Select Language:

Kyle Flynn, Abhishek Gupta, Frank Hrach

Abstract

Review of the relevant literature indicates that significant research has been undertaken to apply electrostatically

separation techniques to dry granular plant-based food (i.e., organic) materials. This development has accelerated in the past 10 – 20 years, with many researchers in Europe and the United States applying electrostatic separation techniques to a wide variety of beneficiation challenges. From this research, it is evident that electrostatic methods have the potential to generate new, higher-value plant products, or offer an alternative to wet processing methods. Although encouraging separations of cereal grain, pulse and oilseed materials have been demonstrated at the laboratory and in some cases, pilot scale, the electrostatic systems used to demonstrate these results may not be suitable or cost-effective processing equipment to perform such separations on a commercial basis. Many electrostatic technologies are not suitable for process finely ground, low-density powders such as plant materials. However, the ST Equipment & Technology (STET) triboelectrostatic belt separator has the demonstrated capability to process fine particles from 500 – 1 µm. The STET belt separator is a high-rate, industrially proven processing device that may be suitable to commercialize the recent developments in organic material processing. The STET belt separator was tested on a sample of whole wheat flour and was found to be successful in removing the bran from the starch fraction. Future testing with the STET separator will be conducted on wheat bran samples, corn flour

and pulses such as soy and lupin.

Keywords: Tribo-Electrostatic, Electrostatic, Separation, Fractionation, Wheat, Grain, Flour, Fiber, Protein, Oilseeds, Pulses

Introduction

Electrostatic separation methods have been utilized for the past 50 years on the commercial-scale beneficiation of

industrial minerals and recycling of waste materials. Electrostatic beneficiation of dry granular plant-based food (i.e, organic) materials have been investigated for over 140 years, with the first patent for electrostatic separation of wheat flour middlings filled as early as 1880. [1] Electrostatic beneficiation allows for separations based on differences in surface chemistry (work function) or dielectric properties. In some instances, these separations would not be possible using size or density separations alone. Electrostatic separation systems operate on similar principles. All electrostatic separation systems contain a system to electrically charge the particles, an externally generated electric field for the separation to occur in, and a method of conveying particles into and out the separation device. Electrical charging can occur by one or multiple methods including conductive induction, tribo-charging (contact electrification) and ion or corona charging. Electrostatic separation systems utilize at least one of these charging mechanisms. [2]

High tension roll electrostatic separation systems have been used in many industries and applications where one

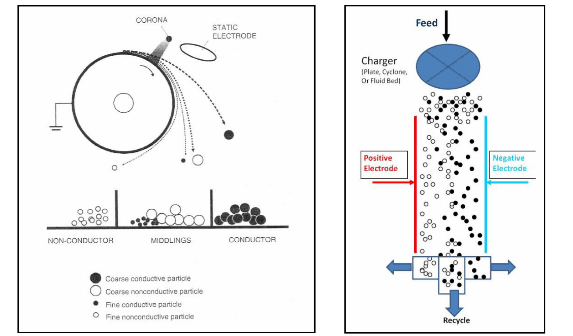

the component is more electrically conductive than the others. Examples of applications for high tension roll separators include titanium bearing minerals separation, as well as recycling applications, for example sorting metal from plastic. There are multiple variations and geometries used for high tension roll systems, but in general, they operate on similar principles. Feed particles are charged negatively by an ionizing corona discharge. Feed particles are dispersed onto a rotating drum, where the drum is electrically grounded. The electrically conductive particles give up their charge upon contacting the surface of the grounded drum. The rotation of the drum causes the conductive particles to be thrown from the surface of the drum and deposited in the first product hopper. The non-conductive particles retain their electrical charge and are pinned to the surface of the drum. Eventually, the electrical charge on the non-conductive particles will dissipate, or the particles will be brushed from the drum after the drum has rotated so that the non-conductive particles are deposited in the non-conductive particle hopper. In some applications, a middlings hopper is placed between the conductive and non-conductive product hopper. The effectiveness of this type of separation device is generally limited to particles which are relatively coarse and/or have high specific gravity, due to the need for all particles to contact the surface of the drum. In addition, particle flow dynamics is important as angular momentum is ultimately responsible for conveying the particles from the surface of the drum to the respective product hoppers. Fine particles and low-density particles are easily influenced by air currents and thus less likely to be thrown from the drum in a predictable area. [2] [3] [4]

The high tension belt separator is a variant of the high tension roll separator described above. Feed particles are dispersed evenly across the width of an electrically grounded conveyor belt. Particles are charged, usually by a negative corona, although other mechanisms of charging are possible. Again the conductive particles give their electrical charge up to the grounded conveyor belt, while the non-conductive particles retain their charge. The conductive particles fall off of the edge of the belt by gravity, while the charged non-conductive particles are “lifted” off of the surface of the belt by electrostatic forces. Again for the separation to be effective, each particle must contact the surface of the belt to allow for the conductive particles to give up their charge to the belt. Therefore, only a single layer of particles can be conveyed by the separator at one time. As the particle size of the feed becomes smaller, the processing rate of the device is reduced. [5] [6]

Parallel plate electrostatic separators are typically based upon separating particles not on the basis of conductivity, but on differences in surface chemistry that allows for electrical charge transfer by frictional contact. Particles are electrically charged by vigorous contact with other particles, or with a third surface such as a metal or plastic will the desired tribo-charging properties. Materials that are electronegative (located on the negative end of the tribo-electric series) remove electrons from the tribo-charging surface and thus acquire a net negative charge. In contact, materials that are on the positive end of the tribo-electric series donate electrons and charge positively. The charged particles are then introduced into an electrical field generated between the two parallel plate electrodes by various transportation means (gravity, pneumatic, vibration). In the presence of the electric field, the charged particles move towards the oppositely charged electrodes and are collected at the corresponding product hoppers. Again, a middlings fraction containing a mixture of particles may or may not be collected, depending on the configuration of the separation device. [4] [7]

Figure 1: Diagram of a high tension roll separator (left) and a parallel plate free fall separator (right).

Table 1: Summary of commonly used electrostatic separation devices.

Case 1 – Wheat and Wheat Bran Beneficiation.

Wheat bran is a by-product of conventional wheat milling, representing 10-15% of the wheat grain. Wheat bran consists of the outer layers including the pericarp, testa, and aleurone. Wheat bran contains most of the micronutrients, fiber, and phytochemicals contained in grain, which have demonstrated health benefits to humans. [8] Significant interest in separating and beneficiating wheat bran has been reported. Historical interest in separating wheat bran was to improve the quality and the value of the flour product. However, more recent interest has been reported in recovering valuable components from wheat bran.

In 1880, Thomas Osborne patented the first commercial electrostatic separator for removing bran from flour middlings. The separator consisted of rolls coated with hard rubber or equivalent material which was capable of being electrically charged via frictional tribo-charging with wool. Although not described, it is assumed the rubber rolls acquired a negative charge relative to wool, consistent with most tribo-electric series. The electrically charged rolls then attracted the positively charged bran fiber particles, conveying them on the surface of the roll until the pinned fiber particles are brushed from the surface of the roll. This (assumed) positive charging of wheat bran is in conflict with results reported by others. Tribo-charging of the bran particles was assisted by fluidizing air introduced at the bottom of the device, which had the additional benefit of causing the less dense bran particles to the surface, closer to the rolls. [1]

In 1958 an apparatus for electrostatic separation of bran and endosperm contained in flour middlings was disclosed in a patent filing by Branstad working at General Mills. The device consisted of a parallel plate separator in which particles were conveyed between the two plates by vibration. Bran particles, charged by frictional contact with endosperm particles, were then lifted to the top electrode through perforations in the top electrode. [9]

In 1988 an apparatus and process for recovering aleurone from commercial wheat bran was disclosed in a patent filing. Commercial wheat bran with a starting aleurone content of 34% was enriched to a concentrate of 95% at 10% mass yield (28% aleurone recovery) by a combination of hammer milling, sizing by screening, air elutriation and electrostatic separation using a parallel plate electrostatic separator. Particles were charged in the air elutriator device, which has a dual role of removing fines (<40 µm) by conveying, while simultaneously tribo-charging the aleurone particles positive (reporting to the negative electrode plate) and the pericarp/testa particles negative. The particle size of the bran mixture was carefully controlled by hammer milling and multi-level screening, to obtain a feed mostly sized in the 130 – 290 µm range. [10]

Recent work on recovering aleurone from wheat bran continues. In 2008, Buhler AG patented an electrostatic separation device for separating aleurone particles from shell particles made of commuted bran. One embodiment of the device consists of a rotor operating in a narrowly sized treatment area, which allows for particle-to-particle and particle-to-wall contact and subsequent tribo-charging. The charged particles are then conveyed mechanically into a separation vessel containing parallel plate electrodes. Particles fall through the separation vessel by gravity, as the differentially charged particles move toward the oppositely charged electrodes under the influence of the electric field. [11] When combined with proper sizing of the feed bran and mechanical sorting methods, aleurone concentrations of up to 90% have been reported. [12] [8]

Figure 2: Reproduced from Hemery et al, 2007 [8].

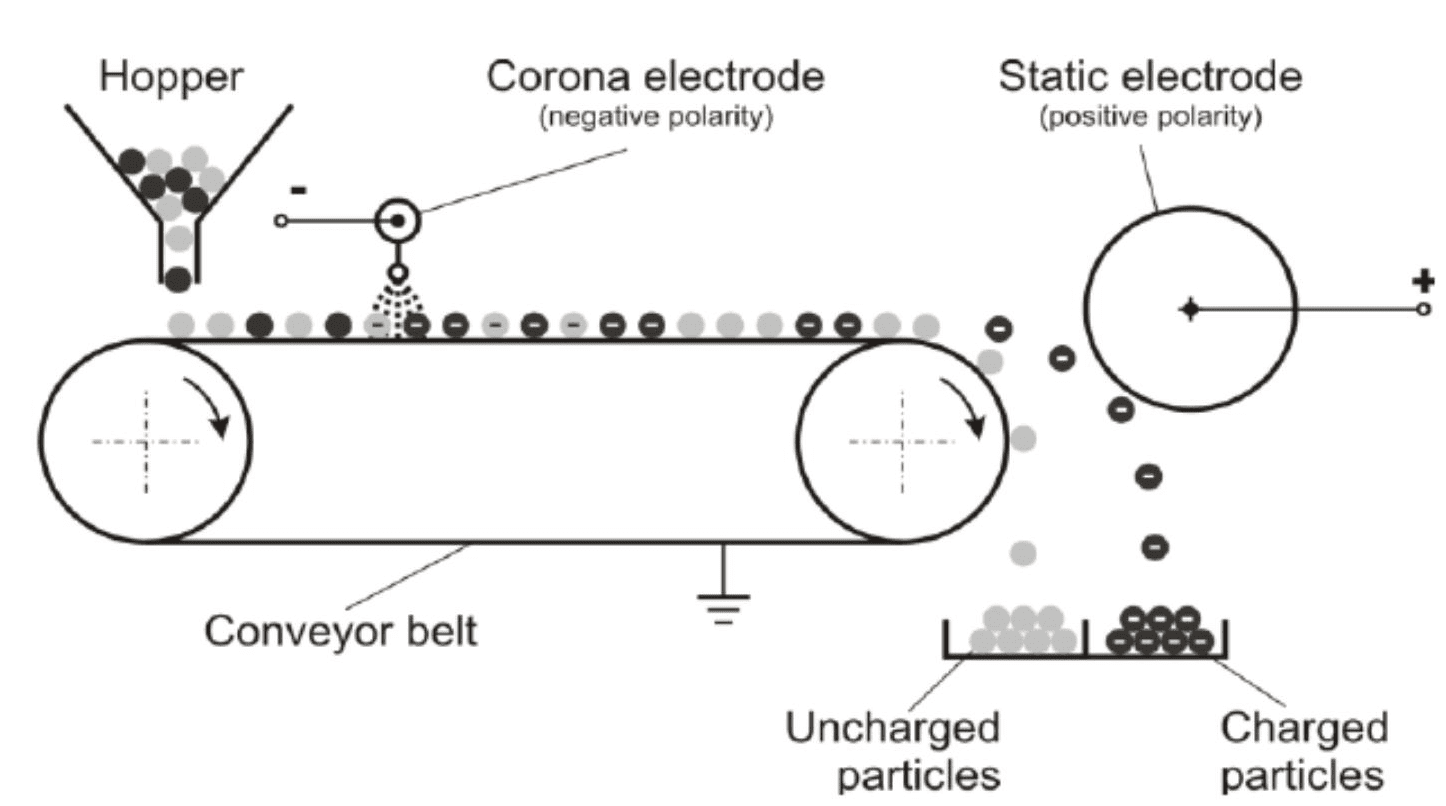

Tribo-charging and corona charging experiments on wheat bran were carried out by workers at the Electrostatics of Dispersed Media Research Unit, University of Poitiers, France in 2010. The researchers measured the surface charge and surface potential decay time on wheat bran with 10% moisture and lyophilized (freeze-dried) wheat bran. A separation test was performed on a sample of 50% freeze-dried wheat bran and 50% freeze-dried aleurone feed using a belt type corona electrostatic separator. (Figure 3) Separation results for the laboratory scale corona separator indicated 67% of aleurone was recovered to the non-conductor hopper, while only 2% of the wheat bran reported to the non-conductor hopper. Tribo-charging experiments were also conducted with wheat bran and aleurone, but only to measure the specific surface charge [µC/g] generated on each fraction, as opposed to recovering products from an electrostatic separation. Both feed materials were charged using Teflon as the contact surface. Both wheat bran and aleurone are reported as charging positive relative to Teflon, which itself is very electronegative. The magnitude of the charge was found to depend on the operating pressures used on the tribo-charger, suggesting that higher turbulence leads to more contacts and more complete tribo-charging. [13]

Figure 3: Reproduced from Dascalescu et al, 2010 [13]

In 2009, researchers evaluated the electrostatic charging properties of aleurone rich and pericarp rich feed materials. [14] In 2011 the researchers performed electrostatic separation testing on samples of finely ground wheat bran using a pilot scale electrostatic plate separator (TEP System, Tribo Flow Separations, Lexington, USA). The TEP System utilizes a charging line, where feed particles are introduced into a turbulent compressed air stream, and pneumatically conveyed through the charging line to the separation chamber. The particles are tribo-charged by the particle to particle contact, as well as particle contact with the surface of the charging line. Results obtained with the TEP System demonstrated that electrostatic separation was effective in upgrading aleurone and beta-glucan content of wheat bran. Interestingly, the fraction of material that was found to contain the highest aleurone cell content, at 68%, was the very fine (D50 = 8 µm) fraction that was recovered from the charging tube. It is not clear why this material was preferentially concentrated in the charging apparatus, however, it does indicate that the ability to process aleurone cell contents may require electrostatic techniques that are capable of processing very fine powders. Furthermore, this work demonstrated that feed preparation for the wheat bran was an important consideration. Samples prepared by cryogenic grinding in a hammer mill were found to be less completely dissociated (liberated) than those ground in an impact type mill at ambient temperature. [15] [16]

Figure 4: Reproduced from Hemery et al, 2011 [16]

Recent work studied the concentration of arabinoxylans from wheat bran by electrostatic methods. The researchers utilized a laboratory scale electrostatic separator consisting of a charging tube and separation chamber containing two parallel plate electrodes. Milled wheat bran was introduced into the charging tube and conveyed pneumatically into the separation chamber using compressed nitrogen. The turbulence and high gas velocity in the charging tube provided the particle contact needed for tribo-charging. The charged particles (products of the separation) were collected from the surface of the electrodes for analysis. Due to the vertical orientation of the electrodes a significant amount of material was not collected. This middlings fraction may be recycled for further processing in conventional electrostatics, however, for the purposes of this experiment, material not collected on the electrodes was considered lost. The researchers reported an increase in both product grade (arabinoxylan content in the product) and separation efficiency as the conveying velocity increased. [17]

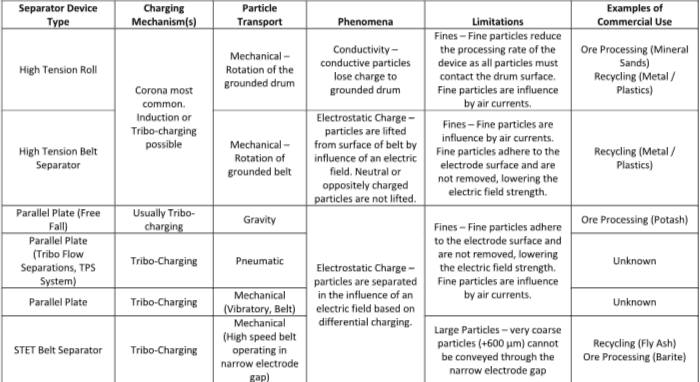

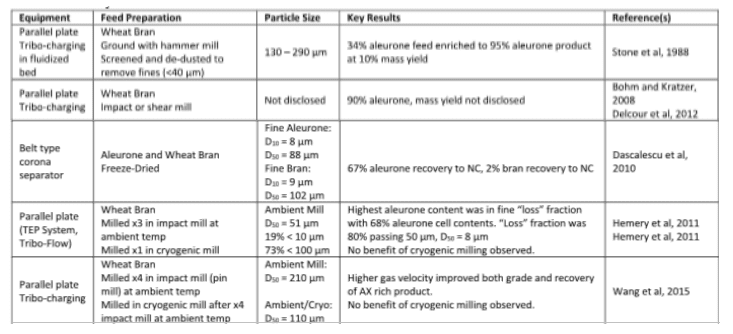

Recent efforts to beneficiate wheat bran using electrostatic methods are summarized below in Table 2.

Table 2: Summary of electrostatic methods evaluated to beneficiate wheat bran.

Case 2 – Protein Recovery from Lupin Flour

Researchers at the Food Process Engineering Group in Wageningen, The Netherlands, evaluated the potential for protein enrichment using legumes. Pea and lupin flour were used as feeds for a variety of protein enrichment techniques including air classification combined with electrostatic separation. Untreated pea and lupin seeds were first milled to approximately 200 µm. Feed materials for classification and electrostatic separation were subsequently milled using an impact type mill with an internal classifier (Hosokawa-Alpine ZPS50). Median particle size (d50) was reported as approximately 25 µm for the pea flour, and approximately 200 µm for the lupin flour, prior to air classification. Finally, a subset of each sample, pea and lupin flour, was then air classified (Hosokawa-Alpine ATP50). The feed to the electrostatic separator consisted of both untreated flours, as well as the course and fine product from air classification. [18]

The electrostatic separation device used during the experiments was a parallel plate type, with charging carried out via triboelectric charging in a 125 mm length charging tube, with particles conveyed pneumatically by compressed nitrogen. The device is similar in configuration to the device used by Wang et al (2015). [17] Electrostatic separation experiments were conducted on ground pea flour and lupin flour, as well as the course and fine fractions of pea flour and lupine flour obtained from air classification. The pea flour demonstrated only minor movement of protein during electrostatic testing. However, the lupin flour demonstrated significant movement of protein in all three samples tested (milled flour – 35% protein, milled classified fines – 45% protein, milled classified coarse – 29% protein). Protein-rich products of approximately 60% were recovered on the grounded electrode for each of the three lupin samples tested. [18]

Case 3 – Fiber Removal from Corn

Researchers at the Department of Agricultural and Biological Engineering, Mississippi State University performed electrostatic testing on ground corn flour, with an objective of removing fiber. The electrostatic separation device consisted of a conveyor belt with a negative electrode placed at the end of the conveyor. The positively charged particles, fiber particles, in this case, were lifted off the conveyor belt and sorted into a second hopper. The non-fiber particles fell off of the conveyor belt by gravity and were deposited into the first product hopper. The authors do not describe how the electrical charging is carried out. The feed material to this separator was relatively coarse, with particle sizes of the feed ranging from 12 mesh (1,532 µm) to 24 mesh (704 µm). It does not appear that the undersize (<704 µm) material was processed during this study. Each test condition was completed using 1 kg of feed material which was uniformly dispersed across the belt. [6]

Figure 5: Reproduced from Pandya et al, 2013 [6]

The Mississippi State researchers completed electrostatic separation testing on the unscreened corn flour, the screened corn flour fractions and the fiber-rich fractions recovered from air classification. Electrostatic testing was not completed on the low-fiber streams recovered from air classification. Analysis of the results of the electrostatic separation is provided below:

Table 3: Results of fiber separation reproduced from Pandya et al, 2013 [6]

Case 4 – Protein Concentration from Oilseeds

Oilseeds such as rapeseed (canola), sunflower, sesame, mustard, soybean-corn germ, and flaxseed generally contain a substantial amount of both protein and fiber. Processing technologies to remove the fiber, and thus increase the protein content, of oilseeds will become increasingly important as global demand for protein increases. [19] Recent work by researchers at the French National Institute for Agricultural Research examined ultrafine milling combined with electrostatic processing of sunflower seed meal, to concentrate protein. The feed sunflower meal samples were ground in an impact mill operating at ambient temperature to a particle size (D50) of 69.5 µm. The electrostatic separator used for the testing was a parallel plate device where the primary charging mechanism was tribo-charging. The tribo-charging was carried out upstream of the electrodes in a tribo-charging line, with particles conveyed through the charging line, and to the electrodes, via pneumatic transport. Protein was found to charge positive (reporting to the negative electrode) and the fiber-rich fraction was found to charge negatively. Protein selectivity was found to be high. Feed protein was 30.8%, with the protein-rich product measuring 48.9% and the protein depleted (fiber-rich) product measuring only 5.1% protein. Protein recovery was 93% to the positive product. Cellulose, hemicelluloses, and lignin were measured and found to report to the negatively charged product, opposite that of protein. [20]

Table 4: Results of sunflower seed meal separation reproduced from Barakat et al, 2015 [20]

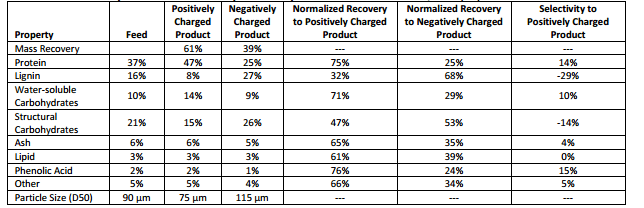

In 2016, an additional study was completed using finely ground rapeseed oil seed meal, or rapeseed oil cakes (ROC), as the feed to an electrostatic separation process. Again ultrafine milling at ambient temperature was performed using a knife mill device (Retsch SM 100). The milled material, with a median particle size (D50) of approximately 90 µm, was processed using a pilot scale parallel plate separator (TEP System, Tribo Flow Separations). The TEP System utilizes triboelectric charging by pneumatic conveying of particles through a high pressure charging line under turbulent conditions. A single pass separation test with the TEP System resulted in the significant concentration of protein, with a feed protein of 37%, a positively charged product protein level of 47% and a negatively charged product protein level of 25%. Additional separation stages were performed, ultimately producing a protein-rich product with 51% protein after 3 successive separation stages. [21]

Table 5: Results of rapeseed oil seed meal separation reproduced from Basset et al, 2016 [21]

Discussion

Review of the relevant literature indicates that significant research has been undertaken to develop electrostatic separation techniques for organic materials. This development has continued or even accelerated in the past 10 – 20 years, with many researchers in Europe and the United States applying electrostatic separation techniques to a wide variety of beneficiation challenges. From this research, it is apparent that electrostatic methods have the potential to generate new, higher value plant products, or offer an alternative to wet processing methods.

Although encouraging separations of cereal grains, pulses, and oilseed materials have been demonstrated at the laboratory and in some cases pilot scale, the electrostatic systems used to demonstrate these results may ultimately not serve as the most suitable or cost-effective processing equipment to perform such separations on a commercial basis. Existing commercial electrostatic systems are most commonly used in separations of minerals, metals or plastics. Minerals and metals are both relatively dense materials with high specific gravity, as compared to plant materials. Even with the high specific gravity of minerals and metals, the effective particle size limitations for the drum roll and parallel plate electrostatic separators is relatively coarse, with few particles below 100 µm for example. Plastics are of lower density than both minerals and metals but are often processed at coarse particle sizes, as plastic flakes for example. The introduction of fine particles creates operational difficulties for both high-tension roll and parallel plate separators. Fine, low-density particles are very sensitive to air currents, especially in comparison to minerals and metals. Small differences in air currents inside the separation device impact the travel path of the fine particles, subjecting them to forces other than those caused by the electrostatic field.

For most parallel plate separator systems, finely ground and low-density particles that are electrostatically charged are collected on the electrodes of the parallel plate separators. If these fine electrically attached particles are not removed on a constant basis, the electric field strength and efficiency of the device degrade. The work of the researchers at The Food Process Engineering Group Wageningen UR (Wang et al, 2015) took advantage of this phenomenon to collect samples off the surface of the electrodes of the parallel plate separator to analyze the products of the separation. Parallel plate separator systems, particularly those that rely upon gravity to convey particles through the electric field, have attempted to address this problem in several ways. Stone et al (1988) described a process in which fine particles were removed upstream of the electrostatic separator by air elutriation. [10] Others have reported maintaining a laminar stream of air flowing across the electrodes to prevent fine particles from being influenced by air currents. [22However, maintaining laminar airflow becomes challenging as the separation device becomes larger, effectively limiting the processing capacity of such devices. Ultimately the particle size in which components are physically separate from other (present as discrete particles), will be the largest driver in determining the particle size at which processing must occur.

As mentioned previously, conventional electrostatic separation devices are limited in processing capacity, especially with low-density and finely ground powders such as plant materials. For high-tension drum and belt separation devices, the effectiveness is limited to particles that are relatively coarse and/or have high specific gravity, due to the need for all particles to contact the surface of the drum. As particles become smaller the processing rate is reduced. Parallel plate separators are further limited by the particle density that can be processed in the electrode zone. Particle loading must be relatively low to prevent space charge effects.

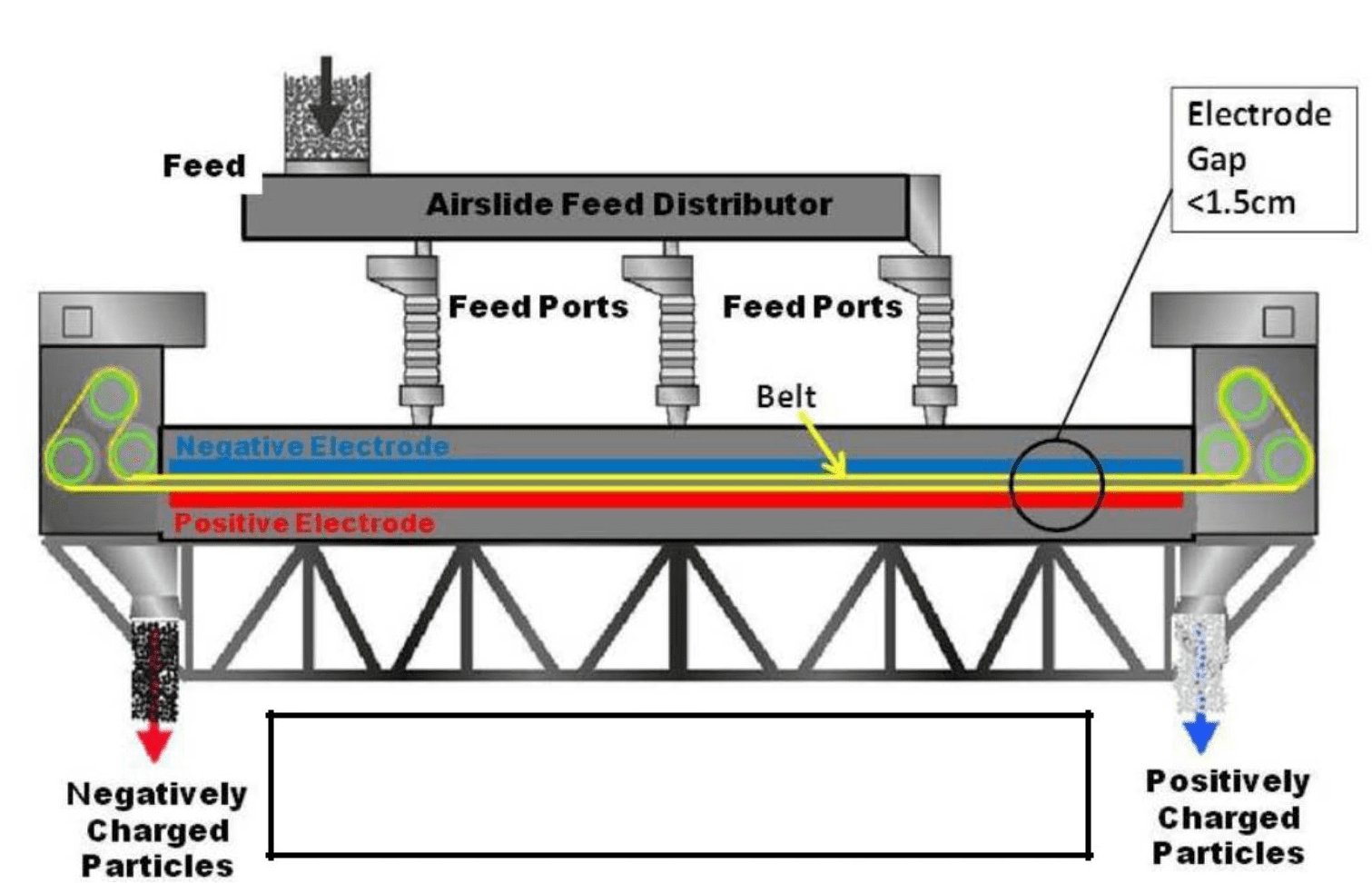

ST Equipment & Technology Belt Separator

The ST Equipment & Technology (STET) triboelectrostatic belt separator has the demonstrated capability to process fine particles from 500 – 1 µm. The STET separator is a parallel plate electrostatic separator, however, the electrode plates are oriented horizontally as opposed to vertically as is the case in most parallel plate separators. (See Figure 6) Furthermore, the STET separator accomplishes the particle tribo-charging and conveying simultaneously by a high-speed open mesh conveyor belt. This feature allows for both a very high specific processing rate of feed, as well as the capability to process powders much finer than conventional electrostatic devices. This type of separation device has been in commercial operation since 1995 separating unburned carbon from fly ash minerals (typical D50 approximately 20 µm) in coal-fired power plants. This electrostatic separation device has also been successful at beneficiating other inorganic materials, including minerals such as calcium carbonate, talc, barite, and others.

The fundamental details of the STET separator are illustrated in Figure 7. The particles are charged by the triboelectric effect through particle-to-particle collisions within the gap between the electrodes. The applied voltage between the electrodes is between ±4 and ±10 kV relative to ground, giving a total voltage difference of 8 – 20 kV across a very narrow electrode gap of nominally 1.5 cm (0.6 inches). Feed particles are introduced to the STET separator at one of three locations (Feed Ports) via a distributor air slide system with knife gate valves. The STET separator produces only two products, a negatively charged particle stream collected on the positively charged electrode, and a positively charged particle stream collected on the negatively charged electrode. The products are conveyed to the respective hoppers at each end of the STET separator by the separator belt and conveyed out of the separator by gravity. The STET separator does not produce a middlings or recycle stream, although multiple pass configurations to improve product purity and/or recovery are possible.

Figure 6: STET Triboelectric Belt Separator

Particles are conveyed through the electrode gap (separation zone) by a continuous loop, open mesh belt. The belt operates at high speed, variable from 4 to 20 m/s (13 – 65 ft/s). The geometry of the belt serves to sweep fine particles off the surface of the electrodes, preventing the accumulation of fine particles that degrade the performance and voltage field of traditional free-fall parallel plate type separation devices. In addition, the belt generates a high sheer, high turbulence zone between the two electrodes, promoting tribo-charging. The counter-current travel of the separator belt allows for continuous charging and re-charging or particles within the separator, eliminating the need for a pre-charging system upstream of the STET separator.

Figure 7: Fundamentals of operation of STET Belt Separator

The STET separator is a high feed rate, commercially proven processing system. The maximum processing capacity of the STET separator is mostly a function of the volumetric feed rate that can be conveyed through the electrode gap by the STET separator belt. Other variables, such as the speed of the belt, the distance between the electrodes and the aerated density of the powder effect the maximum feed rate, typically to a lesser extent. For relatively high-density materials, for example, fly ash, the maximum processing rate of a 42 inch (106 cm) electrode width commercial separation unit is roughly 40 – 45 Tons per hour of feed. For less dense feed materials, the maximum feed rate is lower.

Table 6: Approximate maximum feed rate for various materials processed with STET 42 inch electrostatic separator.

Dust explosions are a major hazard in grain and other organic powder processing operations. The STET separator is suitable for processing combustible organic powders with only minor modifications. There are no heated surfaces in the STET separator. The only moving parts are the separator belt and drive rollers. The roller bearings are located outside of the powder stream on the external shell of the unit. Therefore they are not a risk for overheating/sparking in the material stream. Furthermore, the STET separator bearings are available with factory fitted temperature measurement capability to detect bearing failure well before dangerously high temperatures are reached. The separator belt and drive system pose no higher risk than other conventional rotating machinery. The STET separator high voltage components are also located outside of the material stream and contained in dust-tight enclosures. The maximum energy of a spark across the separator gap is limited by the design of the high voltage components. An additional level of safety can be introduced via nitrogen purging.

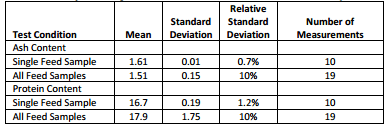

Whole Wheat Flour Processing by STET Separator

Whole wheat flour is derived from grinding the entire grain of wheat (bran, germ, and endosperm). Commercially available, off-the-shelf, whole wheat flour was purchased for use as test material to evaluate the capability of the STET separator to remove the fibrous bran and germ from the starchy endosperm fraction of wheat flour. The whole wheat flour sample was analyzed by STET prior to beginning the testing. Ash content was tested by ICC Standard 104 / 1 (900°C). Repeated ash measurements of the same sample, an unseparated feed sample, measured 10 times, were found to have an ash content of 1.61%, a standard deviation of 0.01 and a relative standard deviation of 0.7%. Particle size analysis was completed by laser diffraction using a Malvern Mastersizer 3000 with a dry dispersion apparatus. Protein analysis was conducted using the DUMAS method, with an Elementary rapid N exceed nitrogen/protein analyzer. A conversion factor of N x 6.25 was used. The various properties of the whole wheat flour sample are summarized below. (See Table 7)

Table 7: Analysis of whole wheat flour feed by STET

Ash content and protein content were found to be very repeatable when tested in the same sample, but significant variability was identified between the multiple bags of whole wheat flour used as the feed sample. (See Table 8) This feed sample variability resulted in some scatter in the test data.

Table 8: Analysis of separation test results of whole wheat flour by STET

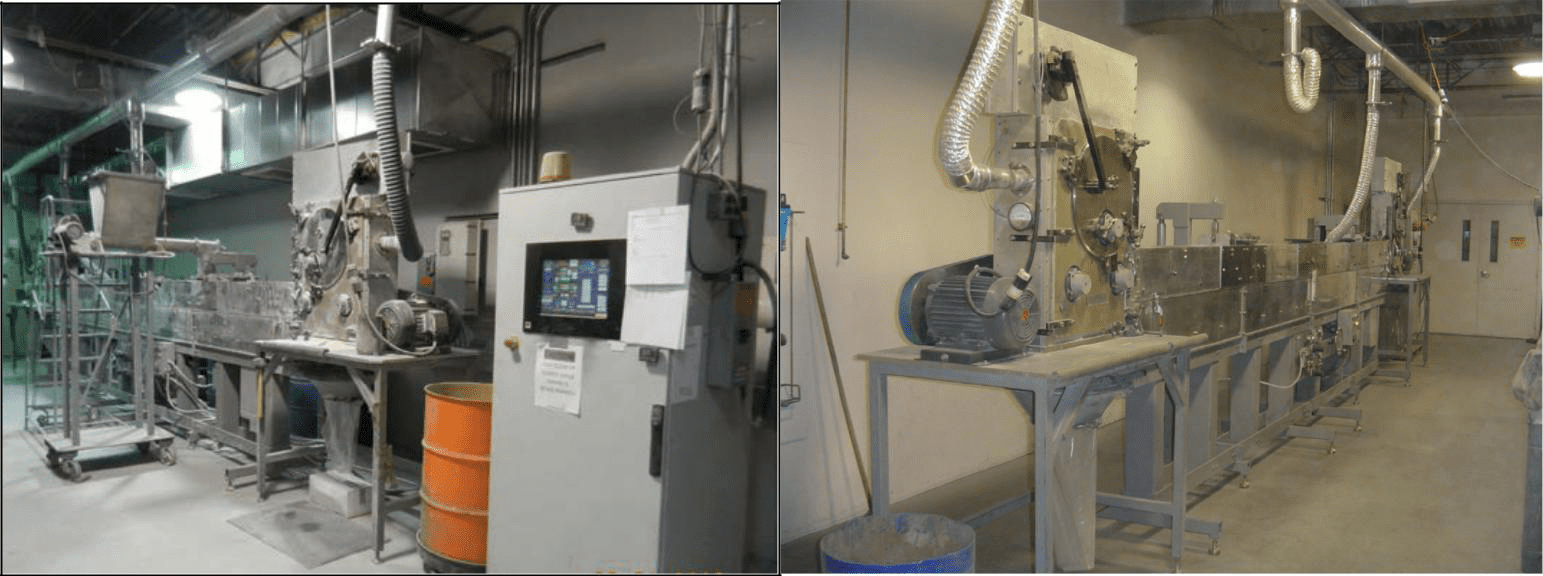

Electrostatic separation testing of the whole wheat flour sample was performed at the ST Equipment & Technology (STET) pilot plant facility in Needham, Massachusetts. The STET pilot plant contains two pilot scale STET separators along with ancillary equipment used to investigate the separation of materials from candidate sources. The pilot-scale STET separators are the same length as a commercial STET separator, at 30 feet (9.1 meters) long, however, the pilot plant separator electrode width is only 6 inches (150 mm), or one-seventh the width of the largest commercial STET separator at 42 inches (1070 mm) electrode width. The feed capacity of the STET separator is directly proportional to the width of the electrodes, therefore, the feed rate of the pilot plant separator is one-seventh the feed rate of the 42-inch wide commercial separator unit. The maximum feed rate with whole wheat flour was 2.3 Tons per hour at pilot scale, which corresponds to 16 Tons per hour for the 42-inch wide commercial separator. In comparison to the scale at which the majority of the electrostatic separation studies have been conducted to date, the STET separator testing was carried out at a considerably higher feed rate. Testing was performed in 10 kg (20 pound) batch tests, due to the practical considerations of supplying 2.3 Tons per hour of feed continuously. For each batch test condition, the products of the separation process were weighed to calculate the mass recovery. Subsamples from each test were collected and analyzed for ash content and protein content.

Figure 8: STET Pilot Plant Separator.

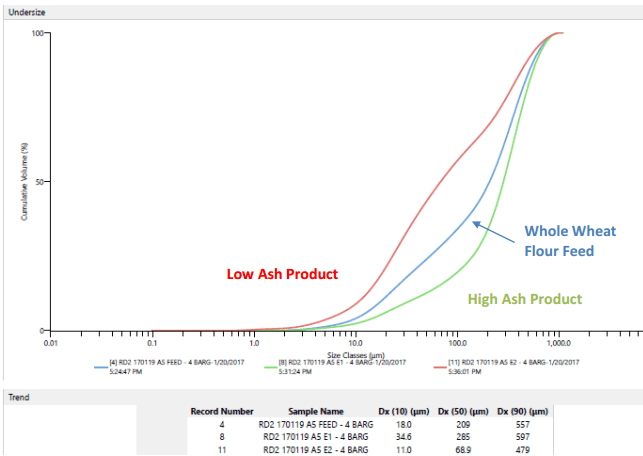

Particle size measurement of the whole wheat flour feed and two product samples is shown below in Figure 9.

Figure 9: Particle size measurement of whole wheat flour feed, and the two separated product samples.

A picture of the recovered separation products is included below. (See Figure 10) A noticeable color shift was observed during the separation, which the high ash content product fraction considerably darker than the feed whole wheat flour sample.

Figure 10: Typical products recovered from the STET separation process.

Ash content for all products from the separation process was measured. (See Figure 11)

Figure 11: Ash content versus the mass recovery of low ash product for whole wheat flour separation tests by STET

Testing of the STET electrostatic separator with whole wheat flour demonstrated significant movement of the high ash (bran) fraction of the wheat kernel to the positive electrode. The reduced ash product was subsequently collected on the negative electrode. Testing was performed on a single pass scheme, however, it is possible to perform further upgrading of either of the separation products by performing another separation stage. Future testing with the STET separator will be conducted on wheat bran samples, as well as corn flour and legumes such as Lupin.

Conclusions

Review of the relevant literature indicates that significant research has been undertaken to develop electrostatic separation techniques for organic materials. This development has continued or even accelerated in the past 10 – 20 years, with many researchers in Europe and the United States applying electrostatic separation techniques to a wide variety of beneficiation challenges. From this research, it is evident that electrostatic methods have the potential to generate new, higher value plant products, or offer an alternative to wet processing methods. Although encouraging separations of wheat, corn and lupin-based plant materials have been demonstrated at the laboratory and in some cases pilot scale, the electrostatic systems used to demonstrate these results may not be the most suitable or cost-effective processing equipment to perform such separations on a commercial basis. Many electrostatic technologies are not suitable for process finely ground, low-density powders such as plant materials. However, the ST Equipment & Technology (STET) triboelectrostatic belt separator has the demonstrated capability to process fine particles from 500 – 1 µm at high rates. The STET belt separator is a high rate, industrially proven processing device that may be suitable to commercialize the recent developments in plant material processing. The STET belt separator was tested on a sample of whole wheat flour and was found to be successful in removing the bran from the starch fraction. Future testing with the STET separator will be conducted on wheat bran samples, as well as corn flour and pulses such as soy and lupin.

References

[1] T. B. Osborne, “Middlings-Purifier”. United States of America Patent 224,719, 17 February 1880.

[2] H. Manouchehri, K. Hanumantha Rao and K. Forsberg, “Review of electrical separation methods – Part 1: Fundamental aspects,” Minerals & Metallurgical Processing, vol. 17, no. 1, pp. 23-36, 2000.

[3] J. Elder and E. Yan, “eForce – Newest generation of the electrostatic separator for the minerals sands industry,” in Heavy Minerals Conference, Johannesburg, 2003.

[4] R. H. Perry and D. W. Green, Perry’s Chemical Engineers’ Handbook Seventh Edition, New York: McGraw-Hill, 1997.

[5] S. Messal, R. Corondan, I. Chetan, R. Ouiddir, K. Medles and L. Dascalescu, “Electrostatic separator for micronized mixtures of metals and plastics originating from waste electric and electronic equipment,” Journal of Physics, vol. 646, pp. 1-4, 2015.

[6] T. S. Pandya, R. Srinivasan and C. P. Thompson, “Fiber Separation for Ground Corn Flour Using an Electrostatic Method,”Cereal Chemistry, vol. 90, no. 6, pp. 535-539, 2013.

[7] L. Brands, P. M. Beier, and I. Stahl, Electrostatic Separation, Weinheim: Wiley VCH Verlag GmbH & Co. KGaA, 2005.

[8] Y. Hemery, X. Rouau, V. Lullien-Pellerin, C. Barron and J. Abecassis, “Dry process to develop wheat fractions and products with enhanced nutritional quality,” Journal of Cereal Science, no. 46, pp. 327-347, 2007.

[9] W. A. Brastad and E. C. Gear, “Method and Apparatus for Electrostatic Separation”. United States of America Patent 2,848,108, 19 August 1958.

[10] B. A. Stone and J. Minifie, “Recovery of Aleurone Cells from Wheat Bran”. United States of America Patent 4,746,073,24 May 1988.

[11] A. Bohm and A. Kratzer, “Method for Isolating Aleurone Particles”. United States of America Patent 7,431,228, 7 October 2008.

[12] J. A. Delcour, X. Rouau, C. M. Courtin, K. Poutanen and R. Ranieri, “Technologies for enhanced exploitation of the health-promoting potential of cereals,” Trends in Food Science & Technology, pp. 1-9, 2012.

[13] L. Dascalescu, C. Dragan, M. Bilici, R. Beleca, Y. Hemery and X. Rouau, “Electrostatic Basis for Separation of Wheat Bran Tissues,” IEEE Transactions on Industry Applications, vol. 46, no. 2, pp. 659-665, 2010.

[14] Y. Hemery, X. Rouau, C. Dragan, R. Bilici and L. Dascalescu, “Electrostatic properties of wheat bran and its constitutive layers: Influence of particle size, composition, and moisture content,” Journal of Food Engineering, no. 93, pp. 114-124, 2009.

[15] Y. Hemery, M. Chaurand, U. Holopainen, A.-M. Lampi, P. Lehtinen, V. Piironen, A. Sadoudi and X. Rouau, “Potential of dry fractionation of wheat bran for the development of food ingredients, part I: Influence of ultra-fine grinding,” Journal of Cereal Science, no. 53, pp. 1-8, 2011.

[16] Y. Hemery, U. Holopainen, A.-M. Lampi, P. Lehtinen, T. Nurmi, V. Piironen, M. Edlemann and X. Rouau, “Potential of dry fractionation of wheat bran for the development of food ingredients, part II: Electrostatic separation of particles,” Journal of Cereal Science, no. 53, pp. 9-18, 2011.

[17] J. Wang, E. Smits, R. M. Boom, and M. A. Schutyser, “Arabinoxylans concentrates from wheat bran by electrostatic separation,” Journal of Food Engineering, no. 155, pp. 29-36, 2015.

[18] P. J. Pelgrom, J. Wang, R. M. Boom, and M. A. Schutyser, “Pre- and post-treatment enhance the protein enrichment from milling and air classification of legumes,” Journal of Food Engineering, no. 155, pp. 53-61, 2015.

[19] D. Chereau, P. Videcoq, C. Ruffieux, L. Pichon, J.-C. Motte, S. Belaid, J. Ventureira and M. Lopez, “Combination of existing and alternative technologies to promote oilseeds and pulses proteins in food applications,” Oilseeds & fats Crops and Lipids, vol. 23, no. 4, pp. 1-11, 2016.

[20] A. Barakat, F. Jerome and X. Rouau, “A Dry Platform for Separation of Proteins from Biomass-Containing

Polysaccharides, Lignin, and Polyphenols,” ChemSusChem, vol. 8, pp. 1161-1166, 2015.

[21] C. Basset, S. Kedidi and A. Barakat, “Chemical- and Solvent-Free Mechanophysical Fractionation of Biomass Induced by Tribo-Electrostatic Charging: Separation Proteins and Lignin,” ACS Sustainable Chemistry & Engineering, vol. 4, pp. 4166-4173, 2016.

[22] J. M. Stencel, J. L. Schaefer, H. Ban, and J. K. Neathery, “Apparatus and Method for Triboelectrostatic Separation”.United States of America Patent 5,938,041, 17 August 1999.