Họrọ asụsụ:

ST Equipment & Technology LLC has developed a process that removes ammonia from fly ash. The usoro Recovers 100% of the fly ash treated and the resulting ash meets all specifications for use in Concrete. STET si amonia mwepụ usoro ike ga-eji naanị ma ọ bụ na Nchikota na ụlọ ọrụ carbon nkewa technology. The carbon nkewa usoro a na-adịghị emetụta ọnụnọ nke amonia na ada uyi. This modular approach offers the lowest cost solution for treating otherwise unusable fly ash…

download PDFNeedham ụzụ Center

Iwepụ amonia si ada uyi

J. Bittner, S. Gasiorowski, na F. Hrach

nkewa Technologies, LLC 101 Hampton Avenue, Needham, Massachusetts, USA

Abstract

The ọkọnọ nke ada uyi maka iji dị ka a pozzolan na ihe nwere ike idiọk mmetụta na mmetụta nke ikuku quality ụkpụrụ na mmekọ osisi arụmọrụ. kpọmkwem, iwu mbelata NOx, particulate, ya mere3 nwere aerosol emission etoju na-atụ anya na-achọ echichi nke akara usoro nke nwere ike iji amonia ka a reagent. Dabere na larịị nke amonia ugbu ke flue gas na unit precipitators, anakọtara ada uyi nwere ike kpamkpam mmeru na amonia isi dị ka ammonium sulfate salts.

ST Equipment & Technology LLC (STET) mepụtara a usoro na-ewepu amonia si ada uyi. The usoro Recovers 100% nke ada uyi emeso na n'ihi ash osobo niile nkọwa maka ojiji na ihe. ST si amonia mwepụ usoro ike ga-eji naanị ma ọ bụ na Nchikota na ụlọ ọrụ carbon nkewa technology. The carbon nkewa usoro a na-adịghị emetụta ọnụnọ nke amonia na ada uyi. Nke a modular obibia awade kasị ala na-eri ihe ngwọta maka ịgwọ ma unusable ada uyi.

The ST amonia mwepụ usoro na-arụ ọrụ na abụọ ebe na USA na otu na Europe. The amonia etoju nke untreated ada uyi nwere iche n'etiti 200 na 3000 mg NH3 / kg ash (akụkụ kwa nde site uka, ma ọ bụ ppm). The ST usoro ọma belatara ash amonia larịị na-erughị 50 mg NH3 / kg ash. N'ime 500,000 tọn ada uyi e rere ka njikere mix ihe na-emepụta si ST si amonia mwepụ usoro.

Amonia mmeru ada uyi

The ọkọnọ nke ada uyi maka iji dị ka a pozzolan na ihe nwere ike idiọk mmetụta na mmetụta nke ikuku quality ụkpụrụ na mmekọ osisi arụmọrụ.1 kpọmkwem, iwu mbelata NOx , particulate, ya mere3 nwere aerosol emission etoju na-atụ anya na-achọ echichi nke akara usoro nke nwere ike iji amonia ka a reagent. Dabere na larịị nke amonia ugbu ke flue gas na electrostatic precipitators, anakọtara ada uyi nwere ike kpamkpam mmeru na amonia isi dị ka ammonium sulfate salts 1,2. N'ihi NOx akara, na flue gas amonia larịị ga-setịpụrụ ego nke amonia "slip‿, i.e. unreacted amonia ugbu mgbe SCR ma ọ bụ SNCR unit. Iji belata particulate ma ọ bụ otú3 aerosol anwuru, amonia na-agbara ndi mmadu n'ime flue gas tupu precipitators na a ga-edebe na ada uyi. Ka ókè nke a emee bụ dabere na NTRE3 ọdịnaya, ofufe ash sọlfọ ọdịnaya, alkalinity nke ada uyi, na amonia ịta, na ash loading na flue gas.

Ojiji nke ofufe ash na ihe na-achọ na iji uyi nwere kpọmkwem anụ ahụ na chemical Njirimara3. The pozzolanic Njirimara nke ash na-arụ ọrụ na ihe site ọgbọ nke ukwuu alkaline free lime si hydration nke ciment. Mgbe ada uyi nwere amonia, a amonia na-atọhapụ dị ka a gas site ihe nke ukwuu alkaline ngwọta nke ihe. The alkalinity akọwa na ịha nke ammonium ion na ngwọta molekụla amonia dị ka ndị na-esonụ akụkụ:

NH4+(aq) + OH–(aq) ↔ NH3(aq) + H2The

The etisasịwo molekụla amonia na-adị mfe ẹkesiode ngwọta dị ka free amonia gas.

ST Equipment & Technology LLC 101 Hampton Avenue Needham, MA 02494 Tel: 781-972-2700

Needham ụzụ Center

Amonia bụ a siri ike esi ísì compound na-eburu inye echiche nke barnyards, nri ma mmamịrị. A ike isi nke amonia bụ adịghị anakwere na ihe na-emeputa, na ngo na-arụ ọrụ na ihe, na kacha ihe ọrụ.4

The okokụre Njirimara nke ihe na-adịghị emetụtawo mgbe eji amonia mmeru ada uyi, ma isi bụ adịghị anakwere, karịsịa ma ọ bụrụ na ihe na-eji na ala ma ọ bụ nchọ oghere.5,6,7 Dabere na nkọwa ndị doro nke ebe, gụnyere ego nke ọhụrụ ikuku mgbasa, amonia isi hụrụ ghara ifọnke mgbe eji ada ntụ nwere 100 ka 200 mg nke NH3 / kg (akụkụ kwa nde site uka, ma ọ bụ ppm). Iji obi sie na-enweghị nsogbu na-okosobode, na amonia ọdịnaya nke ada uyi kwesịrị ukwuu karịa 100 ppm2,8.

Otú ọ dị, na mgbakwunye na nke amonia na ike ọgbọ osisi nwere ike ịkpata ada uyi amonia ọdịnaya nke 200 ka 2500 ppm, na-ejere ndị ada uyi adịghị anakwere maka ojiji na ihe.8 N'ihi ya, mbenata ikuku quality nsogbu site ịchịkwa ikuku umu anwuru nke ike osisi enwekwu a siri ike mkpofu nsogbu na enwekwu CO2 griin haus umu anwuru-amụba ego nke ciment-eji na ihe mmepụta. Mwepụ nke amonia si ada uyi mere na ọ nwere ike ji mee ihe ga-erite uru mmekọ site n'izere siri ike mkpofu, ihe na-emeputa, ọrụ, na kacha nwe site ẹsụhọde na-eri nke ihe ma na-amụba ngwaahịa mma, na gburugburu ebe obibi site na mbenata umu anwuru nke si na greenhouse aputa site cement mmepụta.

The ego nke amonia na ammonium salts hụrụ na ada uyi na-metụtara ego nke amonia ugbu ke flue gas. N'ihi na a na-ahụkarị bibiri coal unit iji ọwụwa anyanwụ bituminous coal na a elu kpo oku uru nke 12,000 BTU / lb (6667 kcal / n'arọ), na flue gas na coal uka ruru bụ mkpokọta 8 ka 9.5. Mgbe ash ọdịnaya nke coal bụ 10%, na 80% nke ash na coal na-natara dị ka ada uyi (20% na ala ash), na flue gas / ash ruru bụ mkpokọta 100. Ọ bụrụ na ihe niile nke amonia umu ugbu ke flue gas na-edebe ọ bụ adsorbed na ada uyi, ịta nke amonia na ash ga-ihe 50 ugboro ukwuu karịa na flue gas na a uka ndabere, e.g. ihe amonia “ileghara” nke 2 ppm site olu ga ịkpata ihe ash nwere 100 mg / kg (ppm site wt.) amonia. Ojiji nha-egosi mmekọrịta a na-ezi.9 Ịta nke amonia na ada uyi ịdị iche iche n'etiti ọrụ nkeji dabere na ash ọdịnaya nke coal na ada uyi na ala ash ruru nakwa dị ka ihe ndị ọzọ.

Amonia injection ka electrostatic precipitators (ESP) mma arụmọrụ ma belata anwụrụ opacity pụrụ ịkpata nnọọ elu etoju nke amonia na ada uyi. Etoju ruo 2500 ppm amonia na ash a hụrụ maka ndị dị otú ahụ na usoro. SNCR arụmọrụ a na-arụ ọrụ na amonia ileghara kasịnụ nke 5 ka 20 ppm, na ash mmeru ka a larịị nke 200 ka 1000 ppm amonia. SCR systems n'ozuzu na-iji na-arụ ọrụ na kacha amonia ileghara etoju nke 2 ma ọ bụ 5 ppm, dabere na ha kpọmkwem nke echichi.10 n'ozuzu, nke ukwuu NH3/NOx ruru, nke ukwuu NOx Mbelata nke ga-enwetara, na a elu amonia ileghara dapụtara. Otú ọ dị, amonia ileghara ukwuu karịa 2 ppm may result in ash-ammonia contents of greater than 100 ppm, amị ihe unmarketable ash.11 Ọtụtụ ike osisi na Japan na Germany na-arụ ọrụ SCR nkeji mere maka a 2 ppm kacha ileghara hụrụ obere mmetụta na marketability nke ada uyi.1,5 Otú ọ dị, ụfọdụ SCR si gburugburu ụwa e mere maka 5 ppm amonia ileghara. Ọrụ ndị a nkeji na a elu ileghara larịị yikarịrị ka ọ ga n'ihi na ukwuu karịa 100 ppm nke amonia na ada uyi.

Ịchịkwa amonia ileghara na ala etoju na-ebelata ịkwụnye na corrosion nke downstream ngwá n'ihi deposition nke ammonium sulfates.1,10 Izere ikuku preheater ịkwụnye ruru ka a onu na-atụ anya na-ọbụna ihe dị mkpa ka unit rụọ mgbe ọkụ elu sọlfọ, US icheku. N'ihi ya, management nke amonia ileghara iwelata unit outage oge ga-a na-enwekwu nchegbu karịa ịchịkwa amonia larịị nke ada uyi. Nsonazụ ahụ

ST Equipment & Technology LLC 101 Hampton Avenue Needham, MA 02494 Tel: 781-972-2700

Needham ụzụ Center

nwere ike ịbụ na ọ dịghị ịrịba nsogbu amalite maka itinye n'ọrụ nke ash na ụfọdụ na ịba uru saịtị, dabere kpọmkwem imewe na ime ihe nke emission akara usoro.

The STET Usoro

STET azụlitewo a usoro na-ewepu amonia si ada uyi.12 The usoro Recovers 100% nke ada uyi emeso na n'ihi ash osobo niile nkọwa maka ojiji na ihe. STET si amonia mwepụ usoro ike ga-eji naanị ma ọ bụ na Nchikota na ụlọ ọrụ carbon nkewa technology. The carbon nkewa usoro a na-adịghị emetụta ọnụnọ nke amonia. Nke a modular obibia awade kasị ala na-eri ihe ngwọta maka ịgwọ ma unusable ada uyi.

Iji wepu amonia ka a gas si ada uyi, na STET usoro utilizes otu isi chemical mmeghachi omume nke na-eweta amonia ntọhapụ na ihe. Ntọhapụ nke amonia si ada uyi na-achọ na ammonium ion

–molekụla amonia ịha ike gbanwere na ihu ọma nke amonia site ọnụnọ nke alkali. Ofufe ntụ na ndammana elu alkalinity mkpa ọ dịghị ọzọ na alkali. Obere alkaline ntụ, ọ bụla siri ike alkali ga-eje ozi. The ọnụ ala isi iyi nke alkali bụ lime (CaO). The mmeghachi omume nke ammonium salts na lime akafak amonia na-ike mfọn chemical ịha. The chemical mmeghachi omume na-adị ngwa ngwa ozugbo ogige na-etisasịwo.

The emeghachi omume n'ozuzu nwere ike generalized ka:

(NH4)2NTRE4(s) + CaO(s) → 2NH3(g) + caso4(s) + H2The(g)

Otú ọ dị, na Alụlụụ nrụgide nke solids bụ nnọọ ala na mmeghachi omume na-apụghị ime na gas ma ọ bụ ihe siri ike na-adọ. Ammonium sulfate bụ ukwuu soluble na mmiri na dissociates ka ammonium ion na sulfate ion.

(NH4)2NTRE4(aq) → 2NH4+(aq) + NTRE42-(aq)

Wayo bụ ukwuu na-ejighị n'aka na n'ebe mmiri, na-erite a ukwuu exothermic mmeghachi omume a maara dị ka “slaking”, amị calcium hydroxide ma ọ bụ hydrated wayo.

CaOs +H2O → Ca(OH)2(s)

The hydrated wayo bụ naanị ufat soluble na mmiri, amị calcium na hydroxide ion.

dị ka(OH)2(s) ↔ dị ka2+(aq) + 2 OH–(aq)

Calcium sulfate bụkwa ufat soluble, ka calcium ion na-mere dị site dissolving na hydrated lime, ha na-isi gwusia site ọdịda nke calcium sulfate.

dị ka2+(aq) + NTRE42-(aq) → caso4(s)

N'ikpeazụ, ihe ịha dị n'etiti ammonium ion na amonia etisasịwo mmiri.

NH4+(aq) + OH–(aq) ↔ NH3(aq) + H2The

ST Equipment & Technology LLC 101 Hampton Avenue Needham, MA 02494 Tel: 781-972-2700

Needham ụzụ Center

Ka ókè ammonium ion na-ghọrọ ka molekụla amonia bụ dabere na onye Onyenwe anyị + nke okenye usoro, elu onye Onyenwe anyị + na-erite guzobe molekụla amonia. Nke a ịha dị mma amaara.13

A isi ihe dị STET usoro bụ ojiji nke a kacha nta mmiri buru ibu (1 ka 4%, a na 2%) na di ntakiri quantities nke alkali (< 2%). Large ichekwa mmiri nwere ike imebi usoro, ibelata ọnụego nke amonia ntọhapụ. Onye Onyenwe anyị + nke dapụtara ash / oroma nkịrịsị / mmiri ngwakọta ga-adị ukwuu karịa onye Onyenwe anyị + 10.0. Nnọọ obere obere nke alkali na-kwukwara na-emesi a onye Onyenwe anyị +, dabere na eke onye Onyenwe anyị + nke ash. A, pekarịrị 1% dị ka(OH)2 ihe achọrọ, ọbụna na-ada uyi na ndammana acidic onye Onyenwe anyị +. Calcium dabeere alkalis na-eji nke N'ihi na ntakiri mgbanwe nke ada uyi onwu. The usoro a rụrụ na ihere okpomọkụ.

Ebe ọ bụ na ndị na-eri nke alkali na-eri nke ihicha ngwaahịa ndị bụ isi na-arụ ọrụ ego na sizing Ịgwakọta na ihicha ngwá bụ isi mmiri nke isi obodo-eri, nlezianya odomo reagent chọrọ maka a kpọmkwem ash dị mkpa na-ebuli ndị akụnụba nke usoro.

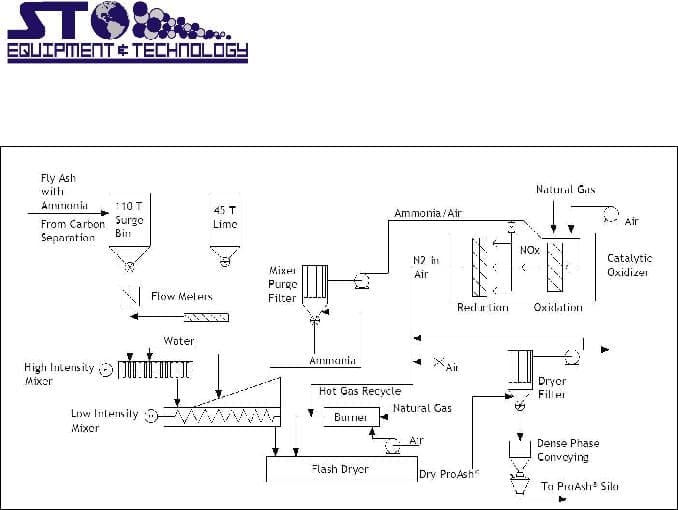

The usoro eruba esereese maka-aga n'ihu ime nke STET usoro a adade ke ọgụgụ 1. Ash, mmiri na alkali achịkwa otosịrị iru na-metered ka a igwekota. Ka obi sie ngwa ngwa Ịgwakọta na edo dispersion nke kwukwara na mmiri na alkali, a akwa siri igwekota na-eji. The obi oge a ụdị igwekota dị ala, na iji nke otu abụọ. Amonia bụ ozugbo a tọhapụrụ ma zuru ezu evolushọn na-achọ agwakọta ugboro of 3 ka 4 nkeji na-ekwe ka nke uka iga nke gas si nnukwu nke ash ka ohere maka uka iga nke gas si nnukwu nke ash.

Iji nweta a Ịgwakọta oge na obi sie ezi iga nke amonia si nnukwu nke ash, a ala ike na ngwaọrụ dị ka a pug na nkume igwe nri na-eji dị ka a abụọ igwekota. Ebe ọ bụ na mmiri ọdịnaya nke ash dị ala, ihe aga site na nke a igwekota dị ka a ukwuu jijiji akọrọ ntụ ntụ. Ammonia gas collected in both the high and low speed mixers is either recycled to the generating unit flue or converted to nitrogen in a two- stage catalytic unit.

ST Equipment & Technology LLC 101 Hampton Avenue Needham, MA 02494 Tel: 781-972-2700

Needham ụzụ Center

Ọgụgụ 1: STET Ammonia Removal Process Flow Diagram

The deammoniated ash na-mịrị amị site n'ikwusara ndị ihe onwunwe site na a flash drier wepụ ngafe mmiri. Due to the minimal amount of water added, mmiri iwesa ke guzobere hydrated calcium sulfate n'elu mmeghachi omume na soluble sulfate na ash, na ọnwụ nke mmiri n'oge ala osisi ike agwakọta ogbo, naanị a obere ego nke mmiri kwesịrị ka a wepụrụ site drier. Nke a na-ebenata ike ina nke ihicha ogbo. Final ash okpomọkụ nke na mkpokọta 150naF are adequate to produce a completely free-flowing, ngwaahịa ada uyi na mmiri ọdịnaya ọma n'okpuru ASTM C 618 nkọwapụta nke 3 wt. %.3

The first full-scale application of STET’s ammonia removal process began operating in 2003 at ST’s ash processing facility at the Jacksonville Electric Authority St. Johns River Power Park in Jacksonville, Florida. This commercial scale operation handles up to 40 tons per hour of contaminated ash, mbenata amonia ọdịnaya na-erughị 30 ppm. Ammonia levels in the incoming fly ash varies from ~200 to 900 ppm. The process is very robust, resulting in 90+% ammonia removal under all trial settings, producing ash well below our target of maximum 50 ppm amonia. Final moisture contents are <0.3%. Representative results are listed in Table 2. N'ime 250,000 tons of ammonia-contaminated ash has been successfully processed at the Jacksonville facility.

ST Equipment & Technology LLC 101 Hampton Avenue Needham, MA 02494 Tel: 781-972-2700

Needham ụzụ Center

Isiokwu 2: Typical commercial scale ammonia system results

|

ndepụta Rate, |

mbụ amonia, |

Final amonia, |

wayo ọnụego, |

mmiri na ọnụego, |

|

tọn / Ọrụ Nchịkwa |

ppm |

ppm |

% nke iri nri |

% nke iri nri |

|

21 |

910 |

25 |

1.35 |

1.9 |

|

25 |

190 |

9 |

0.88 |

2.6 |

|

40 |

350 |

12 |

0.70 |

2.05 |

|

18 |

242 |

20 |

0.82 |

1.52 |

Ofufe ash na Big Bend Station na Tampa, Florida na-metọọ amonia ruru ka ntụtụ amonia n'ime ike osisi nke ESP systems ịchịkwa emission nke NTRE3 aerosol N'ịbụ SCR NOx akara usoro. Na ndị ọzọ ike osisi, amonia ofufe Oputakwara na SNCR NOx akara na ojiji nke amonia aka urughuru collection na ESP usoro. Na Big Bend, na ada uyi amonia etoju maka nkeji na amonia injection nso si 750 ka 3360 ppm amonia. Consequently, the fly ash intended for concrete production must be treated by the ST ammonia removal process.

The design of the STET ammonia removal process installed at Big Bend (Ọgụgụ 2) is the second full scale installation and includes many refinements. Material handling equipment is improved to allow operation at higher rates. The drying system is downsized from the previous design and includes recycling of hot gases to reduce the overall energy requirements of the system. Egbu, the ammonia released in the process is fed to a two-stage catalytic unit where the collected ammonia gas is converted into nitrogen. The okpomọkụ N'ịbụ nke a mmeghachi omume a na-natara na-eji ịgbakwunye ume chọrọ nke ada uyi flash ihicha usoro. The use of the two-stage catalytic system results in minimal NOx emissions. The usoro Recovers 100% nke ada uyi emeso na n'ihi ash osobo niile nkọwa maka ojiji na ihe.

Nke a azụmahịa ọnụ ọgụgụ na ime nwere ike ijikwa elu 52 tons per hour of contaminated ash, mbenata amonia ọdịnaya na-erughị 75 mg / n'arọ. The process is very robust, resulting in 97+% amonia mwepụ, producing ash well below our target of maximum 100 mg / n'arọ amonia. Final moisture contents are <0.5%.

An STET amonia mwepụ usoro a na-arụ ọrụ na RWE npower Aberthaw ojii ash nhazi ụlọ ọrụ na UK ebe 2008. Aberthaw adds ammonia to improve ESP collection efficiency with ammonia levels on the ash typical 200 ppm and the process is designed for 500 ppm maximum.

ST Equipment & Technology LLC 101 Hampton Avenue Needham, MA 02494 Tel: 781-972-2700

Needham ụzụ Center

Ọgụgụ 2: Ammonia removal system at Big Bend Station, Tampa Florida

The Product Ash

The low ammonia fly ash product meets all chemical and physical requirements of the ASTM C 618 standard and resulting concrete properties are identical to ash not subjected to the ammonia removal process. Isiokwu m tụnyere typical Njirimara nke ash si onye-amụba ebe tinyere Njirimara nke osisi ash ebelata ke amonia ọdịnaya site 250 mg / n'arọ 20 mg / kg site na-aga n'ihu ST usoro. Rịba ama na nso nke calcium oxide content hụrụ maka ash n'ebe a bụ 1.4 ka 12%. Na mgbakwunye na nke ruo 1% dị ka(OH)2 (0.75% ka CaO) ga-eme naanị obere mgbanwe na ash onwu, broadening ndị mgbanwe insignificantly.

Concrete testing rụrụ na deammoniated ash gosiri na ọ ga-magburu onwe pozzolanic ihe. Compressive ike mmepe na iji ash bụ dị ka ihe ọma dị ka ọ bụ mma karịa unammoniated ash n'ebe a. Ogologo okwu ihe anwụ ngwa ngwa Njirimara na-magburu onwe, gụnyere mma corrosion eguzogide, sulfate eguzogide, chloride permeability, na lime shrinkage.

ST Equipment & Technology LLC 101 Hampton Avenue Needham, MA 02494 Tel: 781-972-2700

Needham ụzụ Center

Isiokwu m: Ofufe Ash Physical na Chemical Properties.

|

|

ASTM C 618 nkọwapụta |

osisi # 1 Ash Properties, ahụkarị |

osisi # 1 Ash Mgbe amonia mwepụ |

|

|

Chemical mejupụtara |

|

|

|

|

|

Silicon dioxide |

– |

55 – 61 % |

59.8 % |

|

|

aluminum oxide |

– |

15 – 25 % |

23.8 % |

|

|

Iron oxide |

– |

5 – 10.9% |

7.35 |

|

|

Total (SiO2 + Al2The3 + Fe2The3) |

70.0 m. |

78 – 91 % |

90.9 % |

|

|

sọlfọ Trioxide |

5.0 Max |

0.13 – 1.4% |

0.87% |

|

|

calcium oxide |

– |

1.4 – 12 % |

1.79 % |

|

|

mmiri Content |

3.0 Max. |

0.0 – 0.3 % |

0.21% |

|

|

Loss na mgbanye |

6.0 Max. |

0.7 – 2.6 % |

0.91% |

|

|

sodium oxide |

– |

0.1 – 0.7 |

0.14% |

|

|

potassium oxide |

– |

0.5 – 2.2% |

0.56% |

|

|

dị Alkalis (na2The) |

1.5 % Max |

0.5 – 0.8% |

0.51% |

|

|

Physical Test Results |

|

|

|

|

|

Fineness, nọgidere na #325 myọ |

34% Max. |

8 – 16% |

14% |

|

|

Ike Arụ Ọrụ Index |

|

|

|

|

|

Ruru Ejikwa @ 7 ụbọchị |

– |

81 – 95 % |

94.8% |

|

|

Ruru Ejikwa @ 28 ụbọchị |

75% m. |

94 – 102% |

99.5% |

|

|

mmiri Iwu, % nke Control |

105% Max. |

93 – 97% |

94.2% |

|

|

uche zuru, Autoclave Mgbasawanye |

0.8% Max. |

-0.035 – 0.010 |

-0.033 |

|

|

akọrọ shrinkage, dịkwuo @ 28 Day |

0.03% Max. |

-0.01 – 0.010 |

-0.009 |

|

|

njupụta |

– |

2.35 – 2.45 |

2.36 |

|

nchịkọta

Ka ókè ezi mma ada uyi ga-mie dị ka n'ihi NOx ma ọ bụ particulate emission usoro na-eme n'ọdịnihu ga-adabere technology họọrọ ime ihe na utilities iji belata NOx, particulate okwu umu anwuru na anwụrụ opacity. Otú ọ dị, STET si amonia mwepụ usoro nwere ike tinye n'ọrụ wepụ amonia si metọrọ emetọ na ash, amị a elu uru ihe onwunwe maka ojiji na ihe mmepụta. Natara amonia nwere ike itighachi na-amụba unit maka reutilization. This ammonia removal process can be installed as a stand-alone system or can be used in conjunction with STET’s successful fly ash carbon removal system.

1Stewart, B.R., Atụghị mmetụta nke EPA na-adịbeghị anya Ozone Transport Iwu, Ikpe, 1999 Ọgbakọ na Nhọrọ Catalytic na Mbelata Na-abụghị Catalytic maka njikwa NOx, Ka 1999, pp.9-10.

2Sloss, L.L., Hjalmarsson, A-K, Soud, H.N., Campbell, L.M., Stone, D.K., Shareef, G.S., Emmel, T., Maibodi, M., Livengood, C.D., Markussen, J. Nitrogen Oxides Control Technology Fact Book, Noyes Data Corporation, p. 94-95, 1992

3“Standard nkọwapụta maka Kol ada uyi na Raw ma ọ bụ Calcined Natural Pozzolan maka Iji dị ka a Ịnweta admixture na Concrete”, ASTM C 618, American Society for Testing and Materials, Philadelphia, PA.

4majors, R.K., Hill, R., McMurry, R., Thomas, S., A Study nke Mmetụta amonia Ọgwụ na-ere ere na ada uyi tinyere Quality Control usoro, Ikpe, 1999 Conference on Nhọrọ Catalytic na Non-Catalytic Reduction for NOx control, Ka 1999, pp.11-13.

5Site n'ebe Brugghen, F.W., guest, C.H., Van den Berg, J.W., Kuiper, W.H., Visser, R., Nsogbu okosobode N'oge Jiri nke ammonium mmeru ada uyi. Ikpe: EPRI / EPA 1995 Joint mkparita on Station combustion NOx Control, Ka 16-19, 1995. Book 4, oge 8A, p. 1-16.

6Van den Berg, J.W., Cornelissen, H.A.W. ,Mmetụta nke ala NOx Technologies na ada Ash Quality, Ikpe: 13nke International mkparita on Iji na Management of Kol combustion Products, 1999, p. 29-1 – 29-11.

7Koch, H-J., Prenzel, H., Ule na nta Developments na Nkedo nke a Concrete Screed – Iji NH3-Ijiji utu emeru emeru, Concrete Precasting Osisi na Technology, Vol 11, 1989 p. 72-75.

8Fisher, B.C., Blackstock, T. Ada Ash Beneficiation iji ihe na amonia agba Usoro, 12nke Mgbakọ mba ụwa na njikwa na ojiji nke ngwaahịa na-ere ọkụ, 1997 p. 65-1 – 65-8.

ST Equipment & Technology LLC 101 Hampton Avenue Needham, MA 02494 Tel: 781-972-2700

Needham ụzụ Center

9Larrimore, L., Dodgen, D., Monroe, L., Akparamagwa nke amonia mmetụta na Ash na Evaluation nke mwepụ Ụzọ, Ikpe: 13nke International mkparita on Iji na Management of Kol combustion Products, 1999, p. 16-1 – 16-15.

10Control nke nitrogen oxide anwuru: Nhọrọ Catalytic Ibenata mmasi (SCR), Clean Kol Technology, Nde Report Number 9. U.S. Department of Energy na Southern Company Services, Inc. July, 1997.

11O'Connor, D., Larrimore, L, Dodgen, D., Monroe, L., Mmetụta nke Mbelata NOx dabere na Amonia na Fly Ash: Amonia Adsorption na Ash, Ikpe, EPRI-DOE-EPA Jikọrọ Utility Air Mmetọ Control mkparita: The Mega mkparita, August, 1999, akwụkwọ # 16.

12Gasiorowski, S.A., na Hrach, F.J., Method maka Iwepụ amonia si amonia mmeru ada uyi, United States Patent Number 6,077,494, June 20, 2000.

13Thurston, R.V., russo, R.C., Emerson, K., Okenye amonia ịha – Nkọwa nke Pasent Amonia enweghị ionized, United States Environmental Protection, EPA-600 / 3-79-091, August, 1979.

ST Equipment & Technology LLC 101 Hampton Avenue Needham, MA 02494 Tel: 781-972-2700