Seleziona lingua:

Da un'occhiata all'interno del nostro laboratorio.

Si potrebbe pensare che con ST Equipment & Di tecnologia (STET) processo di separazione elettrostatica proprietarie (inventato da uno scienziato del Massachusetts Institute of Technology), we’d be pretty hush hush and clandestine about our operations. But the truth of the matter is we have a fully equipped pilot plant text facility in Needham, Massachusetts that we invite you to utilize.

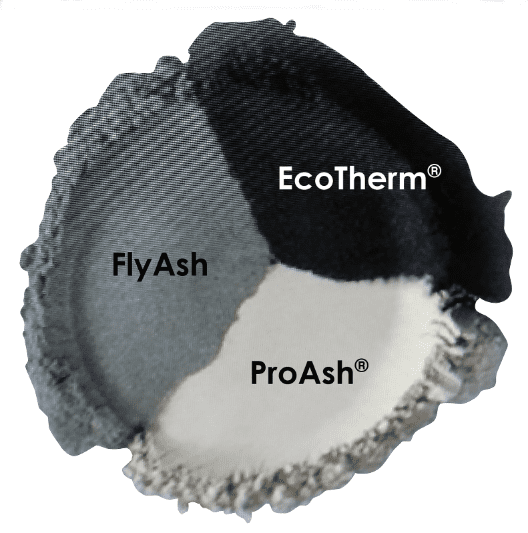

We routinely use the pilot plant to quantify the separation and processing characteristics of a variety of industrially important materials including:

Pulverized coal fly ash

Pulverized coal fly ash

Talco

Calcium bicarbonate

Heavy mineral sands

Feldspato

Iron ore

Graphite

Fosfato

Cloruro di potassio

And many others

Per questo motivo, our team of highly qualified technicians, laboratory chemists and process engineers can optimize the separation performance of your mineral and provide you with meaningful insights into the results.

Infatti, our analytical capabilities include:

Chimica di fluorescenza a raggi x (XRF)

Chimica di fluorescenza a raggi x (XRF)

Mineralogia quantitativa di diffrazione dei raggi x (XDR)

Wet Screening and Dry Ultrasonic Screening

LECO carbonio e analisi dell'umidità

Analisi granulometrica secco Laser

Peso specifico da Gas picnometro e/o boccetta di cherosene

Loss of Ignition (LOI) Testing up to 1100 degrees Celsius

Wet Chemistry Methods Including Acid Dissolution

Moisture by Loss in Weight

Open Microscopy

Interested in learning more? You can start by sending us a small sample of your mined material to us. We’ll use the information you provide to generate a report detailing the results of your sample along with recommendations on how to proceed with pilot scale testing, a quanto applicabile.

Once you have reviewed our recommendations and we can come to a consensus about the goals of your pilot testing program, we’ll issue a pilot plant test proposal.

So as you can see, our doors are wide open, and we stand ready to help you recover the most from your waste streams while producing a higher grade of product from the very start.

We look forward helping you optimize your operations in every way we can.