A.Gupta, K. Flynn and F. Hrach

ST Equipment & Technology, 101 Hampton Avenue, Needham, MA 02494, USA

Abstract

ST Equipment & Technology (STET) is the developer and manufacturer of triboelectrostatic belt separation system that provides the minerals industry a solution to beneficiate fine mineral ores by using a dry technology. The triboelectrostatic belt separation technology has been used commercially to separate a wide range of minerals including calcite/quartz, talc/magnesite, barite/quartz, and aluminosilicates/carbon in fly ash. The high efficiency multi-state separation achieved by particle to particle charging results in superior separation as compared to a conventional free-fall triboelectrostatic separator. It is a dry technology and doesn’t require use of environmentally sensitive chemicals and water, hence no waste water treatment systems are required in the process. In this report, results of a successful pilot plant scale beneficiation test conducted on a mixture of zircon/rutile in mineral sands are published.

Keywords: minerals, dry separation, triboelectrostatic charging, belt separator, mineral sands, zircon, rutile

Introduction

STET triboelectrostatic separator utilizes differences in the surface chemistry between the particles of the feed material to create electrical charge differences. When two dissimilar surfaces are rubbed against each other, charge transfer takes place with material with lower electron affinity losing electrons to the material with higher electron affinity thus charging positive and negative respectively.

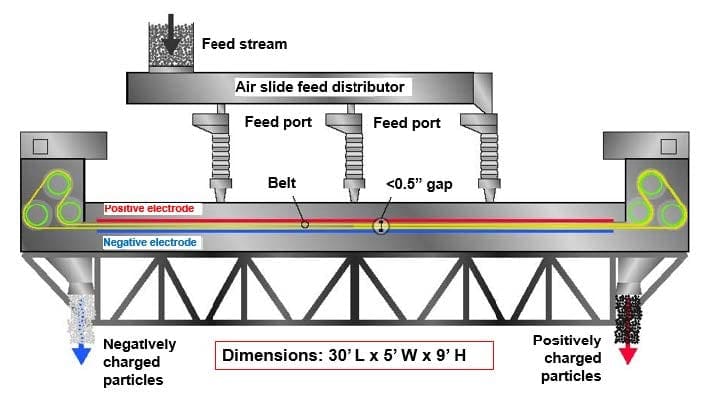

In STET triboelectrostatic belt separator, feed material is fed into a thin gap between two parallel electrodes. There is an open-mesh belt moving between the electrodes at high velocity, upto 65 feet/sec, forming a loop around a set of rollers on both ends (Figure 1). The particles are triboelectrically charged by the vigorous particle to particle contact and are attracted to the oppositely charge electrodes. The belt sweeps the electrodes and carries the different particles to opposite ends of the separator. The counter current flow of the separating particle and continual triboelectric charging by particle to particle collisions provides for a multi-stage dry beneficiation process. The separator design is relatively simple and compact. The overall length is approx. 30 ft (9 m) and width 5 ft (1.5 m) for a full size commercial unit.

STET maintains a research and development laboratory at the STET technical center in Needham, Massachusetts. This facility includes the STET pilot plant and chemistry laboratory, as well as the design, manufacturing and technical support departments for STET’s business development and manufacturing facilities. The pilot plant houses two reduced scale, STET separators along with ancillary equipment used to investigate modifications of the STET process and to evaluate the separation of fly ash and minerals from candidate sources.

Figure 1: STET triboelectrostatic separator schematic

Mineral sands

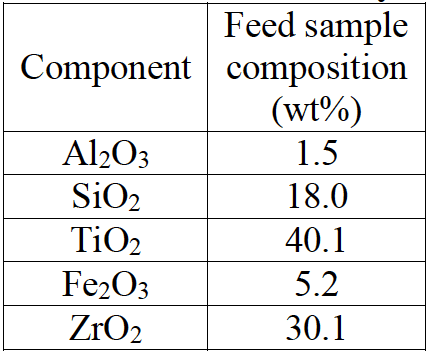

The mineralogy of rutile reject sample was approximately 41% rutile, 33% zircon, 18% ilmenite and 8% other minerals. The objective was to establish processing conditions to recover zircon from the rutile reject sample. STET conducted chemical analysis using wavelength dispersive X-Ray fluorescence (WD-XRF) on feed sample and the results (normalized for LOI) are shown in table 1.

Table 1: Elemental analysis of mineral sands sample (major components shown)

Conventional methods for beneficiating mineral sands involve complicated flow sheets using processes such as wet gravity techniques, magnetic separation and froth flotation (ref. 1,2) which have their own limitations. The magnetic separation process often leads to a middling fraction which require either disposal or recycling back to the feed stream. Magnetic separation using rollers have other limitations in processing fines. The fine particles, even non-magnetic tend to form coatings on the roller, rendering the separation process ineffective. STET separator is well suited for separation of very fine materials with very high throughputs. Wet gravity and froth flotation processes involves heavy wet chemical and water usage, and requires waste water treatment process. For dry final applications, a drying step has to be added downstream of beneficiation step thereby increasing operating costs.

STET’s triboelectrostatic technology provides a unique capability to process the feed dry, with low electricity consumption, typically approx. 1 kWh/ton (ref. 3) and generates two upgraded streams on either end of the separator with no middling fraction.

Results

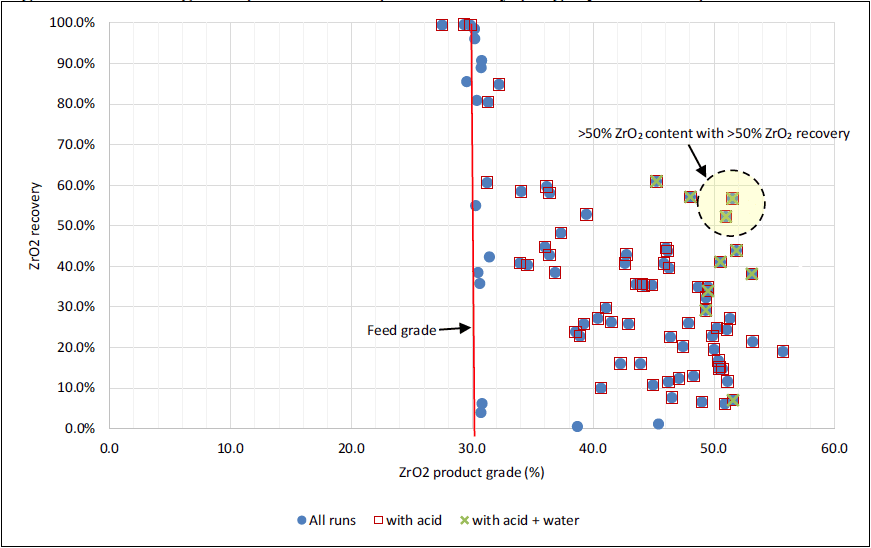

STET demonstrated evidence of effective charging and separation of zircon and rutile mineral particles. It was seen that doping the feed ore with small quantities of aromatic or aliphatic carboxylic acids (electrostatic charge conditioning agents) showed significant improvement in the separation behavior. Figure 2 below shows product grade (ZrO2 content measured using WD-XRF) and ZrO2 recovery to product for all the runs conducted at STET pilot plant. It can be seen that under optimized conditions with feed doped with aromatic carboxylic acid at 2000 gm/ ton dosage and moisture, product grades of >50% ZrO2 content with >50% ZrO2 recovery to product were achieved (see highlighted data). Average ZrO2 content for the feed was approx. 30%.

Figure 3 shows by-product grade (TiO2 content measured using WD-XRF) and TiO2 recovery to by-product for all the runs conducted at STET pilot plant. It can be seen that under optimized conditions with feed doped with aromatic carboxylic acid and moisture, by-product grades of >50% TiO2 content with >80% TiO2 recovery to by-product were achieved (see data highlighted). Average TiO2 content for the feed was approx. 40%.

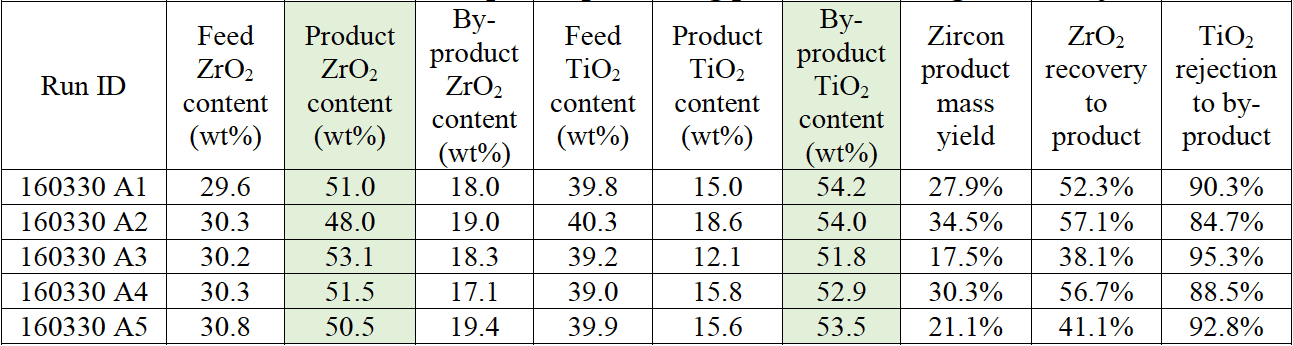

Table 2 below shows the results from runs conducted under optimized conditions. STET was able to achieve >50% ZrO2 content in the product with improved zircon content beneficiating a feed with average 30% ZrO2 content. The rutile fraction of the feed was collected as by-product, with >50% TiO2 content beneficiating a feed with average TiO2 content approx. 40%. Future work will focus on optimizing separation results by reducing the dosage of charge conditioning agents.

Figure 2: Product grade (ZrO2 content) v/s recovery (single pass results)

Figure 3: By-product grade (TiO2 content) v/s recovery (single pass results)

Table 2: Results achieved under optimal processing parameters using “rutile reject” feed

Conclusion

It is successfully demonstrated that STET triboelectrostatic belt separator is capable of effectively beneficiating the zircon/rutile mixture containing mineral sands feed, thereby achieving upgraded zircon and rutile content in the product and by-product respectively. This technique provides a cost-effective, viable alternative and can possibly eliminate wet processing techniques. It doesn’t require use of environmentally sensitive chemicals or water and thus does not require drying of the final material. The energy consumption for the STET separator is low, approx. 1 kWh/ ton of processed feed material.

References

1. R.M. Tyler and R.C.A. Minnitt. A review of sub-Saharan heavy mineral sands deposit: implications for new projects in southern Africa. The Journal of The South African Institute of Mining and Metallurgy, 89-100, March 2004.

2. V.G.K. Murty, D. Rathod, S. Asokan and A. Chatterjee. Beneficiation of Indian Heavy Mineral Sands – Some New Possibilities Identified by Tata Steel. Proceedings of the International Seminar on Mineral Processing Technology, 2006.

3. J.D. Bittner, K.P. Flynn and F.J. Hrach, Expanding Applications in Dry Tribolectric Separation of Minerals. Proceedings of International Mineral Processing Congress, 2014.