Pilih Bahasa:

The American Coal Ash Association (ACAA) annual survey of production and use of coal fly ash reports that between 1966 Dan 2011, over 2.3 billion short tons of fly ash were produced by coal-fired utility boilers. Of this amount, Kira 625 million tons have been beneficially used, mostly for cement and concrete production. Walau bagaimanapun, the remaining 1.7+ billion tons are primarily found in landfills or filled ponded impoundments.

Triboelektrostatik Beneficiation daripada Landdiisi dan Berhujani Abu Terbang

By Lewis Baker,Abhishek Gupta, Stephen Gasiorowski, and Frank Hrach

The American Coal Ash Association (ACAA) annual survey of production and use of coal fly ash reports that between 1966 Dan 2011, over 2.3 billion short tons of fly ash were produced by coal-fired utility boilers.1 Of this amount, Kira 625 million tons have been beneficially used, mostly for cement and concrete production. Walau bagaimanapun, the remaining 1.7+ billion tons are primarily found in landfills or filled ponded impoundments. While use rates for freshly generated fly ash have increased considerably over recent years, with current rates near 45%, Kira 40 million tons of fly ash continue to be disposed of annually. While use rates in Europe have been much higher than in the United States, considerable volumes of fly ash have also been stored in landfills and impoundments in some European countries

Tempahan, interest in recovering this disposed material has increased, partially due to the demand for high-quality fly ash for concrete and cement production during a period of reduced production as coal-fired power generation has decreased in Europe and North America. Concerns about the long-term environmental impact of such landfills are also prompting utilities to find beneficial use applications for this stored ash.

While some of this stored fly ash may be suitable for beneficial use as initially excavated, the vast majority will require some processing to meet quality standards for cement or concrete production. Because the material has been typically wetted to enable handling and compaction while avoiding airborne dust generation, drying and deagglomeration is a necessary requirement for use in concrete because concrete producers will want to continue the practice of batching fly ash as a dry, serbuk halus. Walau bagaimanapun, assuring the chemical composition of the ash meets specifications—most notably the carbon content, measured as loss on ignition (LOI)—is a greater challenge. As fly ash use has increased in the last 20+ tahun, most “in-spec” ash has been beneficially used, and the off-quality ash disposed. Thus, LOI reduction will be a requirement for using the vast majority of fly ash recoverable from utility impoundments.

While other researchers have used combustion techniques and flotation processes for LOI reduction of recovered landfilled and ponded fly ash, Peralatan ST & Technologies (STET) has found that its unique triboelectrostatic belt separation system, long used for beneficiation of freshly generated fly ash, is also effective on recovered ash after suitable drying and deagglomeration.

STET researchers have tested the triboelectrostatic separation behavior of dried landfilled ash from several fly ash landfills in the Americas and Europe. This recovered ash separated very similarly to freshly generated ash with one surprising difference: the particle charging was reversed from that of fresh ash, with the carbon charging negative in relation to the mineral.2 Other researchers of electrostatic separation of fly ash carbon have also observed this phenomenon.3-5 The polarity of the STET triboelectrostatic separator can easily be adjusted to allow rejection of negatively charged carbon from dried landfilled fly ash sources. No special modifications to the separator design or controls are necessary to accommodate his phenomena

In the STET carbon separator (Fig. 1), material is fed into the thin gap between two parallel planar electrodes. Zarah-zarah dicaj secara triboelektik oleh kenalan interparticle. The positively charged carbon and the negatively charged mineral (in freshly generated ash that has not been wetted and dried) are attracted to opposite electrodes. The particles are then swept up by a continuous moving belt and conveyed in opposite directions. Tali pinggang menggerakkan zarah bersebelahan setiap elektrod ke arah hujung bertentangan pemisah. The high belt speed also enables very high throughputs up to 36 tan sejam pada pemisah tunggal. Jurang kecil, high-voltage field, counter—current flow, vigorous particle-particle agitation, and self-cleaning action of the belt on the electrodes are the critical features of the STET separator. Dengan mengawal pelbagai parameter proses, seperti kelajuan tali pinggang, titik suapan, dan kadar suapan, proses STET menghasilkan abu terbang LOI rendah pada kandungan karbon kurang daripada 1.5 untuk 4.5% from feed fly ashes ranging in LOI from 4% kepada lebih 25%.

The separator design is relatively simple and compact. Mesin yang direka untuk memproses 40 tan sejam adalah kira-kira 30 Ft (9 m) panjang, 5 Ft (1.5 m) Luas, Dan 9 Ft (2.75 m) tall. Tali pinggang dan penggelek yang berkaitan adalah satu-satunya bahagian yang bergerak. Elektrod-elektrod adalah alat tulis dan terdiri daripada bahan tahan lama yang sesuai. The belt is made of nonconductive plastic. The separator’s power consumption is about 1 kilowatt-jam satu tan bahan diproses dengan sebahagian besar kuasa yang digunakan oleh dua motor memandu tali pinggang.

Proses ini sama sekali Kering, requires no additional materials other than the fly ash, dan menghasilkan tiada sisa pelepasan air atau udara. Bahan-bahan yang pulih terdiri daripada Abu Terbang mengurangkan kandungan karbon kepada tahap yang sesuai untuk digunakan sebagai satu Tambah pozzolanic dalam konkrit, dan sebahagian kecil tinggi karbon berguna sebagai bahan api. Penggunaan kedua-dua aliran produk menyediakan satu 100% penyelesaian kepada masalah penjualan Abu Terbang.

Empat sumber ash telah diperolehi daripada tapak pelupusan: Sampel A daripada loji janakuasa yang terletak di United Kingdom dan sampel B, C, dan D dari Amerika Syarikat. Semua sampel ini terdiri daripada Abu dari pembakaran arang batu bituminous oleh dandang utiliti yang besar. Disebabkan oleh intermingling bahan di tapak pelupusan sampah di, sebarang maklumat lanjut boleh didapati mengenai keadaan sumber atau pembakaran arang batu yang tertentu.

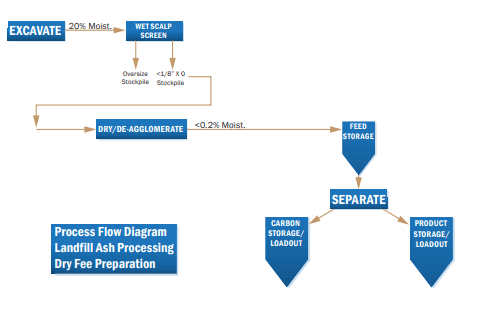

Sampel seperti yang diterima oleh STET terkandung di antara 15 Dan 27% air, yang tipikal untuk bahan-bahan landfilled. The samples also contained varying amounts of large >1/8 In. (3 mm) bahan. Untuk menyediakan sampel untuk pengasingan karbon, runtuhan besar adalah dipenuhi dengan pemeriksaan dan sampel kemudiannya dikeringkan dan deagglomerated sebelum beneficiation karbon. Beberapa kaedah untuk pengeringan/deagglomeration belum dinilai pada skala perintis untuk mengoptimumkan keseluruhan proses. STET telah memilih suapan untuk mendapatkan terbukti memproses sistem yang menawarkan pengeringan serentak dan deagglomeration perlu untuk pemisahan elektrostatik yang berkesan. Carta Aliran Proses umum akan ditunjukkan dalam Rajah. 2.

The properties of the prepared samples were well within the range of Abu Terbang obtained directly from normal utility boilers. Sifat-sifat yang paling relevan untuk kedua-dua pemisah suapan dan produk diringkaskan dalam Jadual 2, bersama-sama dengan produk pulih.

STET pemprosesan pemisah yang dikeringkan, landfilled Abu Terbang

Gambar rajah aliran proses

Carbon reduction trials using the STET triboelectric belt separator resulted in very good recovery of low-LOI products from all four landfill fly ash sources. The reverse charging of the carbon as discussed previously did not degrade the separation in any way as compared to processing fresh ash.

The properties of the low-LOI fly ash recovered using the STET process for both freshly collected ash from the boiler and ash recovered from the landfill is summarized in Table 1. The results show that the product quality for ProAsh® produced from landfilled material is equivalent to product produced from fresh fly ash sources.

The properties of the ProAsh generated from the reclaimed landfill material were compared to that of ProAsh produced from fresh fly ash generated by the utility boilers from the same location. The processed reclaimed ash meets all the specifications of ASTM C618 and AASHTO M 250 standards. Jadual 2 summarizes the chemistry for samples from two of the sources showing the insignificant difference between the fresh and reclaimed material.

Strength development of a 20% substitution of the low-LOI fly ash in a mortar containing 600 lb/yd3 cementitious material (see Table 3) showed the ProAsh product derived from landfilled ash yielded mortars with strength comparable to mortars produced using ProAsh from fresh fly ash produced at the same location. The end product of the beneficiated reclaimed ash would support high-end uses in the concrete industry consistent with the highly valuable position ProAsh enjoys in the markets it currently serves.

The availability of low-cost natural gas in the United States greatly enhances the economics of drying processes, including the drying of wetted fly ash from landfills. Jadual 4 summarizes the fuel costs for operations in the United States for 15% Dan 20% moisture contents. Typical inefficiencies of drying are included in the calculated values. Costs are based on the mass of material after drying. The incremental costs for drying fly ash for STET triboelectrostatic separation processing are relatively low.

Even with the addition of feed drying costs, the STET separation process offers a low-cost, industrially proven process for LOI reduction of landfilled fly ash. The STET process for reclaimed fly ash is one-third to one-half of the capital cost compared to combustion-based systems. The STET process for reclaimed fly ash also has significantly lower emissions to the environment compared to combustion or flotation-based systems. Because the only additional air emission source to the standard STET process installation is a natural gas-fired dryer, permitting it would be relatively simple.

| Feed sample to separator | LOI, % | ProAsh LOI, % | ProAsh fineness, % +325 MeSH |

ProAsh mass yield, % |

|---|---|---|---|---|

| Fresh A | 10.2 | 3.6 | 23 | 84 |

| Landfilled A | 11.1 | 3.6 | 20 | 80 |

| Fresh B | 5.3 | 2.0 | 13 | 86 |

| Landfilled B | 7.1 | 2.0 | 15 | 65 |

| Fresh C | 4.7 | 2.6 | 16 | 82 |

| Landfilled C | 5.7 | 2.5 | 23 | 72 |

| Landfilled D | 10.8 | 3.0 | 25 | 80 |

| Material source | SiO2 | Al2O3 | Fe2O3 | Cao | MgO | K2O | Na2O | SO3 |

|---|---|---|---|---|---|---|---|---|

| Fresh B | 51.60 | 24.70 | 9.9 | 2.22 | 0.85 | 2.19 | 0.28 | 0.09 |

| Landfilled B | 50.40 | 25.00 | 9.3 | 3.04 | 0.85 | 2.41 | 0.21 | 0.11 |

| Fresh C | 47.7 | 23.4 | 10.8 | 5.6 | 1.0 | 1.9 | 1.1 | 0.03 |

| Landfilled C | 48.5 | 26.5 | 11.5 | 1.8 | 0.86 | 2.39 | 1.18 | 0.02 |

| 7-day compressive strength, % of fresh ash control | 28-day compressive strength, % of fresh ash control | |

|---|---|---|

| Fresh B | 100 | 100 |

| Landfilled B | 107 | 113 |

| Fresh C | 100 | 100 |

| Landfilled C | 97 | 99 |

| Moisture content, % | Heat requirement KWhr/T wet basis | Drying cost/T dry basis (natural gas cost $3.45/mmBtu) |

| 15 | 165 | $ 2.28 |

| 20 | 217 | $ 3.19 |

In addition to the low-carbon product for use in concrete— brand-named ProAsh—the STET separation process also recovers otherwise wasted unburned carbon in the form of carbon-rich fly ash, branded EcoTherm™. EcoTherm has significant fuel value and can easily be returned to the electric power plant using the STET EcoTherm Return system to reduce the coal use at the plant. When EcoTherm is burned in the utility boiler, the energy from combustion is converted to high-pressure/high-temperature steam and then to electricity at the same efficiency as coal, typically 35%. The conversion of the recovered thermal energy to electricity in the STET EcoTherm Return system is two to three times higher than that of the competitive technology where the energy is recovered as low-grade heat in the form of hot water, which is circulated to the boiler feed water system. EcoTherm is also used as a source of alumina in cement kilns, displacing the more expensive bauxite, which is usually transported long distances. Using the high-carbon EcoTherm ash either at a power plant or a cement kiln maximizes the energy recovery from the delivered coal, reducing the need to mine and transport additional fuel to the facilities.

STET’s Talen Energy Brandon Shores, SMEPA R.D. Morrow, NBP Belledune, RWEnpower Didcot, EDF Energy West Burton, RWEnpower Aberthaw, and the Korea South-East Power fly ash plants all include EcoTherm Return systems.

STET’s separation process has been used commercially since 1995 for fly ash beneficiation and has generated over 20 juta tan Abu Terbang berkualiti tinggi untuk pengeluaran konkrit. Controlled low-LOI ProAsh is currently produced with STET’s technology at 12 Stesen Janakuasa seluruh Amerika Syarikat, Kanada, United Kingdom, Poland, dan Republik Korea. ProAshfly ash has been approved for use by more than 20 pihak berkuasa lebuh raya negeri, juga kerana banyak agensi spesifikasi. ProAsh has also been certified under the Canadian Standards Association and EN 450:2005 standard kualiti di Eropah. Ash kemudahan pemprosesan menggunakan teknologi STET disenaraikan dalam Jadual 5.

After suitable scalping of large material, drying, and deagglomeration, fly ash recovered from utility plant landfills can be reduced in carbon content using the commercialized STET triboelectric belt separator. The quality of the fly ash product, ProAsh, using the STET system on reclaimed landfill material, is equivalent to ProAsh produced from fresh feed fly ash. The ProAsh product is very well-suited and proven in concrete production. The recovery and beneficiation of landfilled ash will provide a continuing supply of high-quality ash for concrete producers in spite of the reduced production of “fresh” ash as coal-fired utilities reduce generation. Additionally, power plants that need to remove ash from landfills to meet changing environmental regulations will be able to use the process to alter a waste product liability into a valuable raw material for concrete producers. The STET separation process with feed preprocessing equipment for drying and deagglomerating landfilled fly ash is an attractive option for ash beneficiation with significantly lower cost and lower emissions compared to other combustion- and flotation-based systems. ❖

1. American Coal Ash Coal Combustion Products and Use Statistics, http://www.acaausa.org/Publications/Production-Use-Reports.

2. ST Internal Report, Ogos. 1995.

3. Li, T. X.; Schaefer, J. L.; Ban, H.; Neathery, J. K.; and Stencel, J. M., “Dry Beneficiation Processing of Combustion Fly Ash,” Proceedings of the DOE Conference on Unburned Carbon on Utility Fly Ash, Pittsburgh, PA, Mungkin 19-20, 1998.

4. Baltrus, J. P.; Diehl, J. R.; Soong, Y.; and Sands, W., “Triboelectrostatic Separation of Fly Ash and Charge Reversal,” Fuel, V. 81, 2002, PP. 757-762.

5. Cangialosi, F.; Notarnicola, M.; Liberti, L.; and Stencel, J., “The Role of Weathering on Fly Ash Charge Distribution during Triboelectrostatic Beneficiation,” Journal of Hazardous Materials, V. 164, 2009, PP. 683-688.

Lewis Baker is the European Technical Support Manager for ST Equipment & Teknologi (STET) based in the United Kingdom

Abhishek Gupta is a Process Engineer based at the STET pilot plant and lab facility in Needham, MA.

Stephen Gasiorowski is a Senior Research Scientist for ST Equipment & Teknologi (STET) based in New Hampshire.

Frank Hrach is Vice President of Process Engineering based at the STET pilot plant and lab facility in Needham, MA.

| Utility and power station | Lokasi | Start of commercial operations | Facility details |

|---|---|---|---|

| Duke Energy—Roxboro Station | North Carolina | Sept. 1997 | 2 separators |

| Talen Energy—Brandon Shores Station | Maryland | Apr. 1999 | 2 separators 35,000 ton storage dome Ecotherm Return 2008 |

| ScotAsh (Lafarge / Scottish Power Joint Venture)—Longannet Station | Scotland, Uk | Oct. 2002 | 1 separator |

| Jacksonville Electric Authority— St. John’s River Power Park, FL | Florida | Mungkin 2003 | 2 separators Coal/petcoke blends Ammonia removal |

| South Mississippi Electric Power Authority R.D. Morrow Station | Mississippi | Jan. 2005 | 1 separator Ecotherm return |

| New Brunswick Power Company Belledune Station | New Brunswick, Kanada | Apr. 2005 | 1 separator Coal/petcoke blends Ecotherm return |

| RWE npower Didcot Station | England, U | Ogos. 2005 | 1 separator Ecotherm return |

| Talen Energy Brunner Island Station | Pennsylvania | Dec. 2006 | 2 separators 40,000 ton storage dome |

| Tampa Electric Co. Big Bend Station | Florida | Apr. 2008 | 3 separators, pas berganda 25,000 ton storage dome Ammonia removal |

| RWE npower Aberthaw Station (Lafarge Cement UK) | Wales, Uk | Sept. 2008 | 1 separator Ammonia removal Ecotherm return |

| EDF Energy West Burton Station (Lafarge Cement UK, Cemex) | England, Uk | Oct. 2008 | 1 separator Ecotherm return |

| ZGP (Lafarge Simen Poland / Ciech Janikosoda JV) | Poland | Mar. 2010 | 1 separato |

| Korea South-East Power Yeongheung Units 5&6 | Korea Selatan | Sept. 2014 | 1 separator Ecotherm return |

| PGNiG Termika-Siekierki | Poland | Scheduled 2016 | 1 separator Ecotherm return |

| To Be Announced | Poland | Scheduled 2016 | 1 separator Ecotherm return |