Electrostatic separators let processors split mixed powders and granules by exploiting differences in electrical behavior instead of size, weight, or color. Mastering the electrostatic separator’s working principle unlocks cleaner products, lower operating costs, and a significantly smaller environmental footprint compared to water-based circuits.

How Charging Creates Selectivity

When two different solids touch, or when particles pass through an ion cloud, they swap/pick up electrons. That tiny charge difference sets the stage for separation. In a properly tuned field, conductors discharge and fall away while non‑conductors keep their charge and follow a different path. This idea lies at the heart of the modern electrostatic separation and explains why the technology can succeed where screens, spirals, or flotation cells falter.

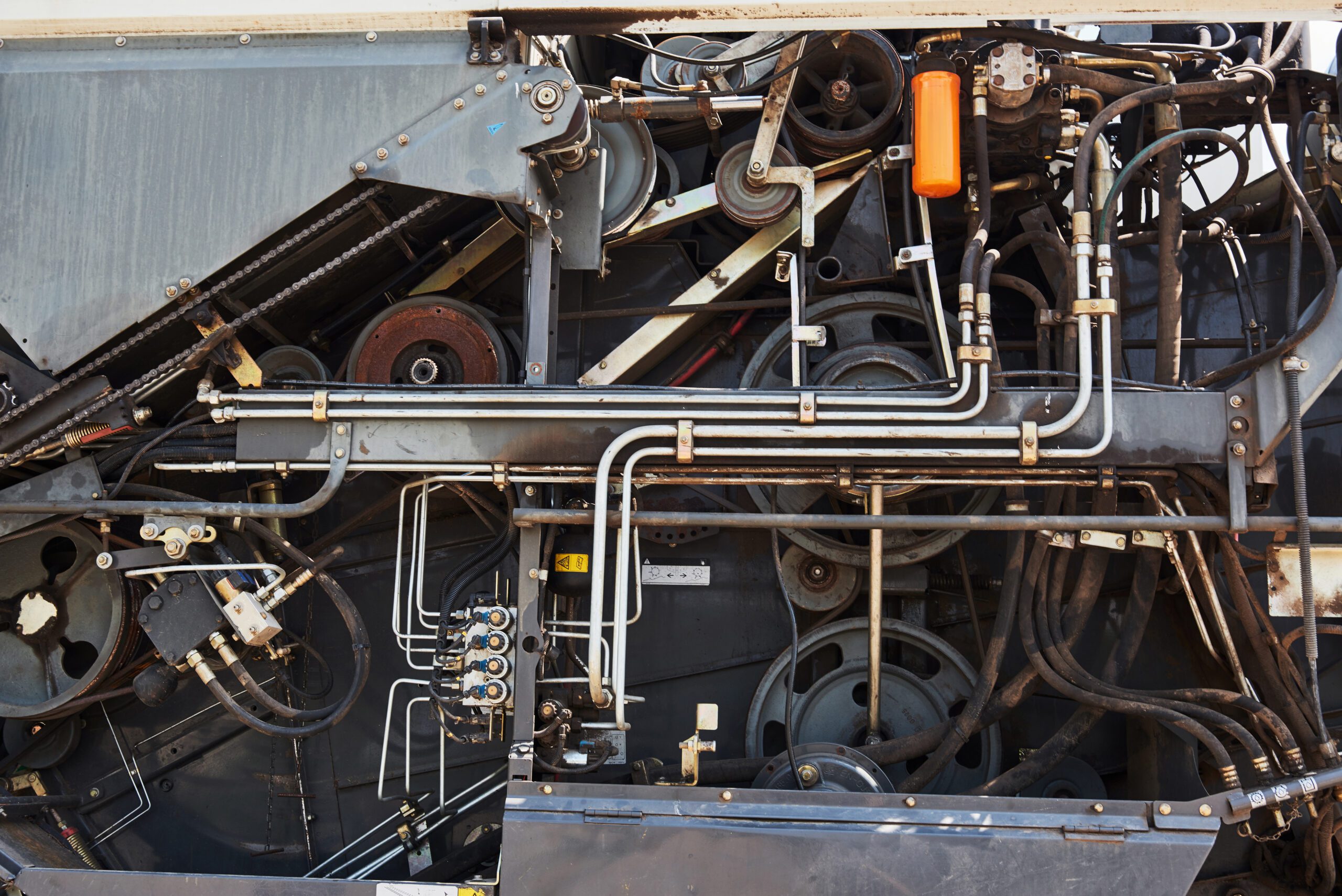

Core Hardware in Every System

A traditional electrostatic separator includes more than just a high‑voltage drum. It also needs a reliable charging device, a controlled feed mechanism, and collection bins that keep fractions apart. By lining those elements in sequence, engineers transform raw feed into distinct products without the use of water, chemicals, or grinding media.

- Charging zone: triboelectric tubes for dry, free‑flowing powders or corona bars for delicate flakes

- Field generator: insulated electrodes powered at 20–50 kV to create a stable electric field

- Transport surface: a belt or rotating drum that meters material through the field at a set speed

- Product chutes: adjustable gates that catch each stream and prevent remixing

- What Happens Inside a Drum Roll Electrostatic Separator

First, material is dried and screened to the preferred size range. It then enters the charging zone, where every particle picks up either a positive or negative charge. Once charged, the feed meets the electric field: conductors discharge on contact with a grounded surface and drop away, while insulators stay charged long enough to follow the field farther downstream. Operators fine-tune the voltage, drum speed, and splitter position until the grade and recovery rates reach their targets, demonstrating the electrostatic separator’s working principle in real-time.

Where the Technology Delivers Value

Electrostatic separation excel when two materials appear identical to the naked eye but behave differently under voltage. Typical wins include recovering low-carbon fly ash for concrete, removing PVC contaminants from PET flakes, and stripping copper wire from shredded e-waste.

In mineral sands, the units cleanly split zircon and rutile from silica without a drop of water—an advantage for water‑scarce sites.

Common Obstacles and Practical Fixes

Moisture neutralizes surface charge, so the feed must remain below 2 percent water content. Ultra‑fine dust can cloud the field; gentle agglomeration or reduced feed rate keeps the curtain uniform. Ultra-fine particles are no problem for the STET separator.

Why Partner with SteqTech

ST Equipment & Technology supplies complete dry‑electric systems specalized for fine and ultra-fine particles. along with laboratory testing, pilot‑scale trials, and on‑site startup support. We help clients validate separation performance, optimize their separation circuit, and integrate real‑time controls that lock in performance shift after shift. Whether you’re reworking tailings, removing fiber from plant protein streams, or recovering valuable metals from waste streams, SteqTech’s engineers apply decades of electrostatic separation expertise to deliver measurable, bankable results.

Ready to turn mixed feed into high‑value products without water or chemicals? Contact SteqTech for a sample evaluation and a tailored roadmap to implementation—the first step toward putting the electrostatic separator working principle to work for your operation.