeun pikeun ngalakukeun pamutahiran salajengna tina salah sahiji produk separation ku ngajalankeun tahap separation sejen. nguji ka hareup jeung SEPARATOR STET bakal dilakukeun dina sampel bran gandum, kitu ogé tipung jagong jeung legumes kayaning Lupin.

conclusions

Review of literatur relevan nunjukkeun yén ieu panalungtikan signifikan geus undertaken ngamekarkeun téhnik separation éléktrostatik pikeun bahan organik. ngembangkeun ieu dituluykeun atawa malah gancangan nu geus kaliwat 10 - 20 taun, kalawan loba peneliti di Éropa sarta Amérika Serikat nerapkeun téknik separation éléktrostatik ka rupa-rupa tantangan beneficiation. Ti ieu panalungtikan nya, nya eta bukti yen metoda éléktrostatik boga potensi pikeun ngahasilkeun anyar, produk pepelakan nilai luhur, atanapi nawiskeun alternatif pikeun baseuh padika ngolah. Sanajan encouraging separations gandum, jagung sarta bahan tutuwuhan basis lupin geus ditémbongkeun di laboratorium sarta dina sababaraha kasus skala pilot, Sistem éléktrostatik anu digunakeun pikeun nunjukkeun hasil ieu panginten sanés alat pangolahan anu paling cocog atanapi paling murah pikeun ngalaksanakeun pamisahan sapertos kitu sacara komersial.. Seueur téknologi éléktrostatik henteu cocog pikeun prosés ditumbuk halus, powders low-dénsitas kayaning bahan tutuwuhan. Sanajan, nu Equipment ST & teknologi (STET) SEPARATOR sabuk triboelectrostatic gaduh kamampuan nunjukkeun pikeun ngolah partikel anu saé 500 - 1 µm dina laju anu luhur. Pamisah sabuk STET mangrupikeun tingkat anu luhur, Alat pangolahan anu kabuktian sacara industri anu tiasa cocog pikeun komersilkeun kamajuan panganyarna dina pamrosésan bahan tutuwuhan. The SEPARATOR STET sabuk diuji dina sampel sakabeh tipung gandum jeung ieu kapanggih janten suksés di nyoplokkeun bran ti fraksi aci. nguji ka hareup jeung SEPARATOR STET bakal dilakukeun dina sampel bran gandum, kitu ogé tipung jagong jeung pulsa kayaning kécap jeung lupin.

rujukan

[1] T. B. Osborne, “Middlings-Nyucikeun”. Amérika Sarikat Amérika Patén 224,719, 17 Pebruari 1880.

[2] H. Manouchehri, K. Hanumantha Rao jeung K. Forsberg, “Tinjauan métode separation listrik – bagean 1: aspék fundaméntal,” mineral & Processing Metalurgi, vol. 17, teu. 1, pp. 23-36, 2000.

[3] J. Sepuh sareng E. Yan, “eForce – Newest generation of the electrostatic separator for the minerals sands industry,” in Heavy Minerals Conference, Johannesburg, 2003.

[4] Urang Sunda. H. Perry and D. W. Green, Perry’s Chemical Engineers’ Handbook Seventh Edition, New York: McGraw-Hill, 1997.

[5] S. Messal, Urang Sunda. Corondan, abdi. Chetan, Urang Sunda. Ouiddir, K. Medles and L. Dascalescu, “Electrostatic separator for micronized mixtures of metals and plastics originating from waste electric and electronic equipment,” Journal of Physics, vol. 646, pp. 1-4, 2015.

[6] T. S. Pandya, Urang Sunda. Srinivasan jeung C. P. Thompson, “Serat separation pikeun Ground Banjarnegara Tepung Ngagunakeun hiji Métode éléktrostatik,”buckwheat Kimia, vol. 90, teu. 6, pp. 535-539, 2013.

[7] L. merek, P. M. Beier, jeung Abdi. Stahl, separation éléktrostatik, Weinheim: Wiley VCH Verlag GmbH & Co. KGaA, 2005.

[8] jeung. Hemery, X. Rouau, V. Lullien-Pellerin, C. Barron sarta J. Abecassis, “prosés garing pikeun ngembangkeun fraksi gandum jeung produk kalawan kualitas gizi ditingkatkeun,” Journal of Élmu buckwheat, teu. 46, pp. 327-347, 2007.

[9] W. A. Brastad jeung E. C. pakakas, “Metoda sarta aparat pikeun éléktrostatik separation”. Amérika Sarikat Amérika Patén 2,848,108, 19 Agustus 1958.

[10] B. A. Batu jeung J. Minifie, “Pamulihan of Sél Aleurone tina Tepung bran”. Amérika Sarikat Amérika Patén 4,746,073,24 Mei 1988.

[11] A. Bohm sarta A. ngagaro, “Metoda pikeun Isolating Aleurone Partikel”. Amérika Sarikat Amérika Patén 7,431,228, 7 Oktober 2008.

[12] J. A. Delcour, X. Rouau, C. M. Courtin, K. Poutanen sarta Sunda. Ranieri, “Panyiaran keur éksploitasi ditingkatkeun tina potensi promosi kaséhatan-of cereals,” Tren di Élmu Kadaharan & teknologi, pp. 1-9, 2012.

[13] L. Dascalescu, C. Dragan, M. Bilici, Urang Sunda. kageulisan, jeung. Hemery sarta X. Rouau, “Basis éléktrostatik pikeun pisah tina Tepung bran jaringan,” Transaksi IEEE on Aplikasi Industri, vol. 46, teu. 2, pp. 659-665, 2010.

[14] jeung. Hemery, X. Rouau, C. Dragan, Urang Sunda. Bilici na L. Dascalescu, “Sipat éléktrostatik tina bran gandum jeung lapisan constitutive na: Pangaruh ukuran partikel, komposisi, jeung eusi Uap,” Journal of Téknik Dahareun, teu. 93, pp. 114-124, 2009.

[15] jeung. Hemery, M. Curnd, The. Holopainen, A.-M. lampu, P. Lehtinen, V. piironen, A. Sadoudi sarta X. Rouau, “Potential of dry fractionation of wheat bran for the development of food ingredients, part I: Pangaruh grinding ultra-halus,” Journal of Élmu buckwheat, teu. 53, pp. 1-8, 2011.

[16] jeung. Hemery, The. Holopainen, A.-M. lampu, P. Lehtinen, T. jukut, V. piironen, M. Edlemann sareng X. Rouau, “Potential of dry fractionation of wheat bran for the development of food ingredients, bagian II: Separation éléktrostatik partikel,” Journal of Élmu buckwheat, teu. 53, pp. 9-18, 2011.

[17] J. Wang, E. Smits, Urang Sunda. M. Boom, jeung M. A. Schutyser, “Arabinoxylans konsentrasi tina dedak gandum ku separation éléktrostatik,” Journal of Téknik Dahareun, teu. 155, pp. 29-36, 2015.

[18] P. J. Pelgrom, J. Wang, Urang Sunda. M. Boom, jeung M. A. Schutyser, “Pra- sareng saatos perlakuan ningkatkeun pengayaan protéin tina panggilingan sareng klasifikasi hawa legum,” Journal of Téknik Dahareun, teu. 155, pp. 53-61, 2015.

[19] D. Chereau, P. Videocoq, C. Ruffieux, L. picon, AD. Motte, S. belaid, J. Ventureira sareng M. Lopez, “Gabungan téknologi nu aya na alternatif pikeun ngamajukeun oilseeds jeung pulsa protéin dina aplikasi dahareun,” Oilseeds & lemak Tanaman na Lipid, vol. 23, teu. 4, pp. 1-11, 2016.

[20] A. Barakat, F. Jerome sarta X. Rouau, “A Platform garing pikeun pisah tina Protéin ti Biomassa-ngandung

polisakarida, lignin, sarta polifenol,” ChemSusChem, vol. 8, pp. 1161-1166, 2015.

[21] C. Basset, S. Kedidi sarta A. Barakat, “kimia- na pangleyur-Free Mechanophysical Fractionation of Biomassa ngainduksi ku Tribo-éléktrostatik Ngecas: Separation Protéin na Lignin,” ACS Kimia sustainable & rékayasa, vol. 4, pp. 4166-4173, 2016.

[22] J. M. Stencel, J. L. Schaefer, H. nyaram, sarta J. K. Neathery, “Aparatur sarta Métode pikeun pisah Triboelectrostatic”.Amérika Sarikat Amérika Patén 5,938,041, 17 Agustus 1999.